Seal structure of leather vacuum drying machine

A technology of vacuum dryer and sealing structure, which is used in leather drying, small raw hide/large raw hide/leather/fur mechanical treatment, raw hide/leather/fur manufacturing equipment, etc., can solve the problem that the sealing effect is not very good and the sealing effect cannot be achieved and other problems to achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

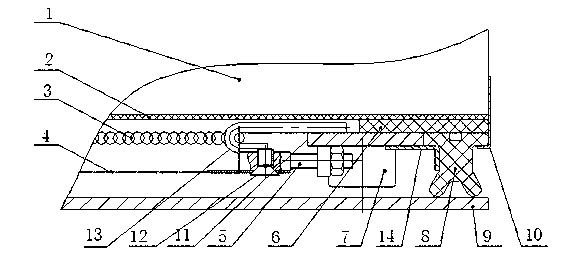

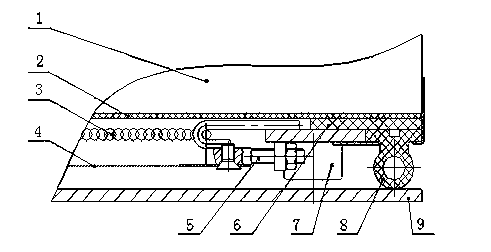

[0010] Depend on figure 1 As can be seen from the schematic diagram shown, the first structure of the leather vacuum dryer sealing structure of the present invention mainly includes a cover frame 1, a worktable 9, a sealing ring 8, a sealing rubber plate 2, a three-dimensional net 3, a fine net 4, a tensioning Screw 5, sealing rubber pad 6, buffer pad 7.

[0011] The cover frame 1 is located above the worktable 9, and the sealing rubber plate 2, the three-dimensional net 3, the fine net 4, the buffer pad 7, the tightening screw 5, the sealing rubber pad 6 and the sealing ring 8 are all arranged on the cover frame 1. in the lumen.

[0012] The sealing rubber plate 2 is arranged at the bottom of the cover frame 1, and the pressure plate 11 passes through the sealing rubber plate 2 through screws so as to be fixed with the cover frame 1, and the three-dimensional net 3 is connected to the pressing plate 11, and the three-dimensional net 3 passes through the net hook 13 It is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com