Vacuum bare fiber introducing device

A technology for introducing device and bare optical fiber, applied in the field of vacuum introducing device for bare optical fiber, can solve the problems of loss at optical fiber connection, optical fiber cannot be replaced, complex structure, etc., and achieve the effects of easy installation and removal, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

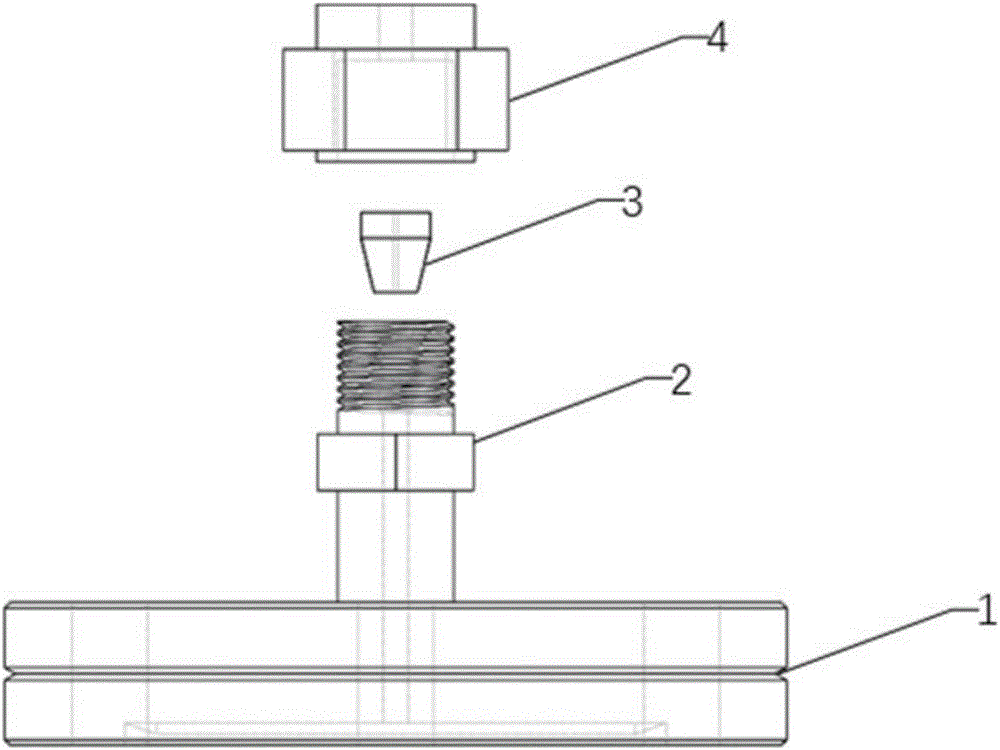

[0022] A bare optical fiber vacuum introduction device, comprising: a flange 1, a ferrule 2 is fixed on the flange 1, and a first through hole is arranged at the place where the ferrule 2 is fixed; the ferrule 2 is far away from the method One end of the flange 1 is provided with a thread, and a second through hole is provided inside, and the second through hole of the tube 2 is connected with the first through hole of the flange 1; the sealing ring 3, the sealing ring 3 has elasticity, and the opening There is a vertical through hole, the lower part shrinks gradually from top to bottom, and it is a rotating body; the tube nut 4, the tube nut 4 is matched with the thread of the tube 2, and the inside is a through hole; the second part of the tube 2 The upper part of the two through holes gradually opens from bottom to top, and cooperates with the sealing ferrule 3. The first through hole of the flange 1, the second through hole of the tube 2, the vertical through hole of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com