Valve rod sealing member with buffer function

A technology of valve stems and seals, which is applied in the direction of engine components, lift valves, machines/engines, etc., can solve problems such as sinking, short service life of valve stems and valve seats, wear of valve stems and valve seats, and achieve The effect of reducing speed, good sealing and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

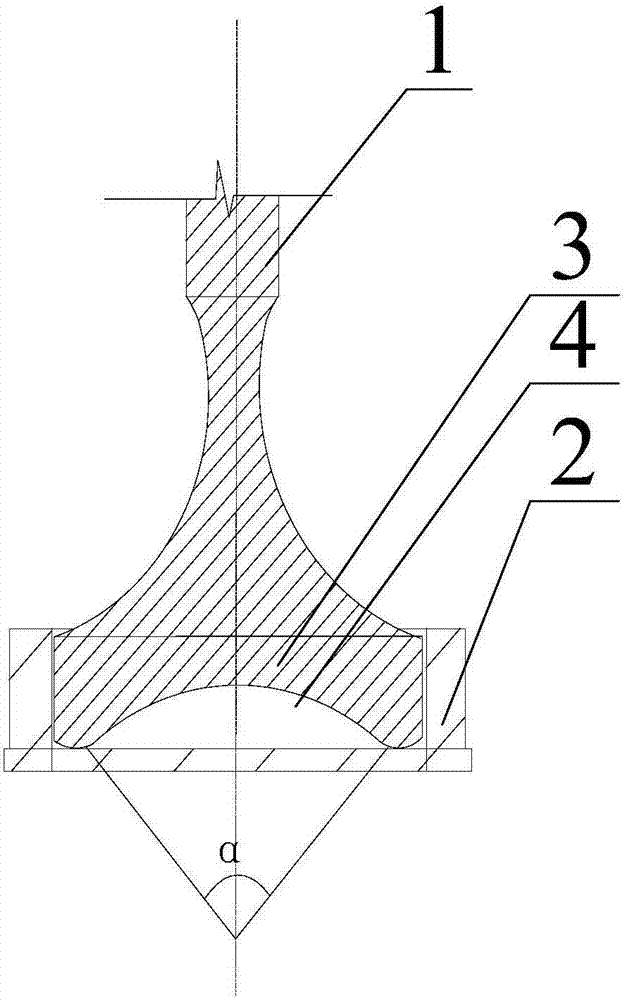

[0017] Such as figure 1 As shown, the present invention has a valve stem seal with a buffer function, including a valve stem 1 and a valve seat 2, the end of which the valve stem 1 contacts with the valve seat 2 is a valve cover 3, and the valve seat 2 is A rectangular groove, the contact end of the valve cover 3 and the bottom of the valve seat 2 is a smooth curved surface, and an arc groove 4 is also formed on the side of the valve cover 3 facing the valve seat 2, the arc The centerline of the arc-shaped groove 4 is on the same straight line as the centerline of the valve stem 1, and the angle of the central angle corresponding to the arc surface of the arc-shaped groove 4 is α, and α is 85°. The above structure solves the existing problems of severe wear between the valve stem 1 and the valve seat 2, which causes the valve to sink due to poor sealing, and the short service life of the valve stem 1 and the valve seat 2.

Embodiment 2

[0019] Such as figure 1 As shown, in the valve stem seal with cushioning function of the present invention, on the basis of Example 1, the bandwidth of the surface of the valve cover 3 in contact with the inner wall of the valve seat 2 is 3.5 mm.

Embodiment 3

[0021] Such as figure 1 As shown, the present invention has a valve stem seal with a buffer function. On the basis of Embodiment 1, the valve cover 3 is made of titanium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com