High-pressure fuel pump

A high-pressure fuel pump, high-pressure technology, which is applied to fuel injection pumps, fuel injection devices, pumps, etc., can solve problems such as laborious installation, achieve good sealing, reduce high-pressure leakage, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

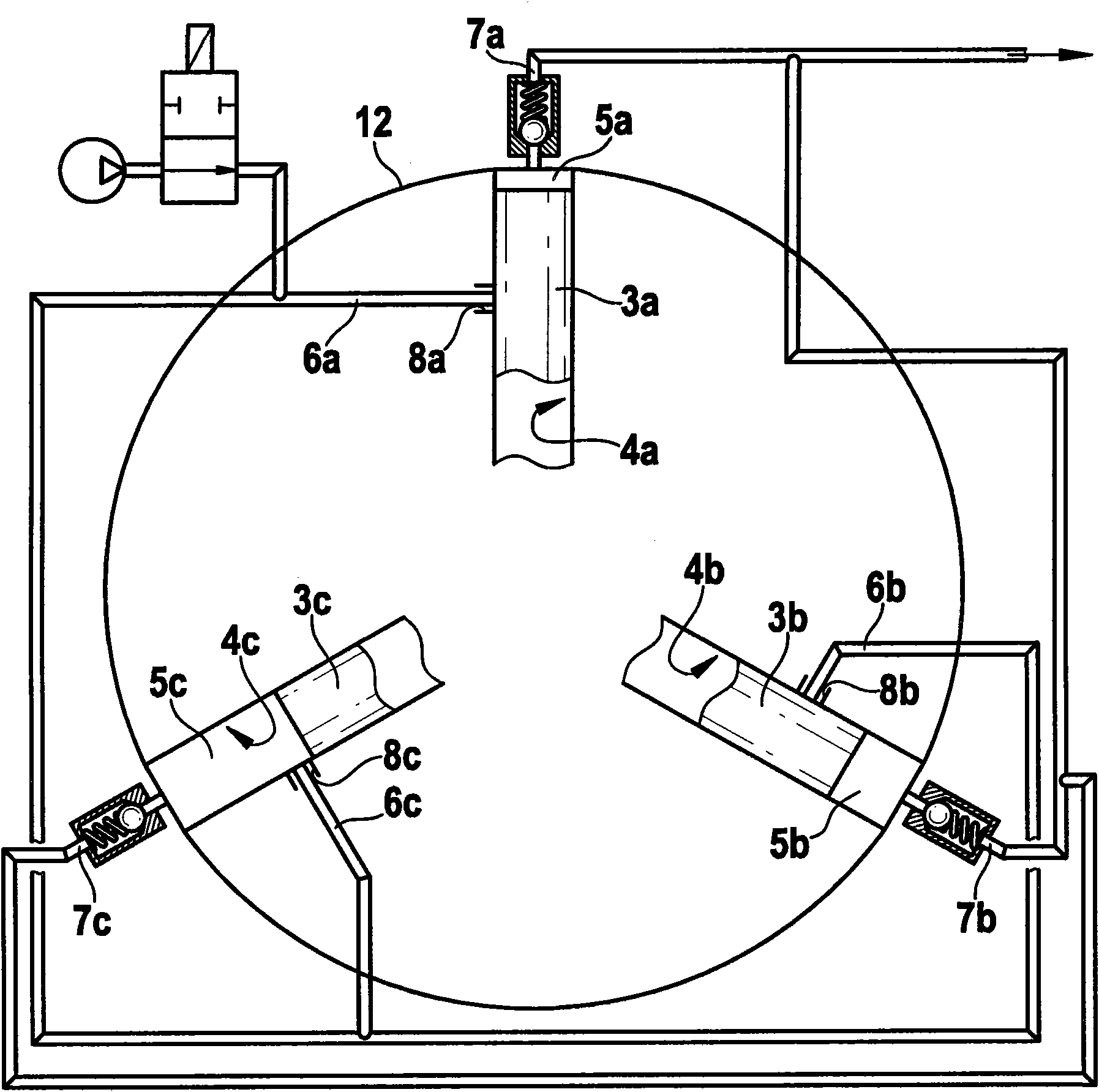

[0015] figure 1 A schematic diagram of a high-pressure fuel pump according to the invention is shown, which is provided with three pump pistons 3a, 3b and 3c. These pump pistons 3a-3c are respectively guided in piston guides 4a, 4b and 4c and are arranged at an angle equidistant from each other on the same circumferential line (12) around the pump camshaft not shown, through which the pump cam The polygonal configuration of the shaft collectively drives the pump pistons. A pressure chamber 5a, 5b and 5c is provided above each pump piston 3a-3c. These pressure chambers 5a-5c are in turn connected with low-pressure feed lines 6a, 6b and 6c respectively and with high-pressure connections 7a, 7b and 7c, which are connected to the feed holes 8a, 8b and 8c in the piston guides 4a-4c. form.

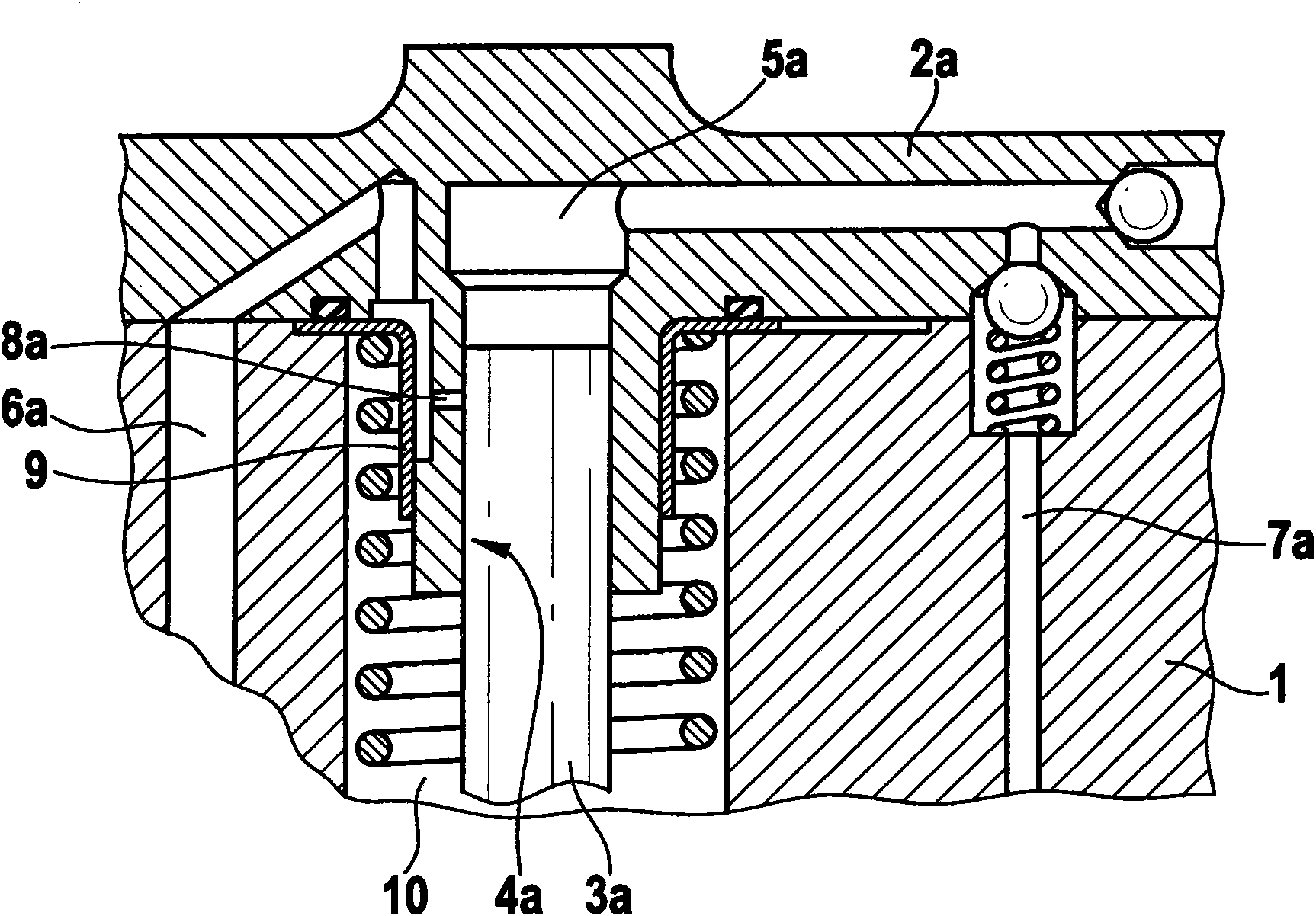

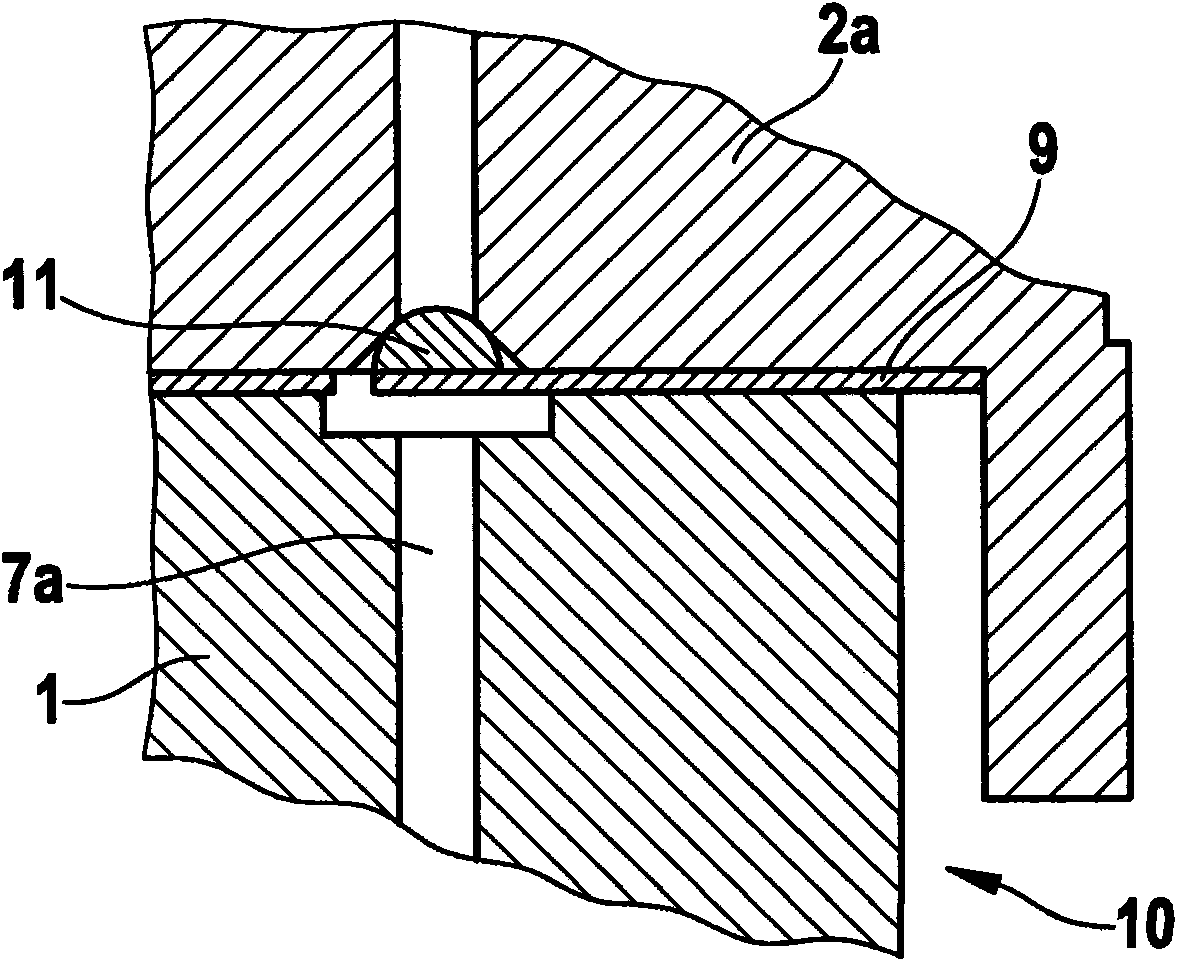

[0016] exist figure 2 A detailed sectional view of a pressure chamber 5a and a pump piston 3a can be seen in FIG. The pressure chamber 5a is supplied with fuel via the inlet opening 8a and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com