High-strength polyvinyl chloride folding-resistant plate and preparation method thereof

A polyvinyl chloride, high-strength technology, applied in the field of high-strength polyvinyl chloride folding resistant board and its preparation, can solve the problems of weak ink adsorption, brittleness at low temperature, easy warping, etc., and achieves strong ink adsorption performance, surface High tension, no chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

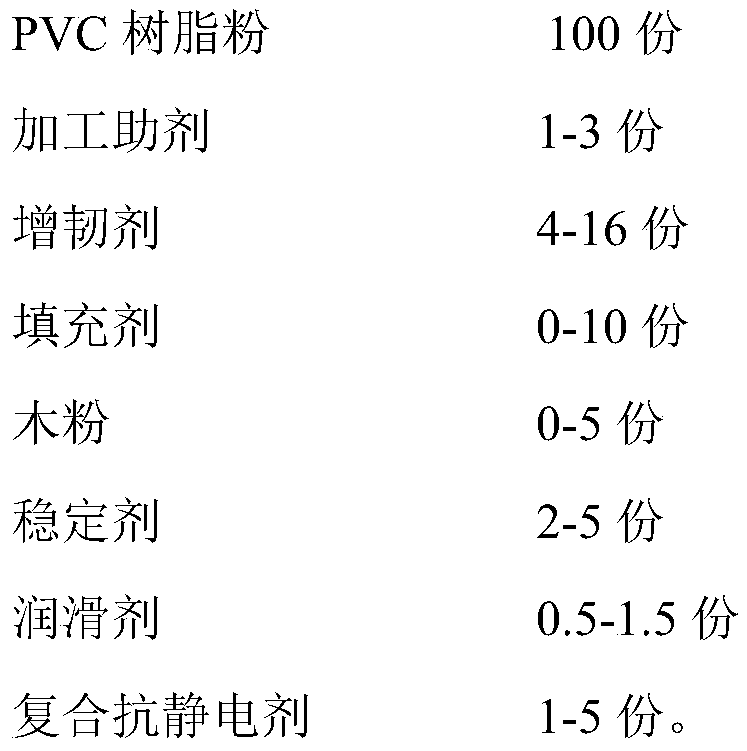

[0030] The high-strength polyvinyl chloride fold-resistant plate described in Example 1 consists of the following raw materials in parts by mass:

[0031]

[0032] in:

[0033] PVC resin powder is a polyvinyl chloride resin with a degree of polymerization of 1000.

[0034] The processing aid is a compound of acrylates and styrenes, and the mass ratio of acrylates to styrenes is 1:1; acrylates are polymers of methyl methacrylate and butyl acrylate; styrene Classes are polymers of styrene and acrylonitrile.

[0035] The toughening agent is a compound of ACM and MBS, MBS is methyl methacrylate-butadiene-styrene; ACM is acrylonitrile-chloro-methyl methacrylate; the mass ratio of ACM to MBS is 6:1 .

[0036] The filler is activated calcium carbonate with a particle size of 600 mesh.

[0037] The wood powder is bamboo wood powder with a particle size of 100 mesh and uniform particle size.

[0038] The stabilizer is a compound of calcium stearate, zinc stearate and hydrotalci...

Embodiment 2

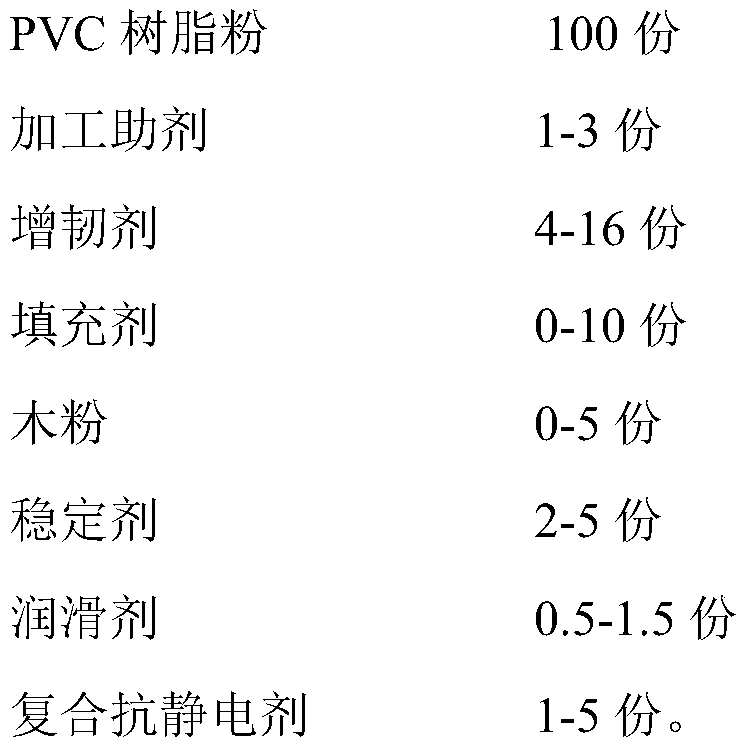

[0048] The high-strength polyvinyl chloride fold-resistant plate described in Example 2 consists of the following raw materials in parts by mass:

[0049]

[0050] in:

[0051] PVC resin powder is a polyvinyl chloride resin with a degree of polymerization of 1000.

[0052] The processing aid is a compound of acrylates and styrenes, and the mass ratio of acrylates to styrenes is 2:1; acrylates are polymers of methyl methacrylate and ethyl acrylate; styrene Classes are polymers of styrene and acrylonitrile.

[0053] The toughening agent is a compound of ACM and MBS, MBS is methyl methacrylate-butadiene-styrene; ACM is acrylonitrile-chloro-methyl methacrylate; the mass ratio of ACM to MBS is 7:1 .

[0054]The filler is heavy calcium carbonate.

[0055] The wood powder is fir wood powder, the particle size is 80 mesh, and the particle size is uniform.

[0056] The stabilizer is a compound of calcium stearate, zinc stearate and hydrotalcite.

[0057] The lubricant is a mix...

Embodiment 3

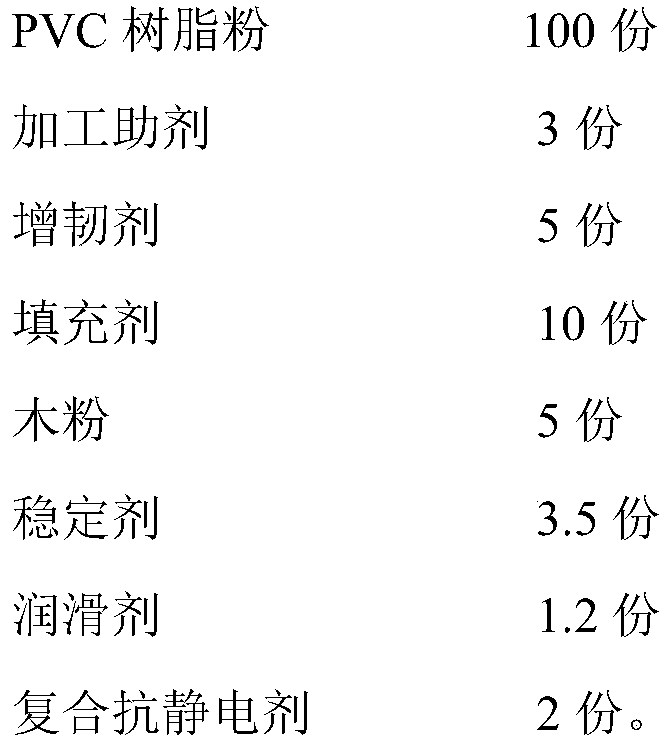

[0066] The high-strength polyvinyl chloride fold-resistant plate described in Example 3 consists of the following raw materials in parts by mass:

[0067]

[0068] in:

[0069] PVC resin powder is a polyvinyl chloride resin with a degree of polymerization of 1000.

[0070] The processing aid is a compound of acrylates and styrenes, the mass ratio of acrylates to styrenes is 3:1; acrylates are polymers of methyl methacrylate and butyl acrylate; styrene Classes are polymers of styrene and acrylonitrile.

[0071] The toughening agent is a compound of ACM and MBS, MBS is methyl methacrylate-butadiene-styrene; ACM is acrylonitrile-chloro-methyl methacrylate; the mass ratio of ACM to MBS is 9:1 .

[0072] The wood flour is poplar wood flour with a particle size of 100 mesh and uniform particle size.

[0073] The stabilizer is a compound of calcium stearate, zinc stearate and hydrotalcite.

[0074] The lubricant is a compound of pentaerythritol fatty acid ester and polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com