An energy-saving door lining brick for a coke oven

An energy-saving, brick-lined technology, which is applied in coke oven bricklaying operations, coke oven doors/closers, coke ovens, etc., can solve the problem of reducing the surface temperature of the furnace door, the structural strength of fasteners is low, and the reduction of the overall furnace Reduce the door weight and other problems, achieve the effect of reducing the surface temperature of the furnace door, reducing the cost of the furnace door, and lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

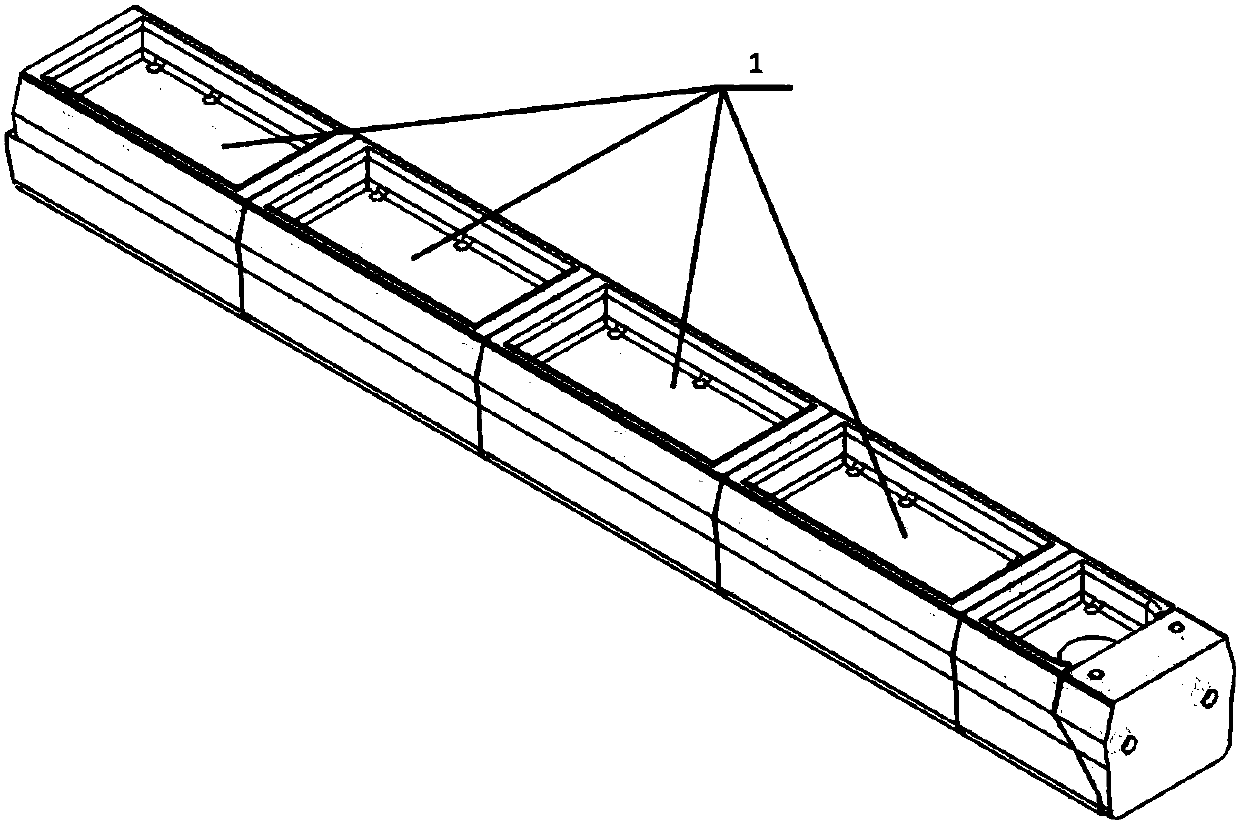

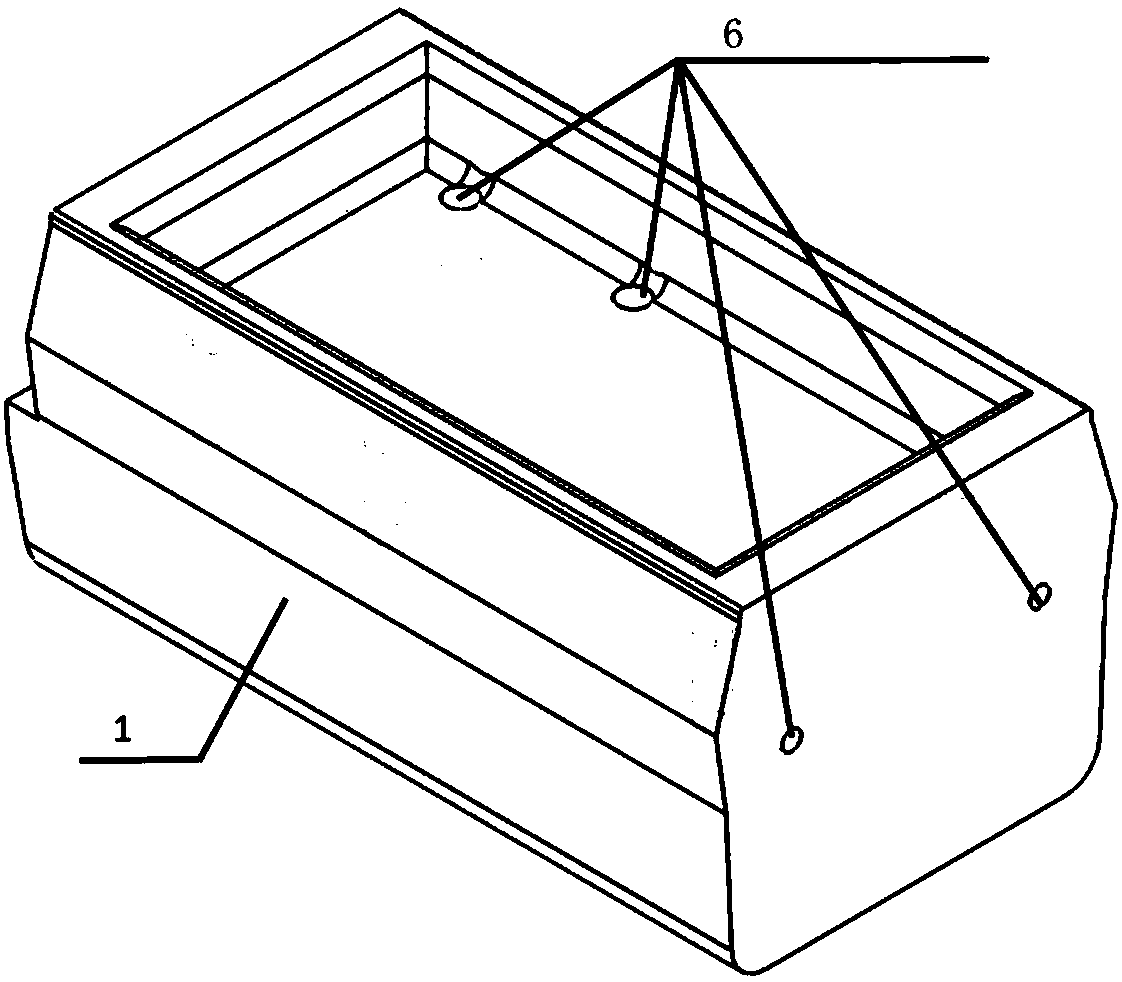

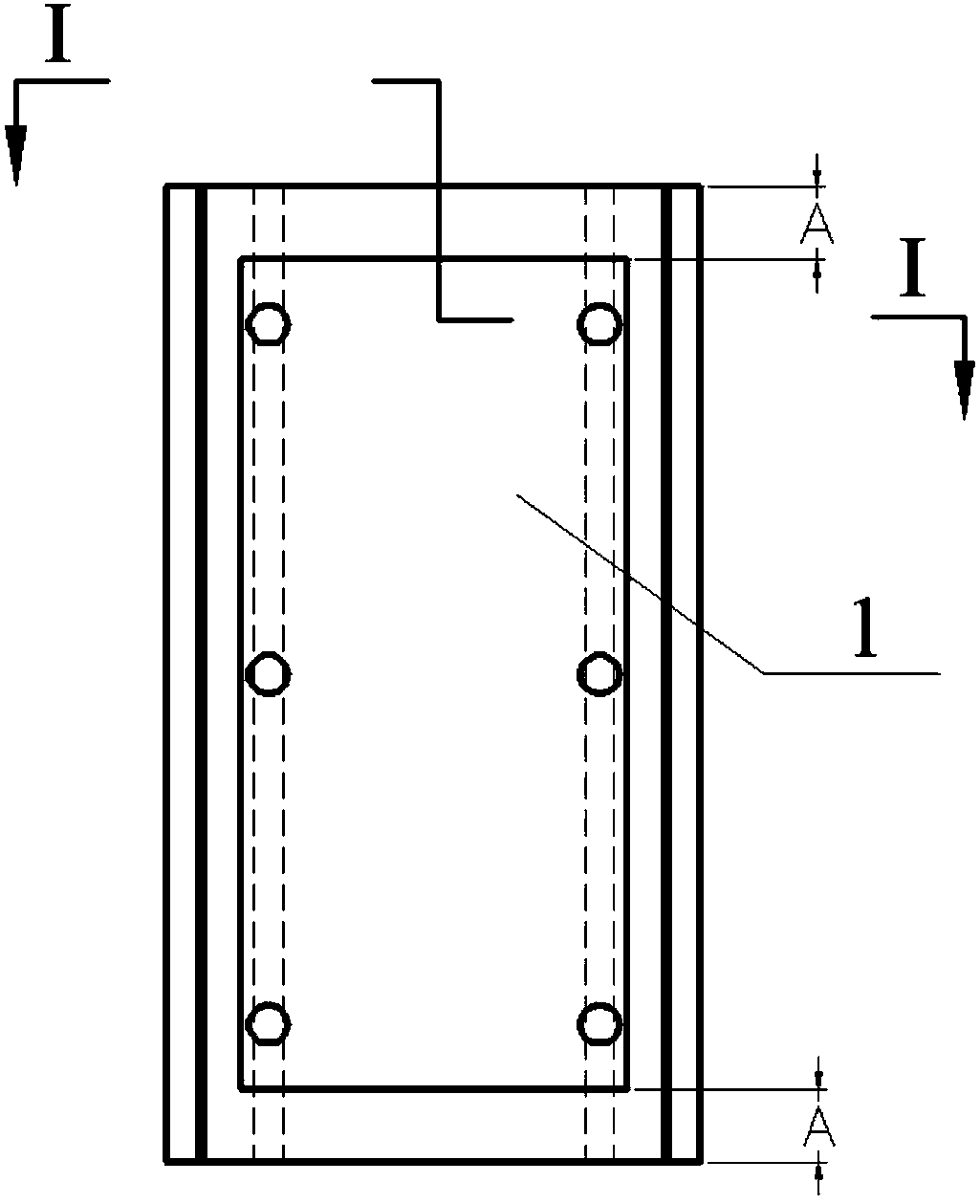

[0028] like Figure 1-4 As shown, an energy-saving coke oven door lining brick includes a lining brick body 1 , a glazed surface 2 , a web 3 and fastening bolts 5 .

[0029] The lining brick is a large refractory prefabricated block lining brick. The height can be designed in sections according to the height of the furnace door frame. The large furnace door can be divided into 5 sections according to needs. The height of each section of the upper 4 sections is 1.3m. Groove combination, using lining bricks with a height of 0.6m. All lining bricks are made of high-alumina cordierite. Normal temperature compressive strength (after firing) ≥ 45Mpa, thermal conductivity ≤ 1.2W / M·K at 1000°C, thermal shock resistance at 1100°C - water cooling ≥ 50 times.

[0030] The lining brick body 1 is a concave square hollow structure near the web surface, and there is one hollow structure 7. The upper surface of the lining brick body 1 is in close contact with the web 3, so that the hollow st...

Embodiment 2

[0039] like Figure 5 , Image 6 as shown,

[0040] The lining brick body 1 is a concave hexagonal hollow structure 7 near the web surface, and there are 10 hollow structures 7. The lining brick body 1 is in contact with the web 3, so that the hollow structure 7 is a closed cavity, ensuring that the lining brick body 1 Based on the overall strength, air insulation is used.

[0041] The surface of the web 3 in contact with the concave hollow structure 7 of the lining brick body 1 adopts the web coating 4, and the web coating 4 adopts a heat-reflective heat-insulating coating with strong reflectivity, so as to avoid the inner brick surface being damaged due to the thickness reduction of the lining brick. The temperature is too high, the radiation heat transfer to the web.

[0042] The fastening bolts 5 are symmetrically arranged in two columns on the left and right on the lining brick body 1, and each lining brick body 1 adopts 3 rows of fastening bolts 5. Fastening bolt hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com