Damper with good sealing performance

A sealing performance and damper technology, which is applied in the direction of shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve the problem of poor sealing performance, easy splashing of damping oil, and reduction of the total amount of damping oil stored in the damper And other problems, to achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

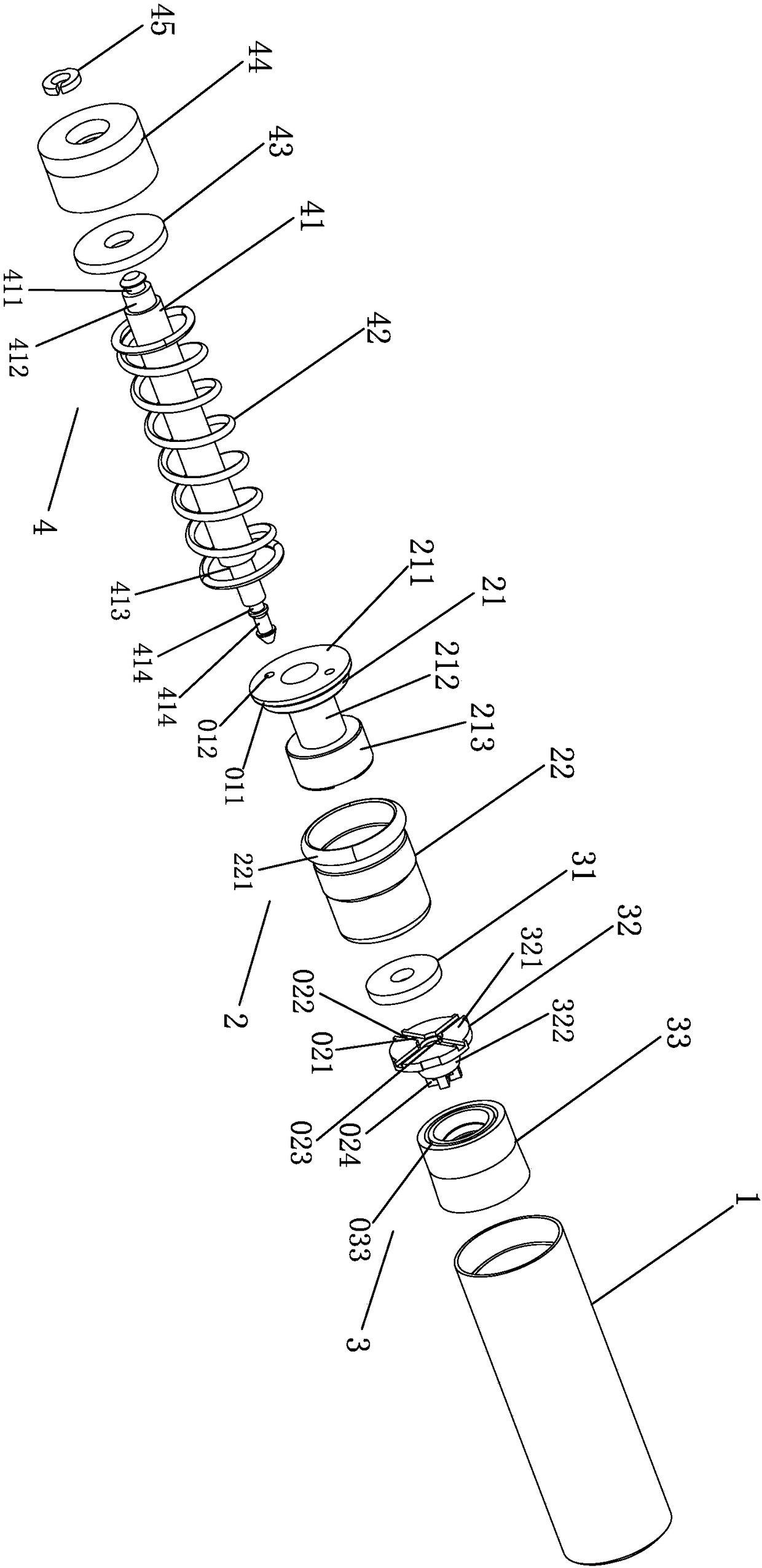

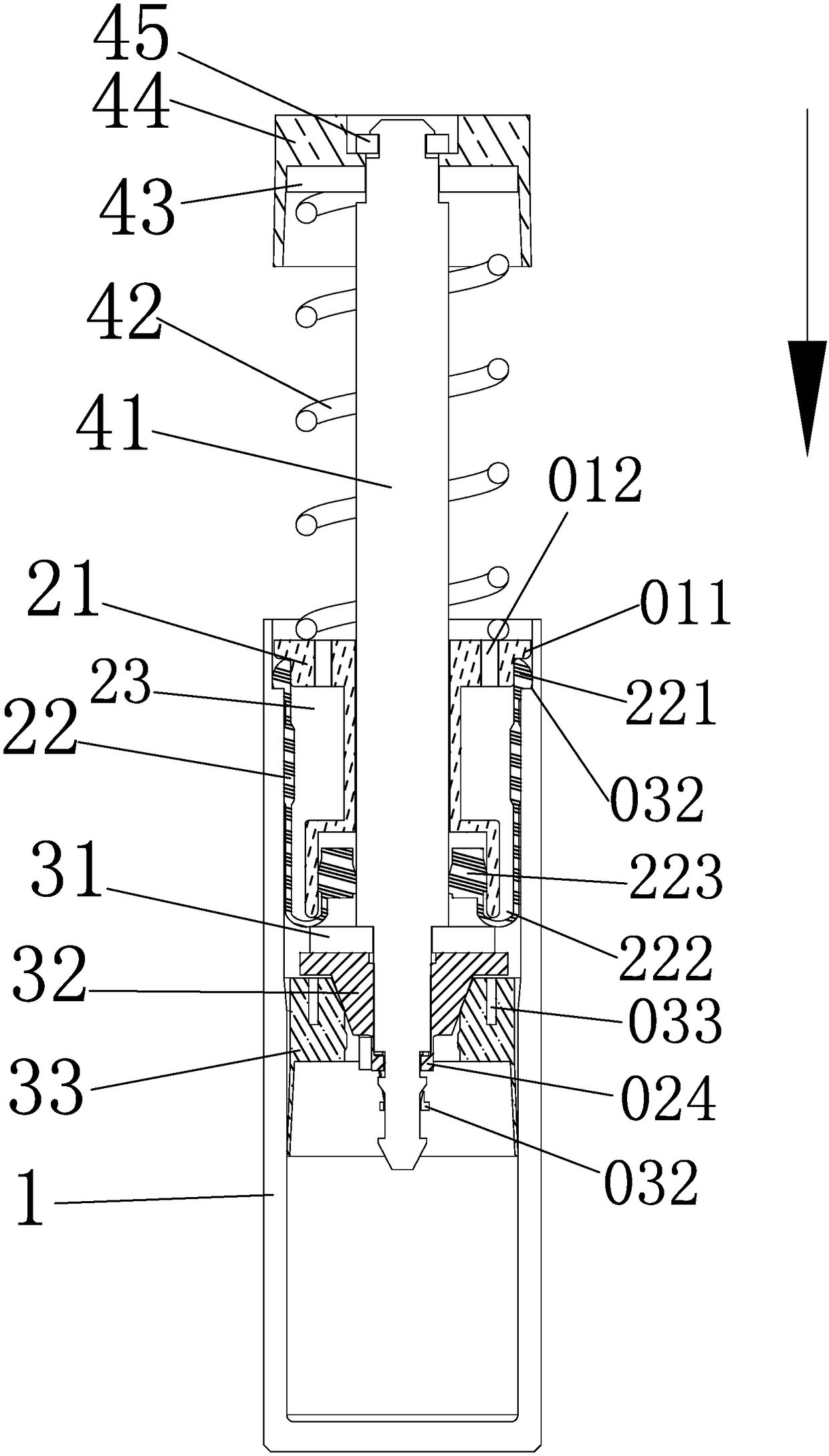

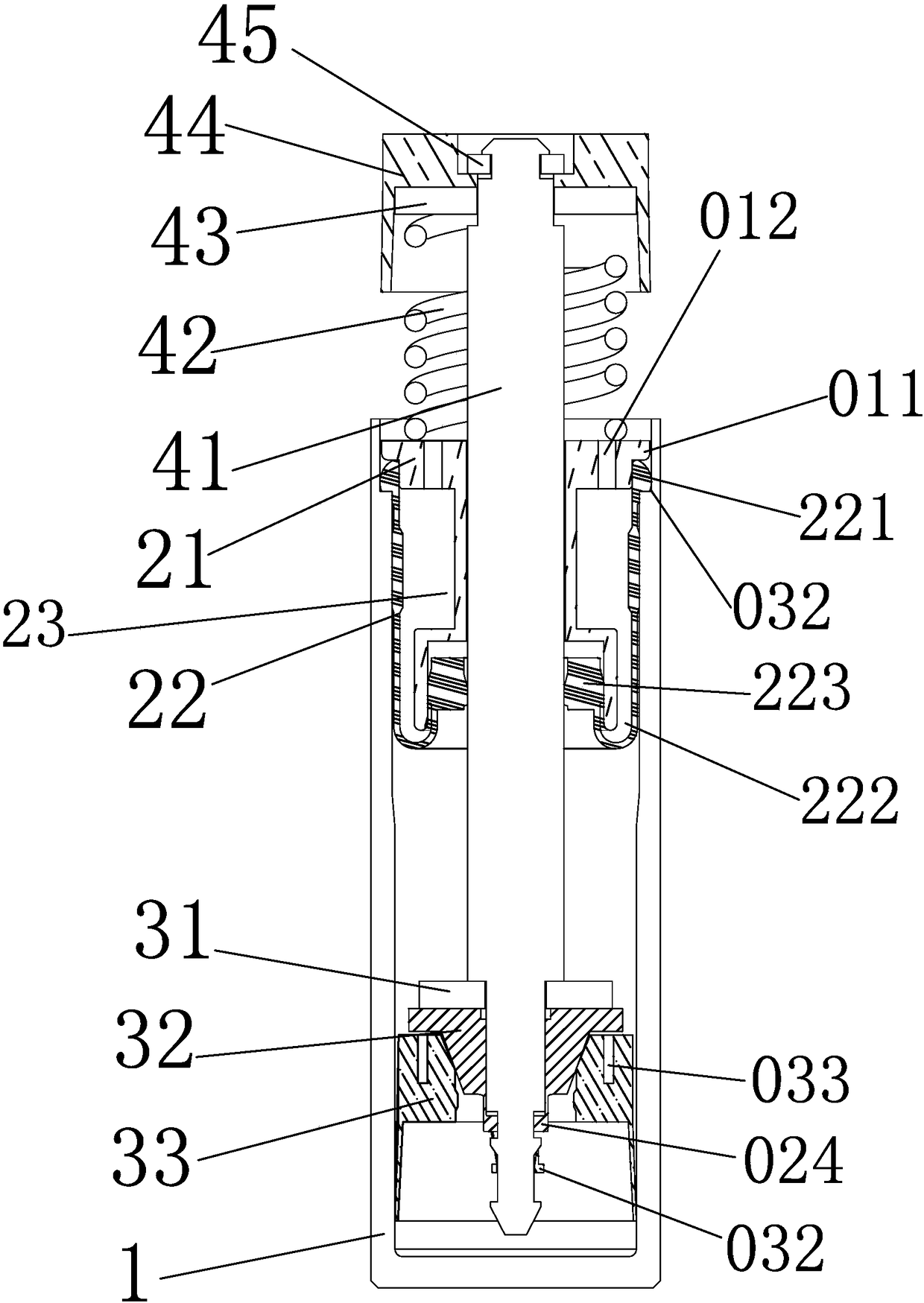

[0015] Such as figure 1 As shown in -4, a damper with good sealing performance includes a cylindrical casing 1, and the casing 1 is provided with a sealing assembly 2, a piston assembly 3 and a driving assembly 4 that drives the piston assembly 3 to move up and down. The sealing assembly 2 includes an end cap 21 and a sealing sleeve 22 sleeved outside the end cap 21. The upper part 211 of the end cap 21 is in the shape of an annular disc and the outer edge of the upper part 211 of the end cap is surrounded by an annular protrusion 011. The upper end surface of the upper part 211 of the end cover is provided with a ventilation hole 012, the middle part 212 of the end cover 21 is a circular tube, the lower part 213 of the end cover 21 is an annular cover shape, and the middle part 212 of the end cover 21 is respectively It communicates with the upper part 211 of the end cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com