Technology for removing and leaching impurity in mixed liquor in production of lutein factice

A technology of mixed liquid and lutein, which is applied in the direction of making medicines into special physical or ingestible devices, liquid delivery, ointment delivery, etc., which can solve problems such as difficult control, large pressure difference, and excessive flow rate of mixed liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, the present invention will be further described as an embodiment in combination with the aforementioned technical solutions and accompanying drawings.

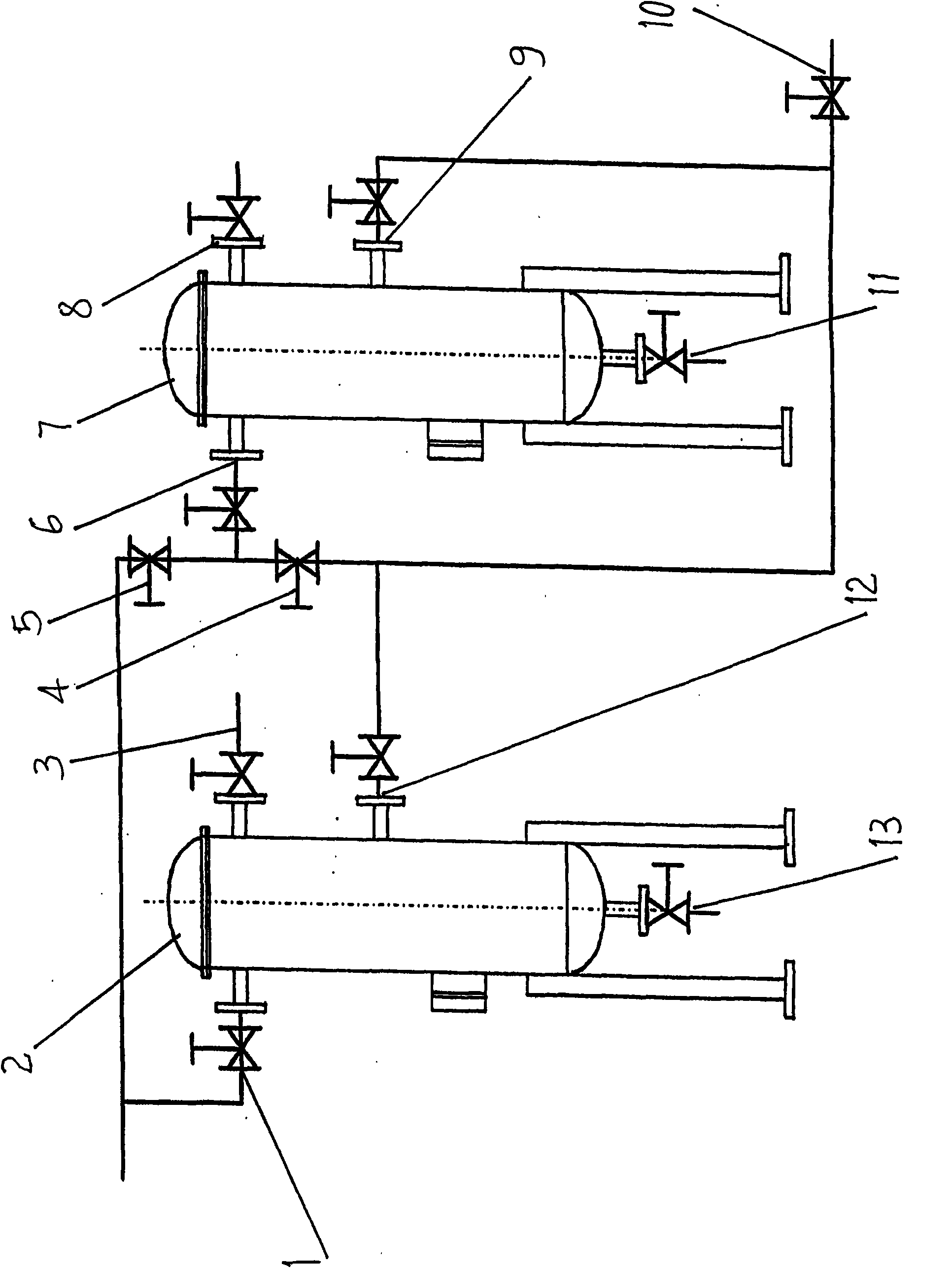

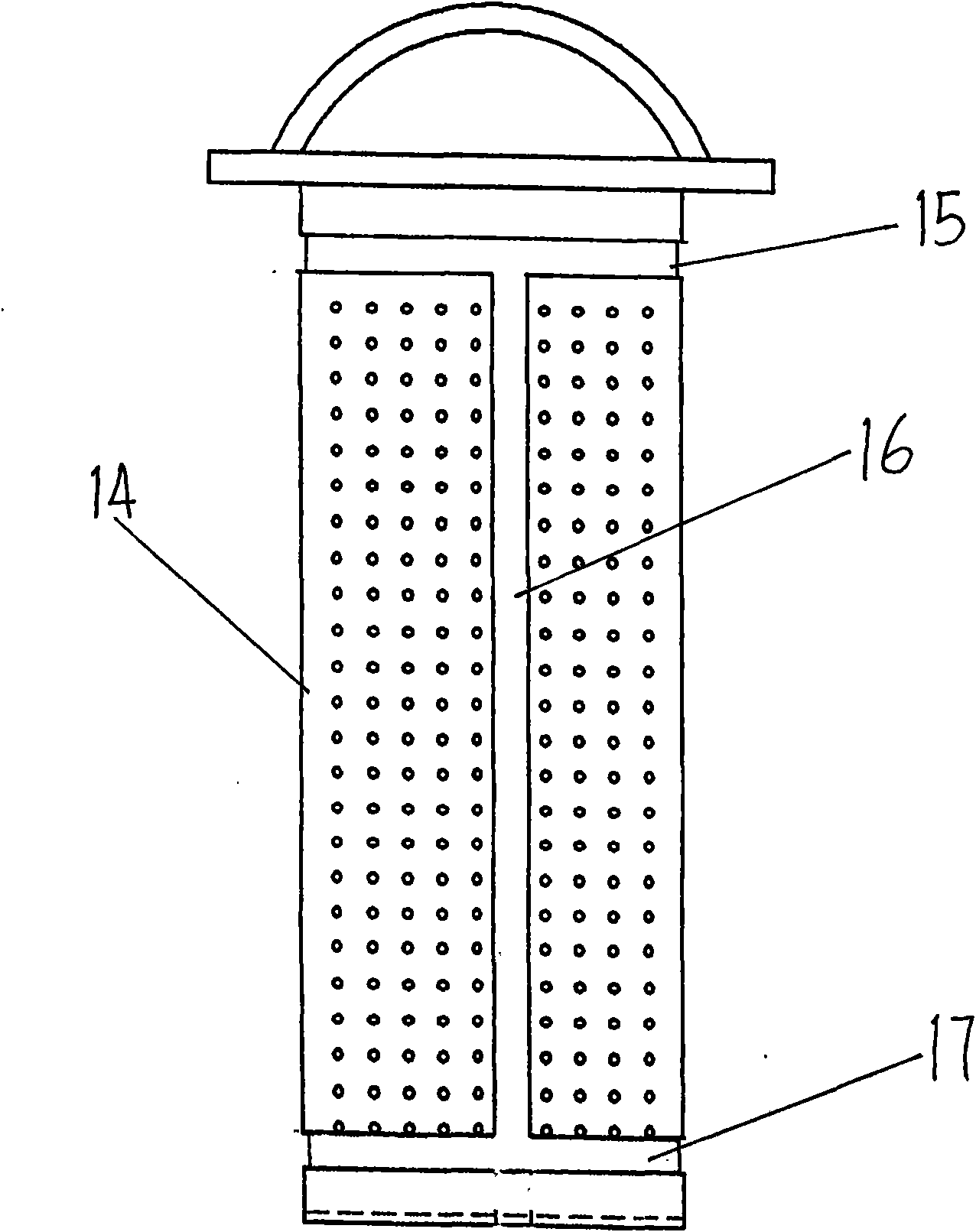

[0032] The production raw material is the dried marigold flower granules after treatment, and the extraction solvent adopted is n-butane. Adopt the same process and equipment as the existing marigolds to produce lutein ointment. The present invention is mainly in the extraction mode, after the extraction is completed, the hydraulic pressure difference control to the evaporation tank or the temporary storage tank, the storage function of the temporary storage tank used in the original production process is changed to the impurity settling function, and the time and temperature of evaporation in the evaporation tank The matching technology and the control technology of the filter inlet and outlet valves constitute the production process technology; in addition, the selection and matching of the filter me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com