Blank machining equipment for graphite thermal field and machining method thereof

A technology for processing equipment and blank parts, which is applied to the processing equipment for blank parts in the graphite thermal field and its processing field, can solve the problems of inconvenient lifting and adjustment of the crucible, cumbersome installation methods, and affecting the personal safety of workers, and solve the problem that the opening of the crucible is not tightly sealed , Reduce labor burden, simplify the effect of operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

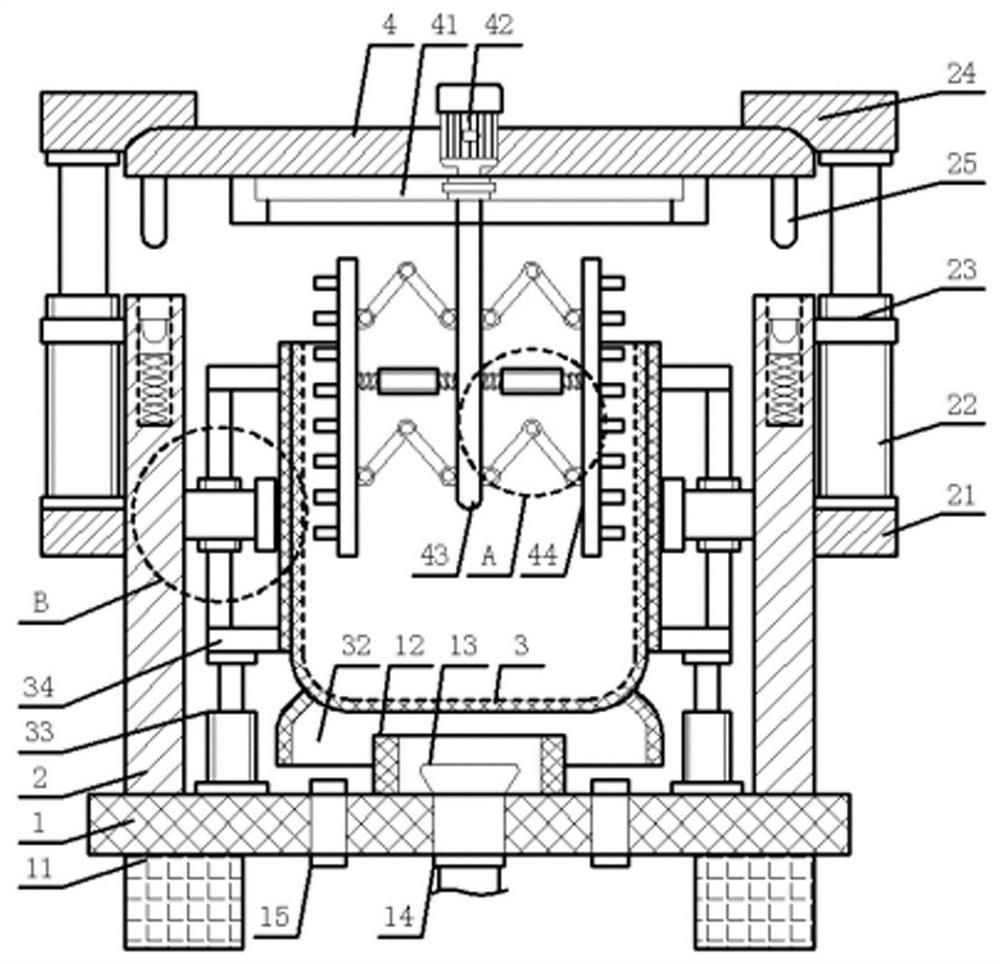

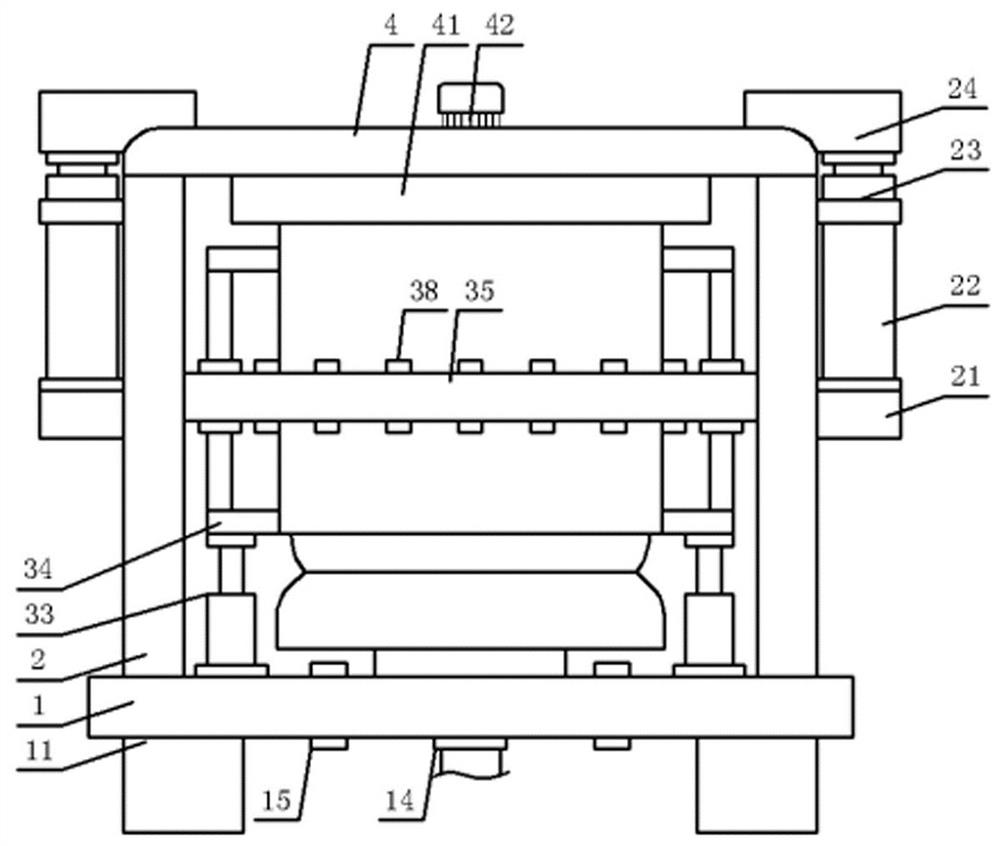

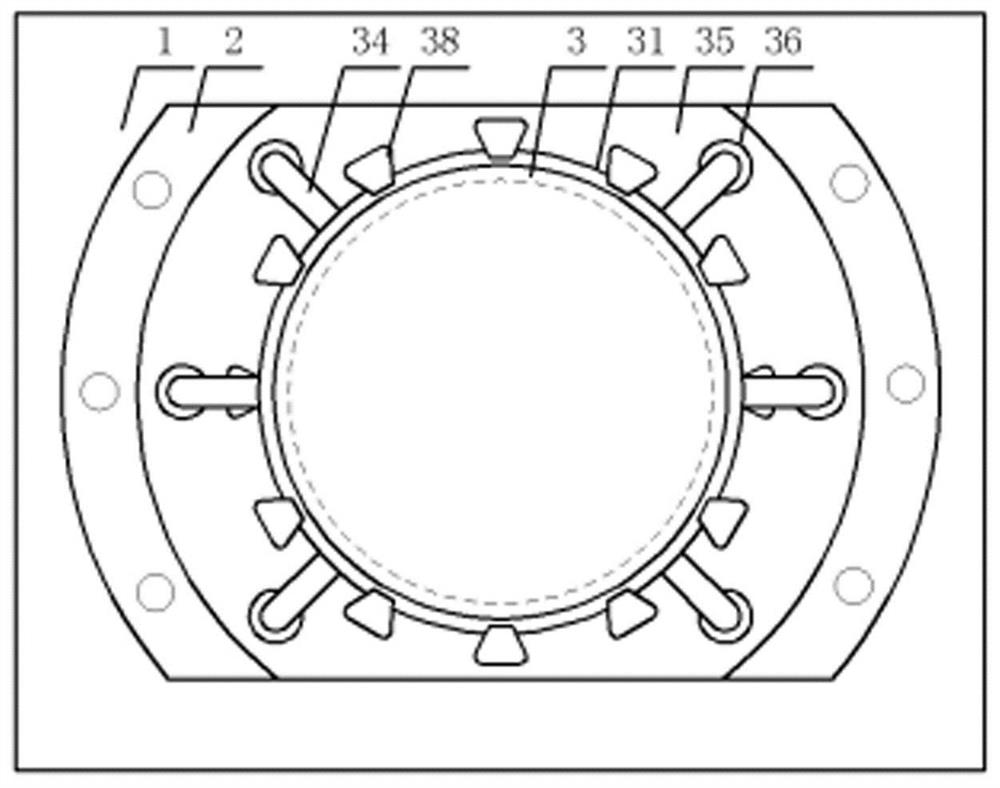

[0035] Embodiment 1: In order to solve the problems of inconvenient installation and lifting of the crucible, uneven stirring of the graphite material, and poor sealing of the crucible opening, and to improve the efficiency of graphite material processing and production, this embodiment proposes blank processing equipment for graphite thermal field , see Figure 1-6 , including a bottom plate 1, an arc-shaped vertical plate 2, a sliding mechanism, a lifting mechanism, and a stirring mechanism, the bottom plate 1 is a rectangular plate placed horizontally and horizontally, and a pair of vertically symmetrical The arc-shaped vertical board 2 is located in the middle of the two arc-shaped vertical boards 2 and is provided with a support plate 35 placed horizontally. A crucible cylinder 3, the outer surface of the crucible cylinder 3 is covered with a thermal insulation cylinder 31, and both sides of the outer wall of the thermal insulation cylinder 31 are slidingly connected to t...

Embodiment 2

[0041] Example 2: see Figure 6 , in the present embodiment, the present invention also proposes the processing method of the blank piece processing equipment used for the graphite heat field, comprising the following steps:

[0042] Step 1, the first telescopic cylinder 33, the second telescopic cylinder 22, and the motor 42 are respectively electrically connected to the external power supply through the power cord, and the graphite material to be processed is poured into the crucible cylinder 3, and the ignition cylinder 13 is connected to the external power supply through the gas pipe 14. The gas tank is connected, and the igniter 13 is ignited, and the flame burns in the limit ring 12;

[0043] Step 2, control the crucible tube 3 to descend through the sliding mechanism, control the telescopic rod of the first telescopic cylinder 33 to shorten, drive the reinforcing rod 34 and the sliding rod 37 to slide down along the sliding cylinder 36 through the first connecting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com