Gravel grading system

A technology of grading and gravel, applied in the direction of solid separation, separation of solids from solids with airflow, swirling devices, etc., can solve the problems of energy waste, large fan power, environmental pollution, etc., and achieve improved winnowing effect , reduce power, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

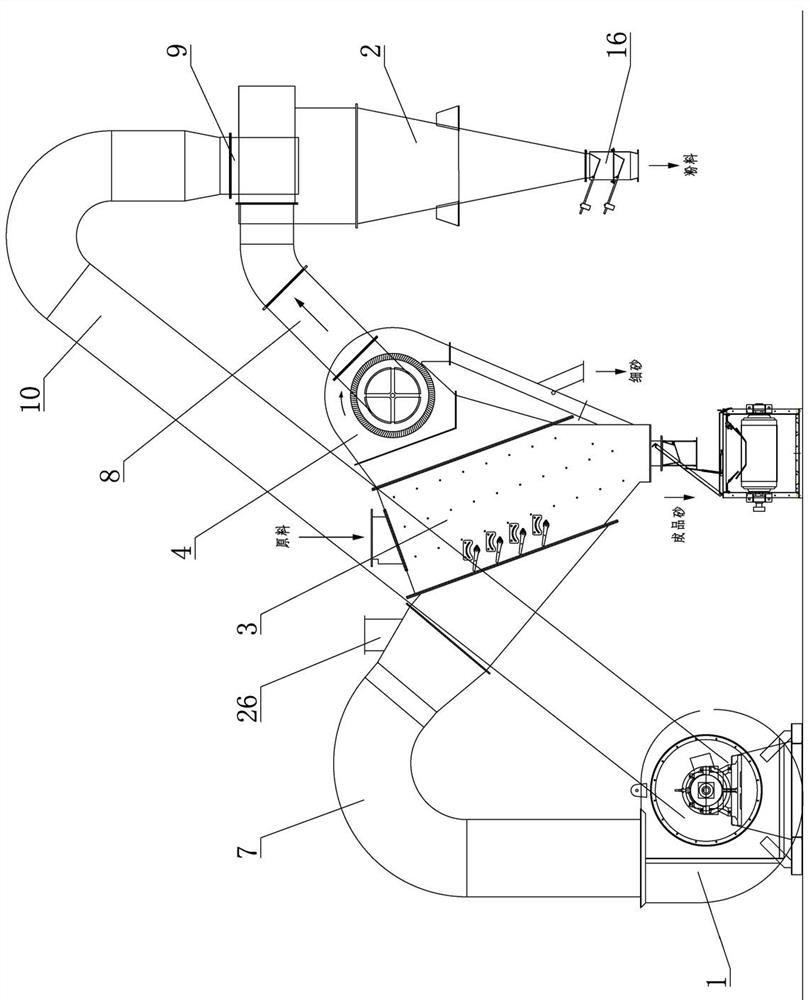

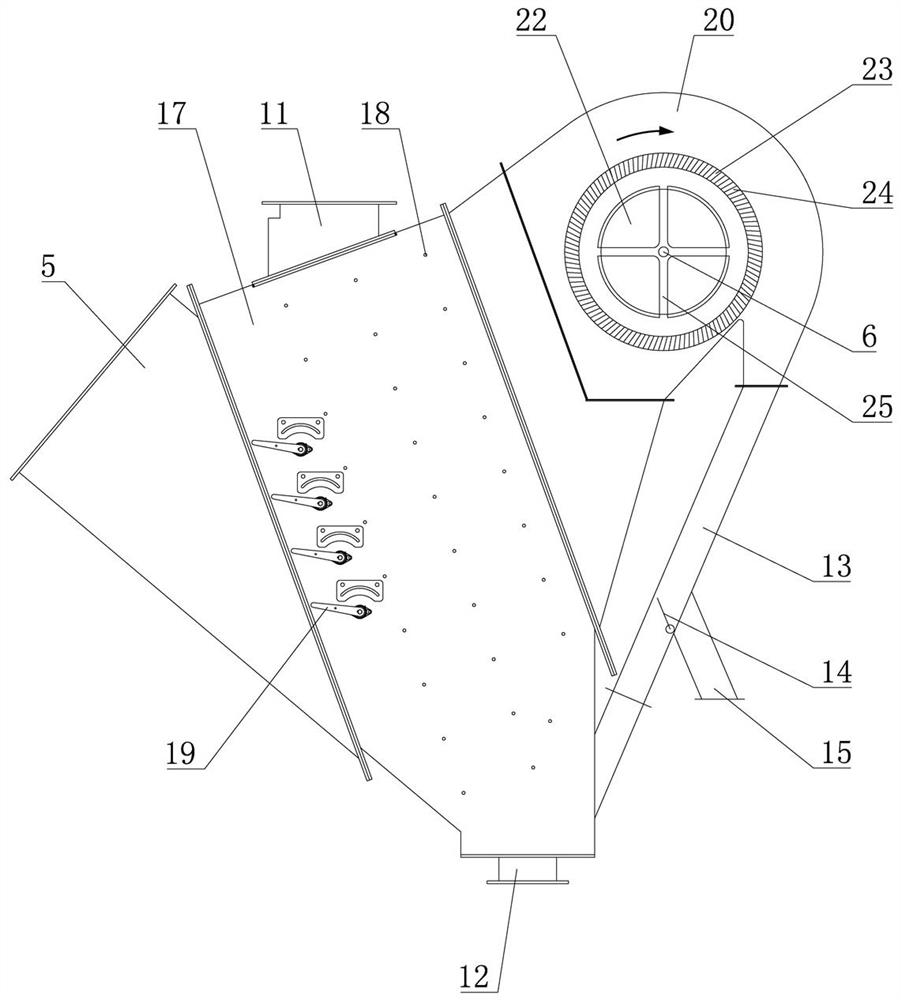

[0013] Depend on Figure 1 to Figure 2 Given, the present invention comprises powder selection device, centrifugal blower 1 and winnowing chamber 2, and powder selection device comprises static powder selection device 3 and dynamic powder selection device 4, and static powder selection device 3 and dynamic powder selection device 4 are respectively provided with inlet The air outlet 5 and the air outlet 6, the centrifugal blower 1 is connected with the air inlet 5 through the first pipeline 7, the winnowing room 2 is connected with the air outlet 6 through the second pipeline 8, and the upper end of the winnowing room 2 is also provided with a return air outlet 9, which returns The tuyere 9 is connected to the centrifugal fan 1 or the first pipeline 7 through the third pipeline 10, so that a negative-pressure air circulation channel is formed between the separation device, the centrifugal fan 1 and the winnowing room 2, which can solve the problem of poor sealing of the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com