Soot blowing method and device for horizontal flue of π-shaped boiler

A boiler horizontal flue and soot blowing device technology, applied in the direction of combustion method, combustion product treatment, solid residue removal, etc., can solve flue gas temperature fluctuation due to temperature difference, cannot accurately reflect flue ash accumulation, and achieve No problems such as soot blowing requirements can be achieved, and the effect of reducing renovation cost, good disturbance effect, shortening construction period and construction difficulty can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

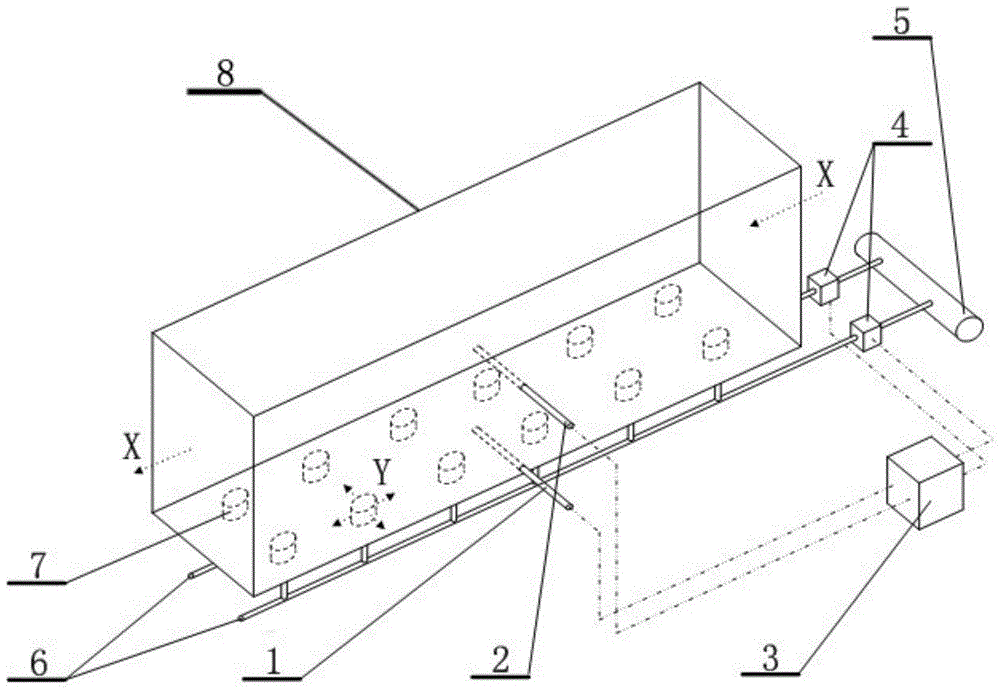

[0036] Such as figure 1 Shown, the soot blowing method of the present embodiment is made up of following steps:

[0037] Step A, measure the instant temperature T1 at this point of the flue 8 by setting the first temperature detector 1 on the bottom wall of the flue 8 at the horizontal direction of the flue 8, that is, at 1 / 3 of the smoke flow direction X in the figure; The second temperature detector 2 arranged at 2 / 3 of the horizontal direction of the flue 8 and 1 / 4 of the height of the flue 8 measures the instant temperature T2 of this point of the flue 8;

[0038] Step B, input T1 and T2 into the PID (proportional-integral-derivative) control module 3 to obtain the difference ΔT between T2 and T1;

[0039] Step C, when ΔT is greater than or equal to 5°C, the PID control module 3 sends a soot blowing signal to the soot blowing system. Pass compressed air into the flue 8 for 10 seconds, and return to step A after the soot blowing is completed; when ΔT is less than 5°C, ret...

Embodiment 2

[0043] Such as figure 1 Shown, the soot blowing method of the present embodiment is made up of following steps:

[0044] Step A, measure the instant temperature T1 at this point of the flue 8 by setting the first temperature detector 1 at the midpoint of the flue 8 in the horizontal direction of the flue 8, that is, the middle point of the smoke flow direction X in the figure, and at 1 / 8 of the height of the flue 8; Measure the instant temperature T2 at this point of the flue 8 by setting it at the middle point in the horizontal direction of the flue 8, in the same section as the first temperature detector 1, and at the second temperature detector 2 at 1 / 2 of the height of the flue 8;

[0045] Step B, input T1 and T2 into the PID (proportional-integral-derivative) control module 3 to obtain the difference ΔT between T2 and T1;

[0046] Step C, when ΔT is greater than or equal to 5°C, the PID control module 3 sends a soot blowing signal to the soot blowing system and no longer...

Embodiment 3

[0050] Such as figure 1 Shown, the soot blowing method of the present embodiment is made up of following steps:

[0051] Step A, measure the instant temperature T1 at this point of the flue 8 by setting the first temperature detector 1 on the horizontal direction of the flue 8, that is, the middle point of the smoke flow direction X direction in the figure, and the bottom wall of the flue 8; The middle point in the horizontal direction of the flue 8 is the same section as the first temperature detector 1, and the second temperature detector 2 at 1 / 2 of the height of the flue 8 measures the instant temperature T2 at this point of the flue 8;

[0052] Step B, input T1 and T2 into the PID (proportional-integral-derivative) control module 3 to obtain the difference ΔT between T2 and T1;

[0053] Step C, when ΔT is greater than or equal to 2°C, the PID control module 3 sends a soot blowing signal to the soot blowing system and no longer sends the soot blowing signal to the soot bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com