Patents

Literature

56results about How to "Increase wall temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

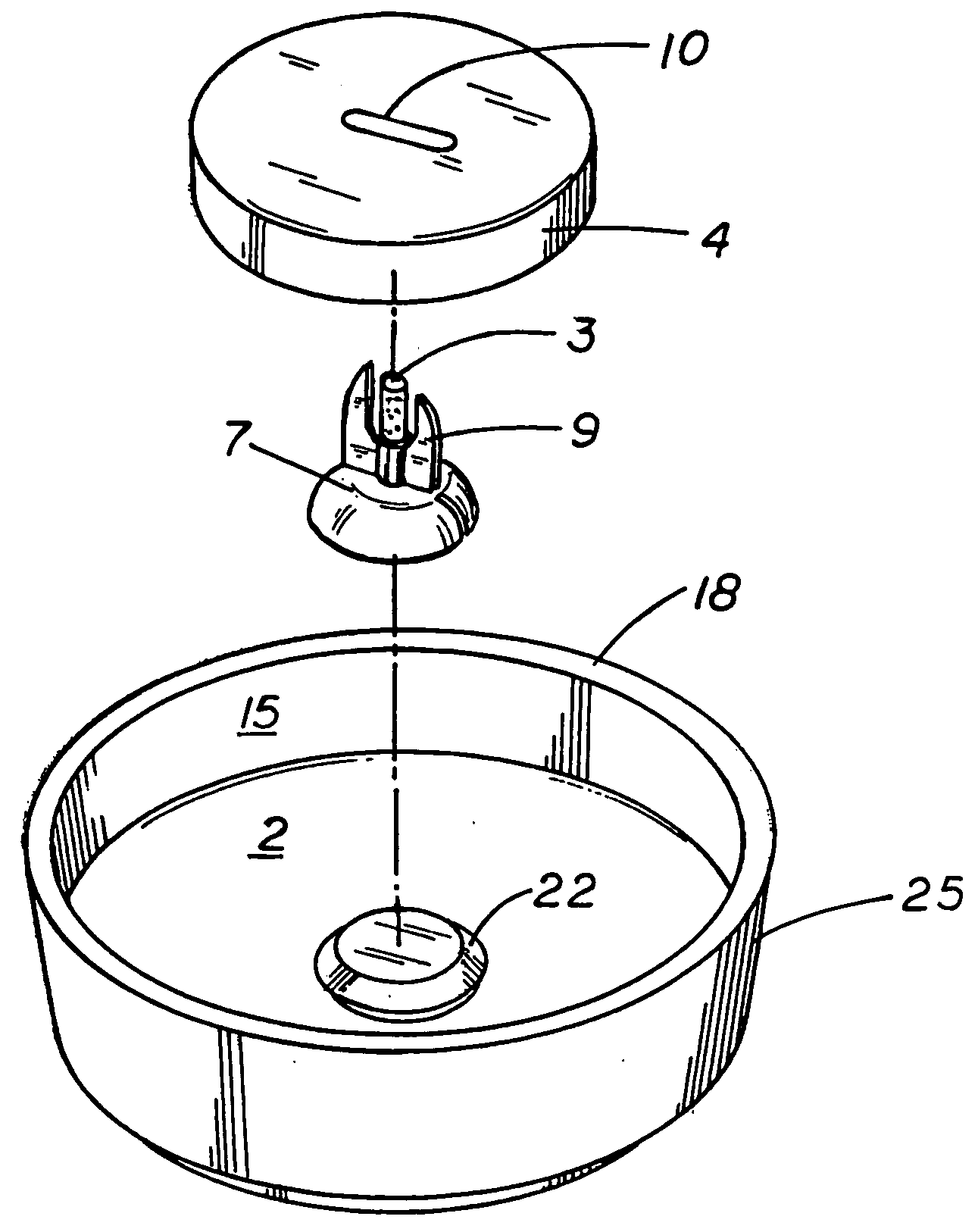

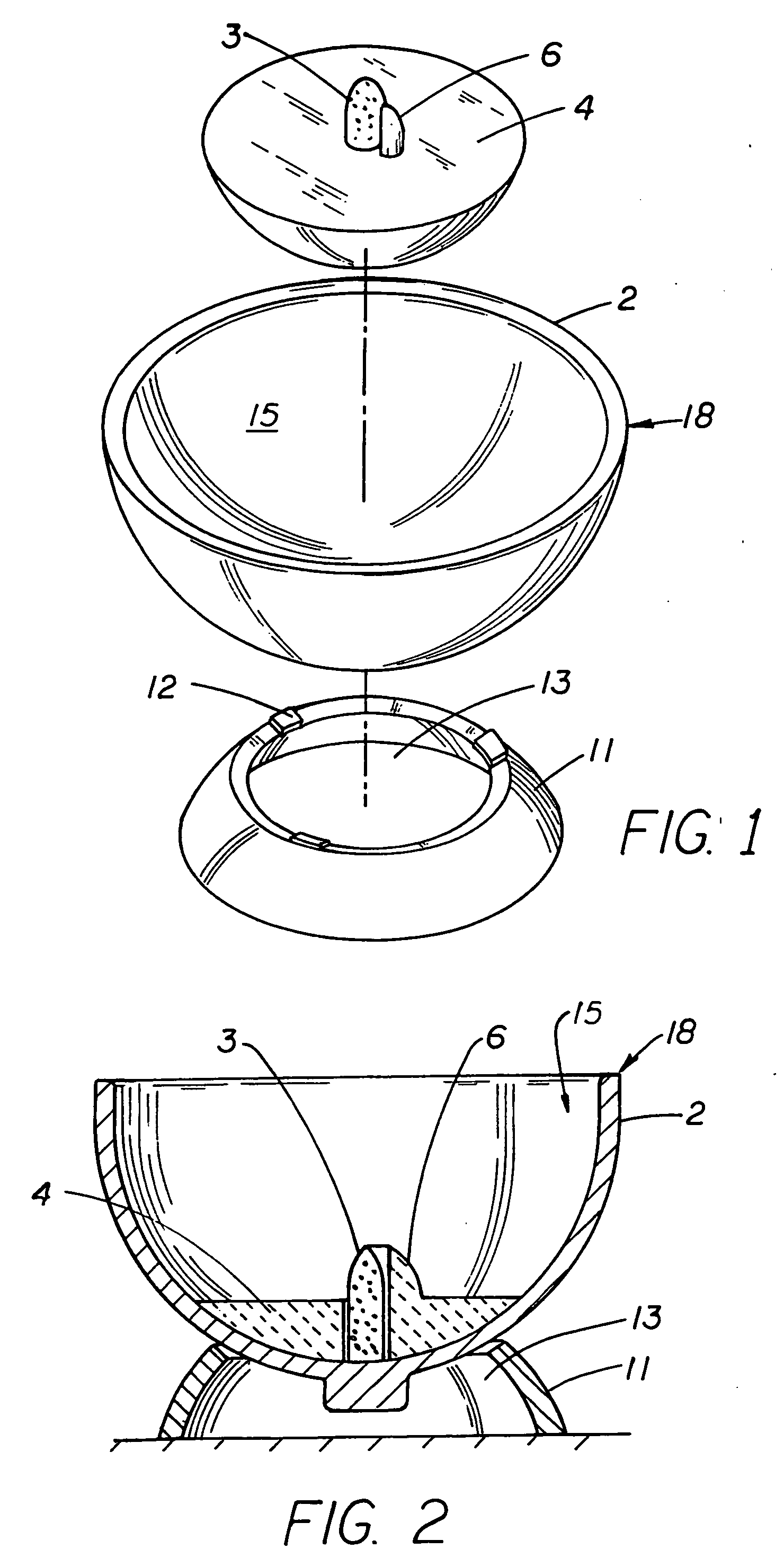

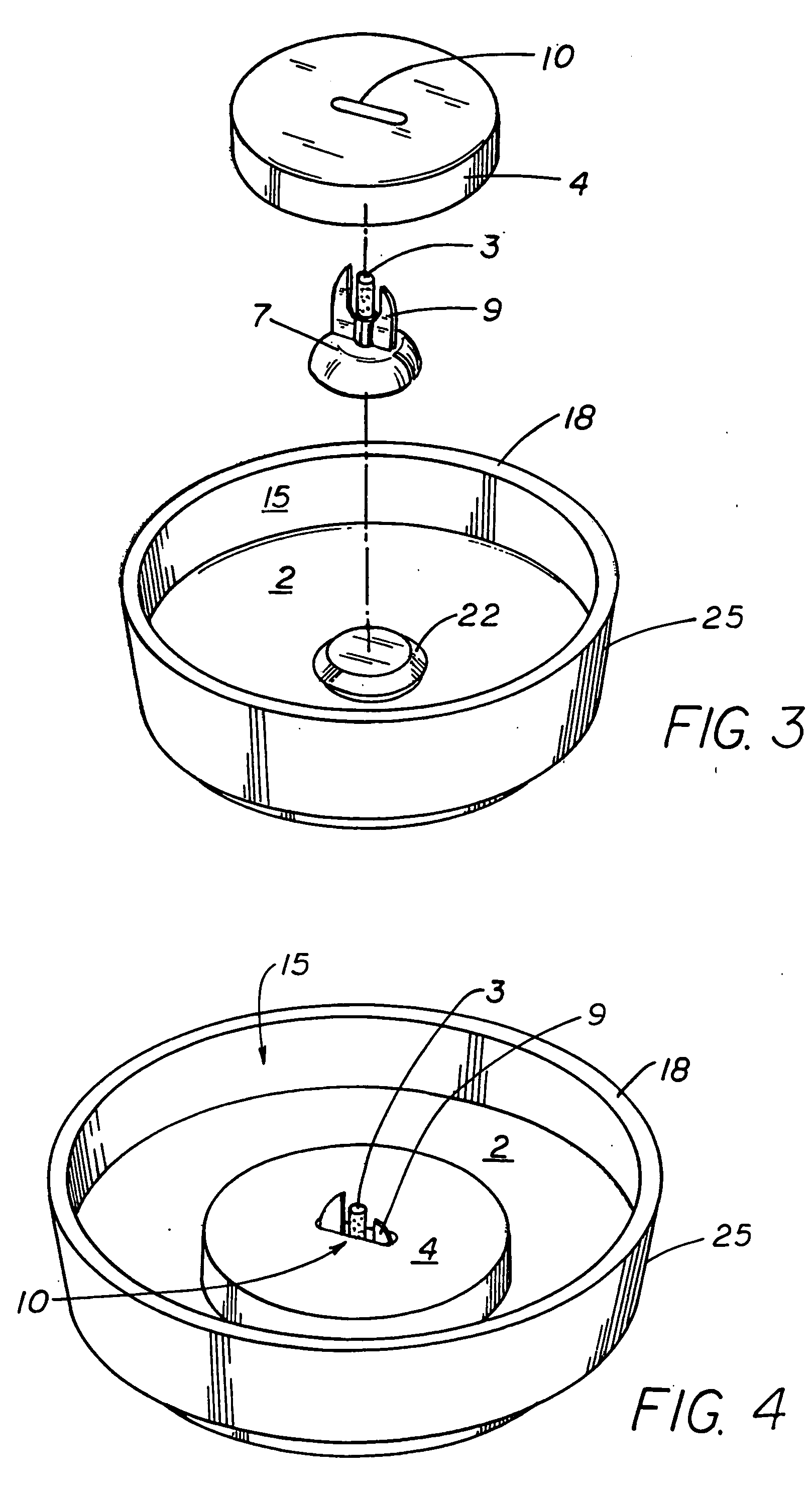

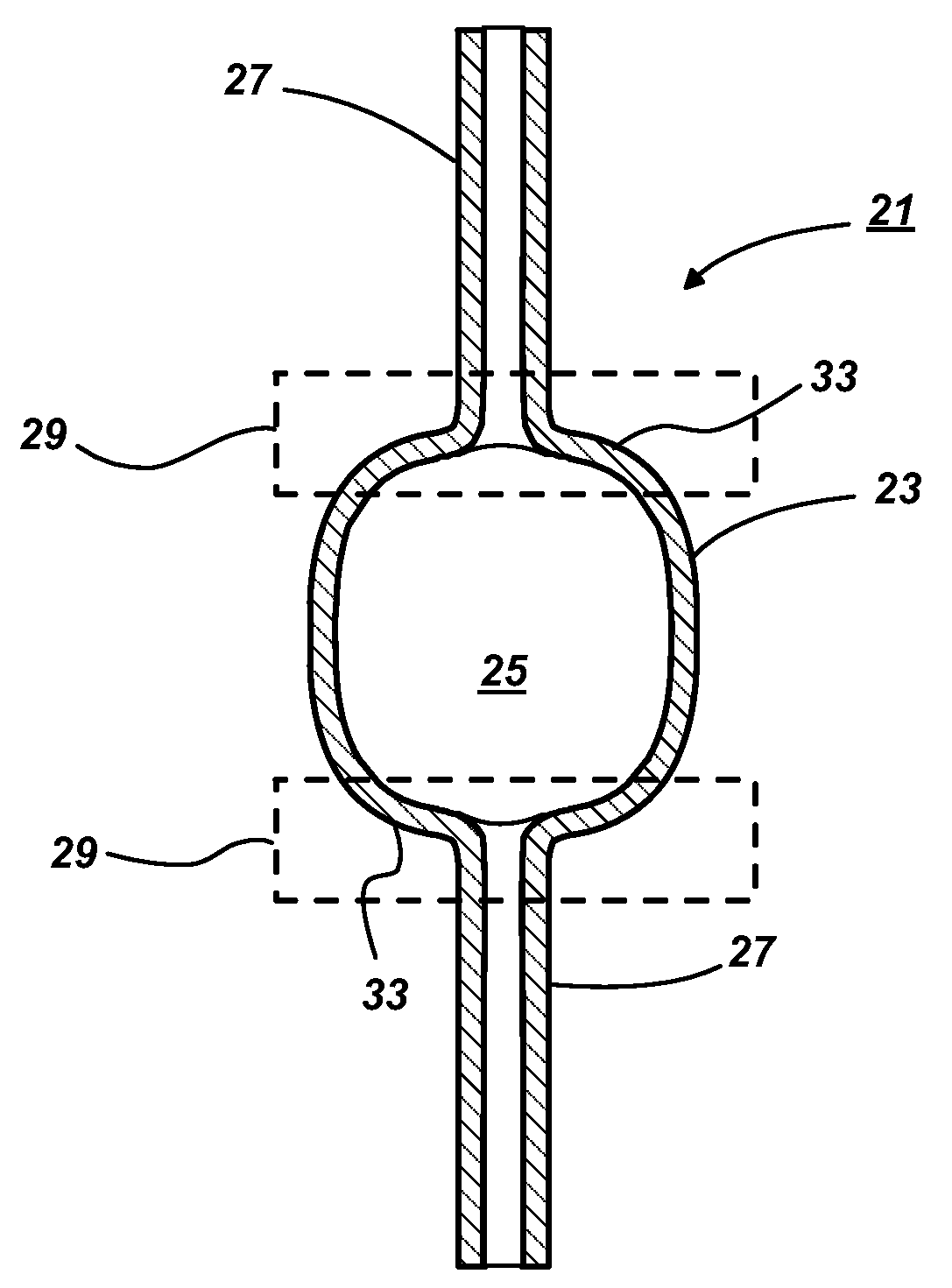

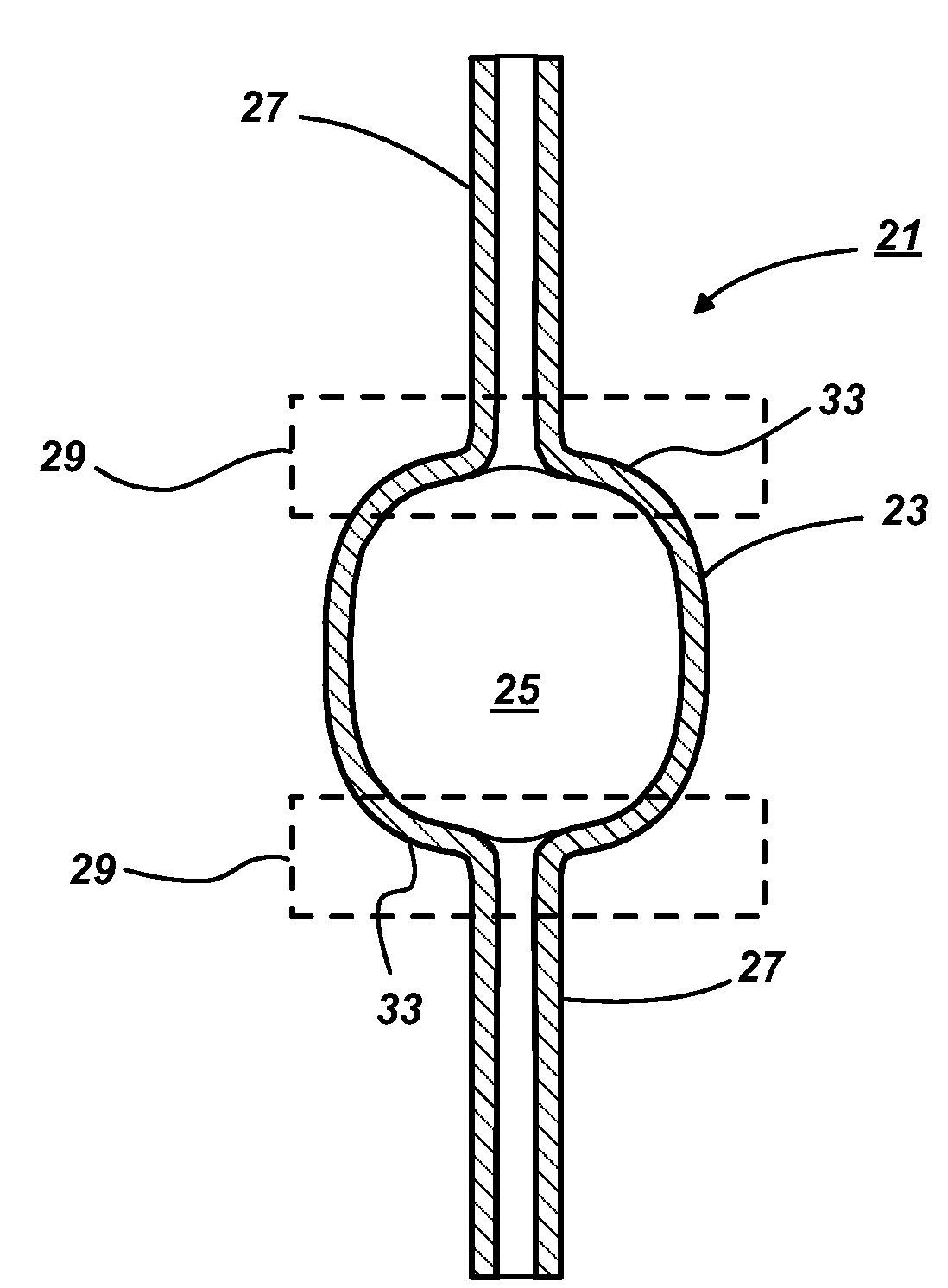

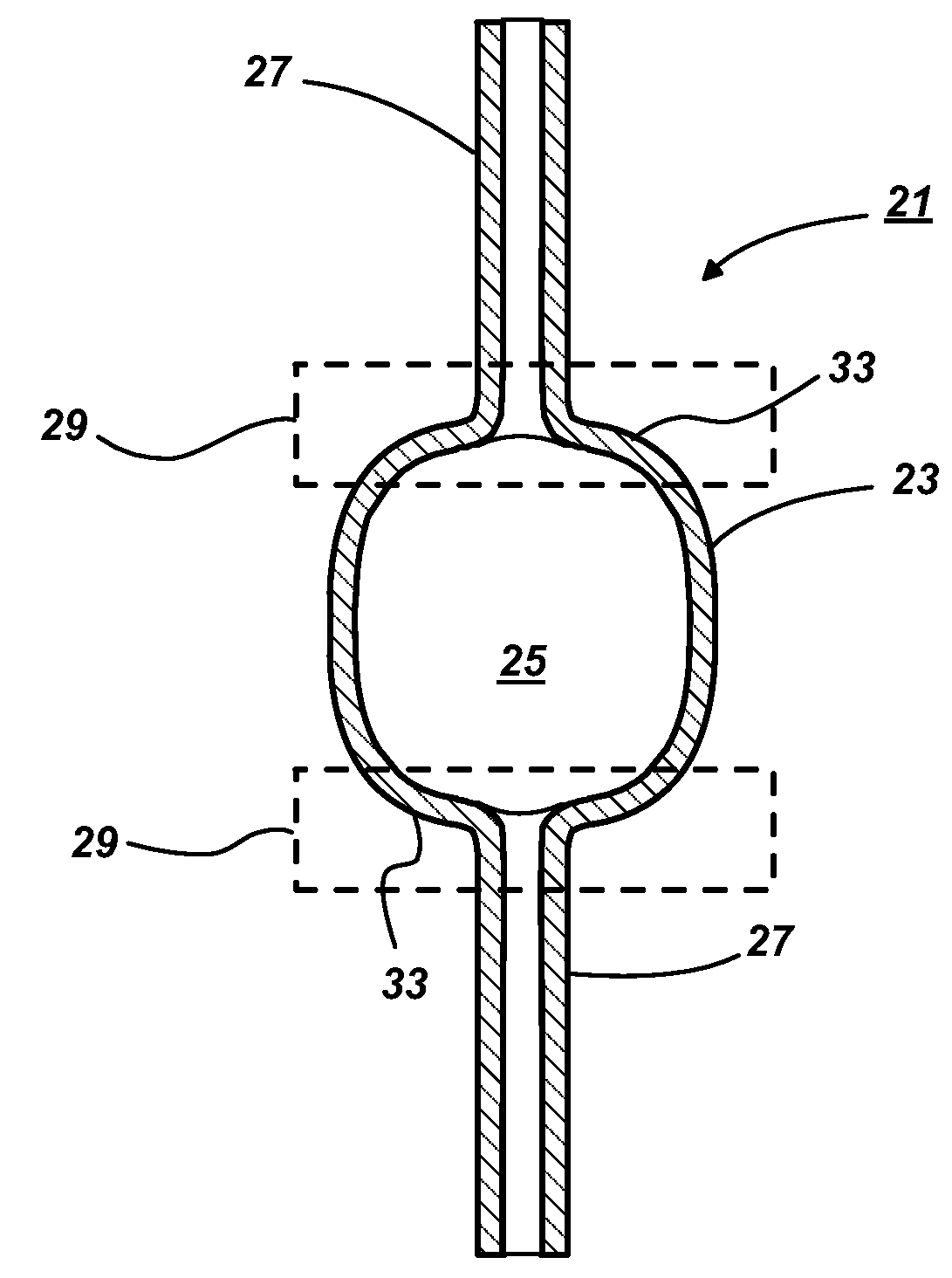

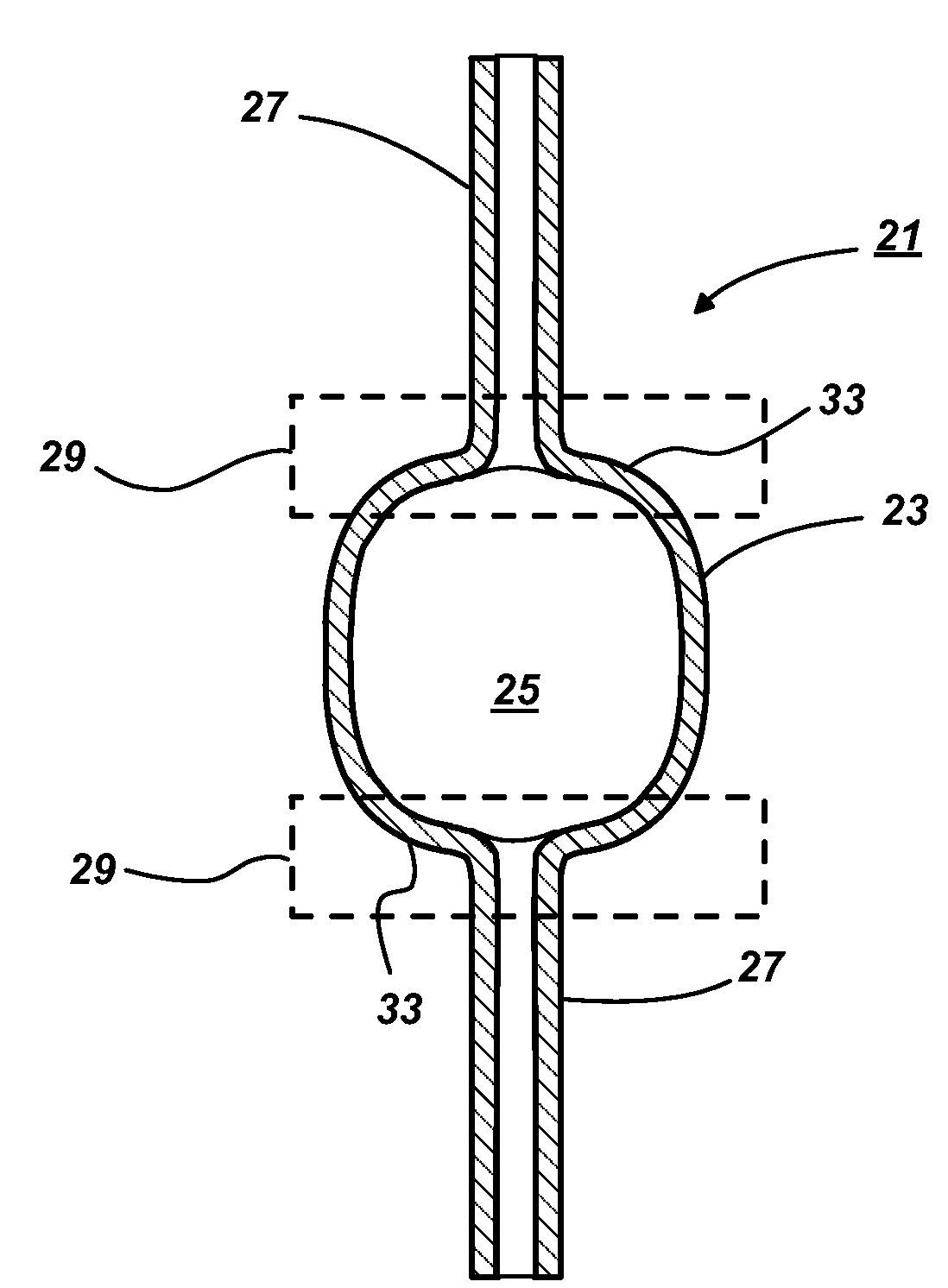

Container candle

InactiveUS20060093979A1Increase wall temperatureEfficiently heat said surfaceCapillary burnersCandle ingredientsParaffin waxLow emissivity

The present invention relates to container candles, such as melting plate candles, which employ heat conductive elements to distribute heat from a burning flame at a wick to a support plate for a solid fuel and to the body of said solid fuel, so as to more rapidly liquefy the solid fuel, such as paraffin wax, and to more uniformly and intensely heat such fuels to increase the efficiency of consumption thereof and to more rapidly release volatile materials contained within said fuels. The container of said candle is treated by the application thereto of a thin layer of a low emissivity coating material, such as a doped tin oxide, and the heat conductive support plate is configured so as to have a capillary pedestal upon the surface thereof, which cooperatively engages a wick holder comprising a preferably consumable wick and heat conductive fins which conduct heat from a flame upon said wick to said support plate, said wick holder further engaging said capillary pedestal in such a locking manner as to resist accidental removal from said pedestal. The fuel may be provided in various forms, configured to cooperatively engage said wick holder and support plate, and may comprise various volatile materials. The capillary pedestal, in conjunction with the wick holder, causes rapid and complete flow of the liquefied fuel to said wick.

Owner:VARANASI PADMA PRABODH +3

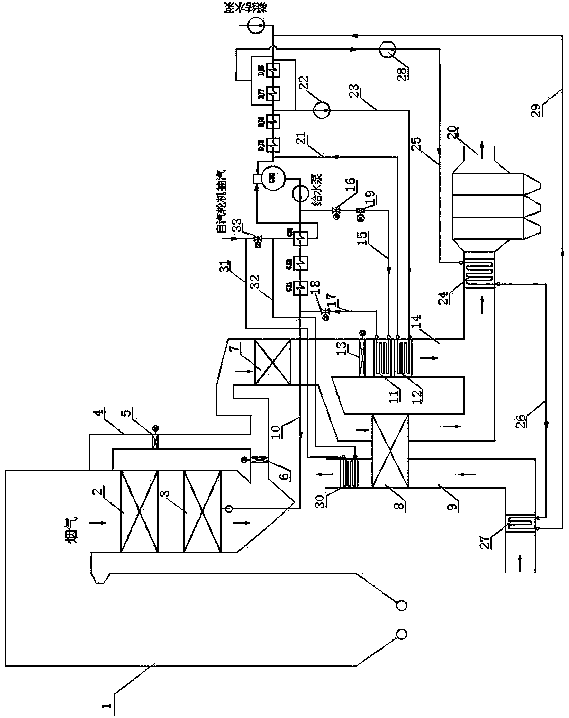

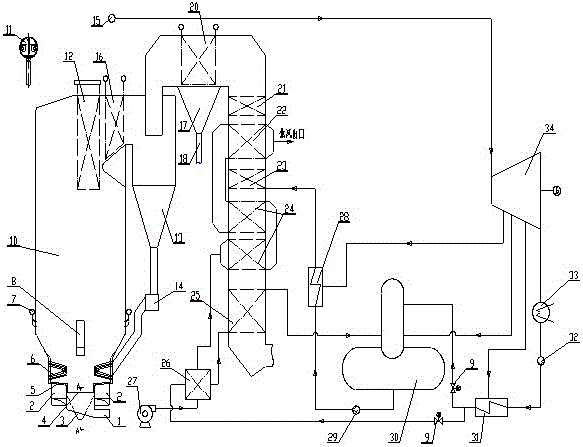

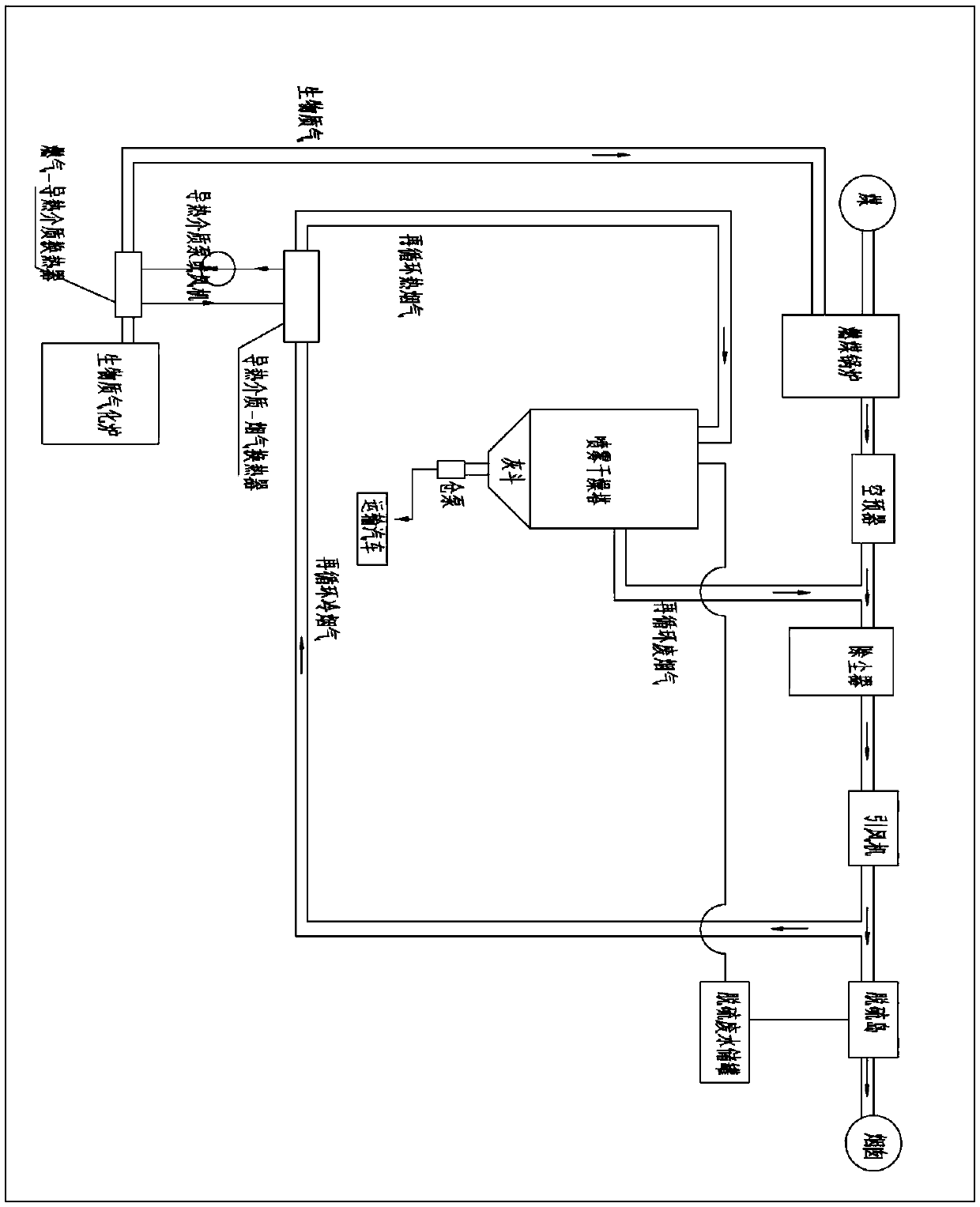

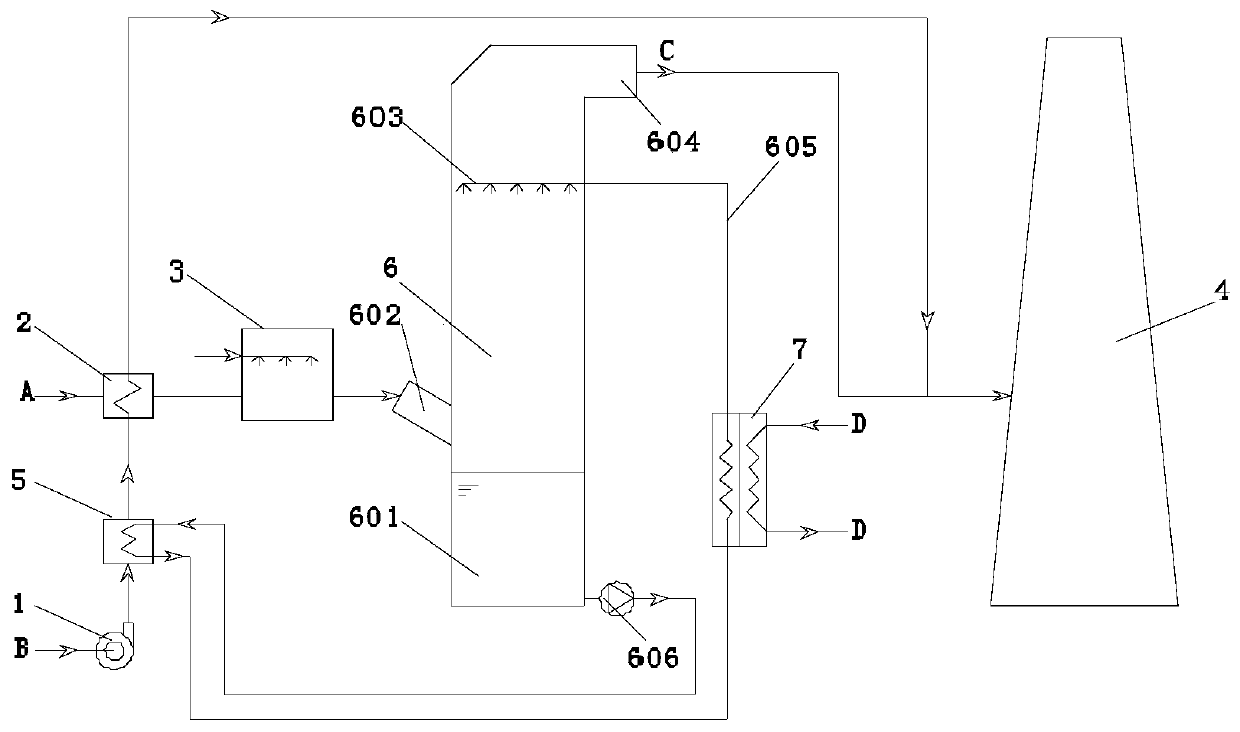

Boiler full-load denitration coupling flue gas waste heat gradient utilization system

PendingCN107687634AEasy to useSolve the problem of decouplingFeed water supplyCombustion processAir preheaterLow load

The invention relates to the field of boiler full-load denitration putting-into-operation and exhausted smoke waste heat utilization and particularly discloses a boiler full-load denitration couplingflue gas waste heat gradient utilization system. The boiler full-load denitration coupling flue gas waste heat gradient utilization system comprises a boiler; a low-temperature heater, a coal economizer, a denitration device, an air preheater and an electric dust remover are sequentially mounted in a flue gas channel of the boiler in the advancing direction of flue gas. The boiler full-load denitration coupling flue gas waste heat gradient utilization system is characterized in that a high-temperature denitration bypass flue is arranged in the position, between an inlet of the low-temperatureheater and an inlet of the denitration device, of the flue gas channel; an air preheater bypass flue is arranged in the position, between an outlet of the denitration device and an inlet of the electric dust remover, of the flue gas channel; and a high-temperature coal economizer and a medium-temperature coal economizer are sequentially arranged in the air preheater bypass flue in the advancing direction of the flue gas. According to the boiler full-load denitration coupling flue gas waste heat gradient utilization system, the denitration device can be effectively put into use under the low load condition of the boiler, and the splitting problem of the denitration device due to decreasing of the load of the boiler is solved; and gradient utilization of waste heat of the flue gas is achieved, high energy level extracted steam is effectively squeezed out, the power generation load is increased, and the overall benefits of a power plant are promoted.

Owner:SHANDONG HONGAO POWER TECHNOLOGY CO LTD

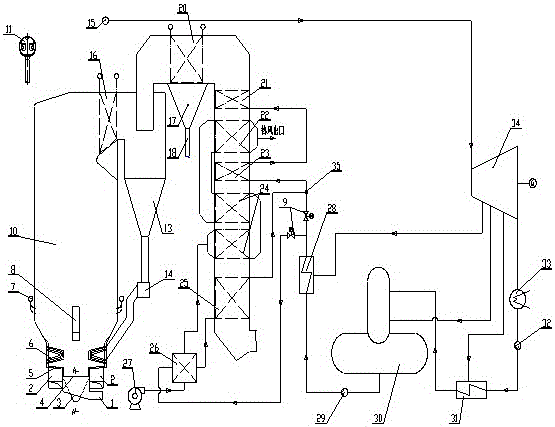

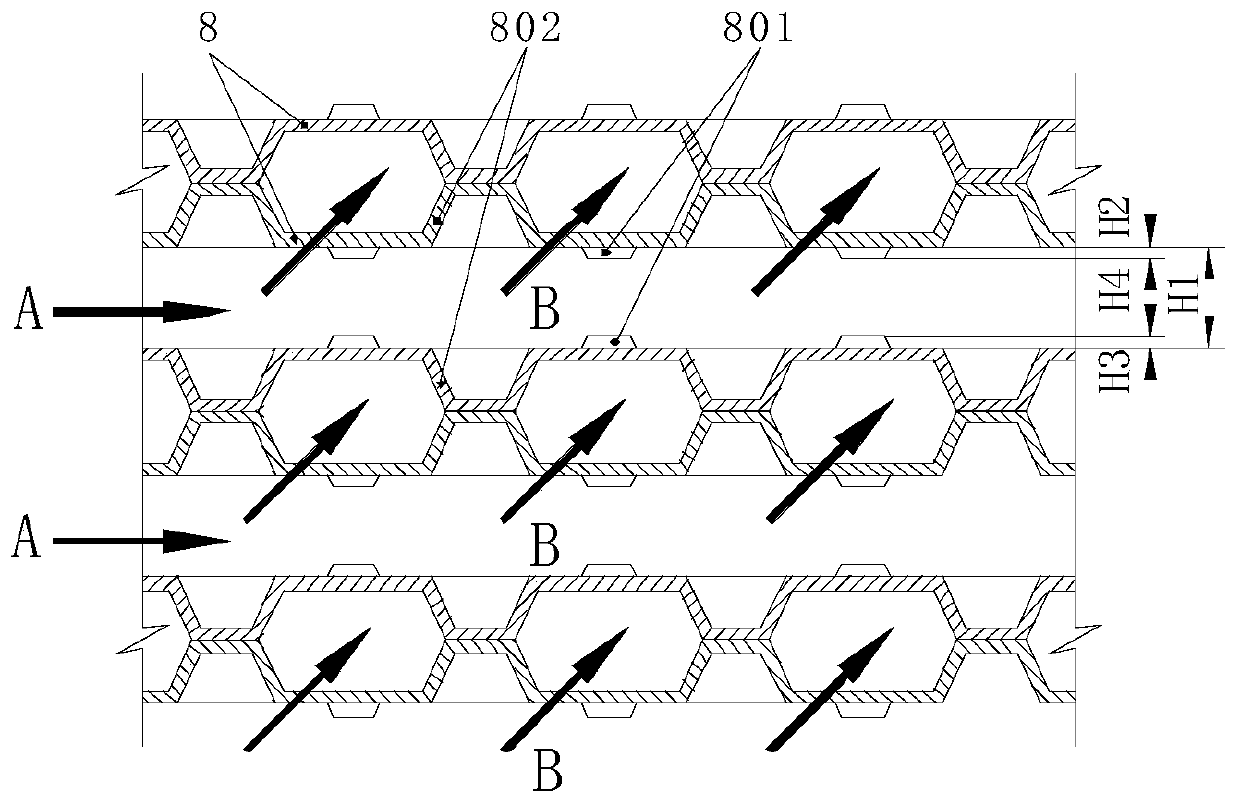

Fluidized bed biomass boiler and system capable of preventing air pre-heater from low-temperature corrosion

InactiveCN106765015AIncrease wall temperatureHigh acid dew point temperatureSteam generation plantsSteam boilersAir preheaterSlag

The invention relates to a high-low differential fluidized bed boiler and system, which combust biomass fuel and are capable of preventing an air pre-heater from low-temperature corrosion. Cold air is heated by hot water in an air-water air pre-heater and then is conveyed into a medium-temperature air pre-heater distributed on a tail flue of a boiler, so that the temperature of a metal wall of the medium-temperature air pre-heater to be higher than acid dew point temperature of flue gas, and furthermore, the low-temperature corrosion of the air pre-heater is prevented. A flue gas water feeding heater is arranged behind the air pre-heater on the tail flue of the boiler and is used for lowering flue gas temperature; meanwhile, the temperature of the air entering the flue gas water feeding heater is about 100 DEG C so that the low-temperature corrosion on the flue gas water feeding heater is also effectively avoided. The technology adopts a V-shaped air distribution plate so that problems of an existing fluidized bed biomass boiler that slag and coke are formed on a bed surface, and debris including iron nails, iron dust and the like is not easy to discharge and the like can also be effectively solved.

Owner:JIANGLIAN HEAVY IND GRP CO LTD

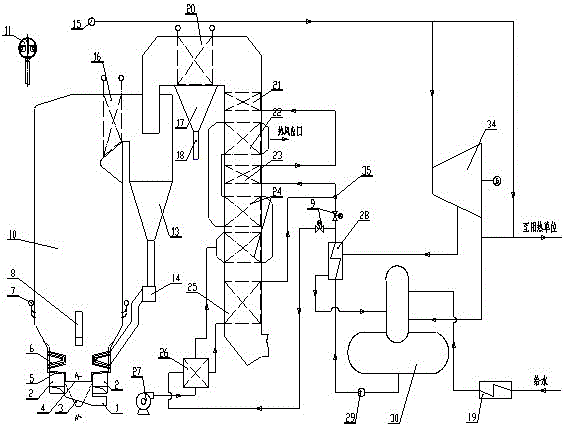

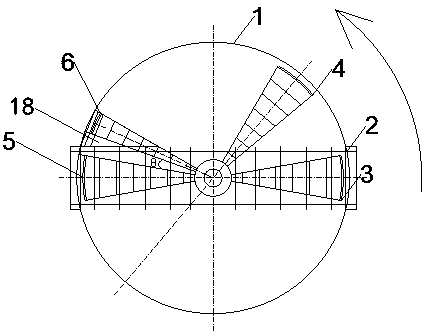

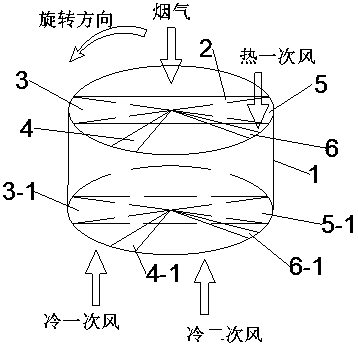

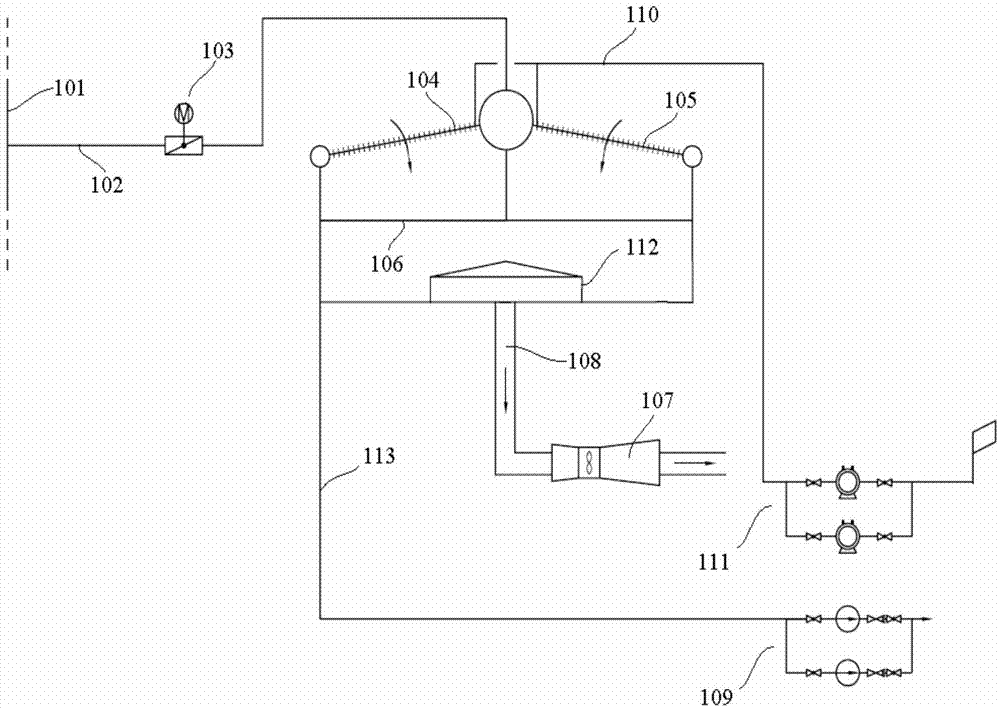

Device and method for relieving blockage of rotary air pre-heater by means of hot primary air preheating and heat storage elements

PendingCN111306568AIncrease wall temperatureFlexible layoutCorrosion preventionIndirect carbon-dioxide mitigationCold airThermodynamics

The invention discloses a device and method for relieving blockage of a rotary air pre-heater by means of hot primary air preheating and heat storage elements. The device structurally comprises a hotprimary air guiding-out pipeline, an adjusting air door, a turning-off air door, a preheating bin hot-end sector plate, a preheating bin cold-end sector plate, a preheating cold air guiding-out pipeline and the like. An independent heat storage element preheating bin is formed between the preheating bin hot-end sector plate and the preheating bin cold-end sector plate and is located in front of anair distribution bin before the rotary air pre-heater is turned to a flue gas branch bin and the flue gas branch bin, the heat storage element is preheated from top to bottom by the aid of hot primary air, and the temperature of the heat storage element entering the flue gas branch bin is increased, so that the purpose of reducing the ammonium bisulfate (ABS) deposition area is achieved, the ABSdeposition area can be cleared by the aid of a soot blower more easily, and the problem that the air pre-heater is blocked seriously due to the fact that ABS adheres to the rotary air pre-heater of aboiler of a coal-fired power plant is solved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

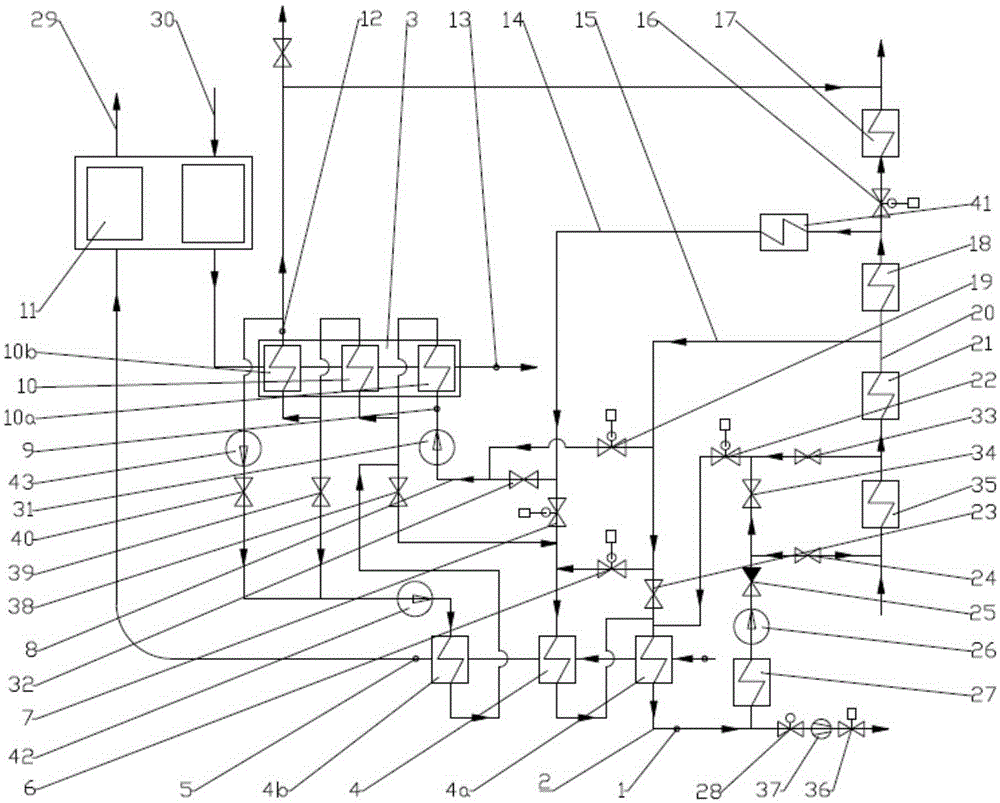

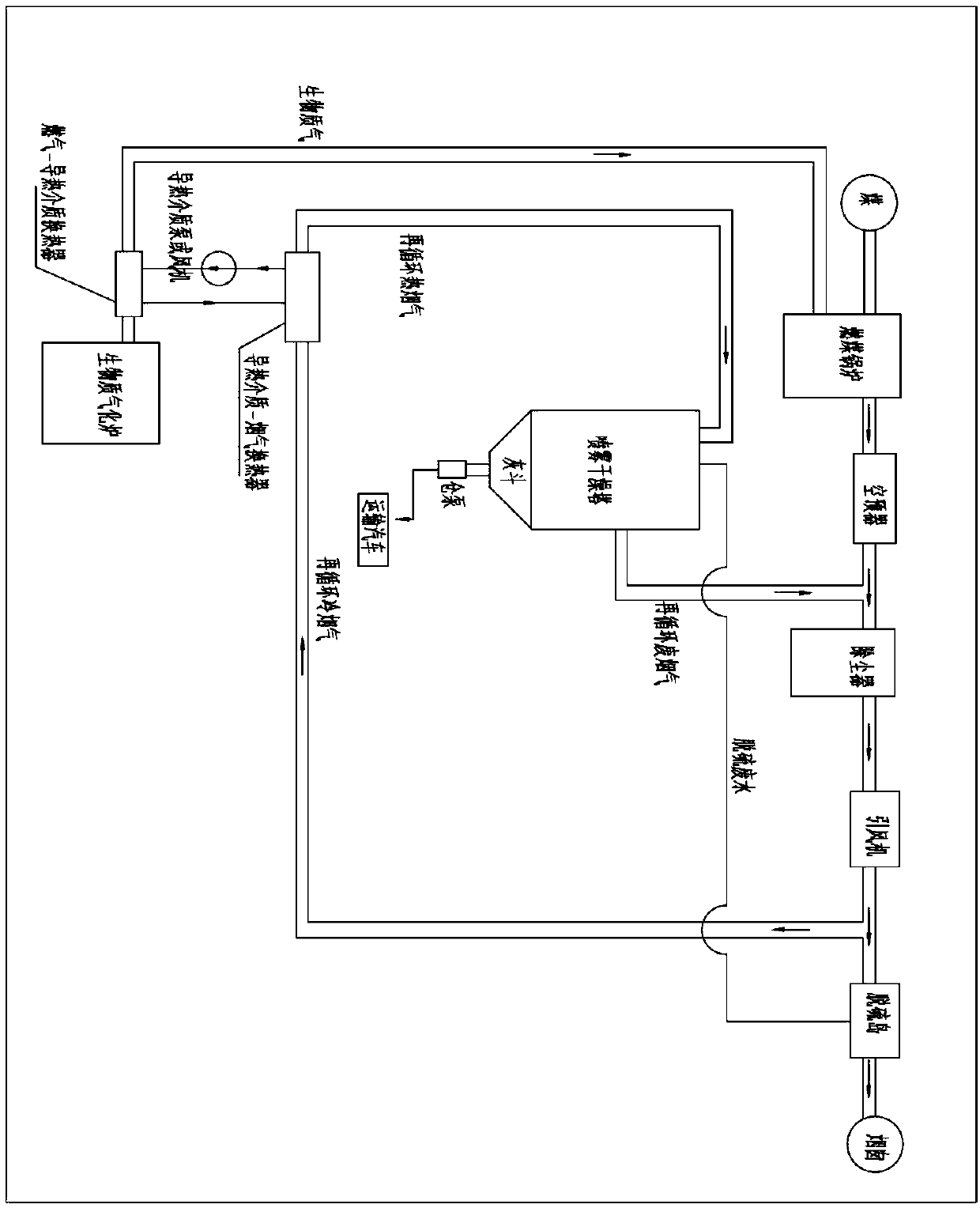

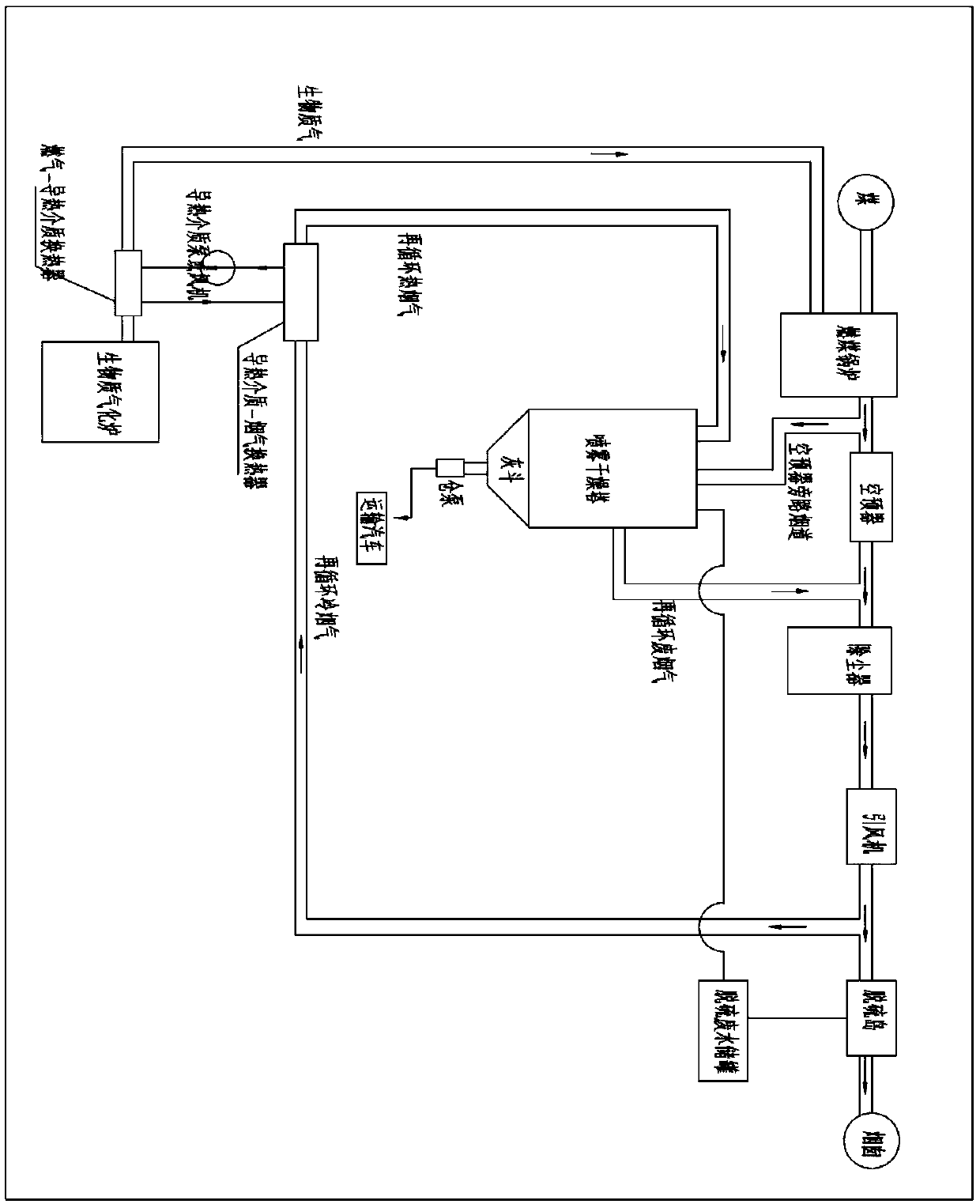

Comprehensive gradient utilization system of recovered heat and waste heat of thermal power generation

InactiveCN105333450ABest Cascade UtilizationImprove energy qualityIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterEngineering

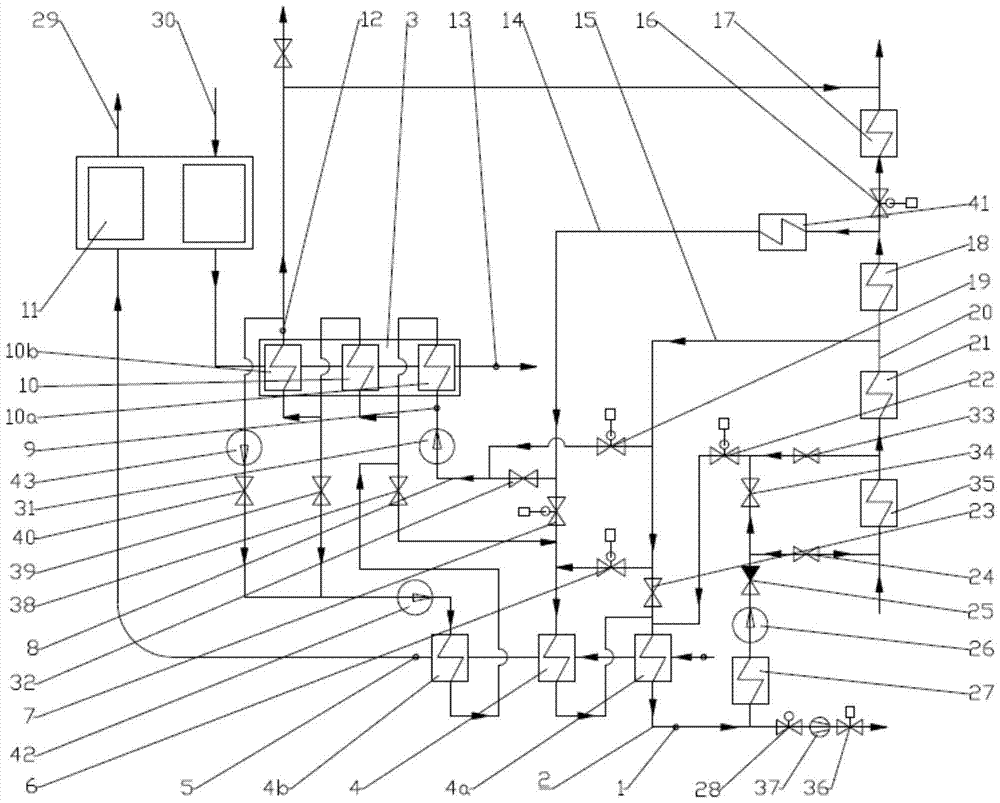

The invention relates to a comprehensive gradient utilization system of recovered heat and waste heat of thermal power generation. The comprehensive gradient utilization system comprises an air pre-heater subsystem, a main condensation water subsystem, a medium temperature condensation water supply subsystem, a low temperature condensation water supply subsystem, a smoke cooling condensation water subsystem and an air heating condensation water subsystem. The air pre-heater subsystem is connected with the smoke cooling condensation water subsystem, the medium temperature condensation water supply subsystem, the low temperature condensation water supply subsystem and the air heating condensation water subsystem and then is connected to the main condensation water subsystem in a collected mode.

Owner:郝江平

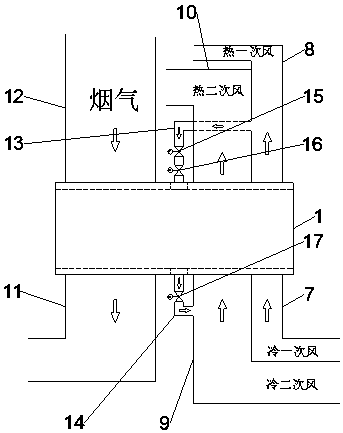

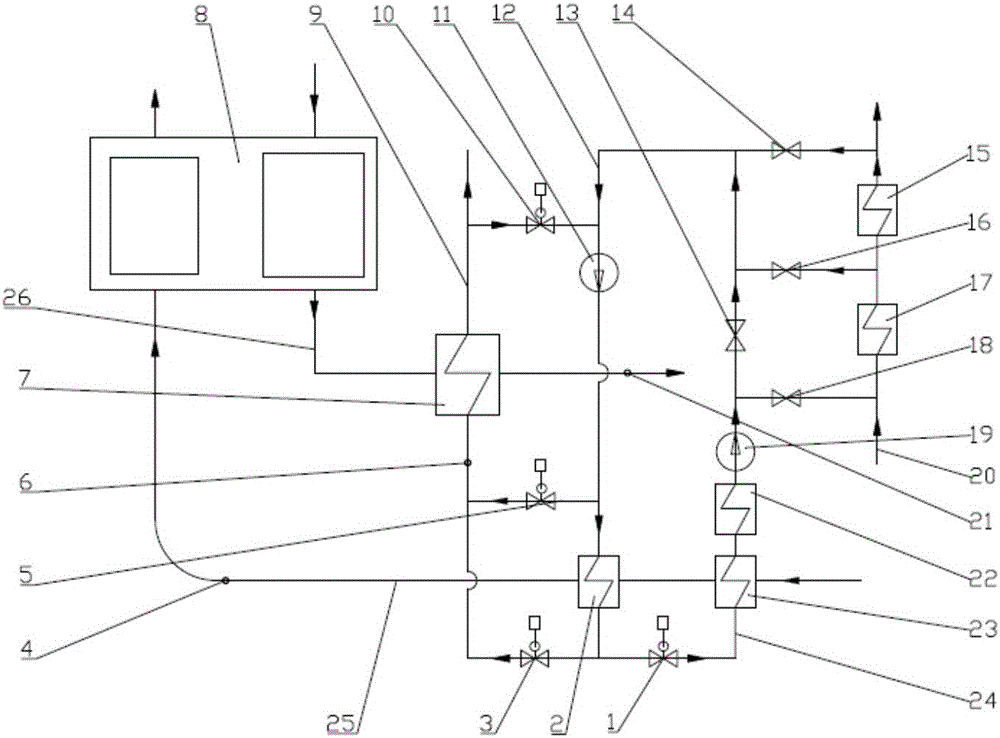

Combined air supply heating depth waste heat recycling system of low-low-temperature economizer of coal-fired unit

The invention relates to the field of smoke exhaust waste heat utilization of a boiler, and particularly discloses a combined air supply heating depth waste heat recycling system of a low-low-temperature economizer of a coal-fired unit. The waste heat recycling system is characterized in that a low-low-temperature economizer high-temperature segment is arranged in a front flue of an electrostatic precipitator, and a low-low-temperature economizer low-temperature segment is arranged at the position from an induced draft fan outlet to a desulfurizing tower inlet flue; the low-low-temperature economizer high-temperature segment is connected with a condensate pipeline of a condenser, and the low-low-temperature economizer low-temperature segment is in parallel connection with a primary air heater and a secondary air heater through low-low-temperature economizer low-temperature segment water outlet pipelines; and the water outlet pipeline of the primary air heater and the water outlet pipeline of the secondary air heater are communicated with a low-low-temperature economizer low-temperature segment water returning pipeline of the low-low-temperature economizer low-temperature segment. The temperature of the smoke of the desulfurizing tower inlet is reduced to about 50 DEG C, coal saving benefits are obtained, meanwhile, the water consumption of a desulfurizing tower is reduced, and the whole running benefits of a power plant is greatly improved.

Owner:SHANDONG HONGAO POWER TECHNOLOGY CO LTD

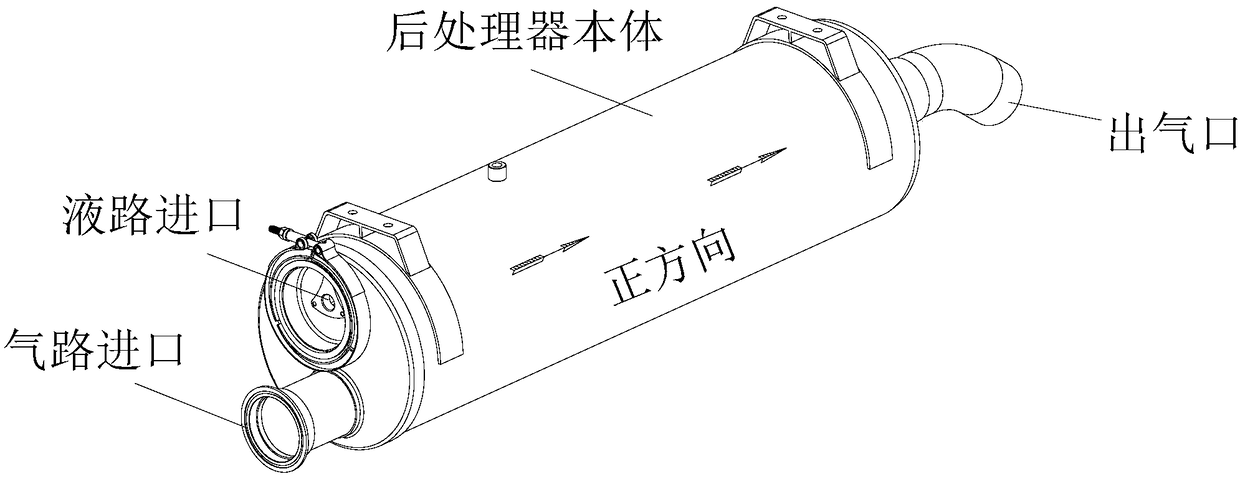

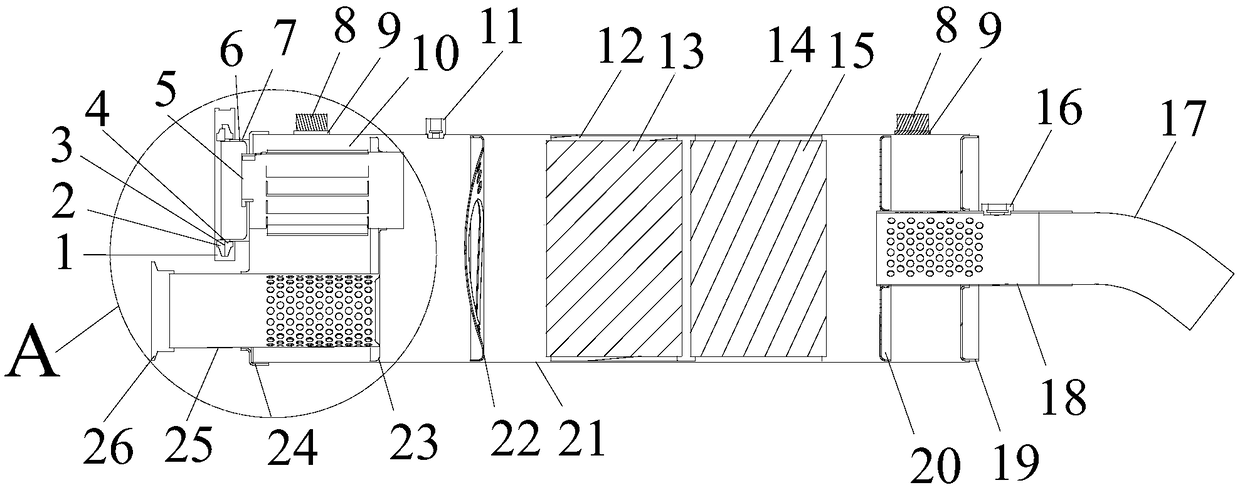

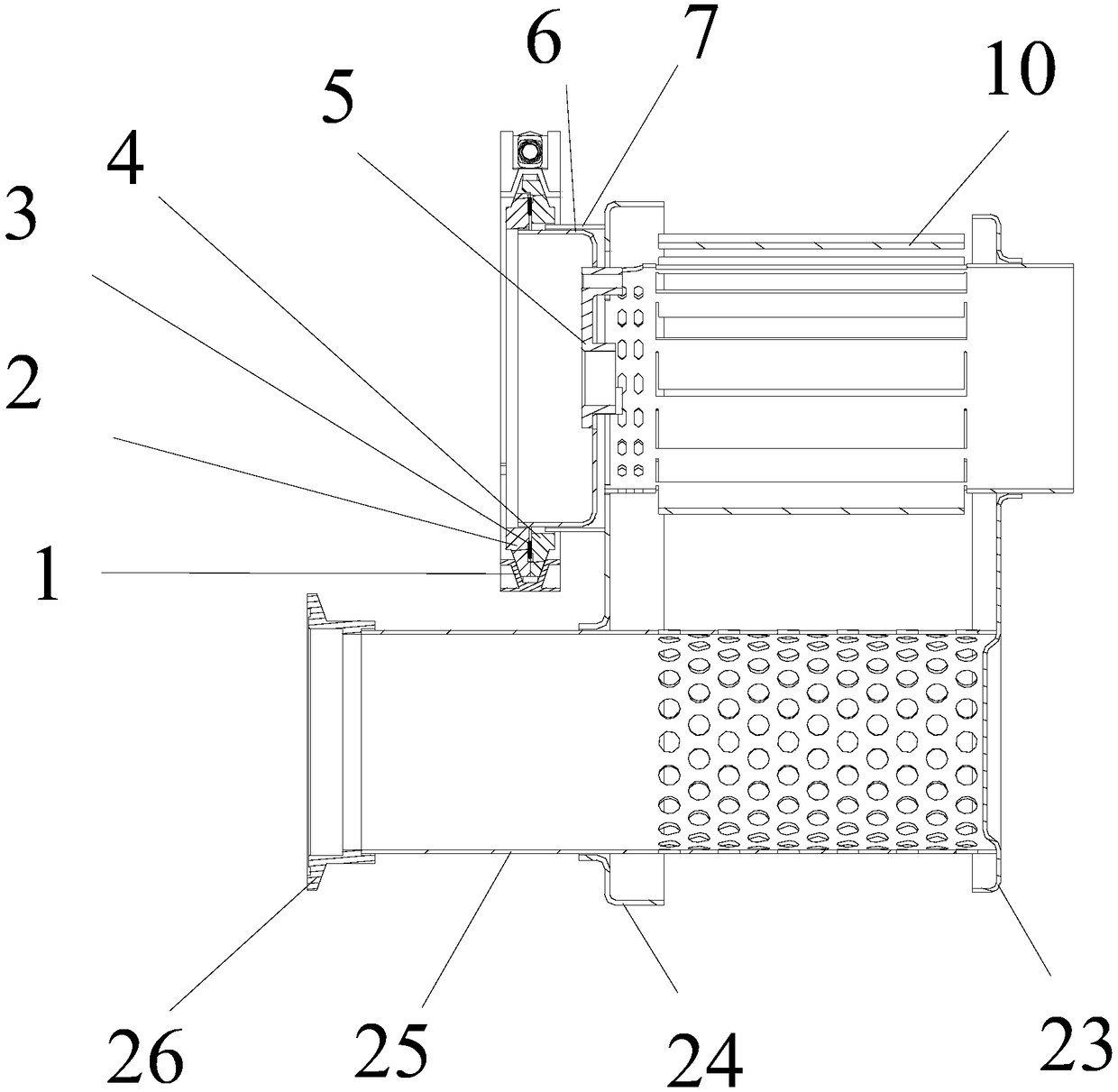

Cylindrical integrated removable urea nozzle post-processor assembly

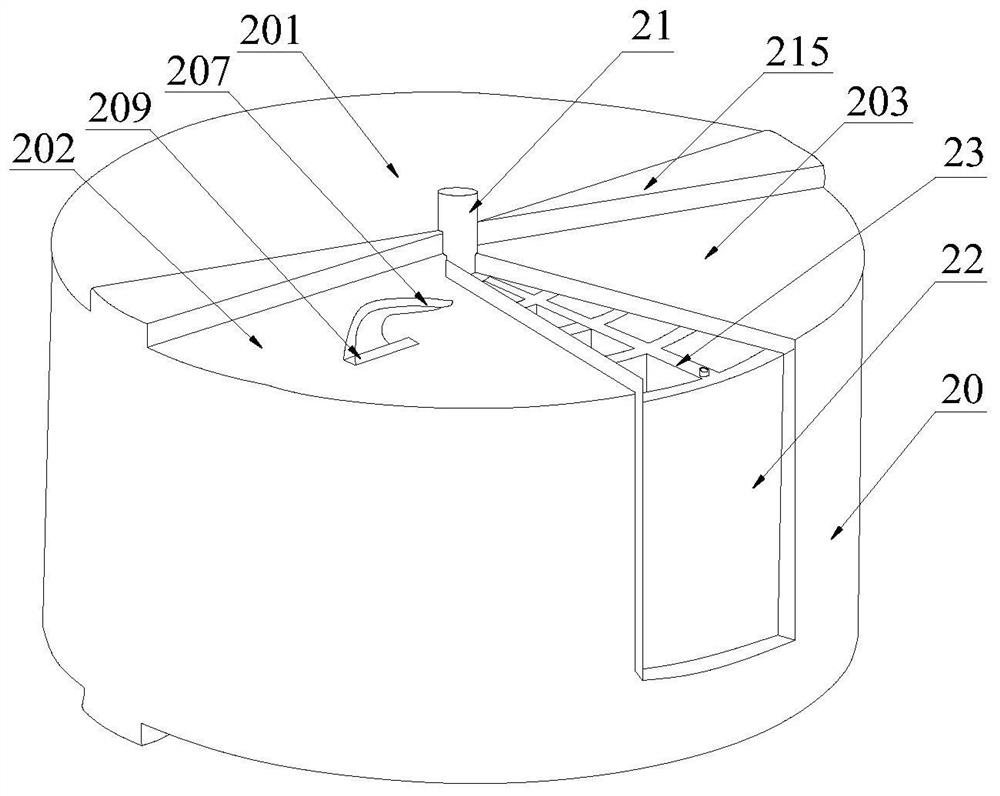

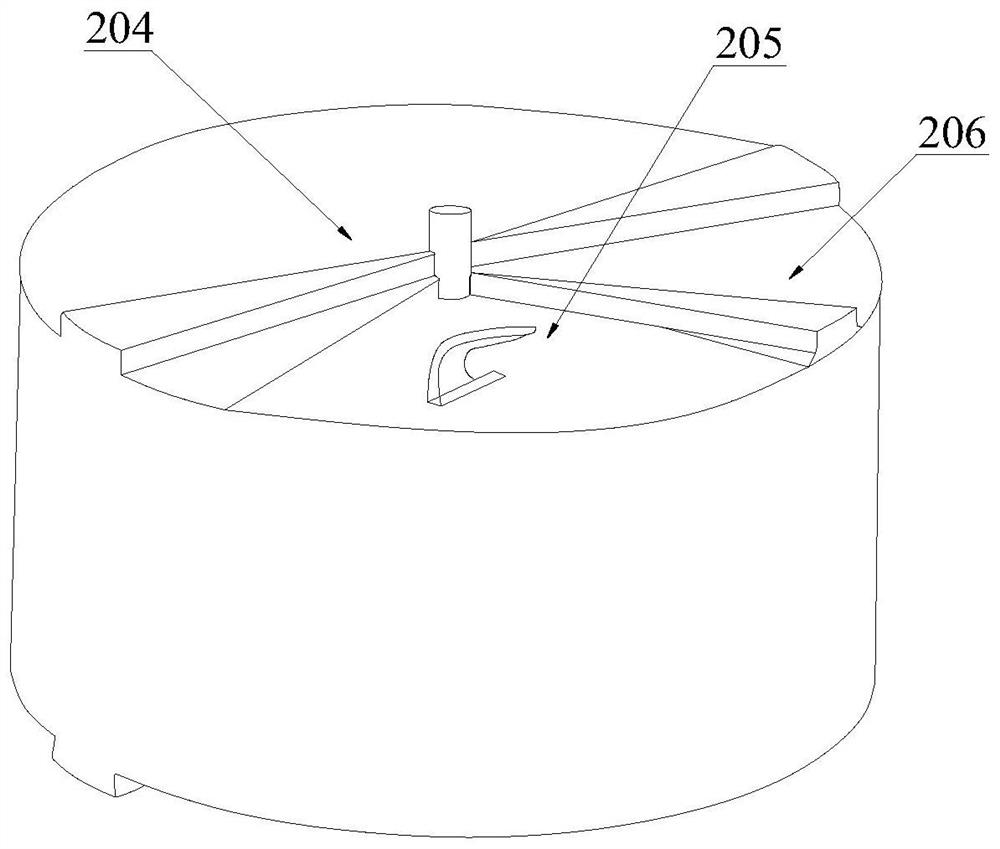

PendingCN108894859AIncrease hydrolysis rateImprove mixing uniformityExhaust apparatusSilencing apparatusPost processorEngineering

A cylindrical integrated detachable urea nozzle post-processor assembly A urea nozzle is disposed directly and integrally on the post-processor and is used in conjunction with the urea mixer, At the same time, the connection between the urea nozzle seat and the post-processor is changed from the traditional welding method of the nozzle seat and the pipeline to the flange gasket connection method,the detachable observable structure of the urea nozzle is ensured while the sealing is ensured, At any time, it is detachable to check whet urea crystals are generate inside that post-processor and the mixer, Urea crystals generated in the interior can be detached and cleaned at any time, the invention is an integrated type, modular, With mixer, detachable cleaning and checking, simple and low cost cylindrical integrated detachable urea nozzle post-processor structure, which can solve the problems of difficult layout of urea nozzle in pipeline, difficult to ensure urea mixing uniformity, insufficient anti-urea crystallization ability, etc., the post-processing system has strong layout advantages and market competitiveness.

Owner:FAW JIEFANG AUTOMOTIVE CO

System and method for high-temperature biomass gas cooling and waste heat utilization

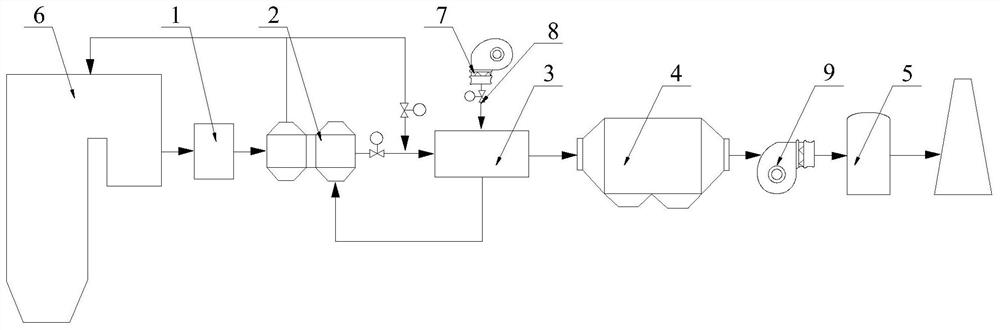

ActiveCN109059027AIncrease wall temperatureAvoid depositionEmission preventionDrying gas arrangementsAir preheaterHeat conducting

The invention discloses a system and method for high-temperature biomass gas cooling and waste heat utilization. A main flue formed by a coal-fired boiler, an air preheater, a dust collector, an induced draft fan and a desulfurization island which are connected in series is included, and a flue gas recirculation pipe, a heat conducting medium-flue gas heat exchanger, a gas-heat conducting medium heat exchanger and a spray drying tower are further included; the spray drying tower is connected to the part, in front of the dust collector, of the main flue, the flue gas recirculation pipe is connected to the part, behind the dust collector, of the main flue, and the main flue communicates with the heat conducting medium-flue gas heat exchanger through the flue gas recirculation pipe; and fluegas of the heat conducting medium-flue gas heat exchanger communicates with the spray drying tower, a heat conducting medium of the heat conducting medium-flue gas heat exchanger is in communication with the gas-heat conducting medium heat exchanger, and gas of the gas-heat conducting medium heat exchanger communicates with the coal-fired boiler. By means of the system and method, sensible heat ofwaste biomass gas is utilized to remove harmful substances in desulfurization waste water, energy saving and environment protection can be achieved, and by-product salt crystals are high in purity and high in added value.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

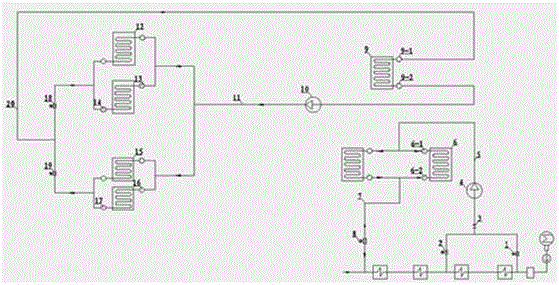

Adjustable boiler air preheating system and method integrating heat regeneration and waste heat utilization

InactiveCN105091020AIncrease independenceBest Cascade UtilizationCombustion processSteam useEngineeringRecuperator

The invention belongs to the fields of thermal power generation and the like and particularly relates to an adjustable boiler air preheating system and method integrating heat regeneration and waste heat utilization. According to the adjustable boiler air preheating system and method, air preheating, waste heat utilization and regenerative heat cycling are made to be combined organically; heat-transmission cycling condensate water is divided into a large open cycle in which a bypass low-pressure heater extrudes a steam turbine to perform high-parameter steam extraction and a small closed cycle in which the low-pressure heater (or an added heat exchanger) is used for absorbing heat to increase low-parameter steam extraction; heat flow is divided according to the temperature level difference, heat source and cold source resources are dynamically and sufficiently used, optimal gradient utilization of heat energy in the power generation thermodynamic cycle is achieved, the energy use quality is improved, and energy losses are reduced. According to the adjustable boiler air preheating system and method, the operation mode of the system can be optimized and adjusted automatically according to the change of the operation condition so that gradient utilization of energy of different qualities can be achieved and energy losses can be reduced, and the thermodynamic cycle efficiency and the system economy are maximized.

Owner:郝江平

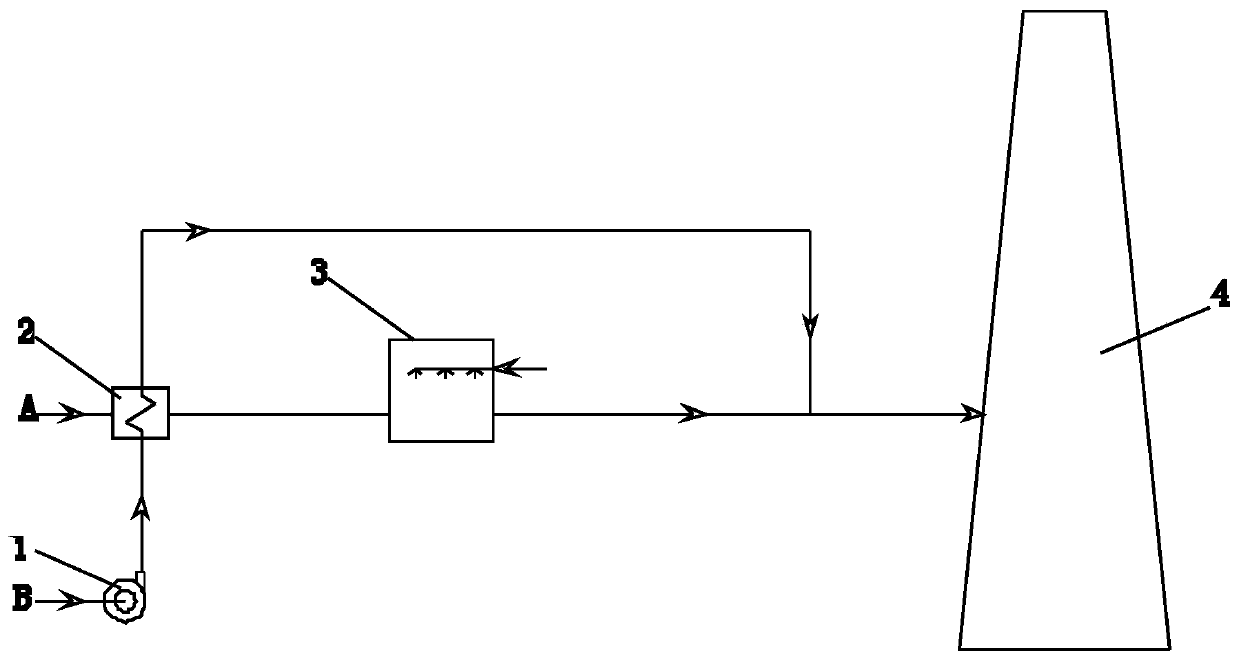

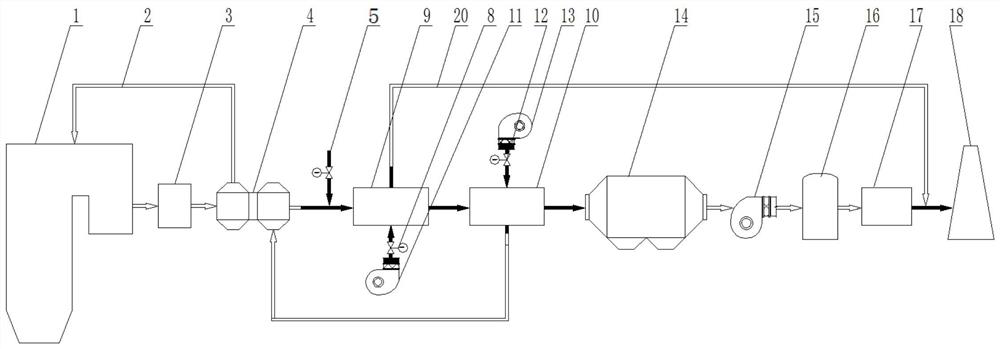

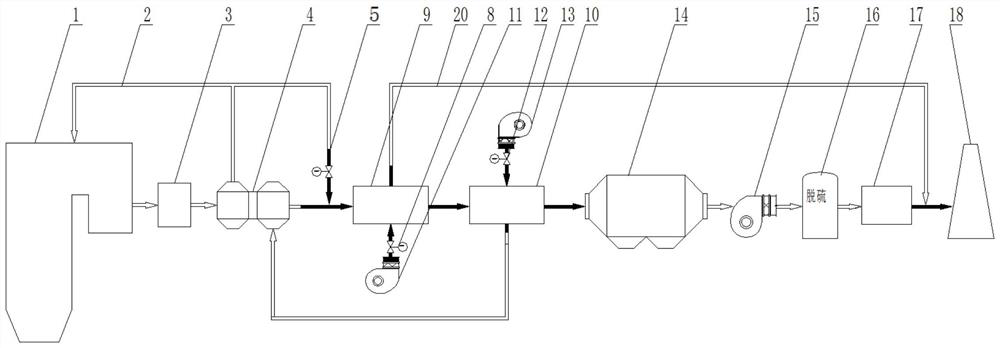

Furnace kiln wet flue gas white-elimination system

PendingCN110180335AReduce the temperatureImprove waste heat recovery efficiencyGas treatmentRecuperative heat exchangersSocial benefitsProcess systems

The invention discloses a furnace kiln wet flue gas white-elimination system, and relates to a white-elimination process of a wet flue gas after spray cooling of furnace kiln flue gas. The system comprises a gas-gas heat exchanger, a flue gas spray cooling apparatus and a fan. A flue gas and air are subjected to heat exchange, the flue gas after cooling enters the flue gas spray cooling apparatus,the wet flue gas after cooling is mixed with hot air to obtain a mixture, the mixture is heated and dehumidified, and then discharging is carried out through a chimney, and thus the white-eliminationrequirement is realized. The process system is simple, emission of air pollution and secondary pollutants is reduced while the consumption of a spray cooling liquid is reduced during a flue gas cooling process, and at the same time, the demand of flue gas white elimination is solved, so that the system has multiple purposes. Moreover, the implementation cost is low, and economic and social benefits are remarkable.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

Boiler blower inlet air heating system

ActiveCN103939935AAchieve heatingReduce exhaustCombustion processIndirect carbon-dioxide mitigationCold airEngineering

The invention relates to the field of the boiler blowing-in technology, and discloses a boiler blower inlet air heating system. The boiler blower inlet air heating system comprises a heat exchanger, a steam extraction pipeline, a vacuumization pipeline, a vacuum pump, a blowing-in box, a blowing-in pipeline, a condensation water pipeline, a drain pipeline and a condensate pump. The two ends of the steam extraction pipeline are communicated with an air-cooling main steam extraction pipeline and the heat exchanger respectively, the two ends of the vacuumization pipeline are communicated with the heat exchanger and outside air respectively, the vacuumization pipeline is provided with the vacuum pump, the two ends of the condensation water pipeline are communicated with the heat exchanger and a condensation water system respectively, the drain pipeline is respectively communicated with the steam extraction pipeline and the condensation water pipeline, the condensation water pipeline is provided with the condensate pump, and the blowing-in box is respectively communicated with the heat exchanger and the blowing-in pipeline. Cold air flowing through the heat exchanger is heated through steam exhaust waste heat of a steam turbine, steam consumption of an original steam air heater system is greatly reduced, and utilization efficiency of steam exhaust waste heat of the steam turbine and economical efficiency of overall operation of a unit are improved.

Owner:BEIJING LONGYUAN COOLING TECH

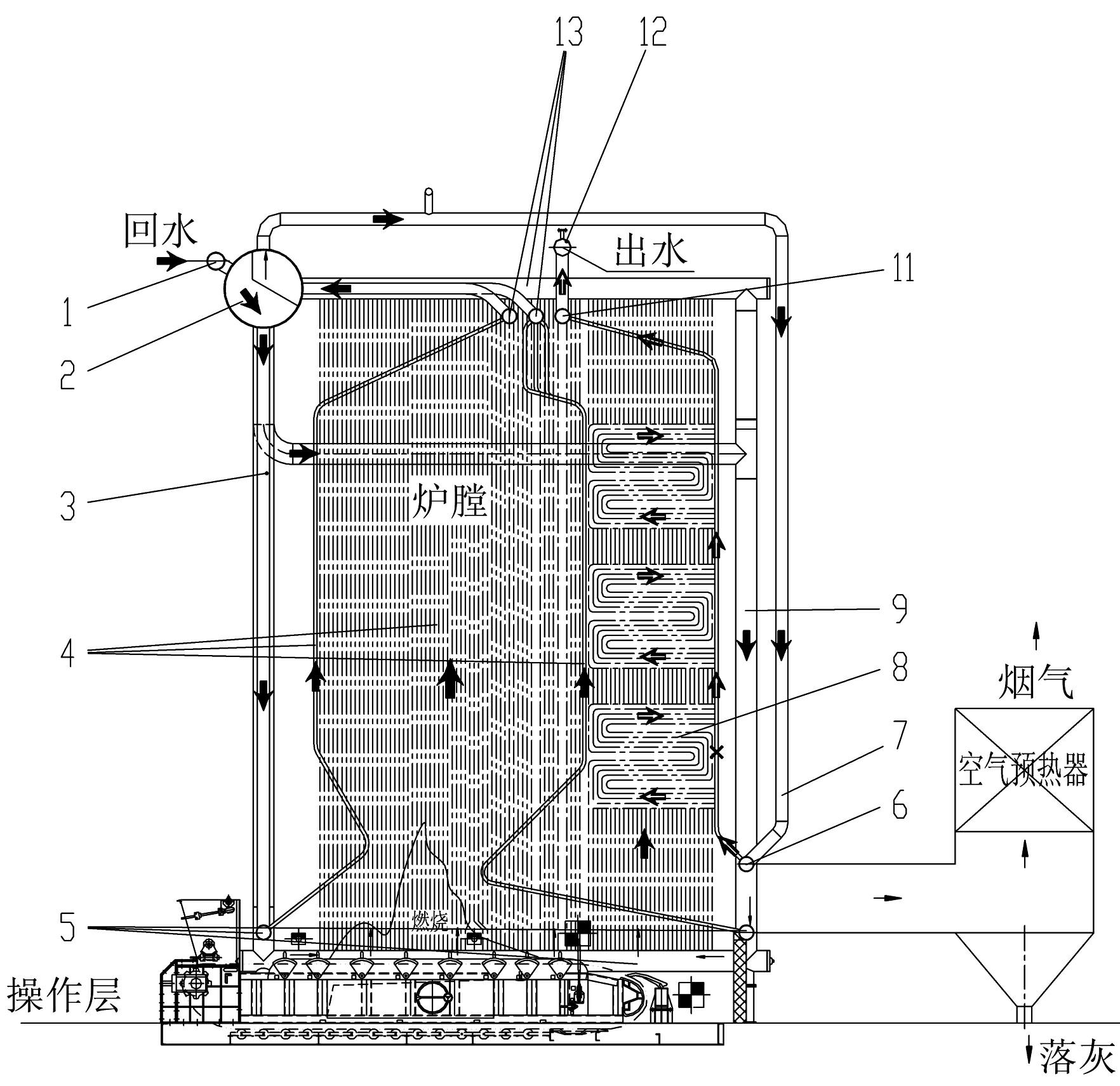

Compound water circulation system in corner tube-type hot-water boiler

The invention discloses a compound water circulation system in a corner tube-type hot-water boiler, and overcomes the defect of high power consumption by adopting a forced circulation mode because the low temperature corrosion of a tube on a heating surface is easy to cause in a common hot-water boiler which adopts a natural circulating mode. The compound water circulation system is formed by combining a natural circulation part and a forced circulation part, wherein the natural circulation part consists of a boiler barrel, a descending tube, an ascending tube and a natural circulation upper colleting box; the forced circulation part consists of a lower collecting box, a flag-type heating surface, a forced circulation upper collecting box, and an outlet water collecting box; and simultaneously, a water partition part provided with a backflow channel is arranged in the boiler barrel. The compound water circulation system has the advantages of compact structure, small volume, low cost, high thermal efficiency, low power consumption and the like, and is widely used in hot-water boiler systems.

Owner:SHANGHAI XINYE BOILER HIGH TECH

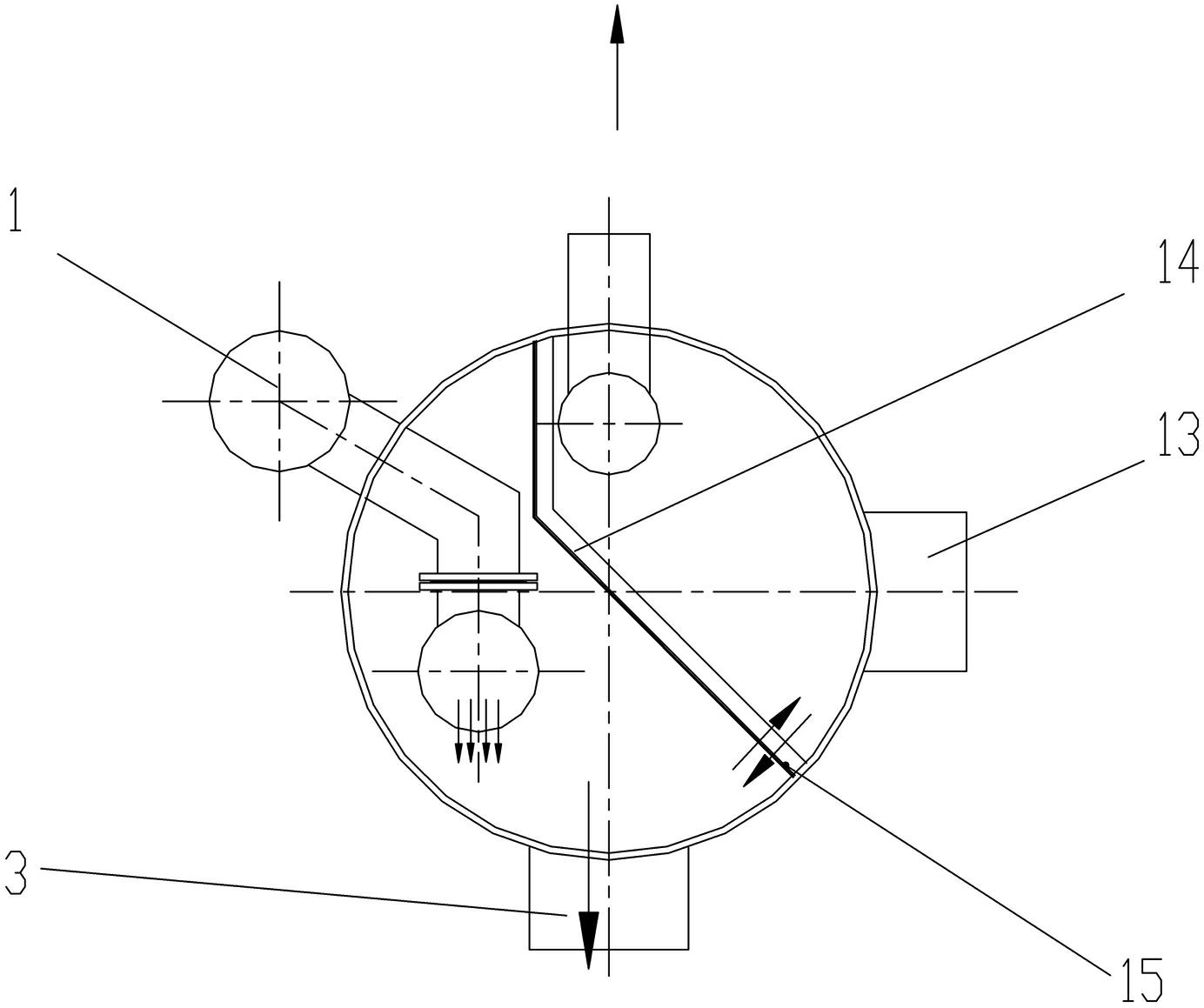

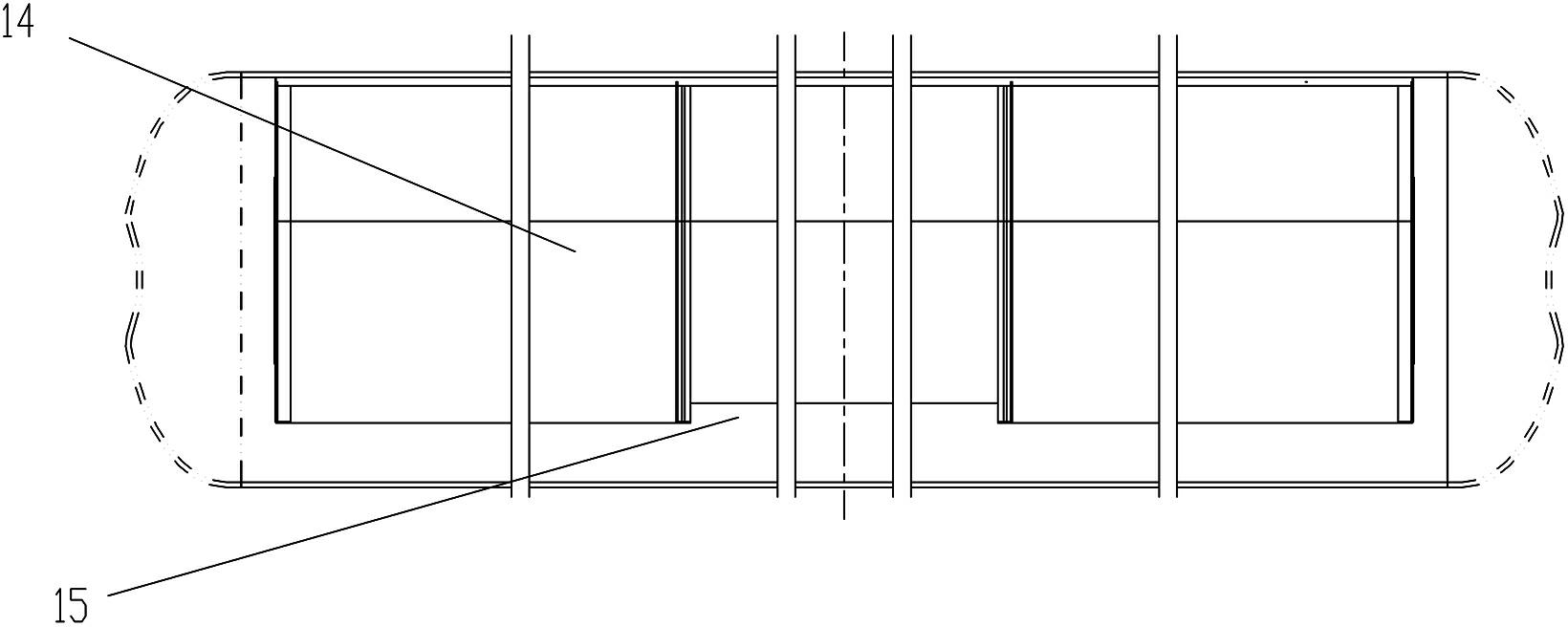

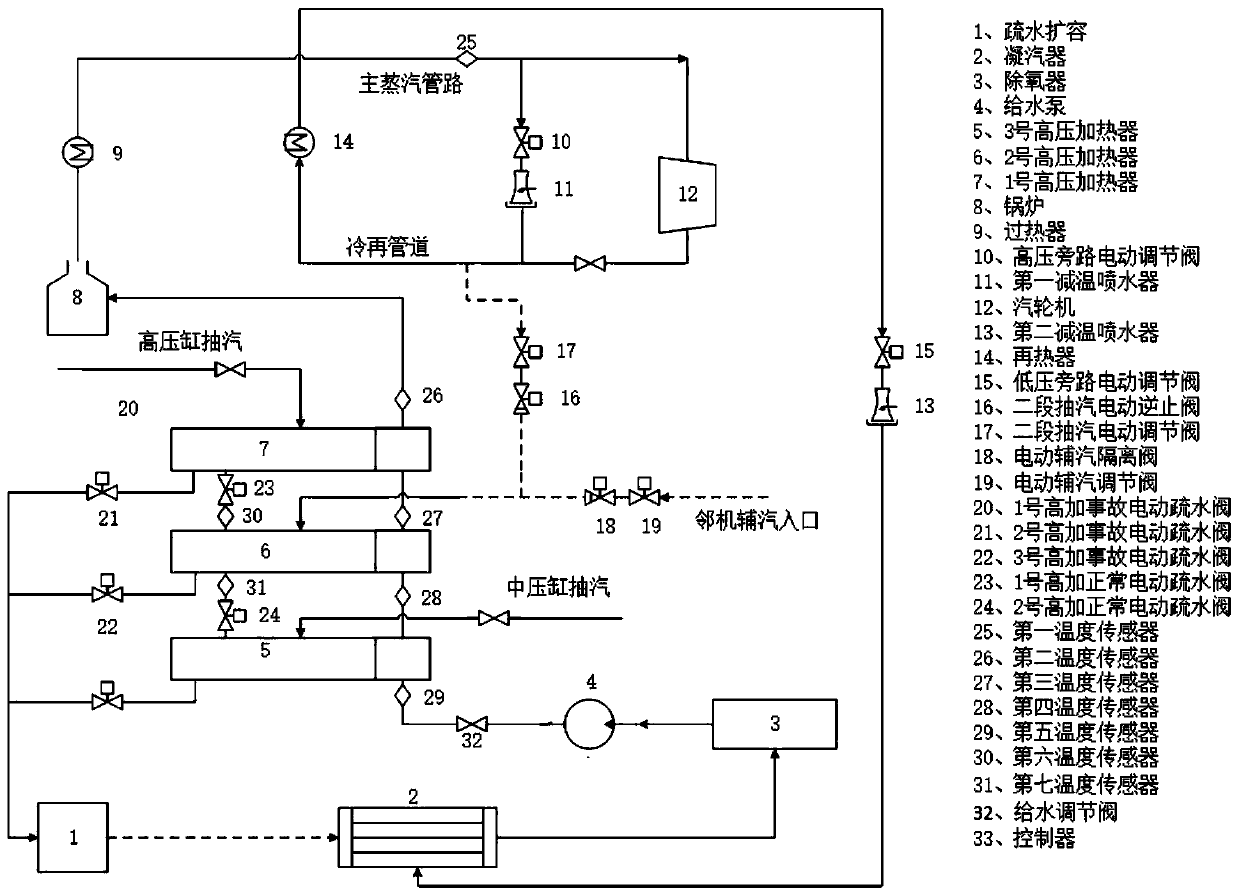

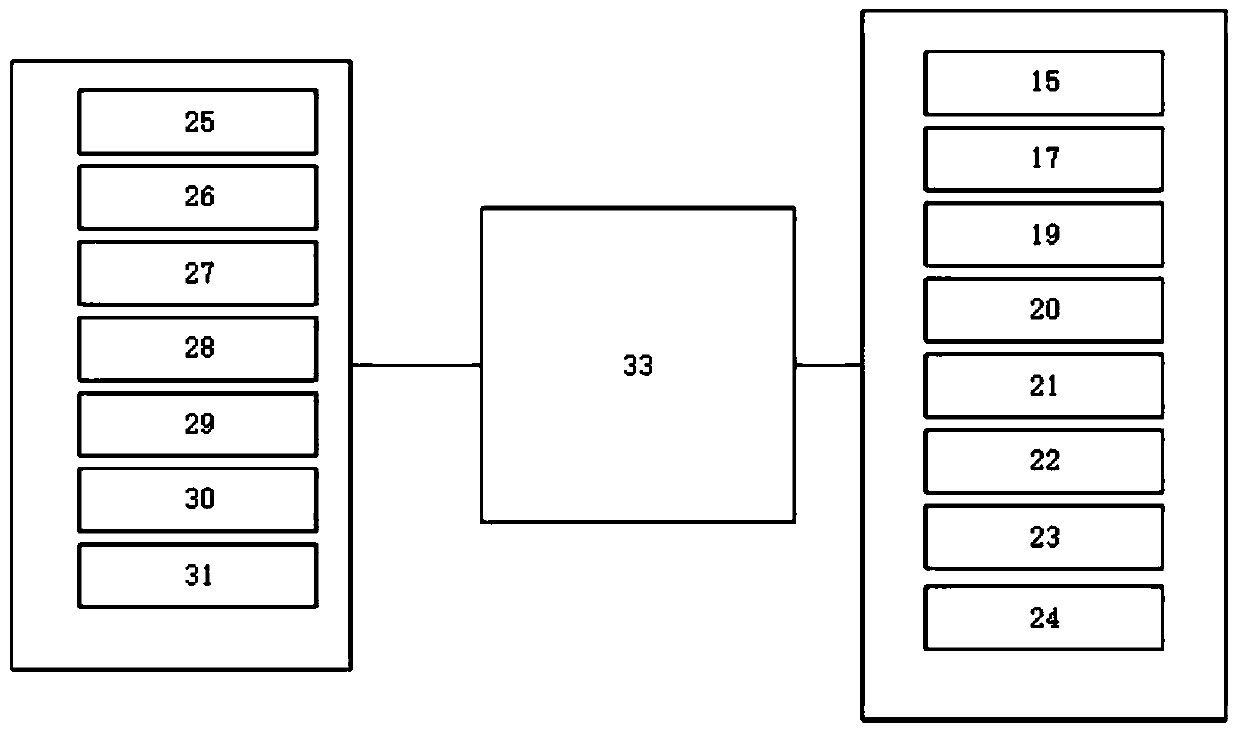

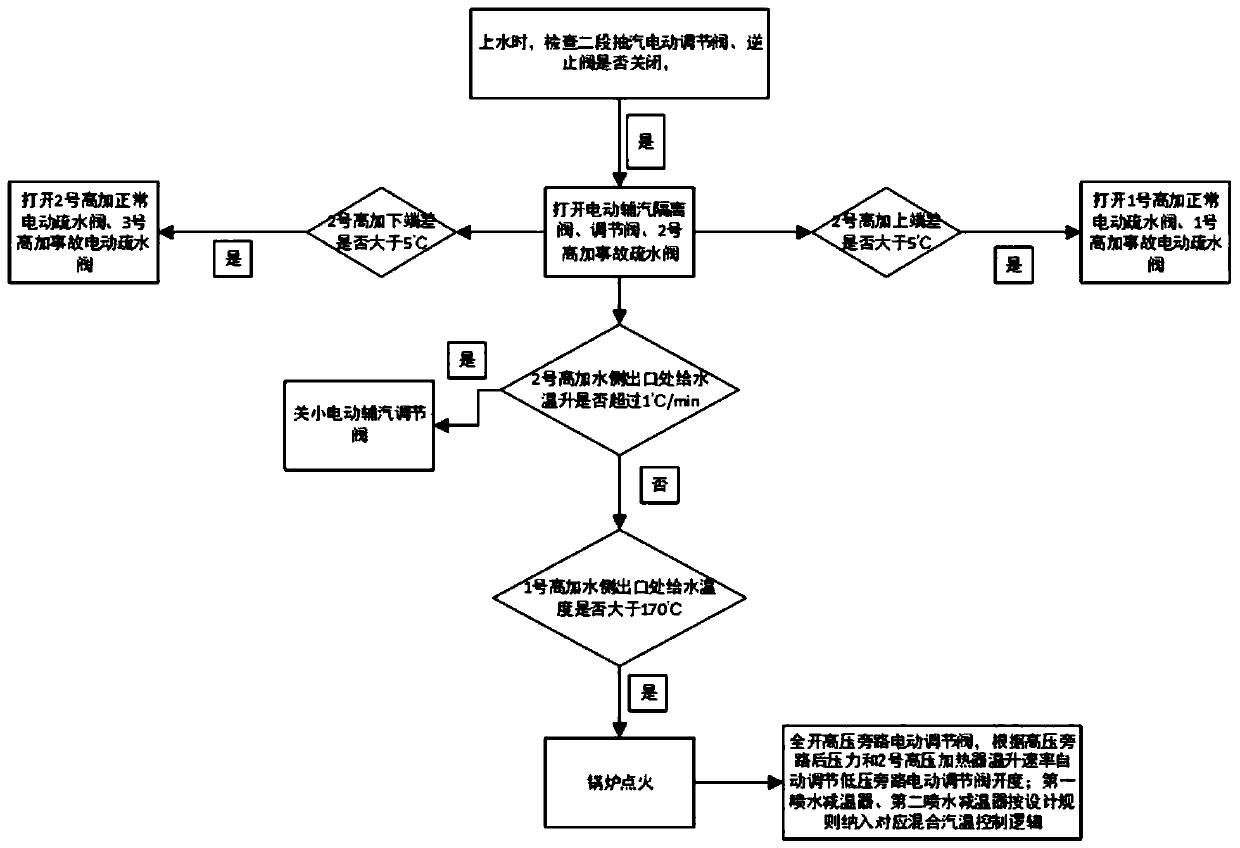

Control system and control method for starting high-pressure heater in advance

ActiveCN111322607AIncrease profitReduce startup timeWater feed controlFeed-water heatersControl systemProcess engineering

The invention relates to a control system and a control method for starting a high-pressure heater in advance. The control system can make full use of steam heat, and accurately controls the steam supply mode of the high-pressure heater through the cooperation between a temperature sensor and a controller. Before a boiler is ignited, steam supply heating is performed on the high-pressure heater No. 2 by an auxiliary steam system of an adjacent machine to increase the water feeding temperature of the boiler, and the wall surface of a heating surface of the boiler is increased by water change toprevent scale falling off due to too high increase speed of the wall temperature when steam flows through a superheater and a reheater after water plugs in a superheater and a reheater are removed when the steam temperature is about 100 DEG C after the boiler is ignited; and after the boiler is ignited and before a steam turbine starts to turn, the high-pressure heater No.2 is used to absorb heatof steam on a high-pressure by-pass to further increase the water feeding temperature and effectively recover the heat of the boiler before grid connection, so that on the one hand, the heating speedof the boiler is increased, and the start-up time is shortened, and on the other hand, the amount of steam discharged to a cold end is reduced, and the loss of a cold source during the start-up process is reduced.

Owner:大唐宝鸡第二发电有限责任公司

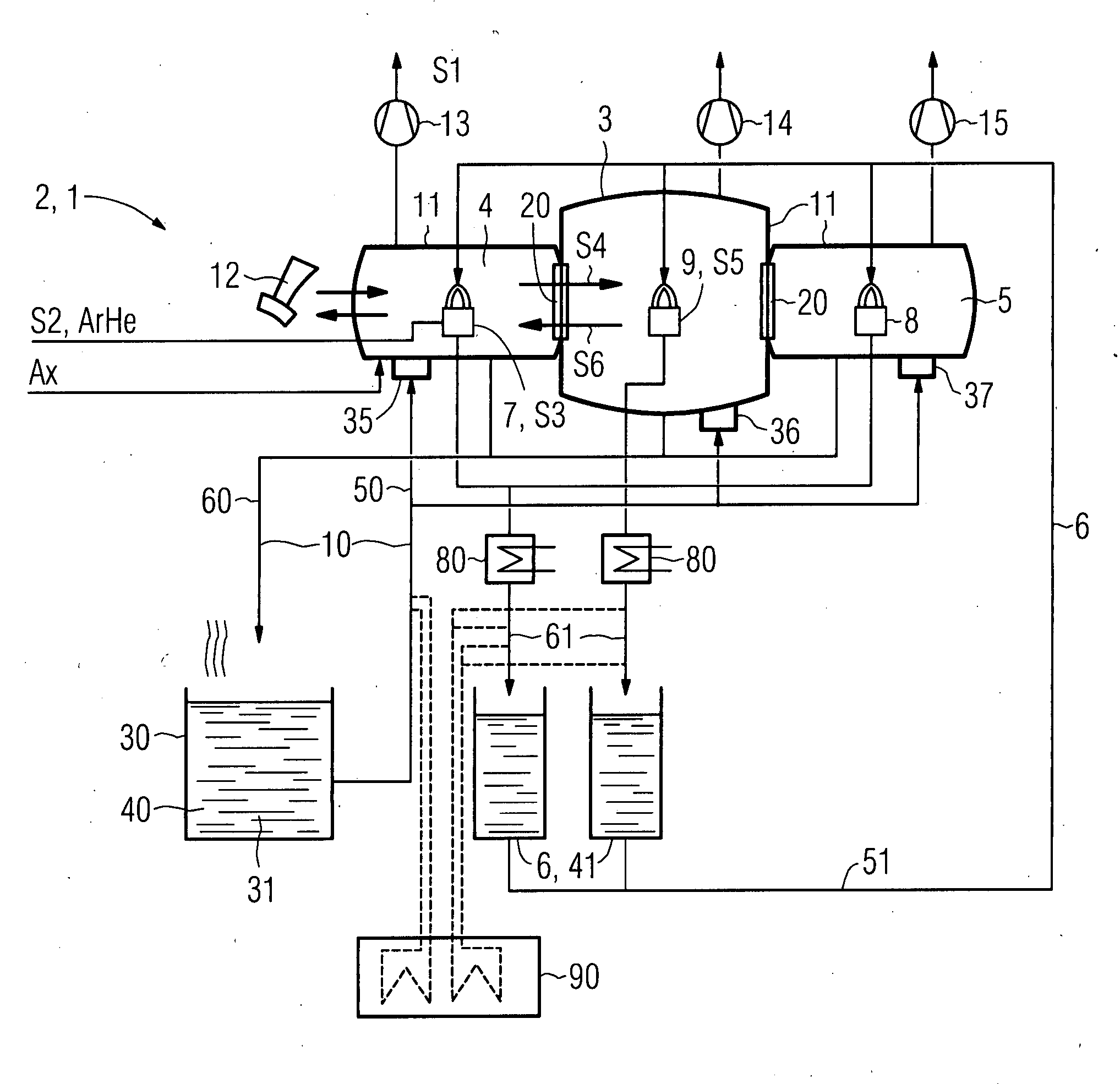

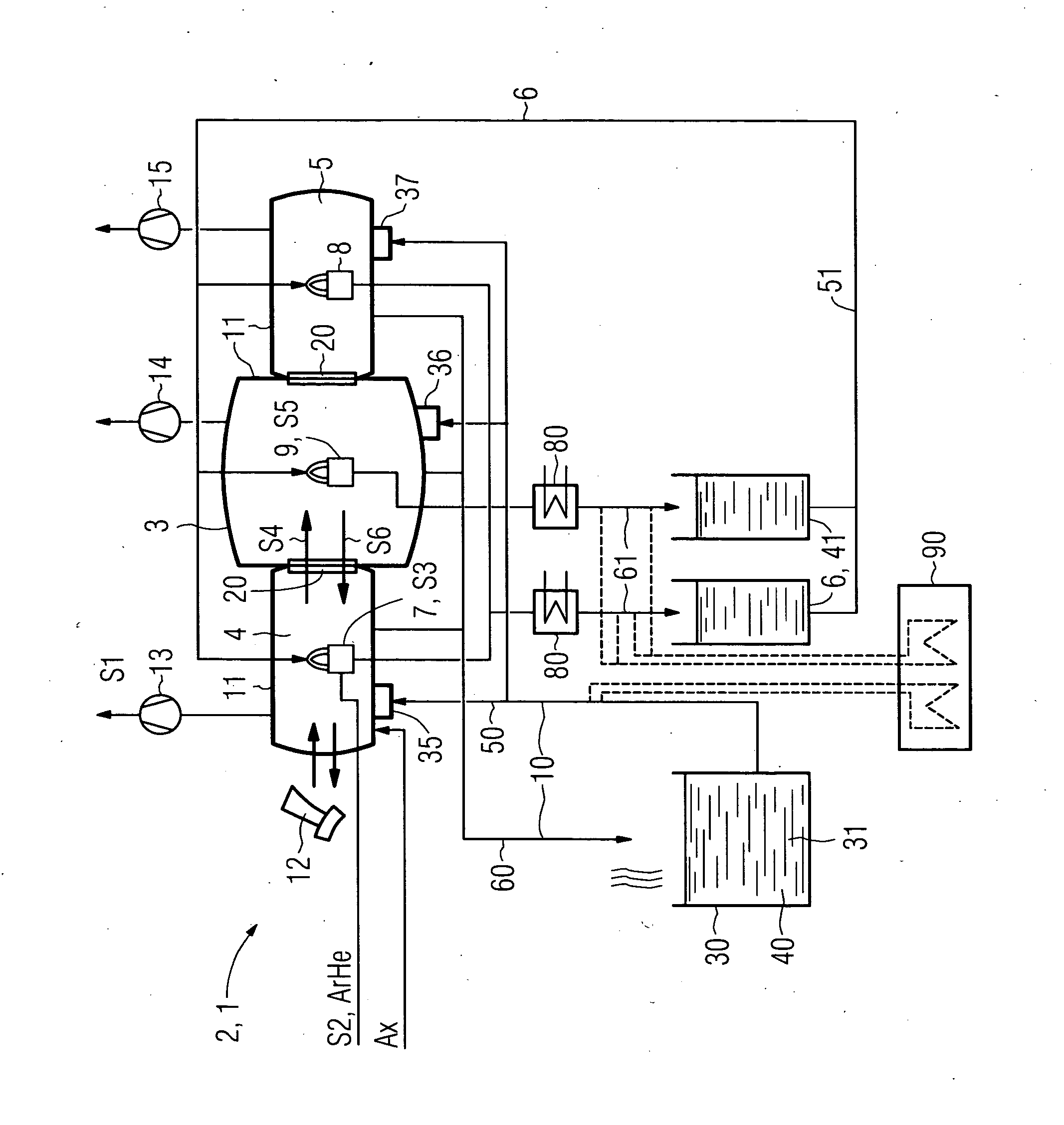

Coating system and coating method

InactiveUS20070186848A1Improve productivityReduce absorptionLiquid surface applicatorsMolten spray coatingTemperature controlCoating system

The invention relates to a coating system, especially a low pressure plasma coating system, with at least one treatment chamber and a coating tool, especially a plasma spraying device, wherein at least one pump is provided for evacuation of the treatment chamber, which treatment chamber is formed to be temperature controllable. In addition there is a coating method for low pressure plasma coating with a temperature controlled and evacuated treatment chamber, in which a workpiece is coated by means of at least one coating tool. For acceleration of the coating process, especially the evacuating of the treatment chamber, it is proposed that at least the walls of the treatment chamber and / or the inside of the treatment chamber are temperature controlled at a temperature between 45° C. and 75° C.

Owner:SIEMENS AG

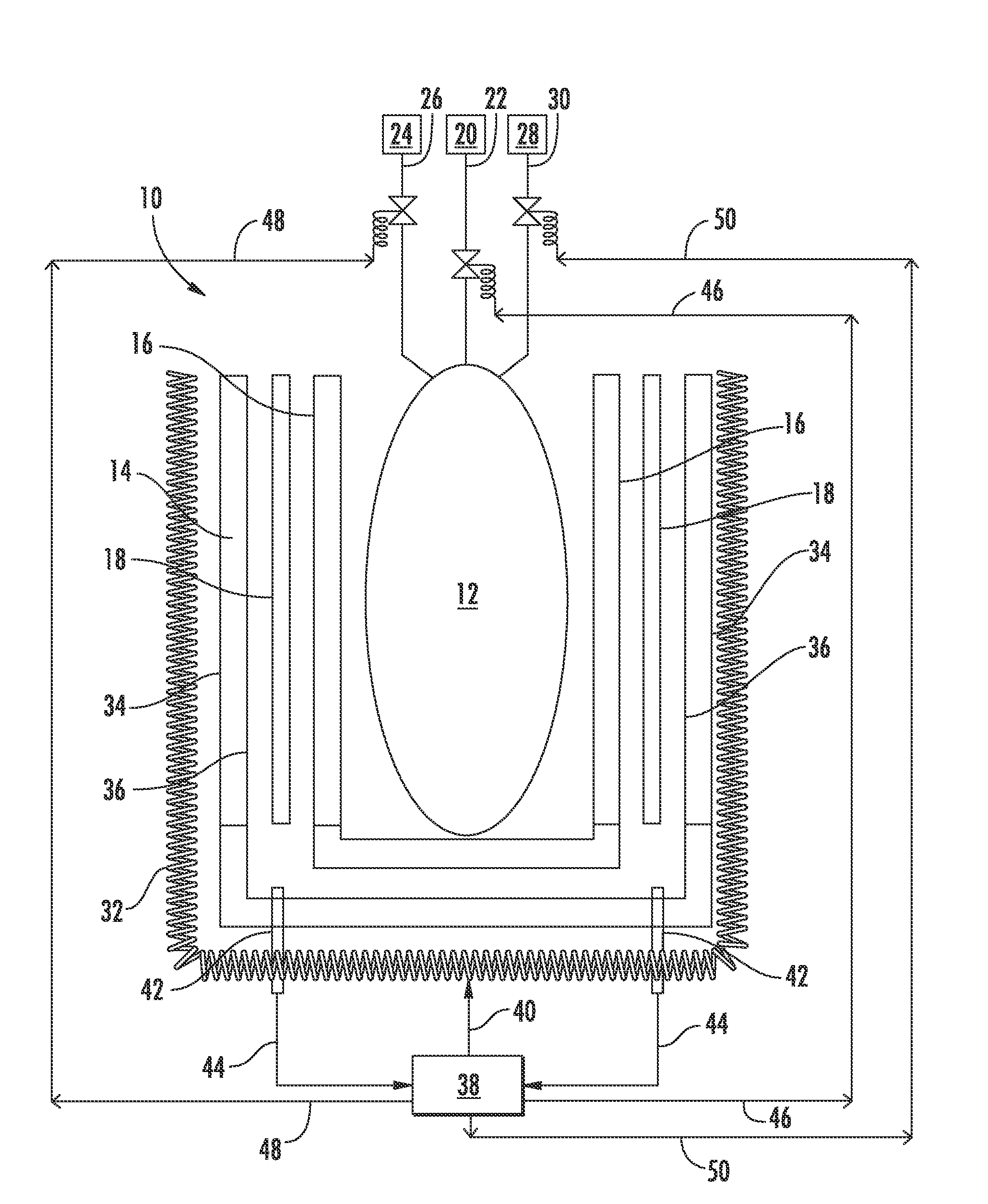

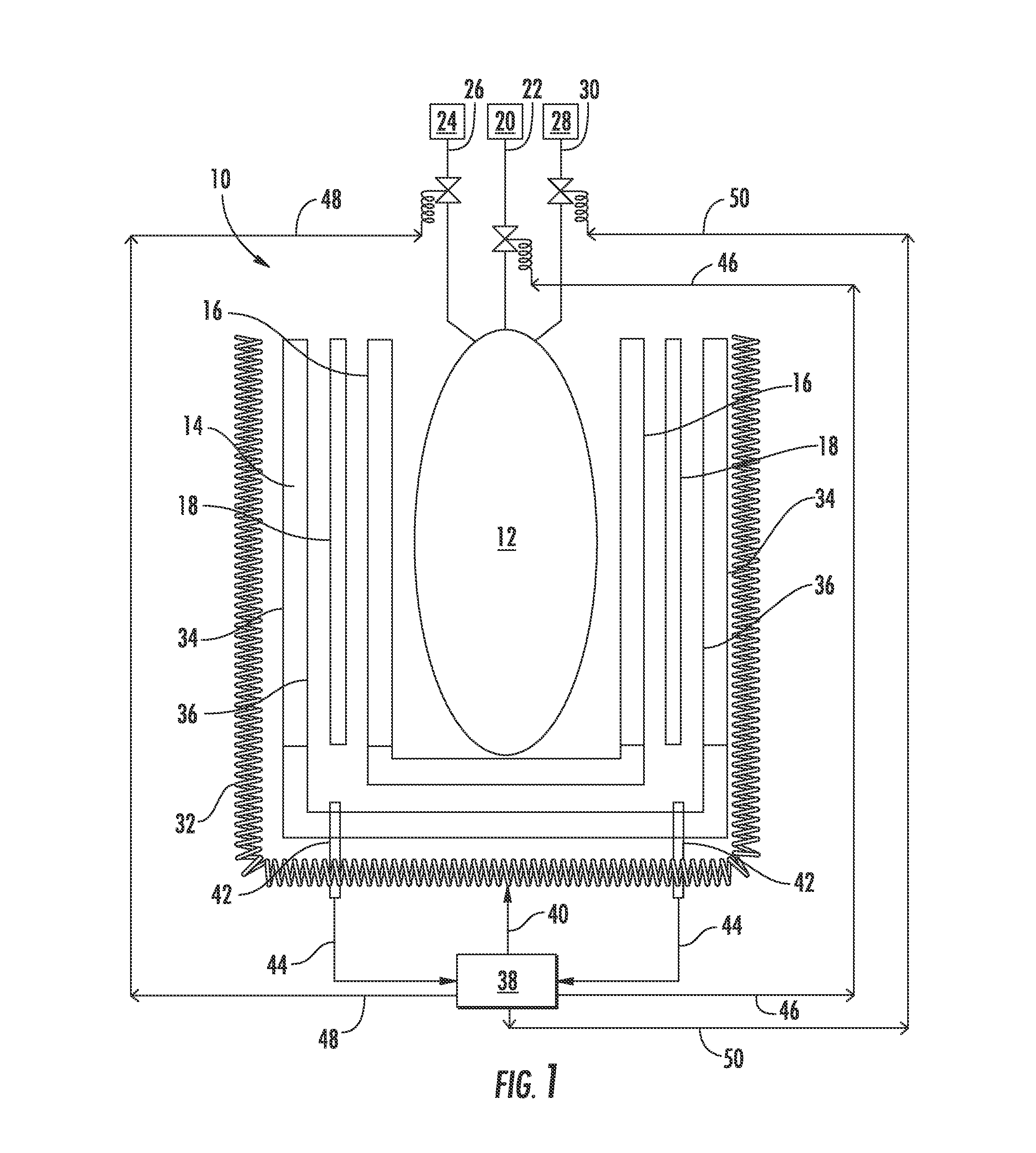

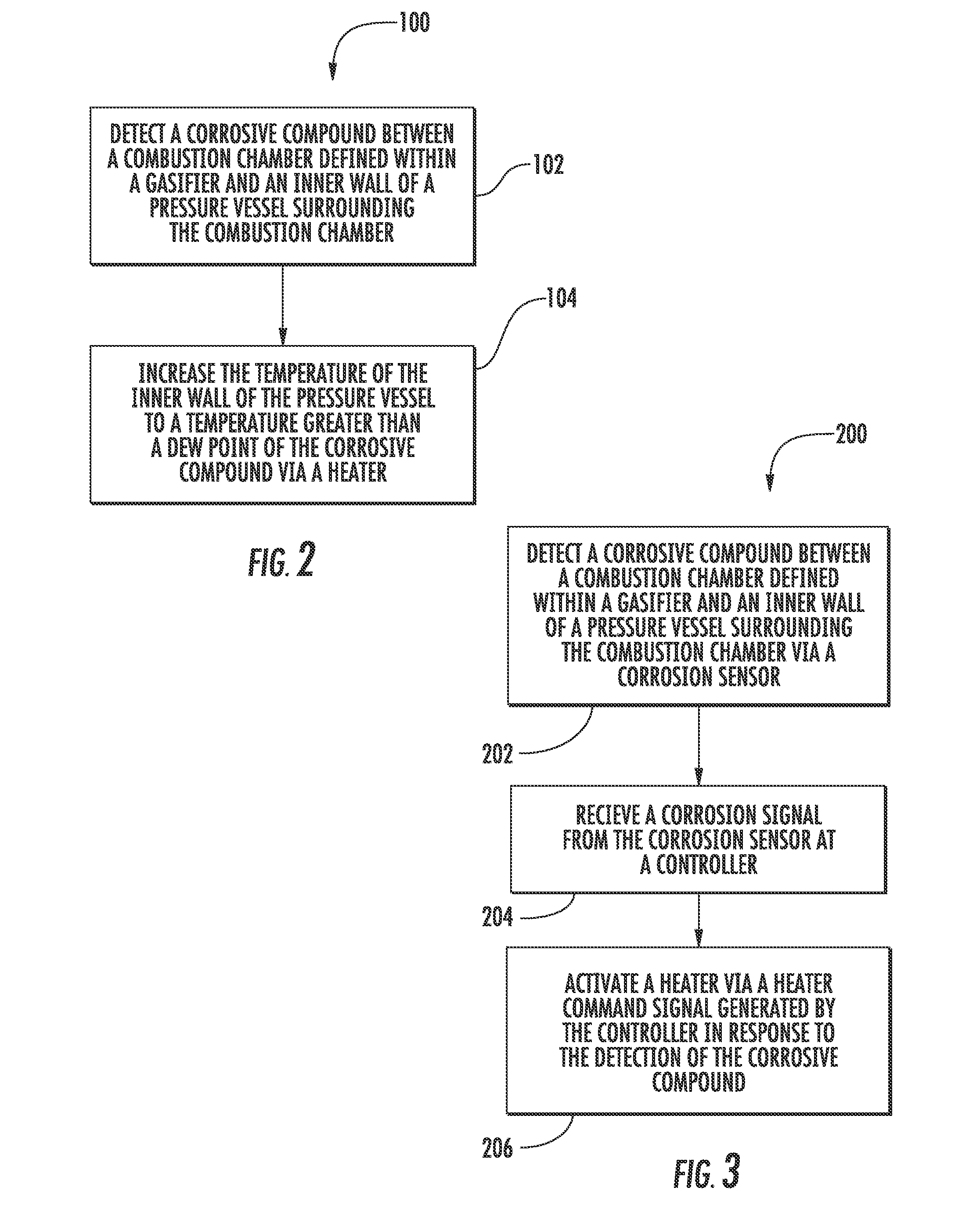

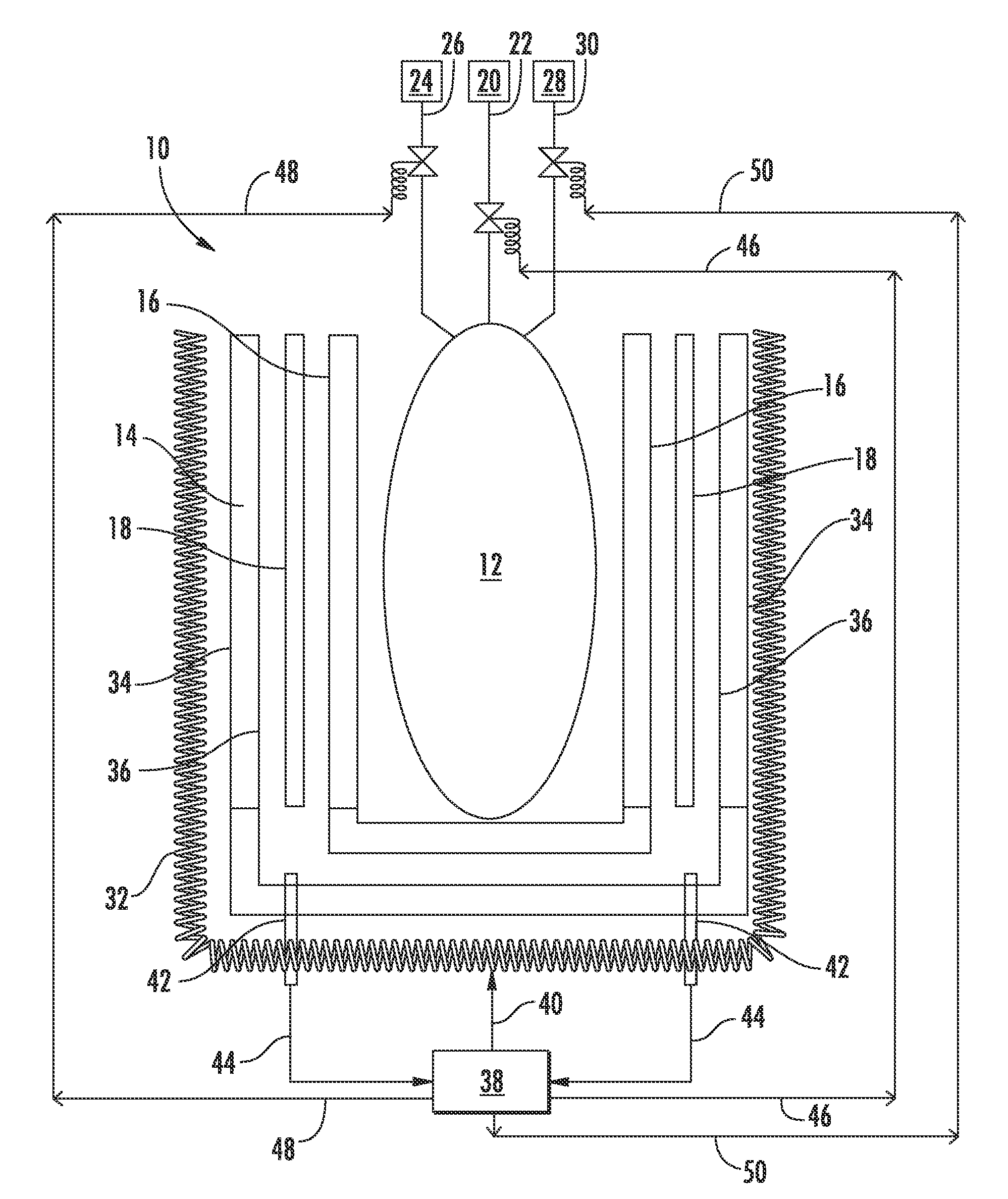

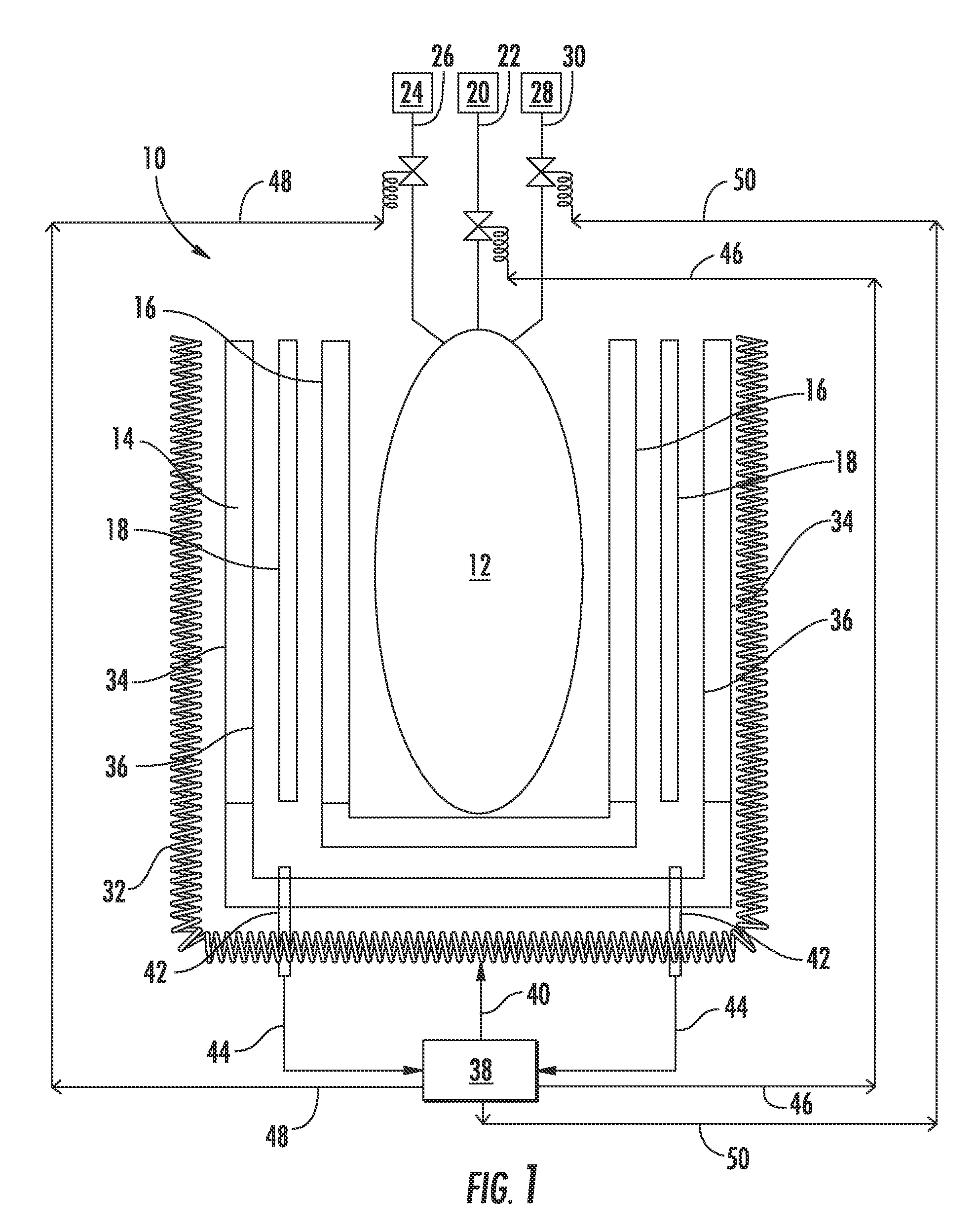

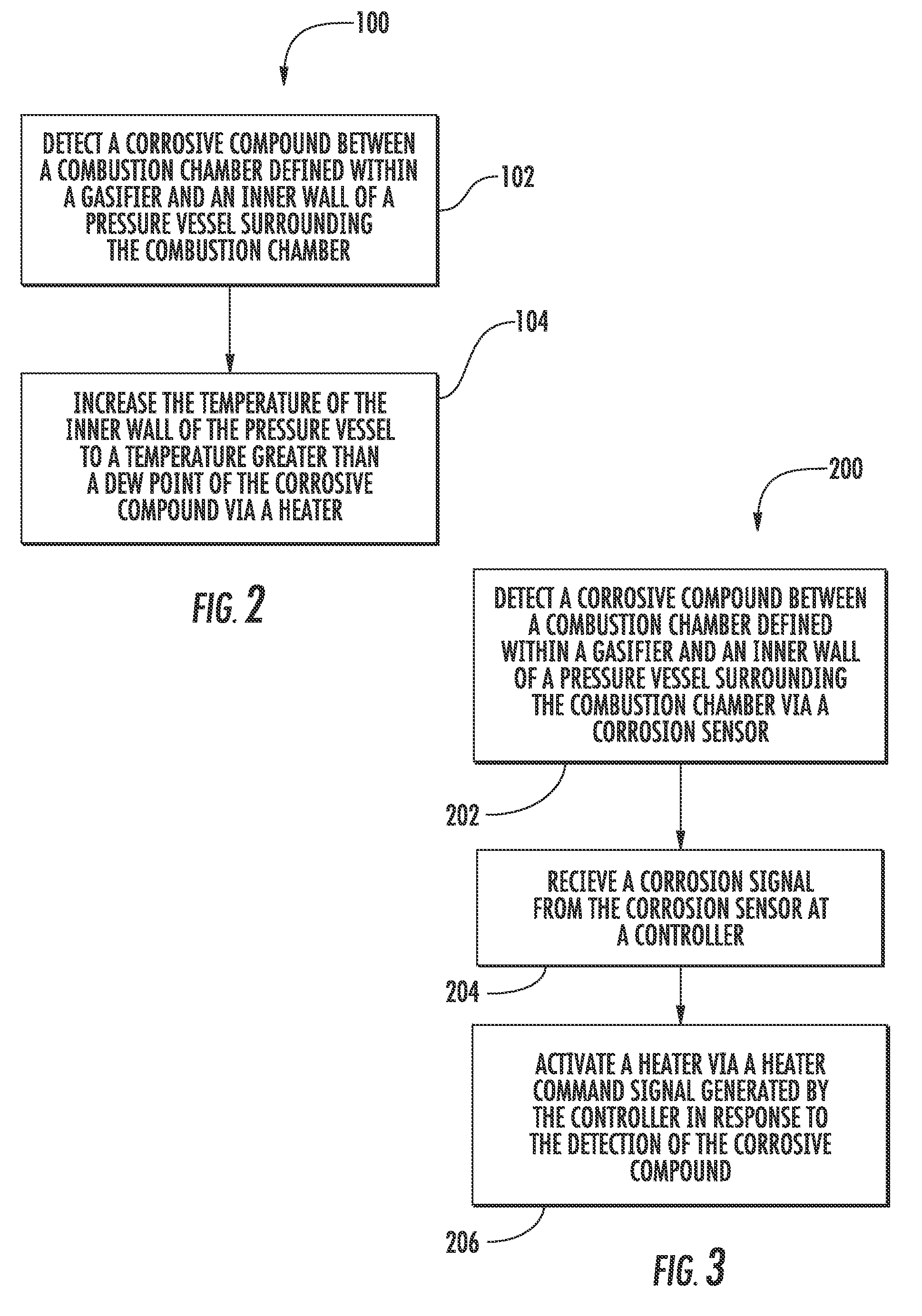

Method for operating a gasifier

ActiveUS20140157668A1Increase wall temperatureHydrogenGasification processes detailsDew pointCombustion chamber

A method for operating a gasifier includes detecting a corrosive compound between a combustion chamber defined within the gasifier and an inner wall of a pressure vessel that at least partially surrounds the combustion chamber via a corrosion sensor and increasing the temperature of the inner wall of the pressure vessel to a temperature that is greater than a dew point of the corrosive compound via a heater that at least partially surrounds the pressure vessel. The method may also include adjusting a flow of at least one of a fuel, an oxidant and a diluent to the gasifier in response to the detection of the corrosive compound so as to modify the dew point of the corrosive compound.

Owner:AIR PROD & CHEM INC

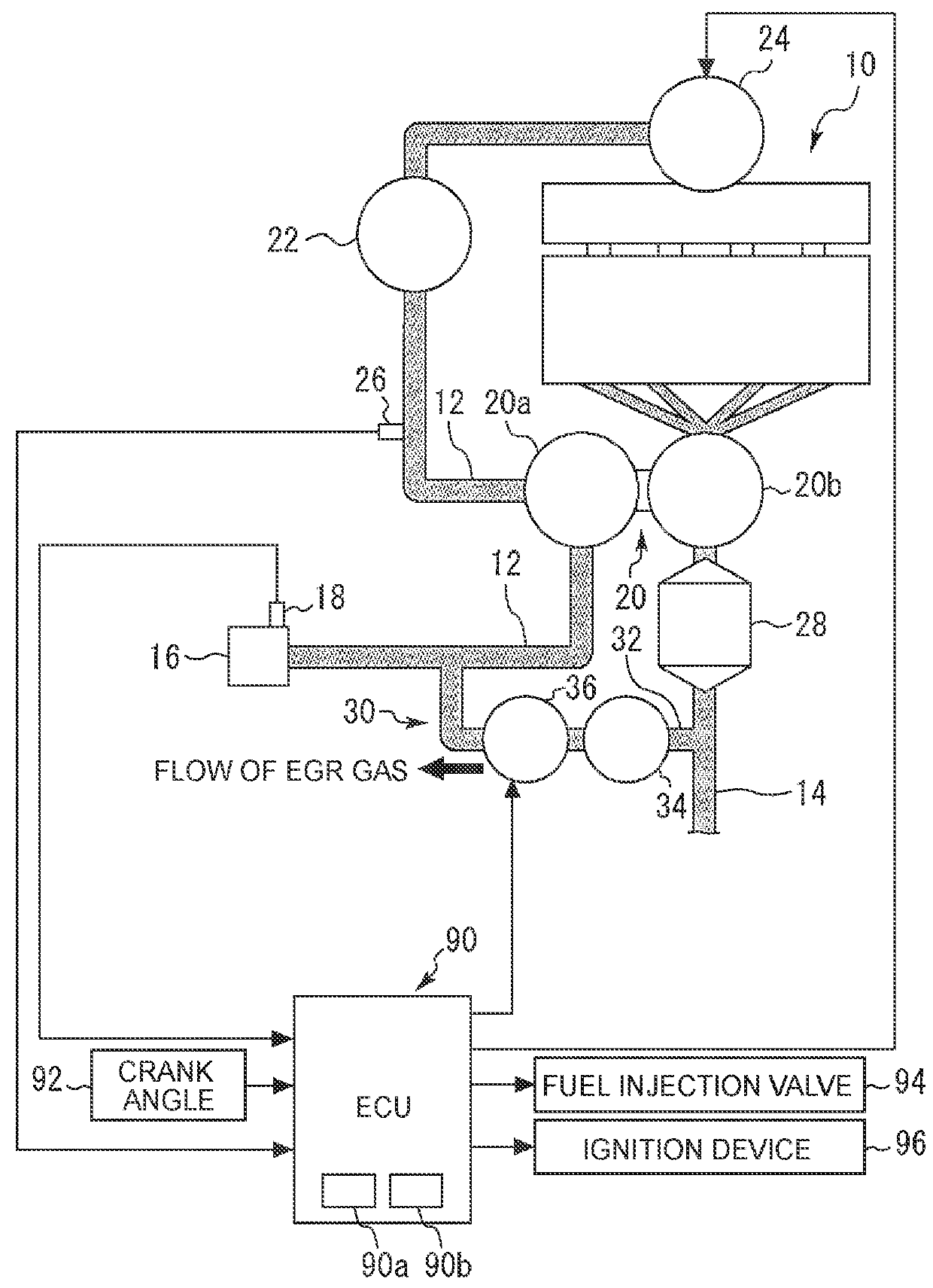

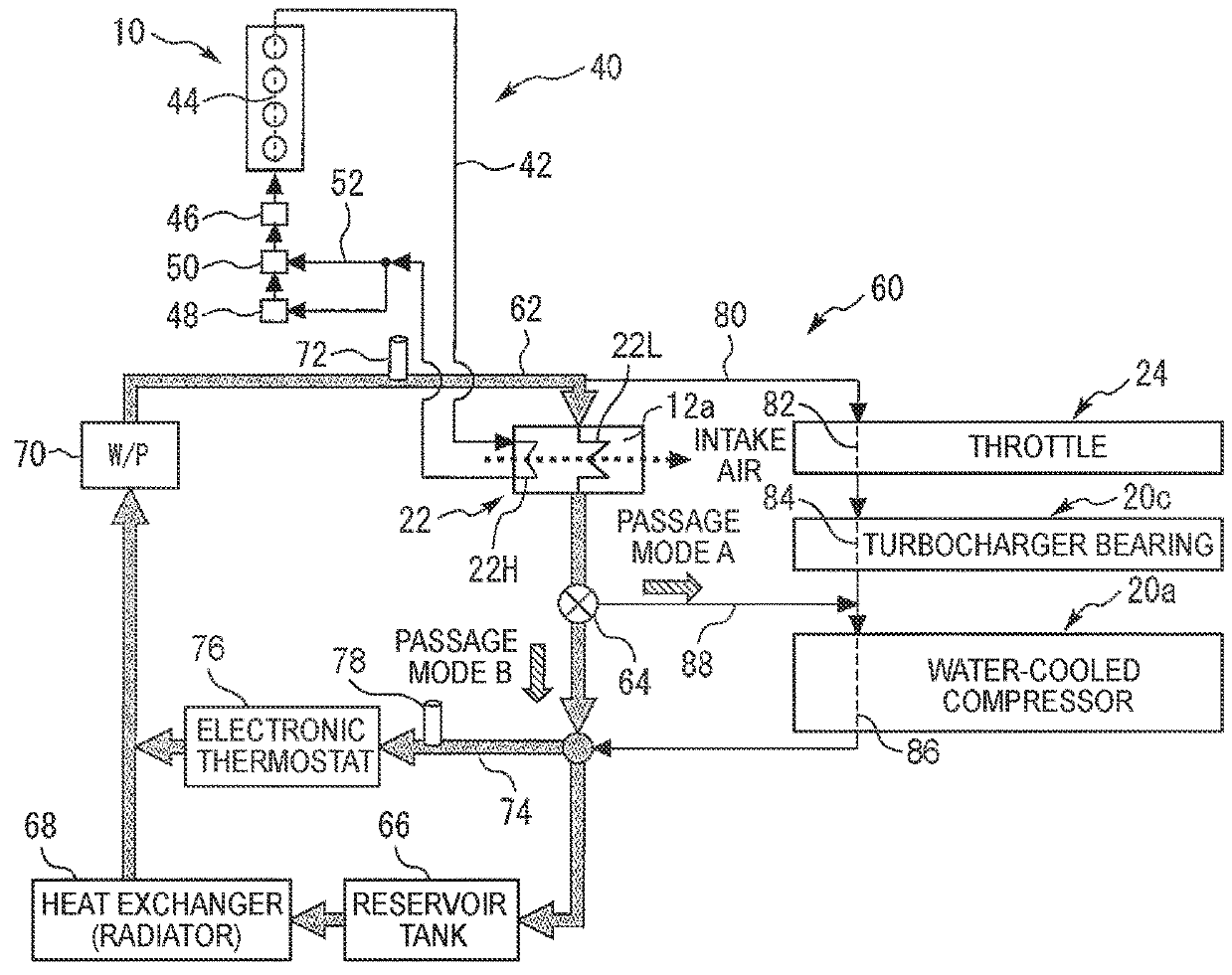

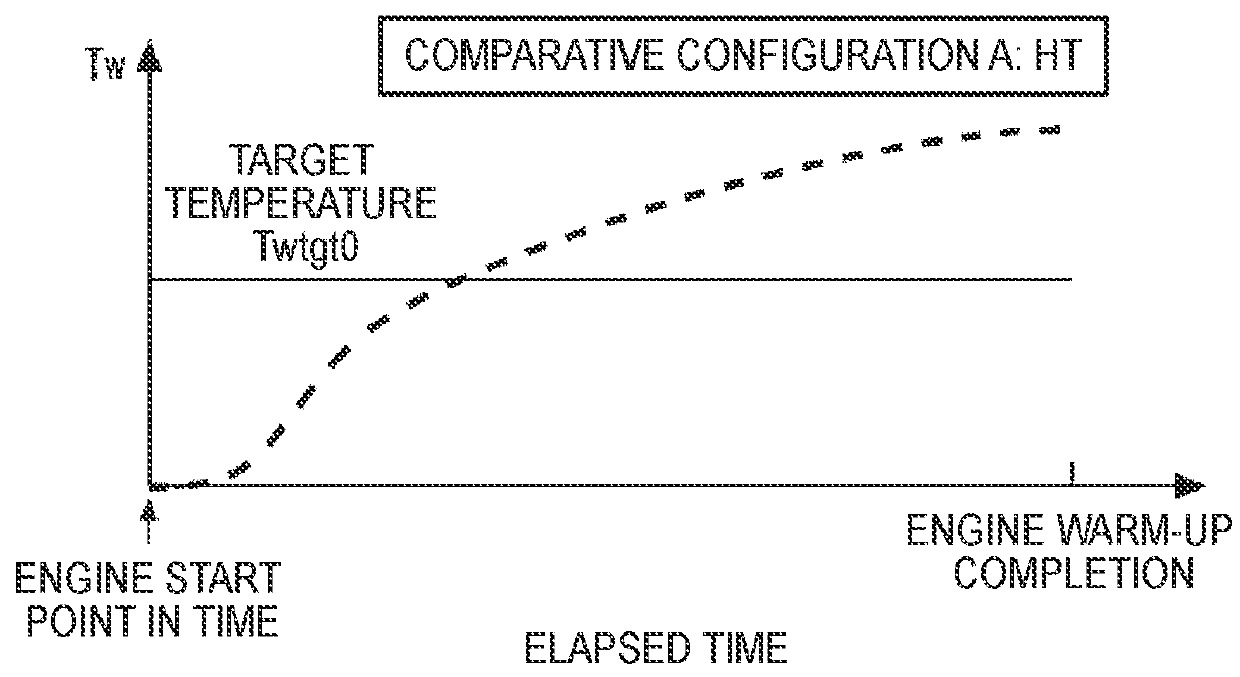

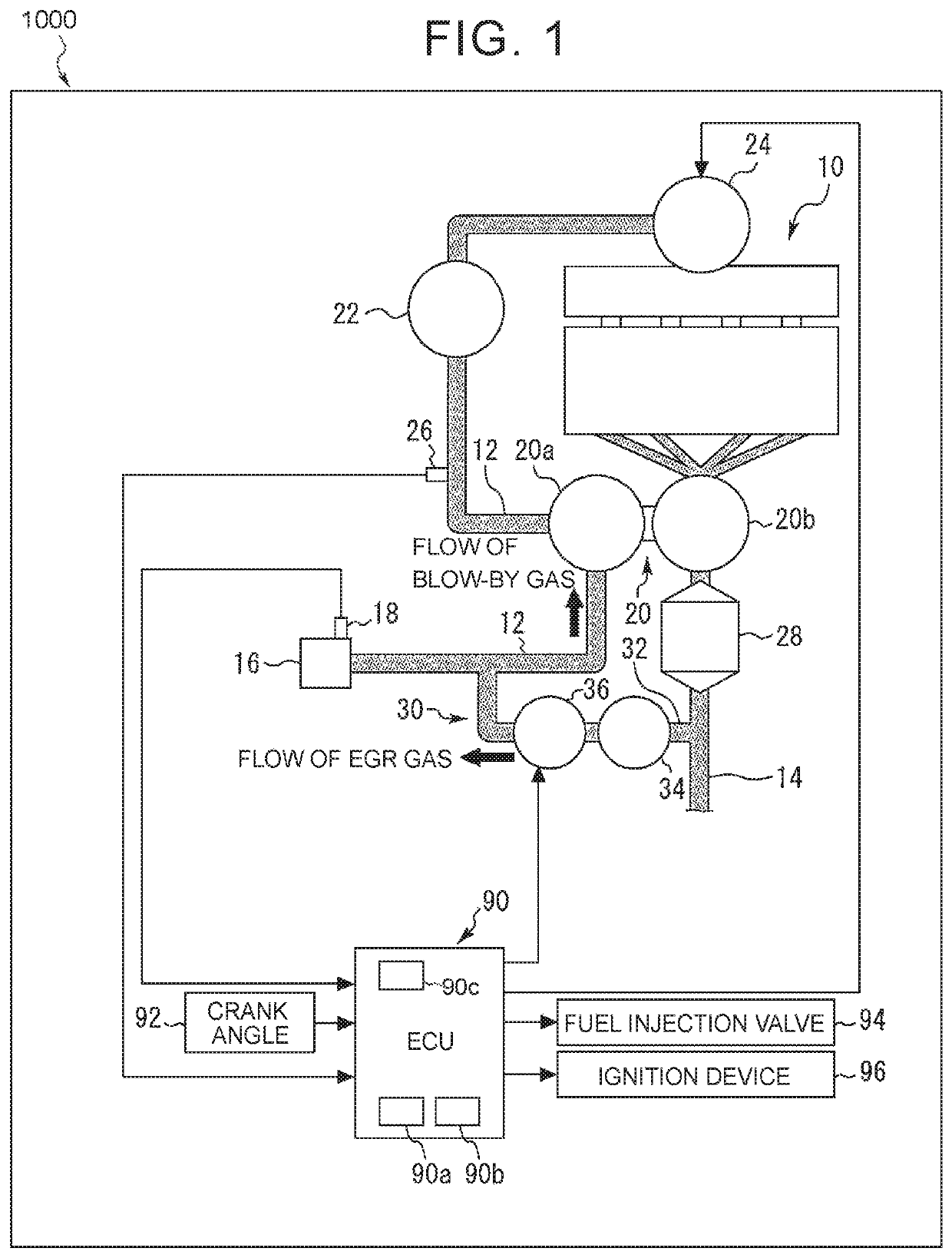

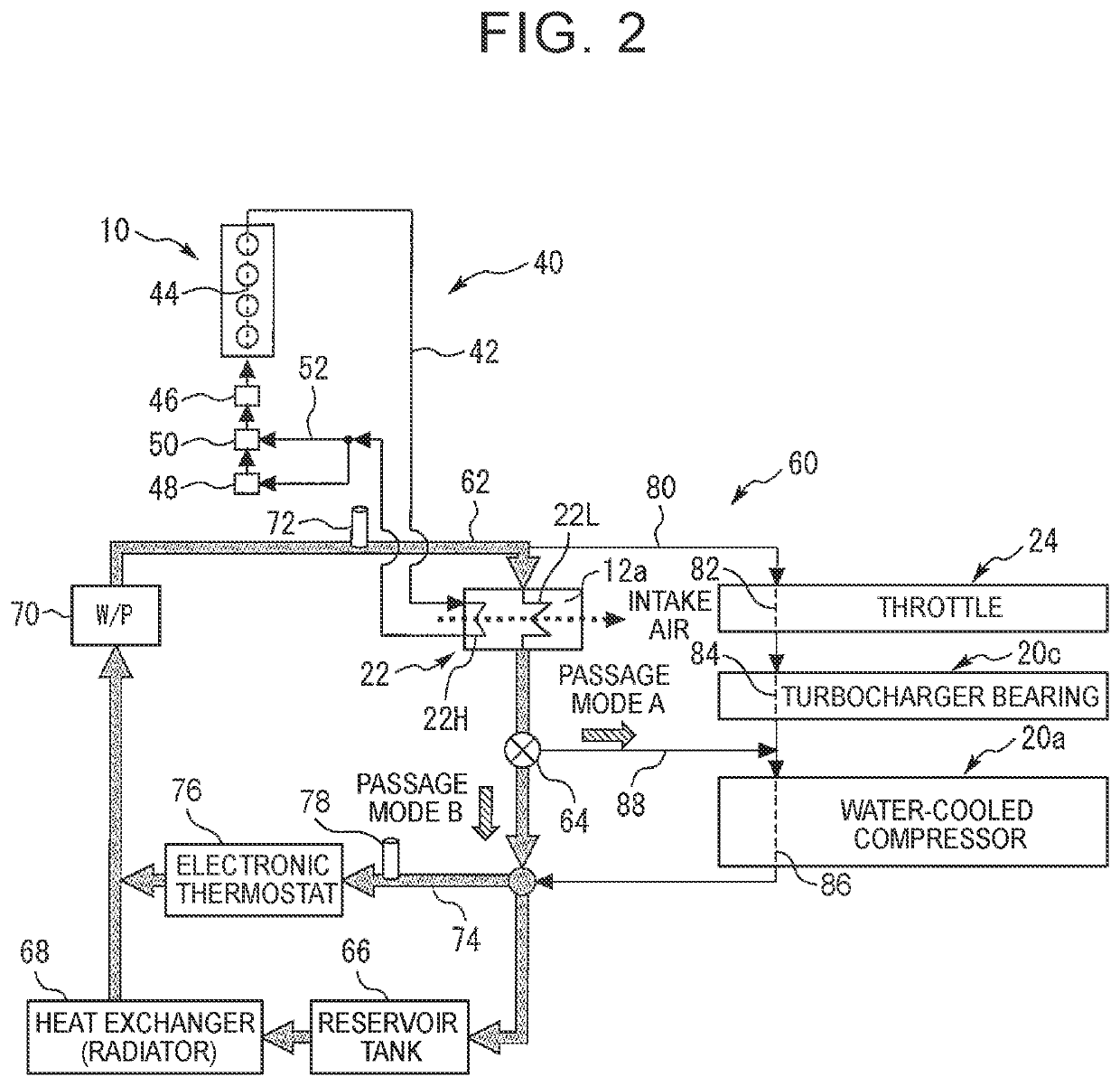

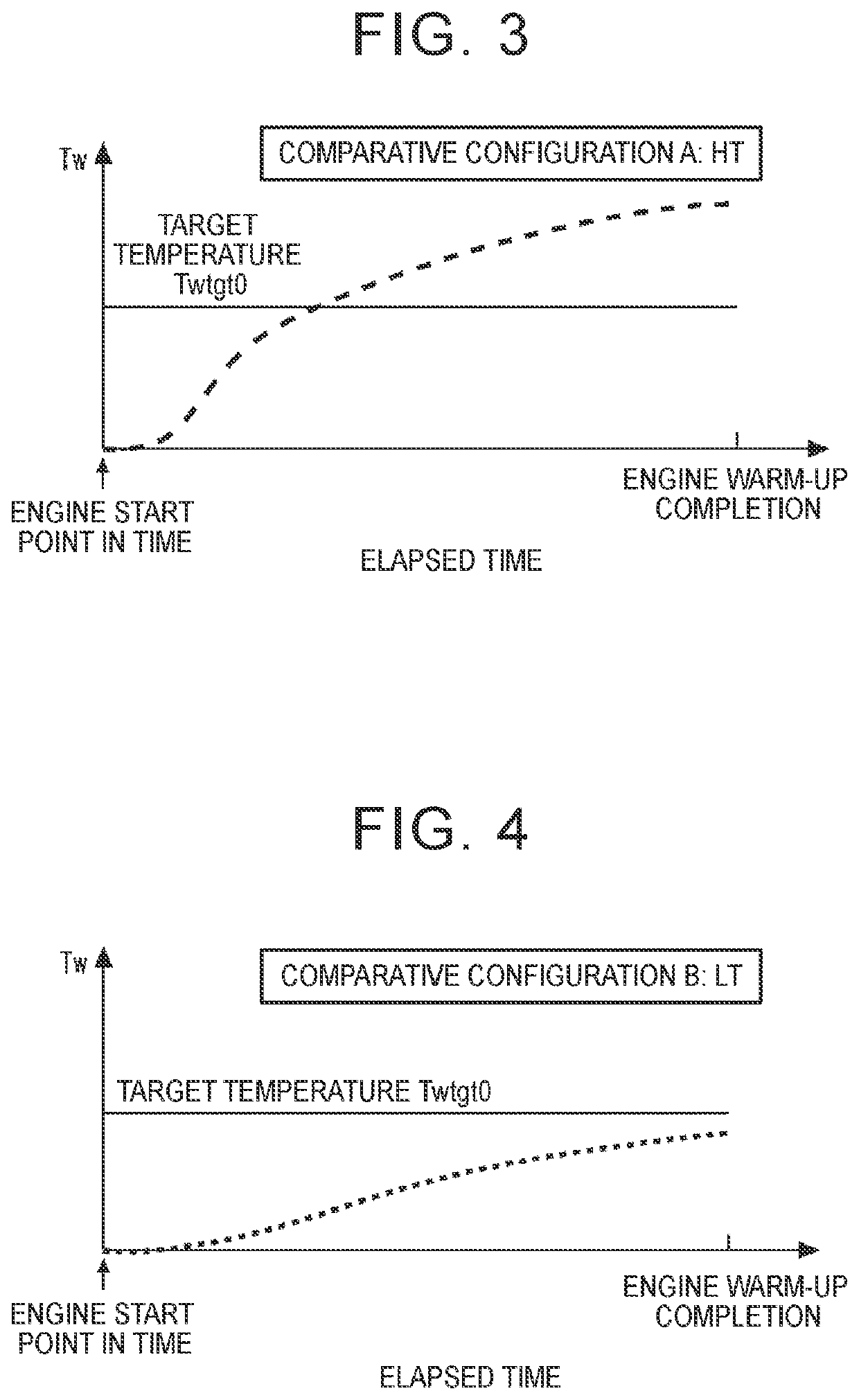

Engine system

ActiveUS20180179946A1Reduce productionEasy transferLiquid coolingCoolant flow controlIntercoolerEngineering

An engine system includes an internal combustion engine, a compressor, a high-temperature coolant circulation circuit, a low-temperature coolant circulation circuit, an intercooler, and an electronic control unit. The intercooler is configured to transfer heat of the high-temperature coolant to the low-temperature coolant via intake air. An in-compressor passage of the compressor is arranged in the low-temperature coolant circulation circuit at a location at which the low-temperature coolant that exits from an in-cooler low-temperature water passage during a predetermined period from beginning of cold start is introduced into the in-compressor passage without passing through a low-temperature radiator. The electronic control unit is configured to increase the flow rate of the low-temperature coolant that flows through the low-temperature coolant circulation circuit during the predetermined period as compared to the flow rate after the predetermined period.

Owner:TOYOTA JIDOSHA KK

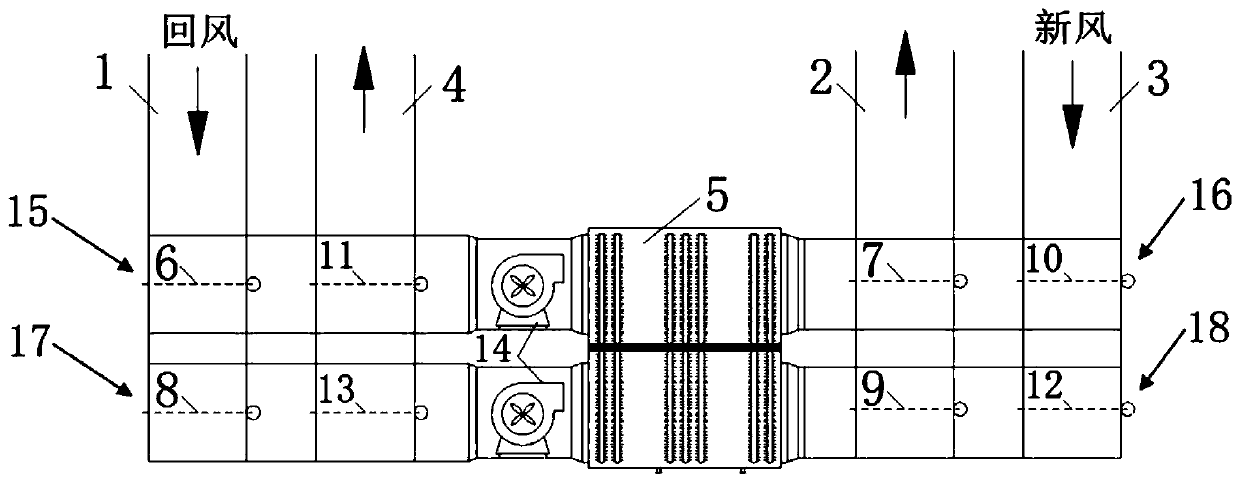

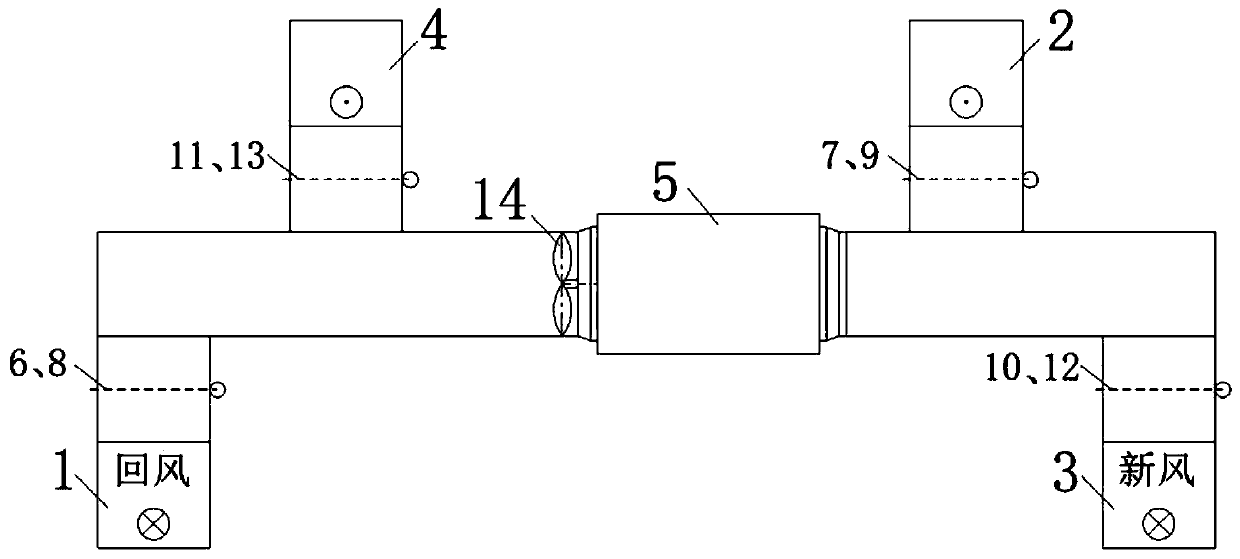

Waste heat utilization system of well air

PendingCN110207521AReach coolingNot easy to damageIndirect heat exchangersTunnel/mines ventillationFresh airEngineering

The invention provides a waste heat utilization system of well air. The system comprises a return air inlet path, a return air exhaust path, a fresh air inlet path, a fresh air exhaust path, a heat exchanger, axial-flow fans and valves, wherein the return air inlet path and the fresh air exhaust path are connected to one end of a first air flue and one end of a third air flue, and joints are equipped with valves; the other end of the first air flue and the other end of the third air flue are connected to the heat exchanger; the return air inlet path, the return air exhaust path and the fresh air inlet path are connected to one end of a second air flue and one end of a fourth air flue, and joints are equipped with valves; the other end of the second air flue and the other end of the fourthair flue are connected to the heat exchanger; and the axial-flow fans are arranged in the first air flue and the third air flue and / or the second air flue and the fourth air flue. The system recycleswaste heat in underground return air in winter to preheat air flues for fresh air circulation. In summer, return air is used as a cold source through valve conversion, so that the effects of cooling the air flues for fresh air circulation and reducing heat damages are reduced.

Owner:国能龙源蓝天节能技术有限公司上海分公司

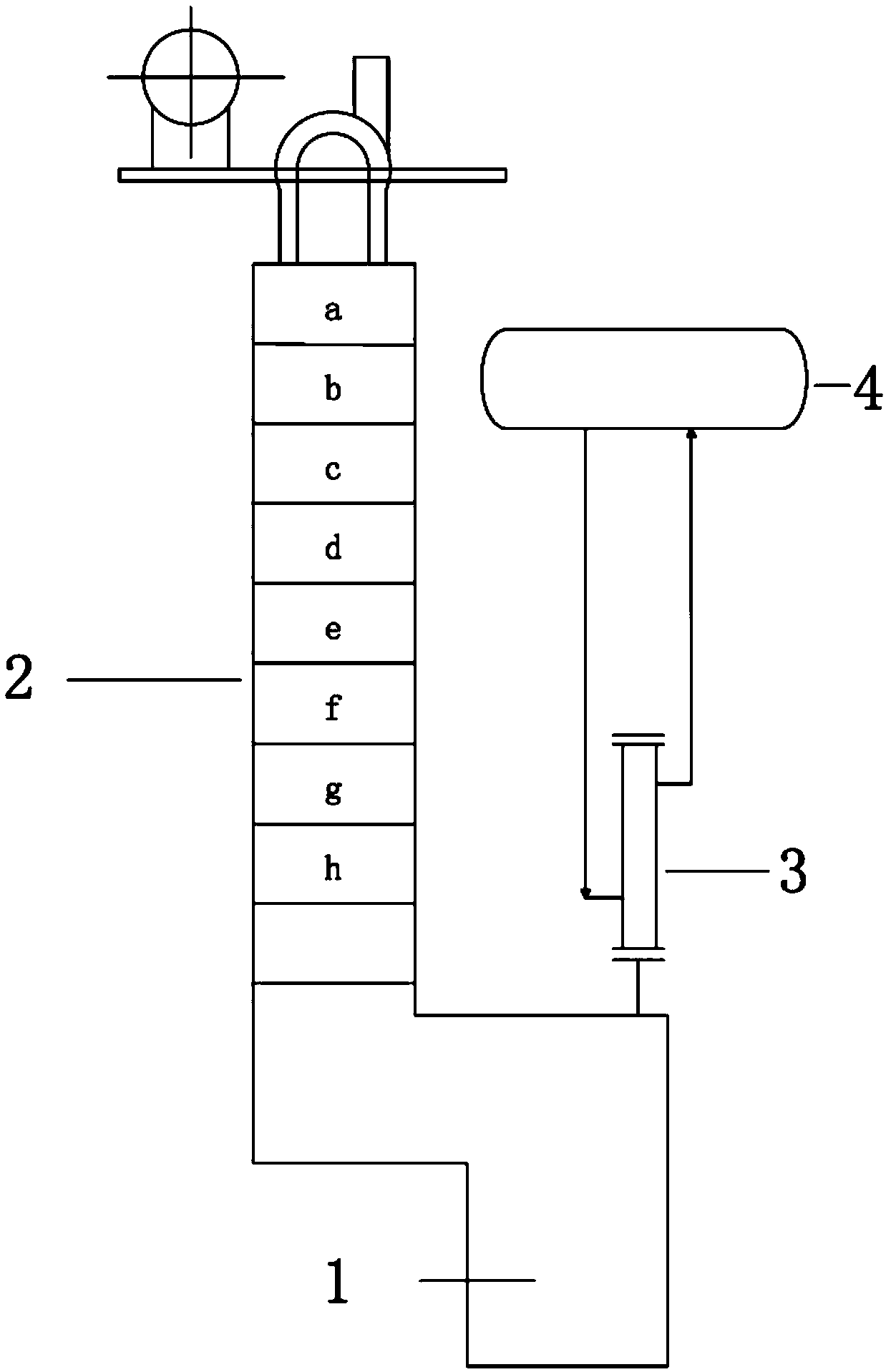

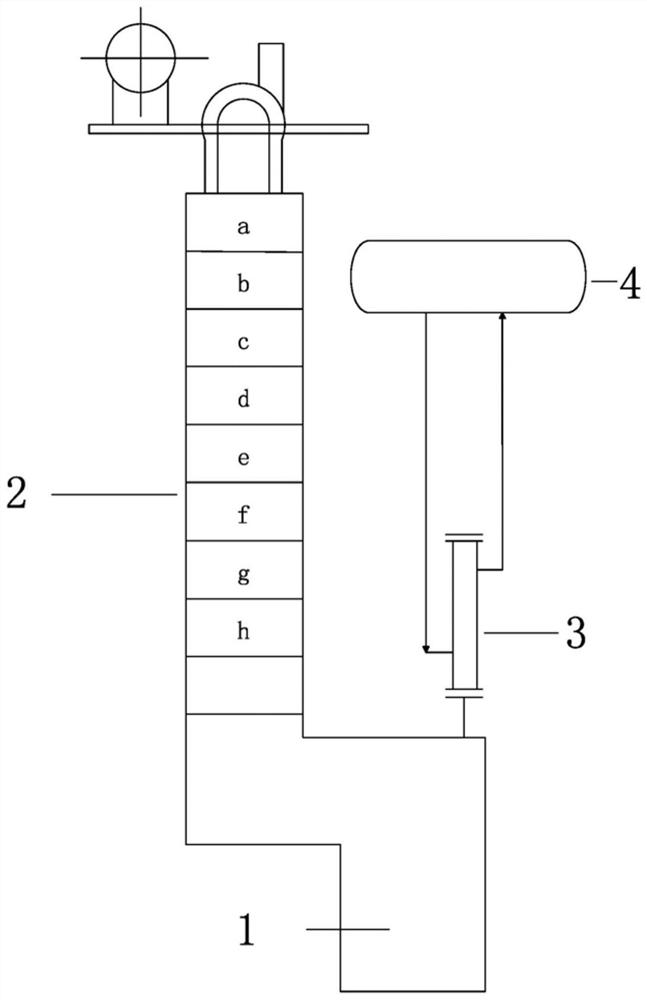

Recycling device and system for crude gas waste heat of coke oven

PendingCN109282260ASmall diameterIncrease wall temperatureLiquid degasificationEnergy inputSteam pressureHeat conducting

The invention discloses a recycling device and system for crude gas waste heat of a coke oven. The recycling device for crude gas waste heat of the coke oven comprises an inner barrel and an outer barrel which are concentrically arranged in a sleeving manner inside and outside, wherein the axes of the inner barrel and the outer barrel extend up and down; connecting flanges are arranged at the upper and lower ends of the inner barrel and the outer barrel; a crude gas inlet is formed in the lower end of the inner barrel; a crude gas outlet is formed in the upper end of the inner barrel; the space between the inner barrel and the outer barrel is filled with a heat-conducting material layer; a spirally arranged heat exchange pipe is arranged in the heat-conducting material layer; the heat exchange pipe is a spiral coil; the axis of the spiral coil coincides with the axes of the inner barrel and the outer barrel; a medium inlet is formed in the lower end of the heat exchange pipe; and a medium outlet is formed in the upper end of the heat exchange pipe. According to the recycling device and the recycling system for crude gas waste heat of the coke oven, the spiral coil-type heat exchange pipe is utilized, enough heat exchange area can be arranged on the limited length, the diameter of the heat exchange pipe can be decreased, water supply and steam pressure is improved, high-level steam is produced, and the defect that only low-pressure steam can be produced through a water jacket structure is overcome; and the heat-conducting material layer is arranged, so that the coking problem caused by low temperature of the inner wall is solved.

Owner:江苏中圣压力容器装备制造有限公司

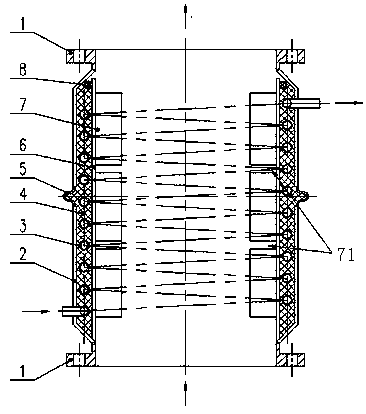

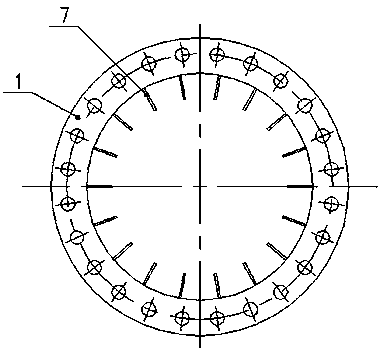

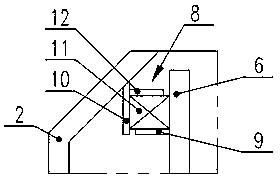

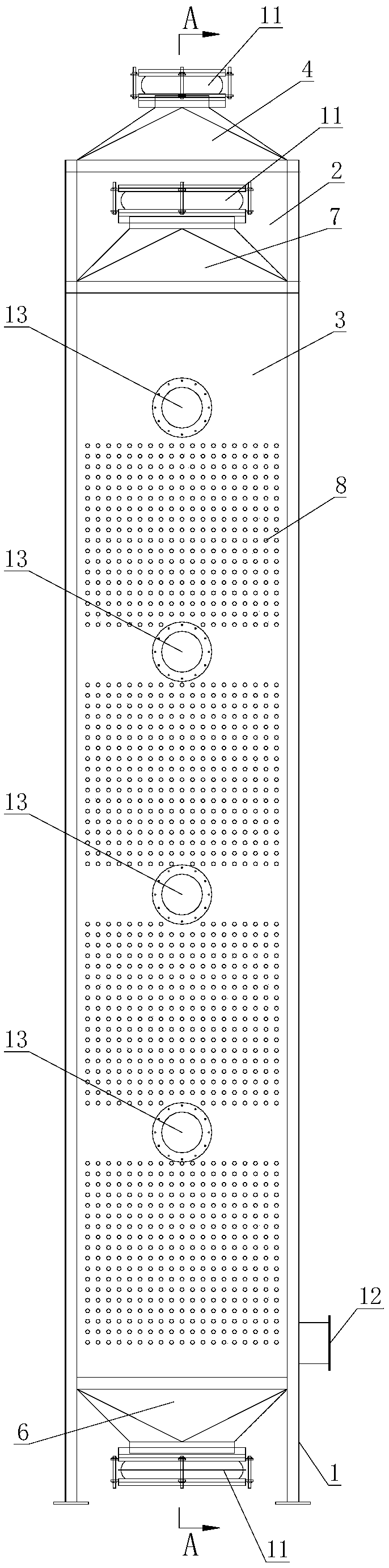

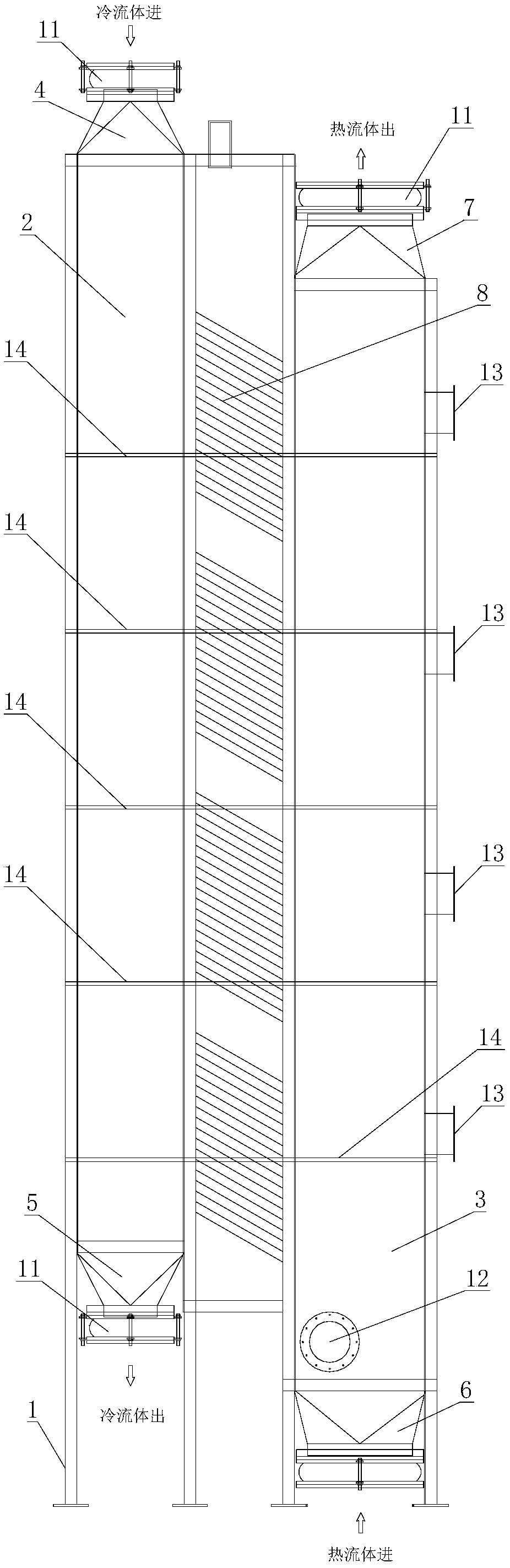

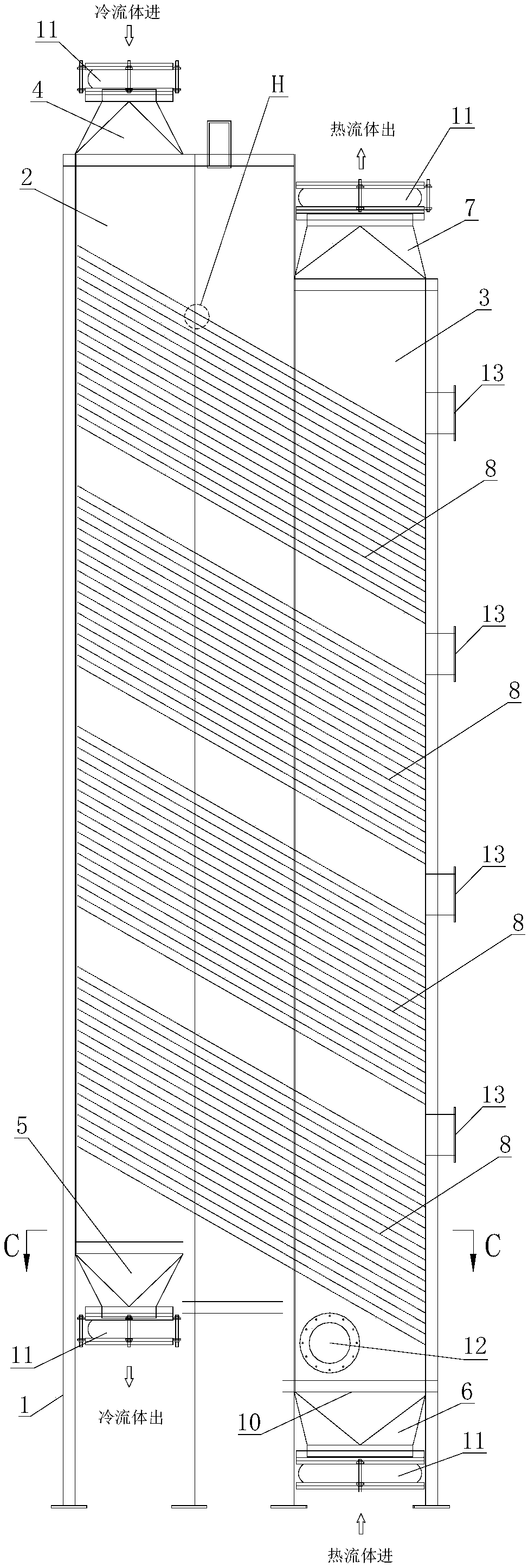

Three-section heat pipe cyclone heat exchanger

PendingCN109269330ADoping will not occurImprove safety and reliabilityIndirect heat exchangersCycloneEvaporation

The invention discloses a three-section heat pipe cyclone heat exchanger which comprises a frame. A cold fluid tank and a hot fluid tank are not contacted and arranged on the frame, and a space is reserved between the cold fluid tank and a hot fluid tank. An inlet of the cold fluid tank is provided with a cold fluid inlet flared opening while an outlet is provided with a cold fluid outlet flared opening, and an inlet of the hot fluid tank is provided with a hot fluid inlet flared opening while an outlet is provided with a hot fluid outlet flared opening. A plurality of heat exchange units formed by a plurality of heat pipes are arranged between the hot fluid tank and the cold fluid tank along a fluid flow direction. One end of each heat pipe extends into the hot fluid tank while the otherend extends into the cold fluid tank. Each heat pipe is partitioned into a heat pipe evaporation section in the hot fluid tank, a heat pipe insulation section between the hot fluid tank and the cold fluid tank and a heat pipe condensation section in the cold fluid tank by the cold fluid tank and the hot fluid tank. The three-section heat pipe cyclone heat exchanger has advantages of high heat exchange efficiency and wide temperature adaptive range.

Owner:江苏龙净节能科技有限公司

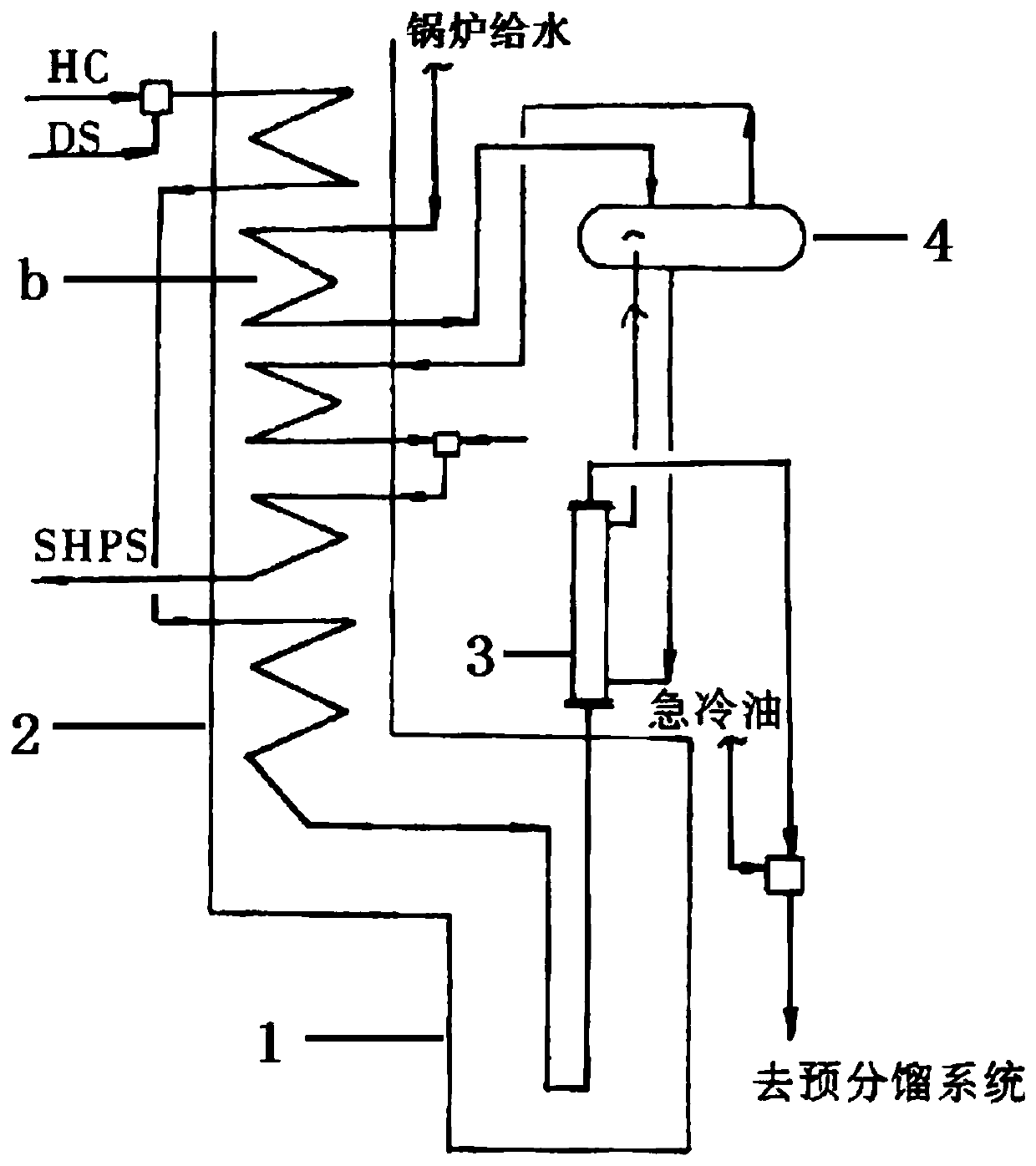

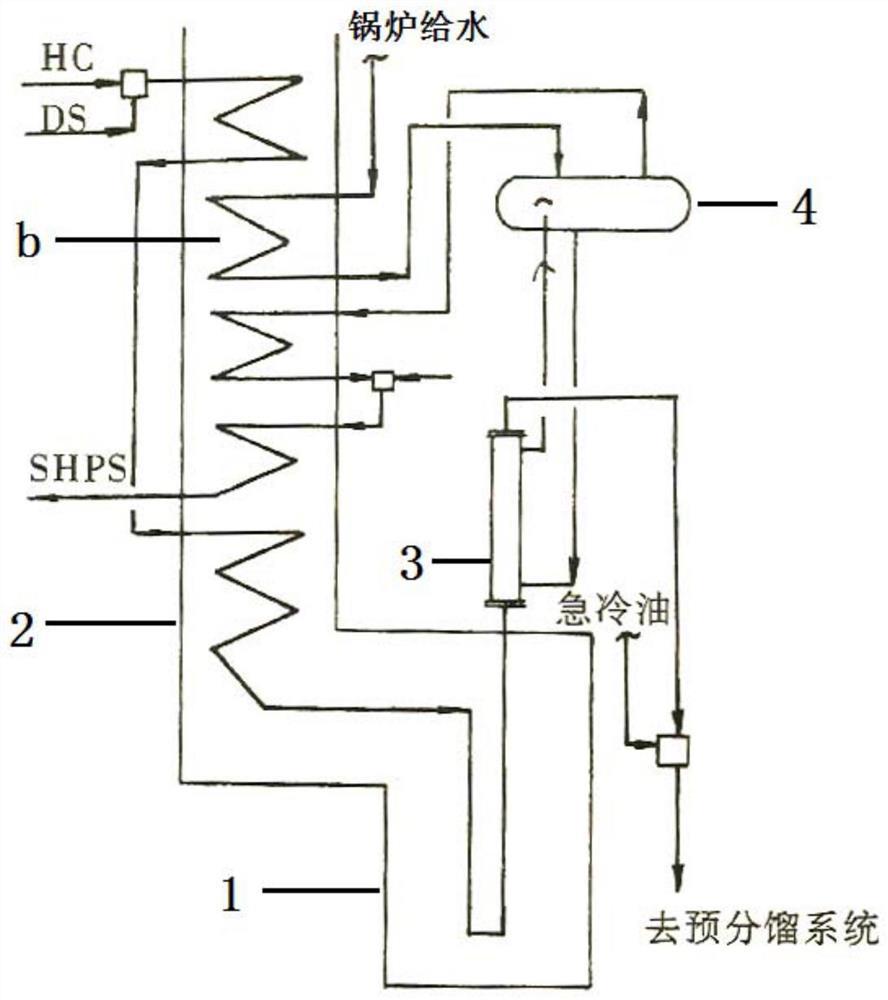

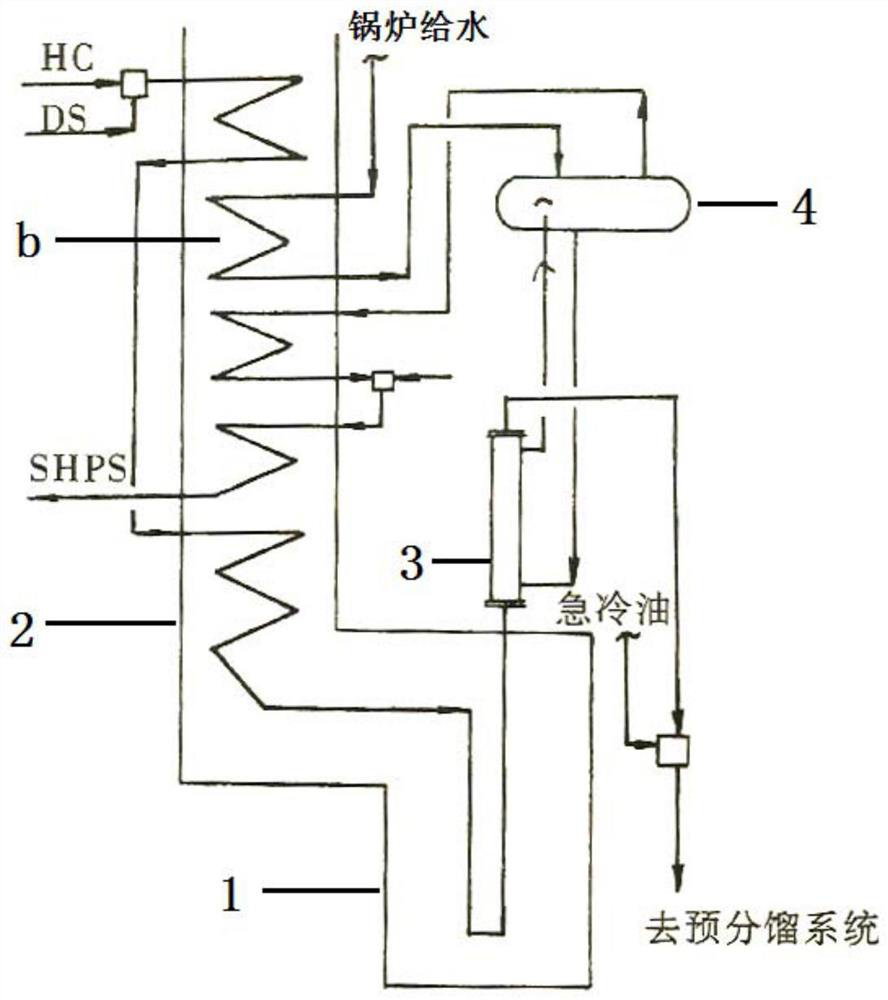

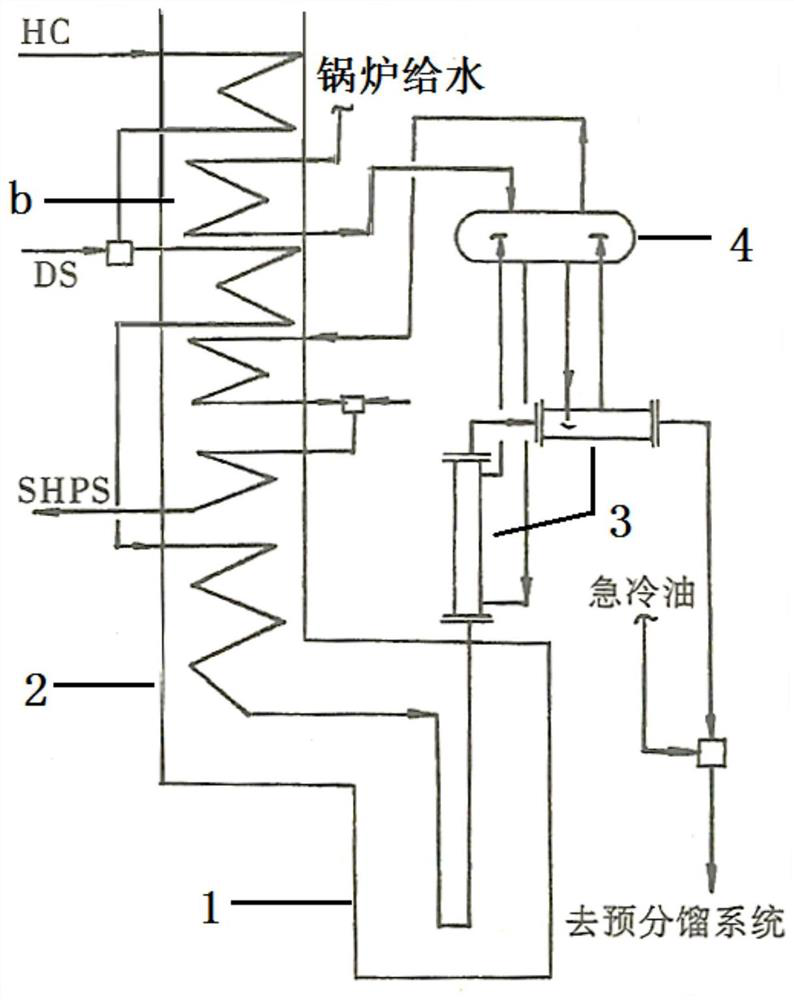

Heat exchange process and heat exchange system for ethylene cracking furnace

ActiveCN110630998AFlexible operationReduce condensation cokingSteam boilersProcess engineeringPetrochemical

The invention belongs to the field of petrochemical engineering, and relates to a heat exchange process and a heat exchange system for an ethylene cracking furnace. During the heat exchange process, the boiler water supply preheated through a convection section of the cracking furnace is divided into two channels, one channel enters the convection section continuously for further preheating, andthen enters a steam pocket to perform heat exchange with pyrolysis gas in a first quenching heat exchanger group, the other channel enters a second quenching heat exchanger group to perform heat exchange with the pyrolysis gas from the first quenching heat exchanger group so that the temperature of the pyrolysis gas is further reduced, meanwhile, the boiler water supply is heated further so as torecover the heat of the pyrolysis gas further. The energy-saving process of the invention significantly improves the energy utilization of the device, realizes the energy-saving and cost-reducing during a production process, while increasing the yield of super high steam, and improving the economic efficiency of the ethylene cracking device. In addition, this process technology is helpful for theburning process of a furnace tube and a quenching heat exchanger in the device, and is beneficial to the safe, long-term and efficient operation of the production device.

Owner:SINOPEC ENG +1

Ceramic discharge vessel having an opaque zone and method of making same

InactiveUS8040061B2Low emissivityIncrease temperatureVessels or leading-in conductors manufactureSolid cathode detailsEmissivityHigh intensity

An opaque zone in the polycrystalline (PCA) discharge vessel of a high intensity discharge lamp may be made by creating residual pores in predetermined regions of the final-sintered discharge vessel. The control over the placement of the opaque zone is achieved by forming a carbonaceous residue in a specific region of the discharge vessel prior to final sintering. During sintering, the carbonaceous material causes residual porosity in the sintered PCA. The higher emissivity of the opaque PCA provides localized cooling in order to provide more control over the condensate behavior in the discharge vessel.

Owner:OSRAM SYLVANIA INC

Ceramic Discharge Vessel Having an Opaque Zone and Method of Making Same

InactiveUS20090066251A1Low emissivityIncrease temperatureVessels or leading-in conductors manufactureSolid cathode detailsEmissivityHigh intensity

An opaque zone in the polycrystalline (PCA) discharge vessel of a high intensity discharge lamp may be made by creating residual pores in predetermined regions of the final-sintered discharge vessel. The control over the placement of the opaque zone is achieved by forming a carbonaceous residue in a specific region of the discharge vessel prior to final sintering. During sintering, the carbonaceous material causes residual porosity in the sintered PCA. The higher emissivity of the opaque PCA provides localized cooling in order to provide more control over the condensate behavior in the discharge vessel.

Owner:OSRAM SYLVANIA INC

Engine system

ActiveUS10655529B2Reduce productionEasy transferLiquid coolingCoolant flow controlIntercoolerInternal combustion engine

An engine system includes an internal combustion engine, a compressor, a high-temperature coolant circulation circuit, a low-temperature coolant circulation circuit, an intercooler, and an electronic control unit. The intercooler is configured to transfer heat of the high-temperature coolant to the low-temperature coolant via intake air. An in-compressor passage of the compressor is arranged in the low-temperature coolant circulation circuit at a location at which the low-temperature coolant that exits from an in-cooler low-temperature water passage during a predetermined period from beginning of cold start is introduced into the in-compressor passage without passing through a low-temperature radiator. The electronic control unit is configured to increase the flow rate of the low-temperature coolant that flows through the low-temperature coolant circulation circuit during the predetermined period as compared to the flow rate after the predetermined period.

Owner:TOYOTA JIDOSHA KK

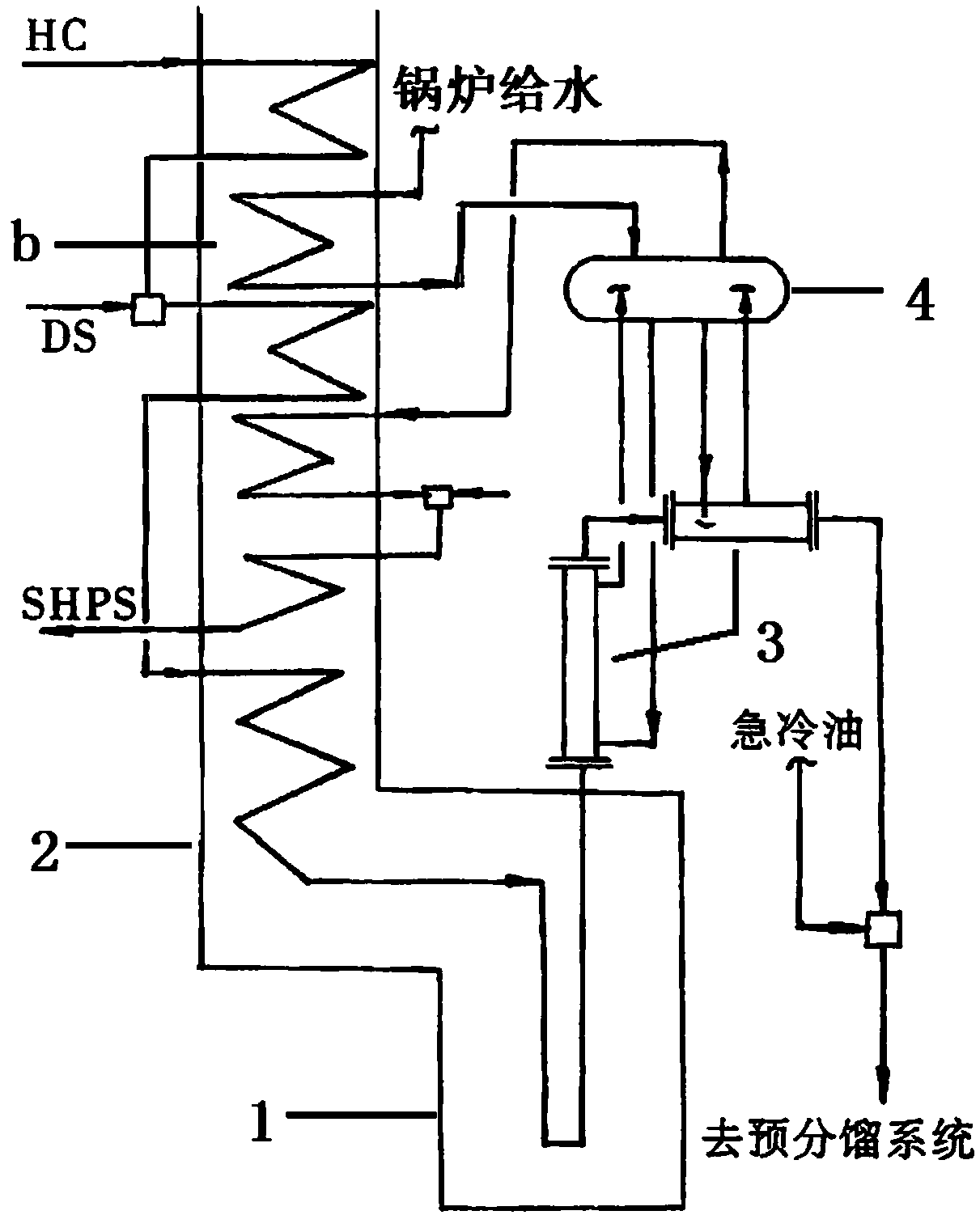

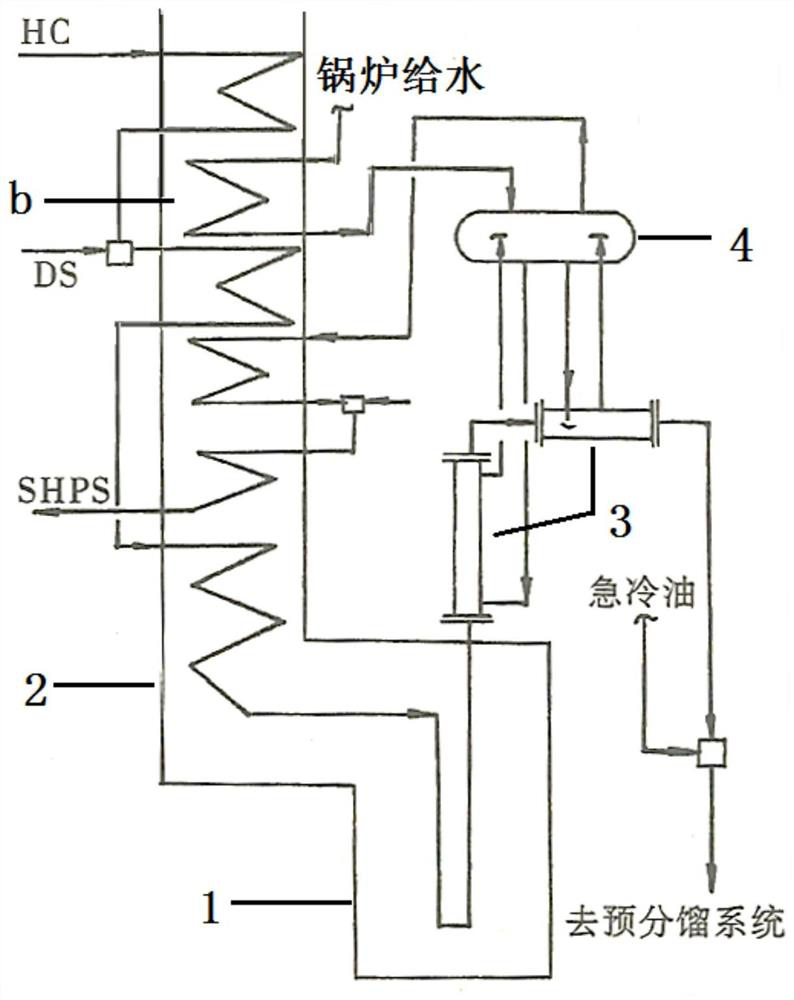

Method for flexibly preheating boiler feed water and recovering pyrolysis gas heat, and heat exchange system of ethylene cracking furnace

ActiveCN111944556AFlexible operationIncrease wall temperatureThermal non-catalytic crackingChemical industryProcess engineeringPetrochemical

The invention belongs to the field of petrochemical engineering, and relates to method for flexibly preheating boiler feed water and recovering pyrolysis gas heat, and a heat exchange system of an ethylene cracking furnace. According to the invention, boiler feed water from a boundary area is preheated in a boiler feed water preheater of a convection section of the cracking furnace, and the boilerfeed water preheater comprises an upper boiler feed water preheater and a lower boiler feed water preheater which are independently arrange; the boiler feed water from the boundary area is divided into two paths which respectively enter the upper boiler feed water preheater and the lower boiler feed water preheater for preheating; and cracking gas at the outlet of a radiation sectionthe of the cracking furnace sequentially enters a first quenching heat exchanger group and a second quenching heat exchanger group for heat exchange. According to the flexible process in the invention, the energyutilization rate and the production flexibility of a device are remarkably improved, energy conservation and consumption reduction in the production process are achieved, the yield of ultrahigh-pressure steam is increased, a coking reaction is delayed, and the overall economy of the ethylene cracking device is improved.

Owner:SINOPEC ENG +1

Boiler energy saving and flue gas white smoke removal system, process and application

ActiveCN112097287AReduce the temperatureEliminate the risk of leakageCombustion processAir heatersAir preheaterPetrochemical

The invention provides a boiler energy saving and flue gas white smoke removal system, process and application. The boiler energy saving and flue gas white smoke removal system comprises a boiler, a denitration device, a rotary air preheater, an air mixing heater, a flue gas air heater, an electrostatic dust collector, a desulfurization tower and a chimney which are connected in sequence. The process comprises the following steps that ambient air is taken as a cold medium of the flue gas air heater and the air mixing heater, warm air of 80-140 DEG C generated by heat exchange of the flue gas air heater is taken as a cold medium of the rotary air preheater, mixed hot air over 160 DEG C obtained by heat exchange of the air mixing heater is introduced into a flue between the desulfurization tower and the chimney to heat clean flue gas, the flue gas sequentially passes through the rotary air preheater, the air mixing heater and the flue gas air heater for heat exchange to obtain flue gas of 85-120 DEG C, and the flue gas of 85-120 DEG C flue gas enters the electrostatic dust collector. The boiler energy saving and flue gas white smoke removal system is high in cost performance, can beused for preventing secondary blockage of ammonium bisulfate of a coal-fired unit, and can be applied to the coal-fired unit in the fields of petroleum, chemical engineering, metallurgy, electric power, ships, central heating, machinery, food, pharmacy and the like.

Owner:重庆鑫顺盛达科技有限公司

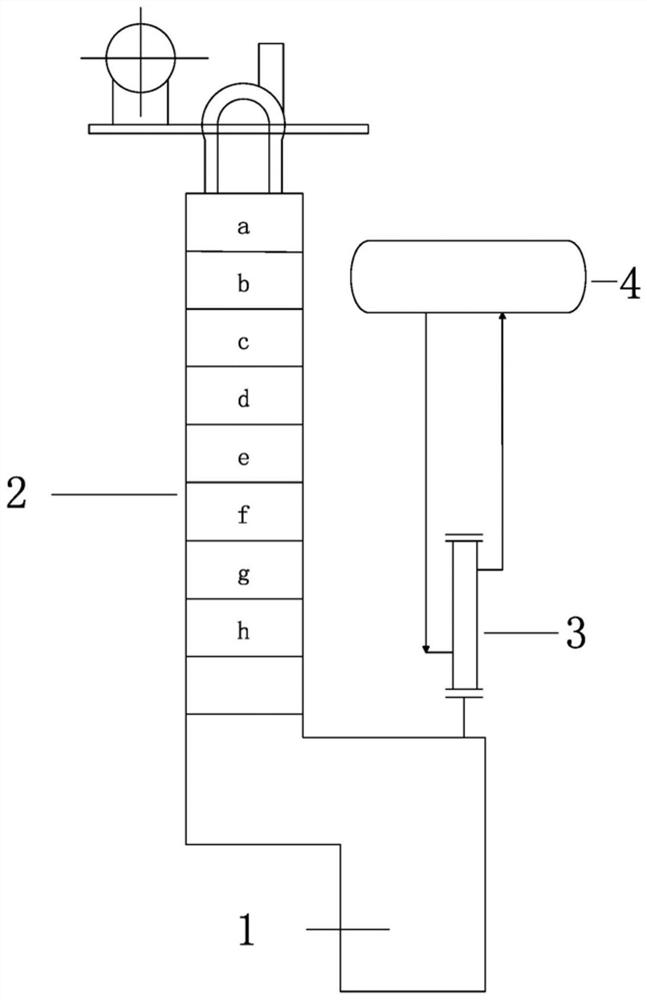

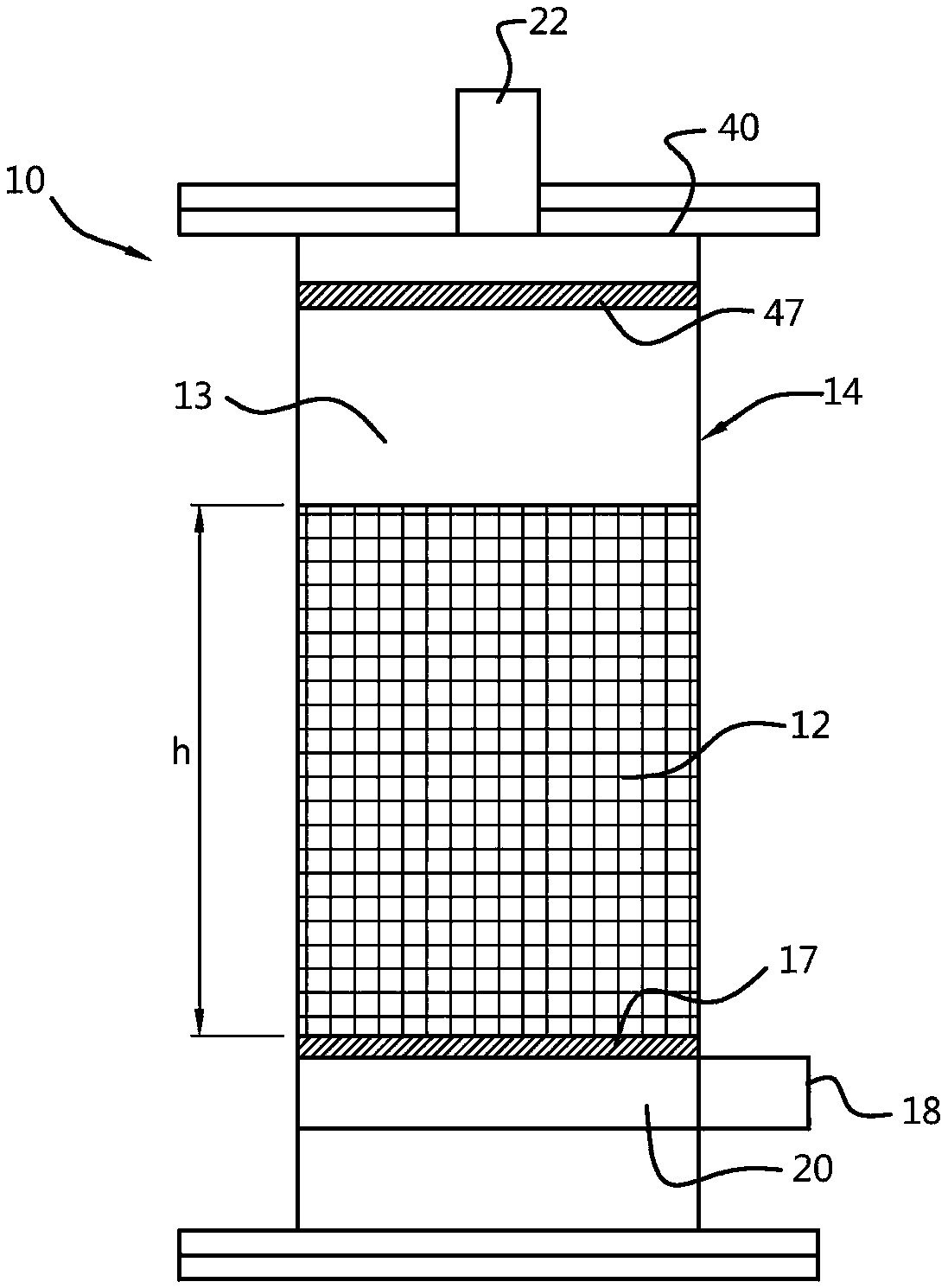

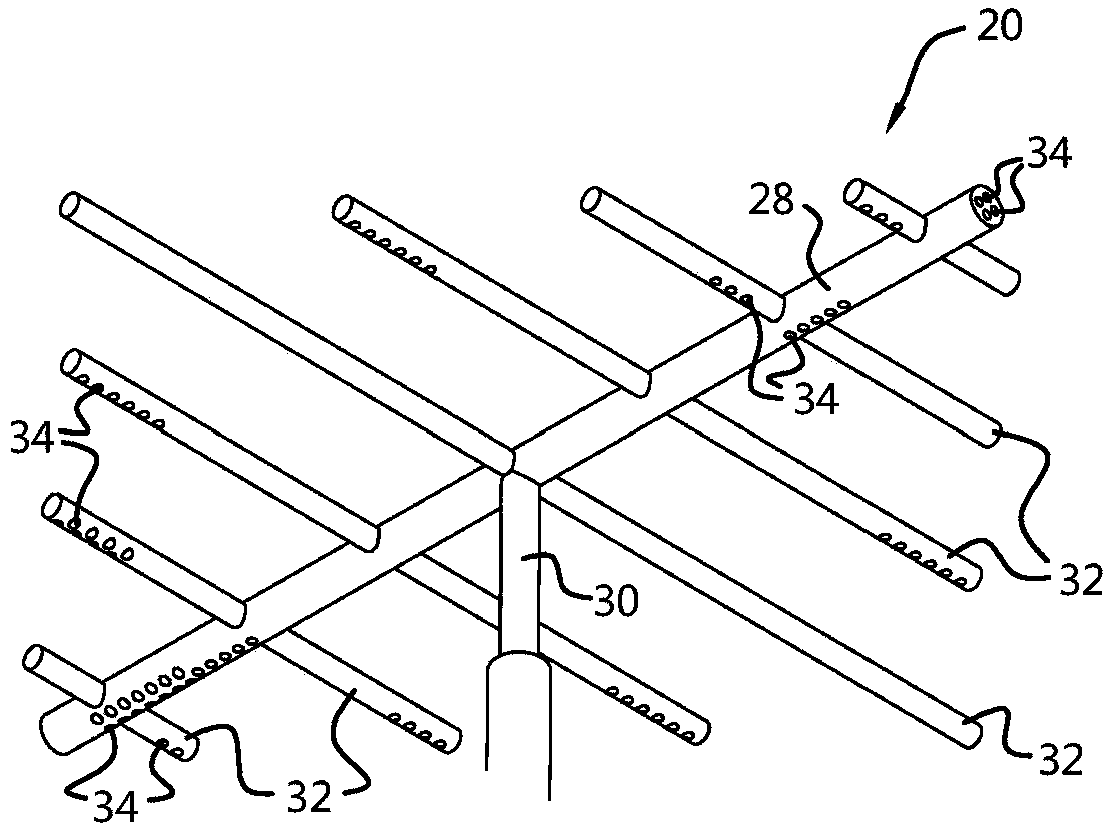

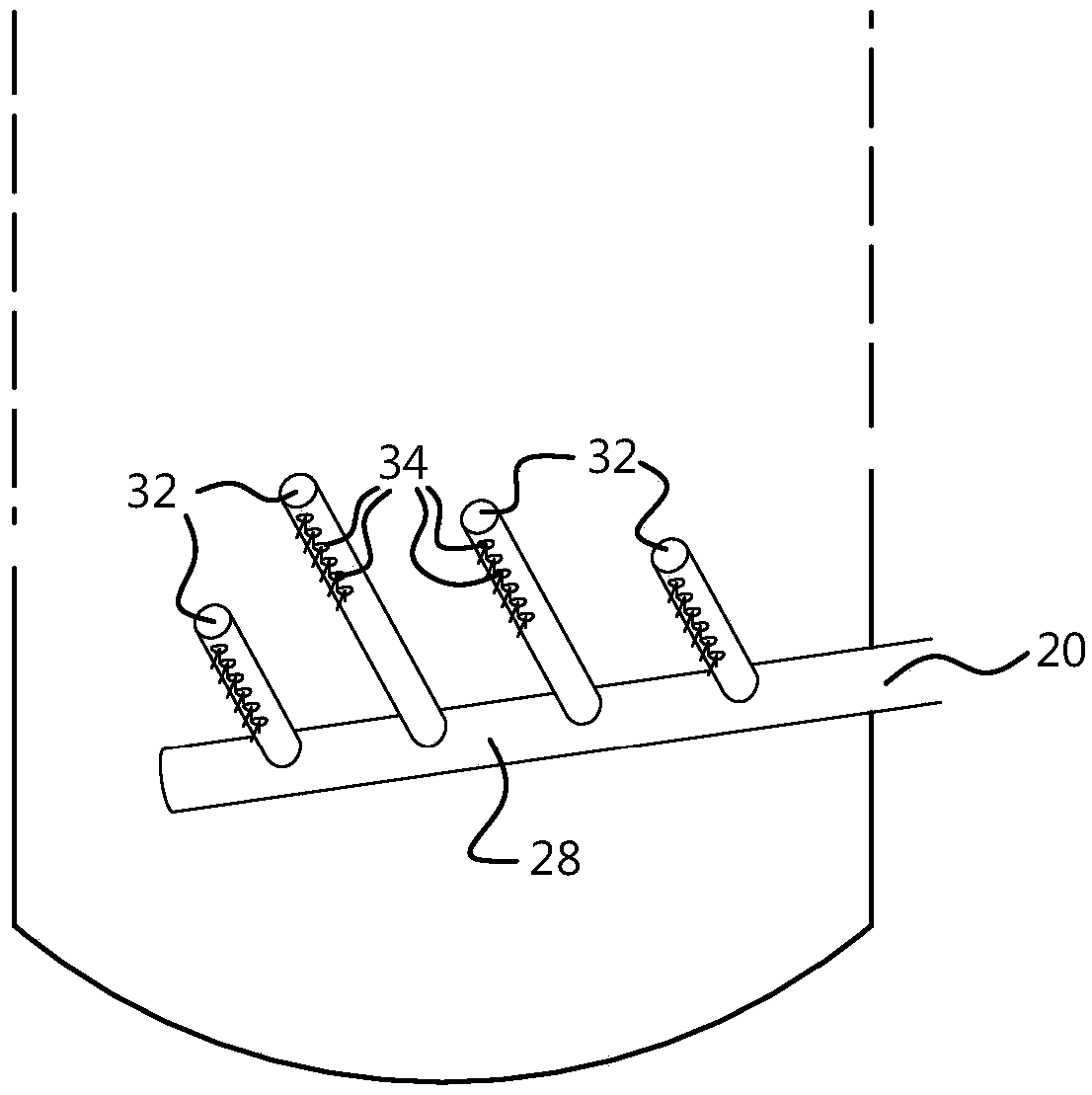

Method for producing dihydroxy compounds

PendingCN109562343APrevent crystallizationIncrease wall temperatureOrganic chemistryOrganic compound preparationPtru catalystPolycarbonate

The invention is directed to the use of an upflow reactor for producing a dihydroxy compound, to a method for producing a dihydroxy compound, and to a method for manufacturing polycarbonate. The upflow reactor for producing a dihydroxy compound of the invention comprises: a vessel; a catalyst bed disposed in said vessel; a distributor in fluid communication with an inlet through which reactants are introduced to said distributor, said distributor being disposed at a lower end of said vessel and comprising distributor perforation(s) disposed in said distributor, at least part of which distributor perforations are in a direction facing away from said catalyst bed; and a collector through which said product dihydroxy compound is removed, said collector being disposed at an upper end of said vessel.

Owner:SABIC GLOBAL TECH BV

A system for comprehensive cascade utilization of heat recovery and waste heat in thermal power generation

InactiveCN105333450BBest Cascade UtilizationImprove energy qualityIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterEngineering

The invention relates to a comprehensive gradient utilization system of recovered heat and waste heat of thermal power generation. The comprehensive gradient utilization system comprises an air pre-heater subsystem, a main condensation water subsystem, a medium temperature condensation water supply subsystem, a low temperature condensation water supply subsystem, a smoke cooling condensation water subsystem and an air heating condensation water subsystem. The air pre-heater subsystem is connected with the smoke cooling condensation water subsystem, the medium temperature condensation water supply subsystem, the low temperature condensation water supply subsystem and the air heating condensation water subsystem and then is connected to the main condensation water subsystem in a collected mode.

Owner:郝江平

Boiler flue gas treatment system with efficient air preheater

PendingCN113915635ARaise the inlet air temperatureIncrease wall temperatureIndirect carbon-dioxide mitigationSolid removalAir preheaterFlue gas

The invention discloses a boiler flue gas treatment system with an efficient air preheater, and belongs to the technical field of boiler flue gas treatment and preparation. The problems that in the prior art, a treatment system is prone to generating ammonium bisulfate blockage, dust accumulation and air leakage are solved. The boiler flue gas treatment system comprises an SCR denitration reactor, the air preheater, a flue gas air heater, an electrostatic dust collector and a desulfurizing absorption tower, all of which are sequentially connected, air outlets of the air preheater are connected in parallel to form two branch ends, one end flows back to a boiler, the other end communicates with an inlet of the flue gas air heater, and an outlet of the flue gas air heater further flows back to air inlets of the air preheater. The flue gas air heater is additionally arranged in the flue gas treatment system, the inlet air temperature of the air preheater is increased, ammonium bisulfate blockage is avoided, a sound wave ash remover is arranged in the air preheater, ammonium bisulfate blockage in a shell is effectively removed, the rotating speed of the shell is changed in real time, and dust and dirt cannot be accumulated in the shell; and by means of a flexible sealing assembly, the problem of air leakage caused by deformation of the shell is avoided.

Owner:JIANGSU FENGYE TECH ENVIRONMENTAL PROTECTION GRP CO LTD

A method for flexible preheating of boiler feed water and heat recovery of cracked gas and heat exchange system for ethylene cracking furnace

ActiveCN111944556BFlexible operationIncrease wall temperatureThermal non-catalytic crackingChemical industryUltra high pressurePetrochemical

The invention belongs to the field of petrochemical industry, and relates to a flexible preheating of boiler feed water and a heat recovery method of cracked gas and a heat exchange system of an ethylene cracking furnace. The boiler feed water from the boundary area is preheated in the boiler feed water preheater in the convection section of the cracking furnace, and the boiler feed water preheater includes an independently set upper boiler feed water preheater and a lower boiler feed water preheater. The boiler feed water in the zone enters the upper boiler feed water preheater and the lower boiler feed water preheater respectively for preheating in two ways; the cracked gas at the exit of the radiant section of the cracking furnace enters the first quenching heat exchanger group and the second quenching heat exchanger in turn. Heat exchangers are exchanged. The flexible flow process of the invention significantly improves the energy utilization rate and production flexibility of the device, realizes energy saving and consumption reduction in the production process, increases the output of ultra-high pressure steam, delays the occurrence of coking reaction, and improves the overall performance of the ethylene cracking device. economical.

Owner:SINOPEC ENG +1

Method for operating a gasifier

ActiveUS9260673B2Increase wall temperatureGasification processes detailsCombined combustion mitigationCombustion chamberDiluent

A method for operating a gasifier includes detecting a corrosive compound between a combustion chamber defined within the gasifier and an inner wall of a pressure vessel that at least partially surrounds the combustion chamber via a corrosion sensor and increasing the temperature of the inner wall of the pressure vessel to a temperature that is greater than a dew point of the corrosive compound via a heater that at least partially surrounds the pressure vessel. The method may also include adjusting a flow of at least one of a fuel, an oxidant and a diluent to the gasifier in response to the detection of the corrosive compound so as to modify the dew point of the corrosive compound.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com