System and method for high-temperature biomass gas cooling and waste heat utilization

A biomass gas, high temperature technology, applied in combustion methods, reduction of greenhouse gases, treatment of combustion products, etc., can solve the problems of long flue length, increased cost, and many elbows, etc., and achieves high purity and added value. High, avoid tar deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

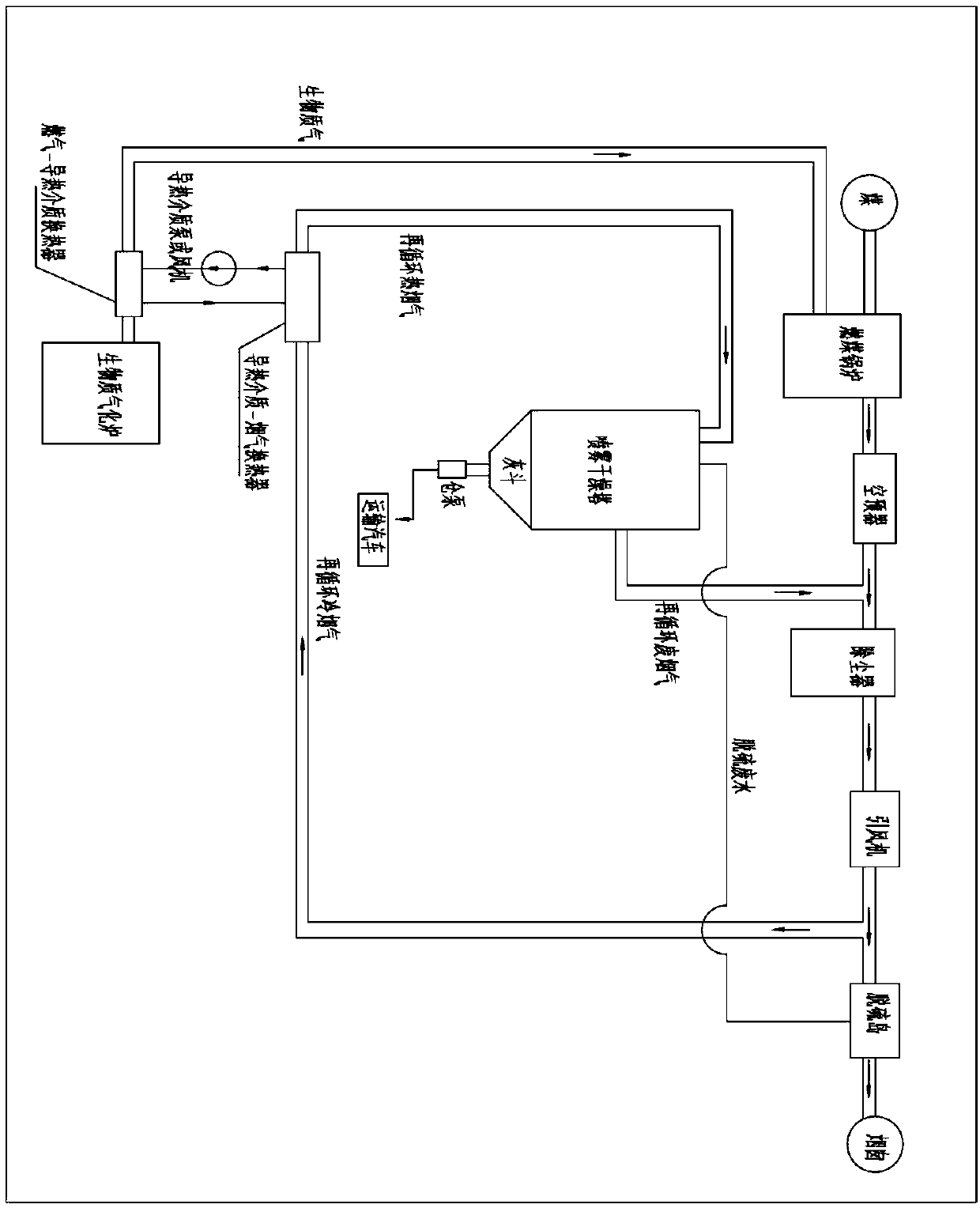

[0044] In one or more embodiments, a system for cooling high-temperature biomass gas and utilizing waste heat is disclosed, such as figure 1 As shown, it includes: the coal-fired boiler is connected in series with the air preheater, the dust collector, the induced draft fan and the desulfurization island to form the main flue; the desulfurization wastewater generated by the desulfurization island enters the spray drying tower through the pipeline. The flue gas recirculation flue is drawn out from the flue after the induced draft fan and before the desulfurization island. The flue gas recirculation flue is connected with the heat transfer medium-flue gas heat exchanger, and the flue gas enters the heat transfer medium-flue gas heat exchanger for heat exchange. , the flue gas after heat exchange is discharged from the heat transfer medium-flue gas heat exchanger into the spray drying tower to realize the evaporation and crystallization of desulfurization wastewater. Most of the p...

Embodiment 2

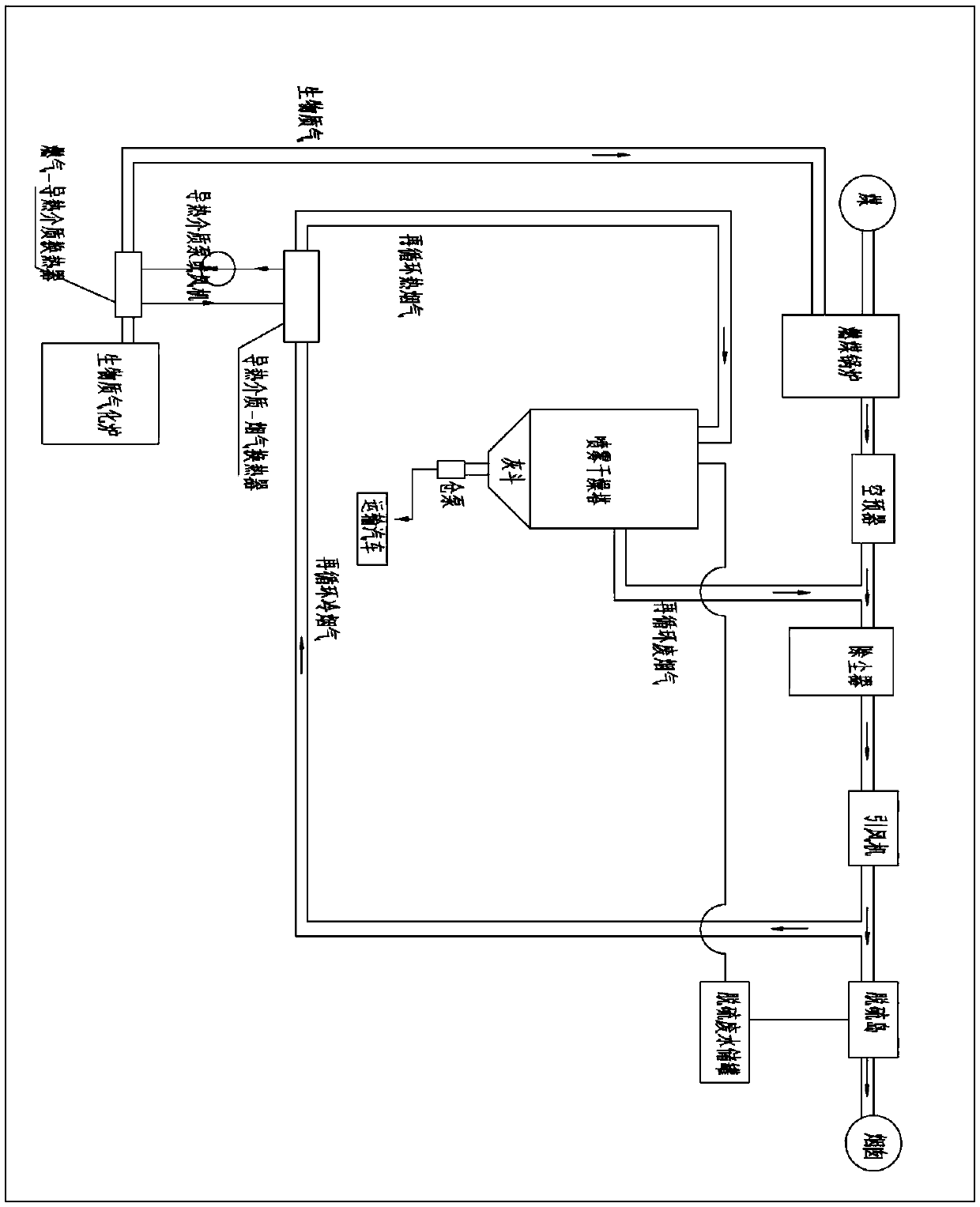

[0050] In other embodiments, a high-temperature biomass gas cooling and waste heat utilization system is disclosed, such as figure 2 As shown, a desulfurization wastewater storage tank is set between the desulfurization island and the spray drying tower, the desulfurization wastewater outlet of the desulfurization island is connected to the inlet of the desulfurization wastewater storage tank, and the outlet of the desulfurization wastewater storage tank is connected to the inlet of the spray drying tower. When the biomass gasifier is out of operation for a short period of time, the desulfurization wastewater generated by the coal-fired unit is temporarily stored in the desulfurization wastewater storage tank due to the shutdown of the biomass gas. When the biomass gasifier is put into operation, Then spray the desulfurization wastewater in the desulfurization wastewater storage tank into the spray drying tower.

[0051] It should be noted that the definition of the length of...

Embodiment 3

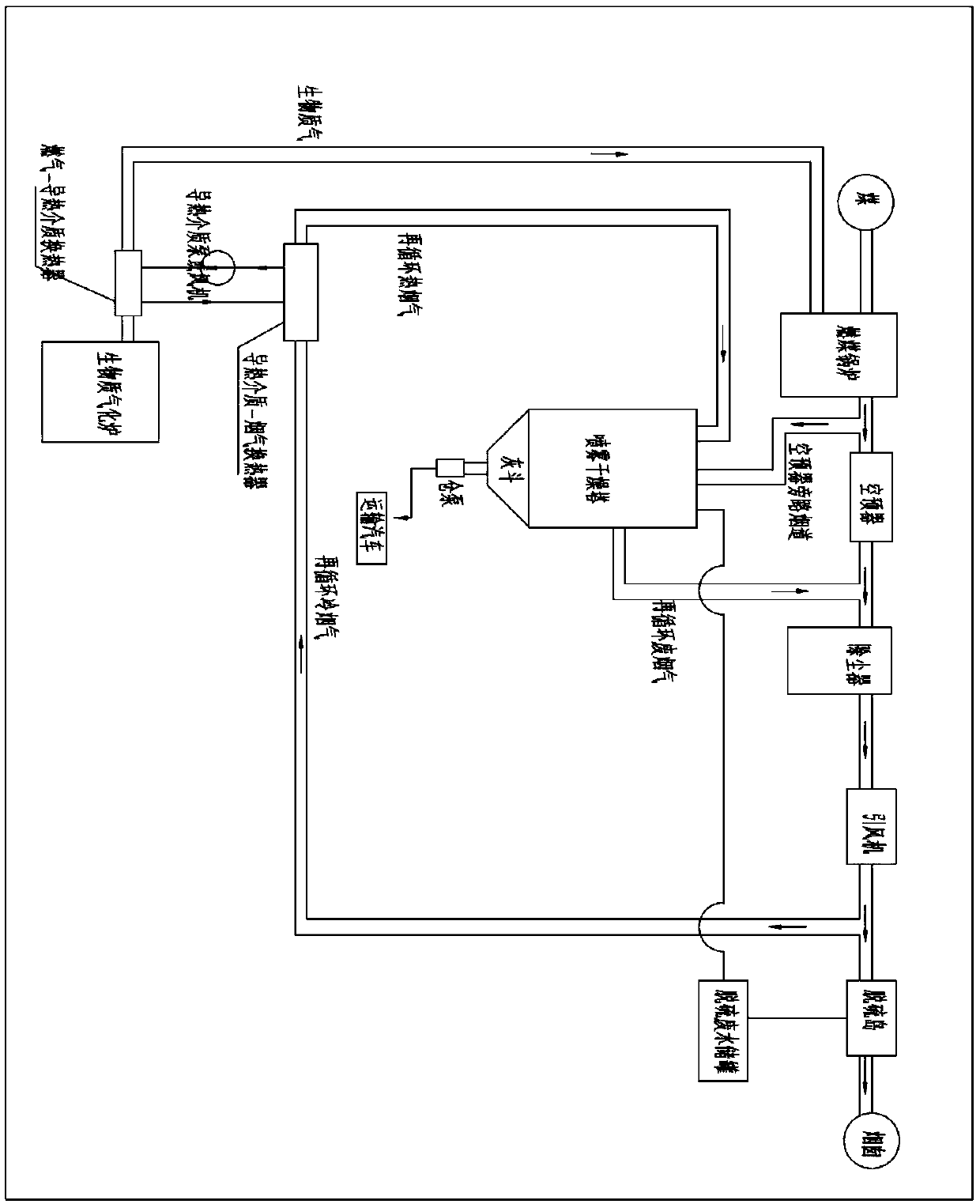

[0054] In other embodiments, a high-temperature biomass gas cooling and waste heat utilization system is disclosed, such as image 3 As shown, a desulfurization wastewater storage tank is set between the desulfurization island and the spray drying tower, the desulfurization wastewater outlet of the desulfurization island is connected to the inlet of the desulfurization wastewater storage tank, and the outlet of the desulfurization wastewater storage tank is connected to the inlet of the spray drying tower. When the biomass gasifier is out of operation for a short period of time, the desulfurization wastewater generated by the coal-fired unit is temporarily stored in the desulfurization wastewater storage tank due to the shutdown of the biomass gas. When the biomass gasifier is put into operation, Then spray the desulfurization wastewater in the desulfurization wastewater storage tank into the spray drying tower.

[0055] In addition, an air preheater bypass flue connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com