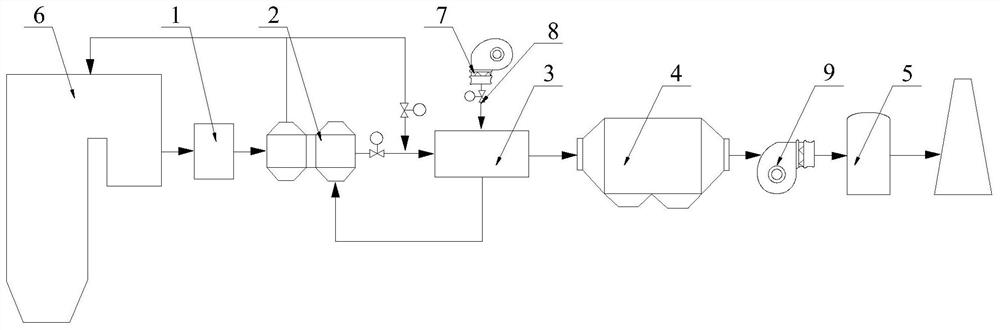

Boiler flue gas treatment system with efficient air preheater

An air preheater and boiler flue gas technology, which is applied in the field of boiler flue gas treatment, can solve problems such as ammonium bisulfate is difficult to remove, cold air leaks into the flue gas, and low-temperature corrosion, so as to avoid ammonium bisulfate clogging and reduce smoke exhaust Temperature, the effect of realizing waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

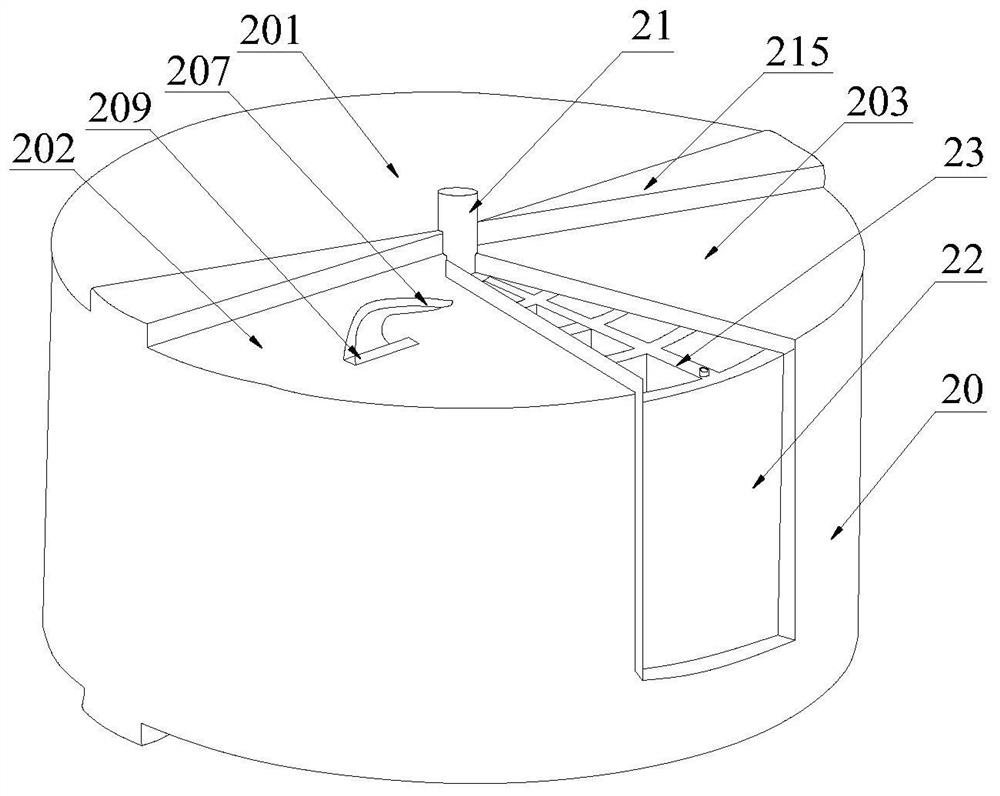

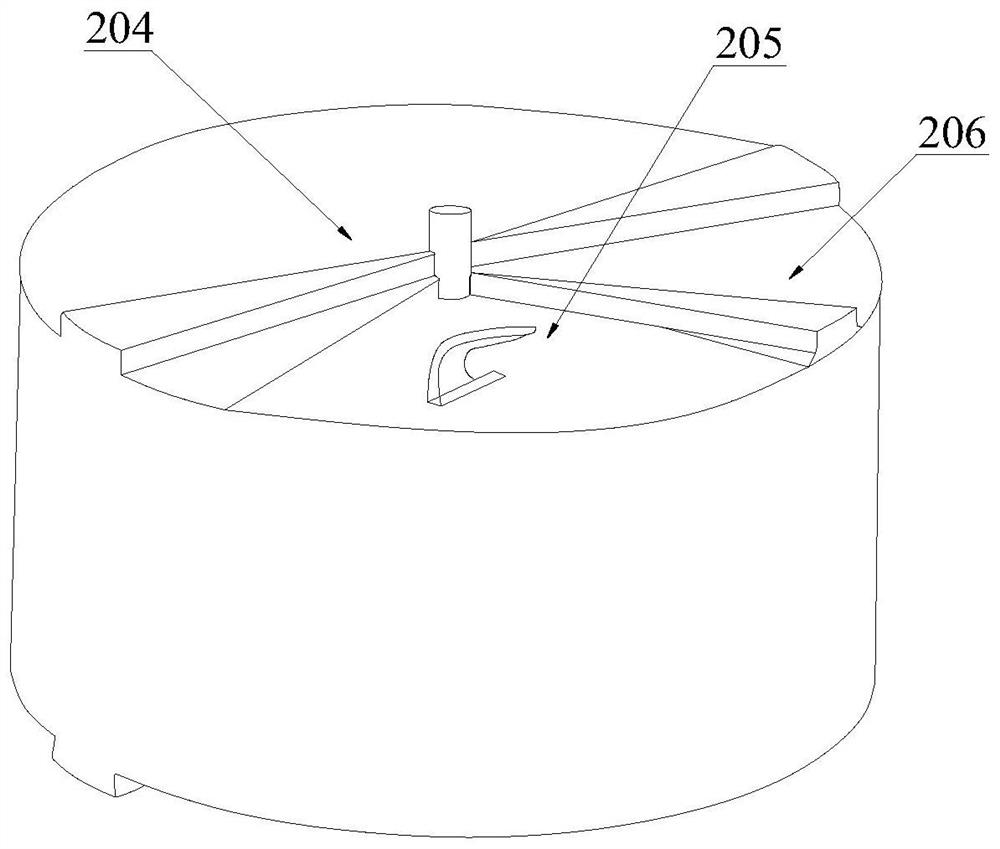

[0026] Below in conjunction with accompanying drawing and specific embodiment, the invention is further described:

[0027] During the boiler flue gas desulfurization and denitrification process, when the air preheater is seriously blocked, the overall operating efficiency of the system is low. The reason is that sulfur trioxide in the flue gas combines with water vapor to form sulfuric acid vapor. The higher the dew point, it can reach 140-160°C or even higher. The lower inlet air temperature makes the minimum metal wall temperature of the heat exchange plate always lower than the acid dew point temperature, and low-temperature corrosion will inevitably occur. At the same time, in order to ensure the denitration efficiency, spray Excessive ammonia, ammonia and sulfur trioxide produce ammonium bisulfate, and form ammonium bisulfate crystals on the metal surface with a wall temperature lower than 147°C. The crystals adsorb fly ash, making it difficult to remove effectively by co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com