Energy-saving comprehensive heat supply system

A technology of heating system and water supply tank, applied in heating system, heat recovery system, energy-saving heating/cooling, etc., can solve the problems of low utilization of heating heat energy, single heating equipment, waste of heat energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

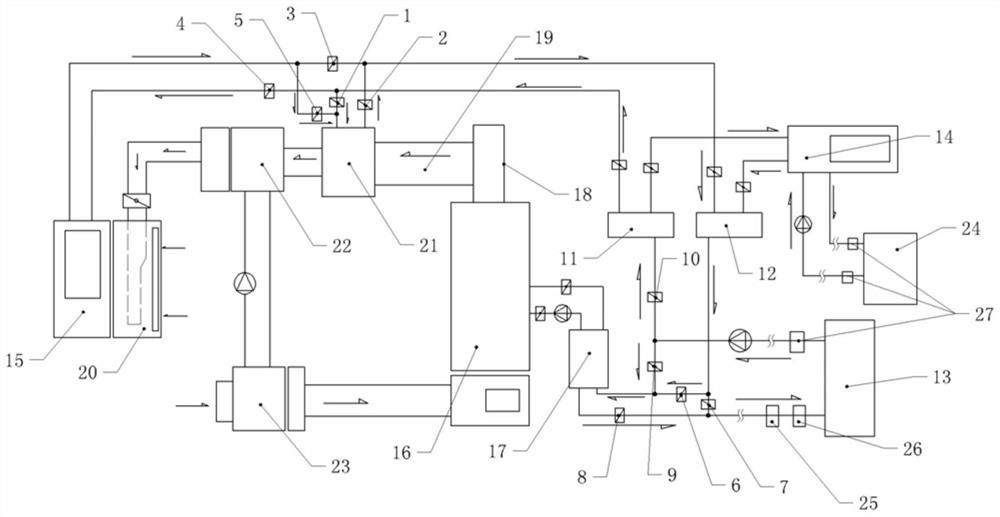

[0020] Embodiment 1 is basically as attached figure 1 Shown: an energy-saving comprehensive heating system, including heat user unit 13, boiler 16 heating unit, water source heat pump 14 heating unit, air energy heat pump 15 heating unit, heat recovery circulation unit, water tank, the water tank includes water supply tank 12 and return water tank 11. The heat recovery circulation unit is connected to the exhaust pipe 18 of the boiler 16 through the smoke introduction pipe 19, and the heat user unit 13 is connected to the heating unit of the boiler 16 through the water supply pipe and the return pipe to form the first heat supply circuit. The water supply pipe is detachably connected with The branch pipe of the water supply tank, one end of the branch pipe of the water supply tank is connected with the water outlet of the water supply tank, the return pipe can also be detachably connected with the branch pipe of the return water tank, and one end of the branch pipe of the retur...

Embodiment 2

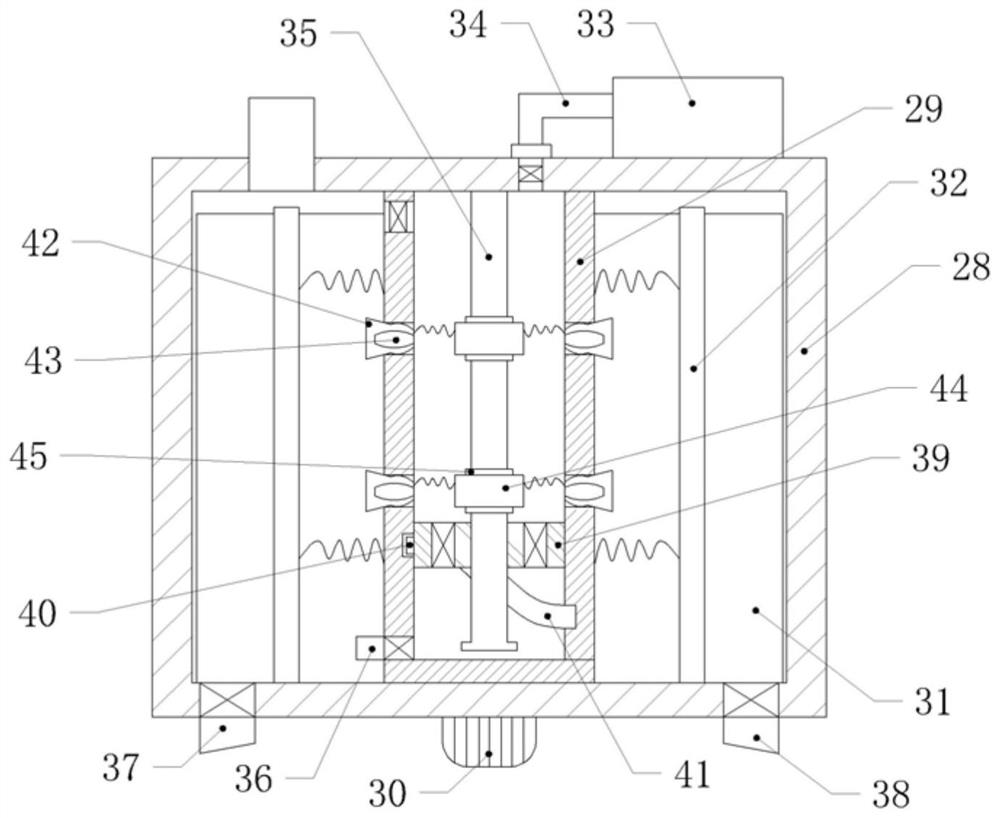

[0030] Example 2 as figure 2 As shown, the same parts as in Embodiment 1 will not be repeated. The above-mentioned water tank is provided with a descaling device. The descaling device includes a hollow rotating cylinder 29, a driving motor 30, a first scraper 31 and a scavenger box 33. The driving motor 30 is fixed on the The bottom of the box body 28 and the bottom of the rotating cylinder 29 are fixedly connected with the output shaft of the driving motor 30, the upper end of the rotating cylinder 29 is open and the upper surface of the opening is rotatably connected with the inner wall of the top plate of the water tank body 28, and the upper end of the rotating cylinder is provided with a first electric valve on the wall; The scavenger box 33 is arranged on the top of the water tank and is fixedly connected with the outer wall of the top plate of the water tank by bolts. The scavenger box 33 is connected with a scavenger pipe 34 by threads. Inside, the scavenger pipe is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com