A method for flexible preheating of boiler feed water and heat recovery of cracked gas and heat exchange system for ethylene cracking furnace

An ethylene cracking furnace and boiler feed water technology, applied in the field of petrochemical industry, can solve the problems of insufficient energy utilization, short production cycle, poor flexibility, etc., achieve better heat transfer effect, slow down coking, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

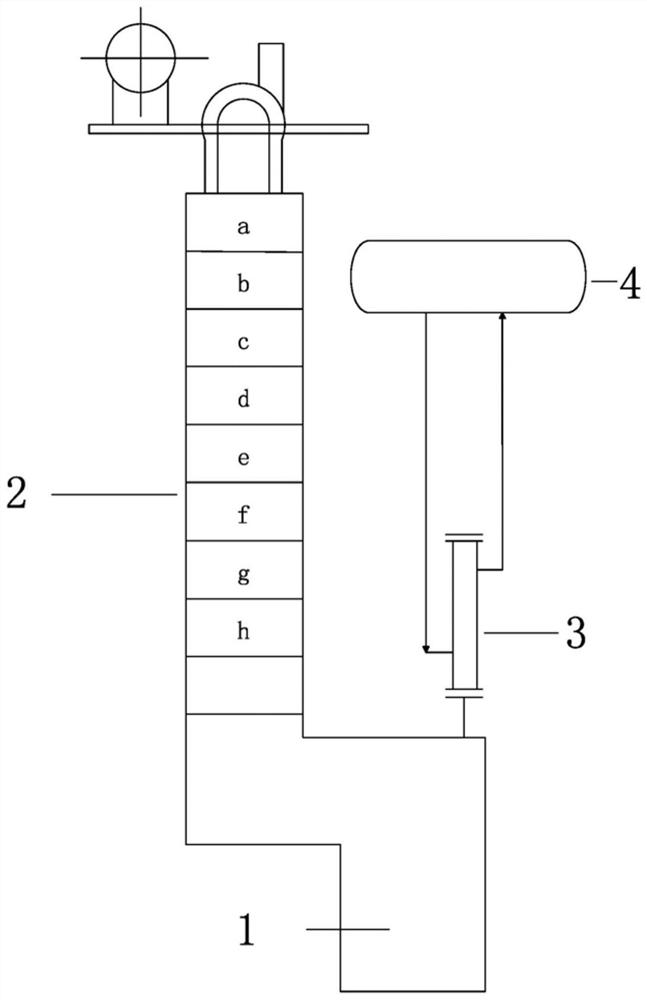

Image

Examples

Embodiment 1

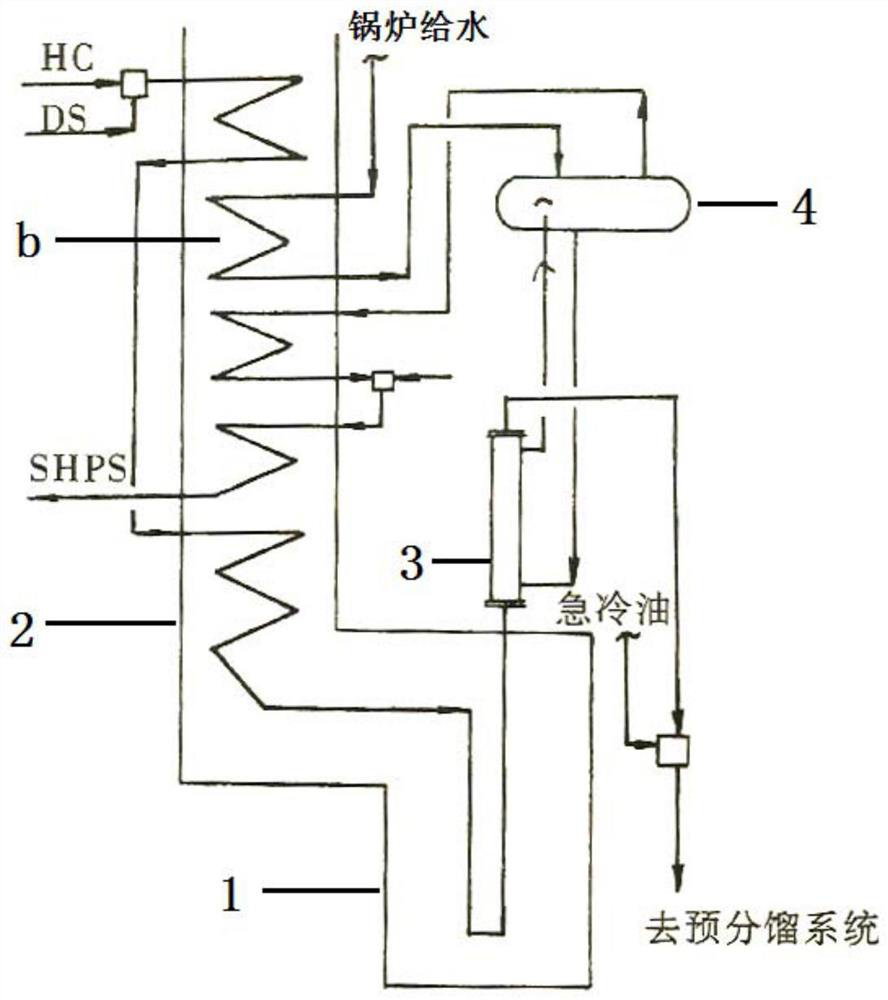

[0051] In the present embodiment 1 (flexibility process 1), use such as Figure 5 The cracking furnace of the ethylene plant shown. The heat exchange system includes a steam drum 4, a first quenching heat exchanger group 3 and a second quenching heat exchanger group 3; the first quenching heat exchanger group 3 includes two-stage series quenching heat exchangers, respectively A first-stage quenching heat exchanger, a second-stage quenching heat exchanger; the second-stage quenching heat exchanger group 3 includes a first-stage quenching heat exchanger, which is a third-stage quenching heat exchanger; the first-stage quenching heat exchanger The heat exchanger is a vertical linear quenching heat exchanger; the second-stage quenching heat exchanger and the third-stage quenching heat exchanger are horizontal shell-and-tube quenching heat exchangers. The boiler feedwater preheater b of the ethylene cracking furnace includes an independently set upper boiler feedwater preheater BF...

Embodiment 2

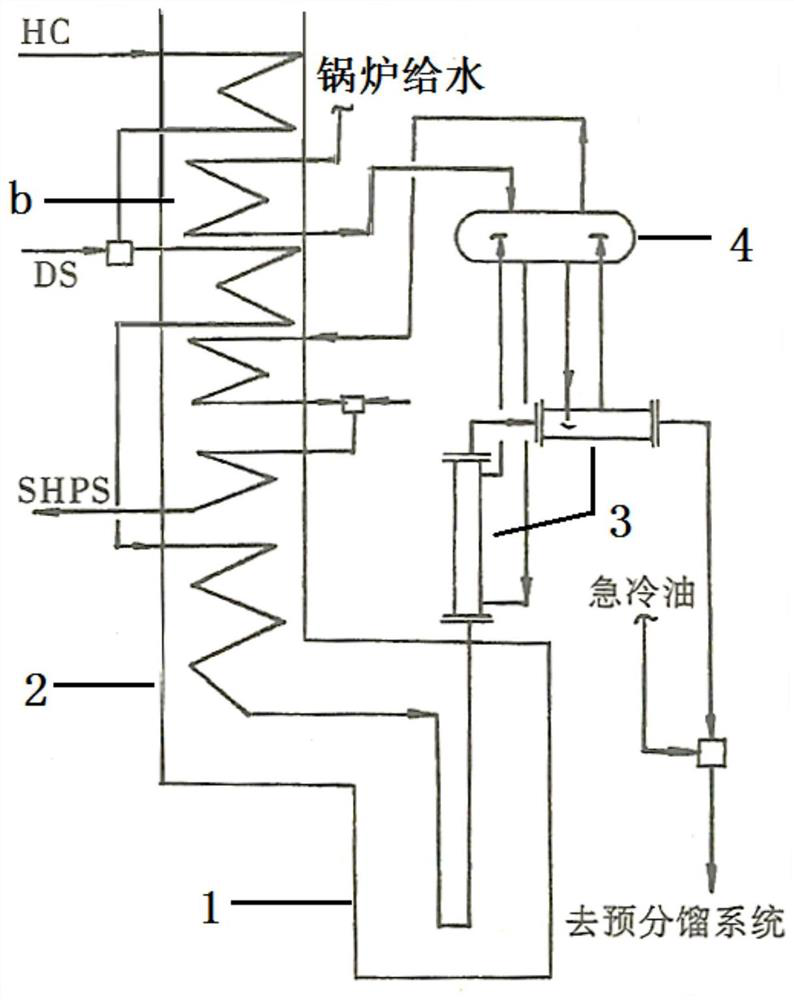

[0063] In the present embodiment 2 (flexibility process 2), use such as Image 6 The cracking furnace of the ethylene plant shown. The difference from Example 1 is that only two-stage quenching heat exchangers are provided in the process.

[0064] After the cracked gas comes out of the furnace tube of the radiant section of the cracking furnace, it passes through the first-stage quenching heat exchanger and the second-stage quenching heat exchanger in turn for heat exchange; wherein, the cracking gas passes through the first quenching heat exchanger and is heated with the The boiler feed water of the steam drum conducts heat exchange, and in the second-stage quenching heat exchanger, it exchanges heat with a boiler feed water preheated by the upper boiler feed water preheater to realize heat recovery.

[0065] The boiler feed water from the boundary area is divided into two paths into the upper boiler feed water preheater BFW-I and the lower boiler feed water preheater BFW-II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com