Boiler full-load denitration coupling flue gas waste heat gradient utilization system

A flue gas waste heat, full-load technology, applied in preheating, lighting and heating equipment, combustion methods, etc., can solve the problems of low efficiency and low energy level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

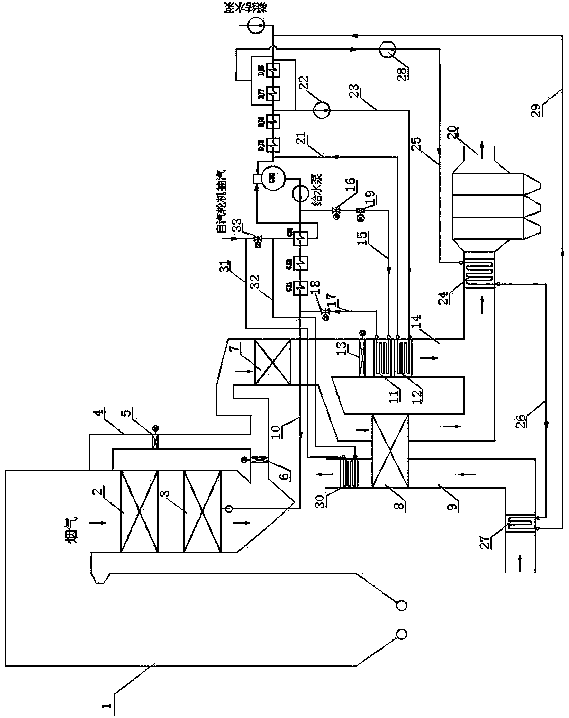

[0025] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a boiler 1 connected to an air supply pipe 9. A low-temperature heater 2, an economizer 3, a denitrification device 7, an air preheater 8, and an electric precipitator are sequentially installed in the flue gas passage of the boiler 1 along the advancing direction of the flue gas. 20, wherein the air preheater 8 is installed in the air supply pipe 9 at the same time, and the flue gas channel is provided with a high-temperature denitration bypass flue 4 between the entrance of the low-temperature superheater 2 and the entrance of the denitration device 7, and the high-temperature denitration bypass The bypass flue cut-off baffle A5 is set in the road flue 4, the main flue adjustment baffle 6 at the outlet of the economizer 3 and the low-temperature economizer at the entrance of the electrostatic precipitator 20 are installed in the flue gas channel 24. The flue gas ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com