Cylindrical integrated removable urea nozzle post-processor assembly

A urea nozzle and post-processor technology is applied in the field of selective catalytic reduction of environmental protection parts for commercial vehicles, which can solve the problems of inability to observe and clean crystals, difficult layout of urea nozzles in pipelines, and difficulty in ensuring urea mixing uniformity. Layout advantages and market competitiveness, improve urea hydrolysis rate and mixing uniformity, and improve the effect of mutual impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

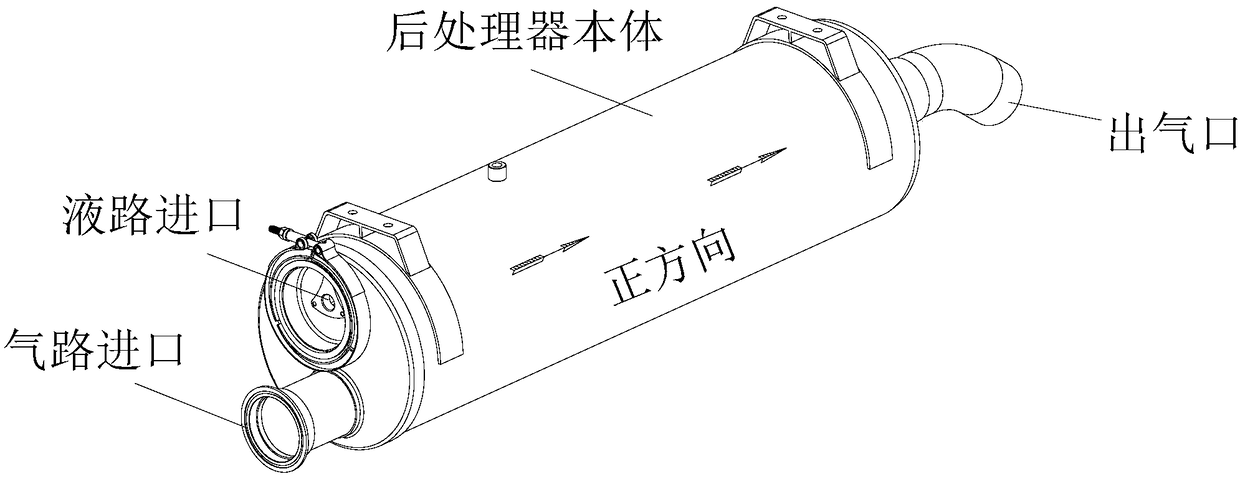

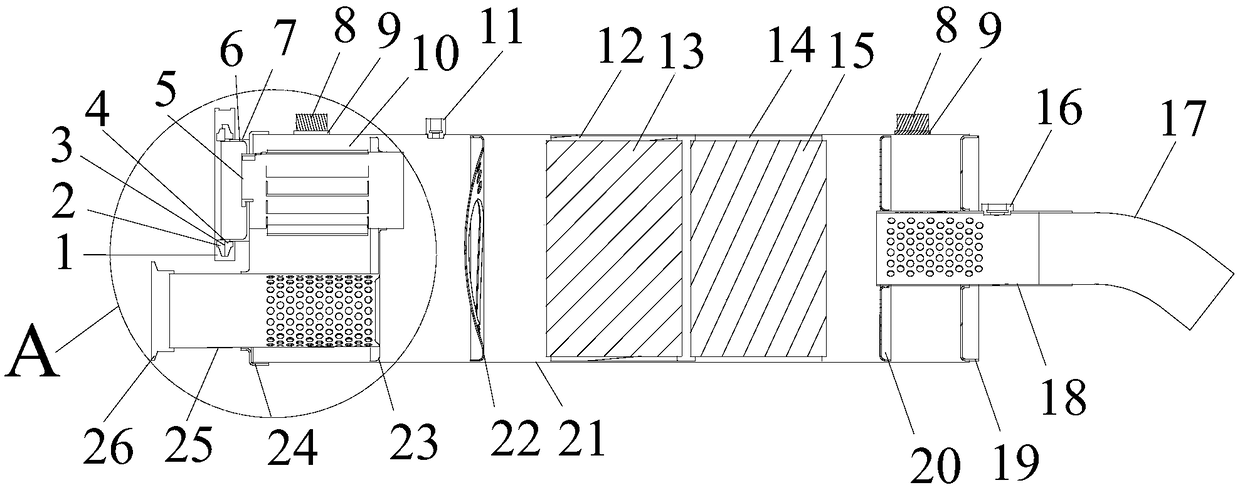

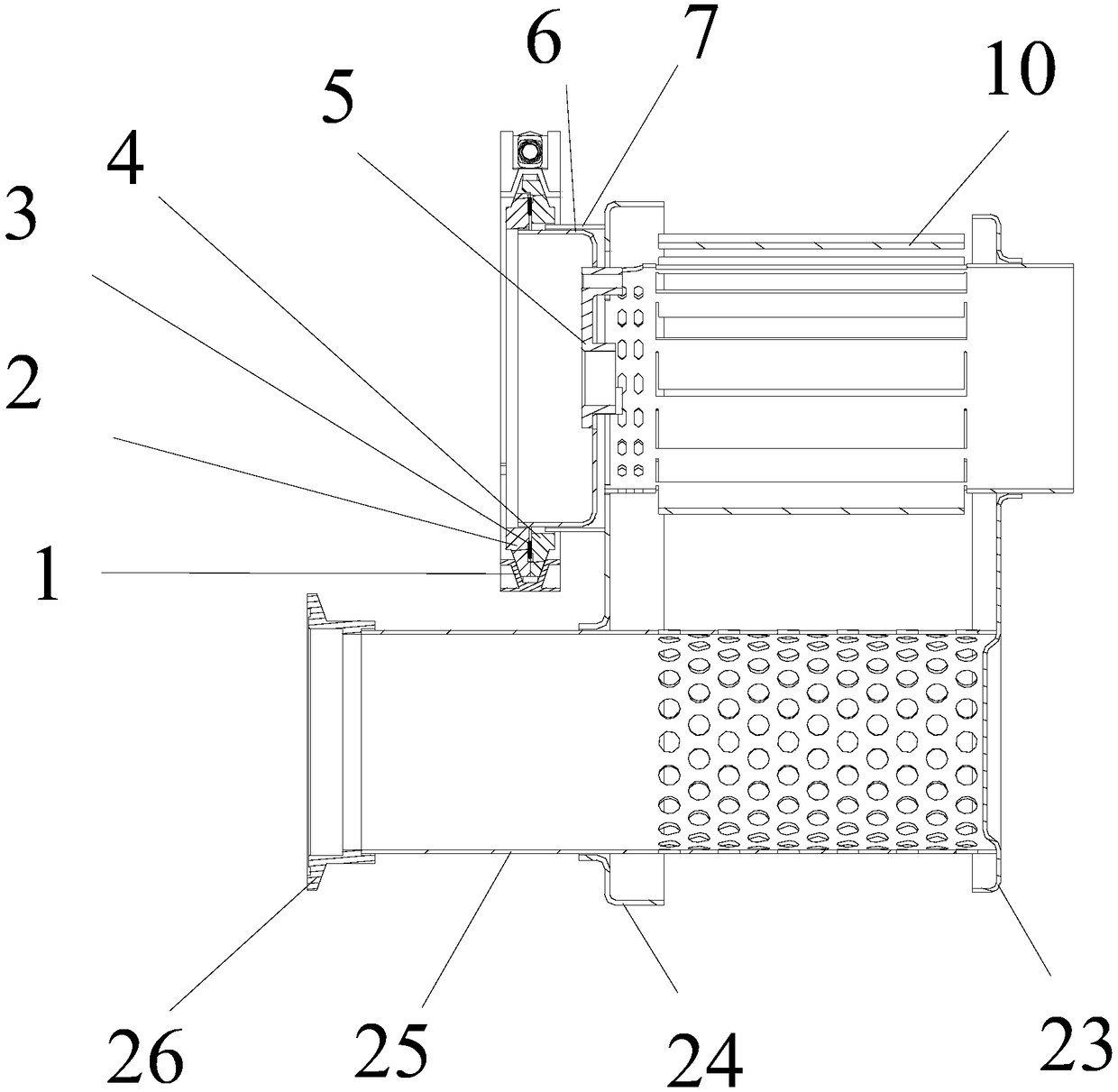

[0036] A post-processor structure with a cylindrical detachable integrated urea nozzle, the inlet includes a gas path and a liquid path. Included in order from front to back of assembly (as attached figure 1 ) a gas path inlet and a liquid path inlet connected in parallel up and down, followed by a post-processor body and a gas outlet in series. The positive direction of air flow is the direction in which the air flow flows along the parallel gas path inlet and liquid path inlet to the post-processor body and then to the gas outlet. The gas path inlet and liquid path inlet side are the front side, and the gas outlet side is the rear side. Among them, the liquid passage inlet consists of clamp assembly 1, step flange with gap 2, gasket assembly 3, step flange with positioning stop 4, urea nozzle seat 5, urea nozzle seat welding base 6, urea nozzle seat welding base 7 and por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com