Control system and control method for starting high-pressure heater in advance

A high-pressure heater and control system technology, applied in the direction of feed water heater, control feed water, lighting and heating equipment, etc., can solve the problem of not considering the temperature rise rate of feed water, the end difference of high pressure heater, not giving auxiliary steam and high Problems such as the timing of side steam supply, low utilization rate of auxiliary steam and high side steam, etc., to achieve the effect of speeding up normal use, early start-up, safety and reliability, and shortening start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

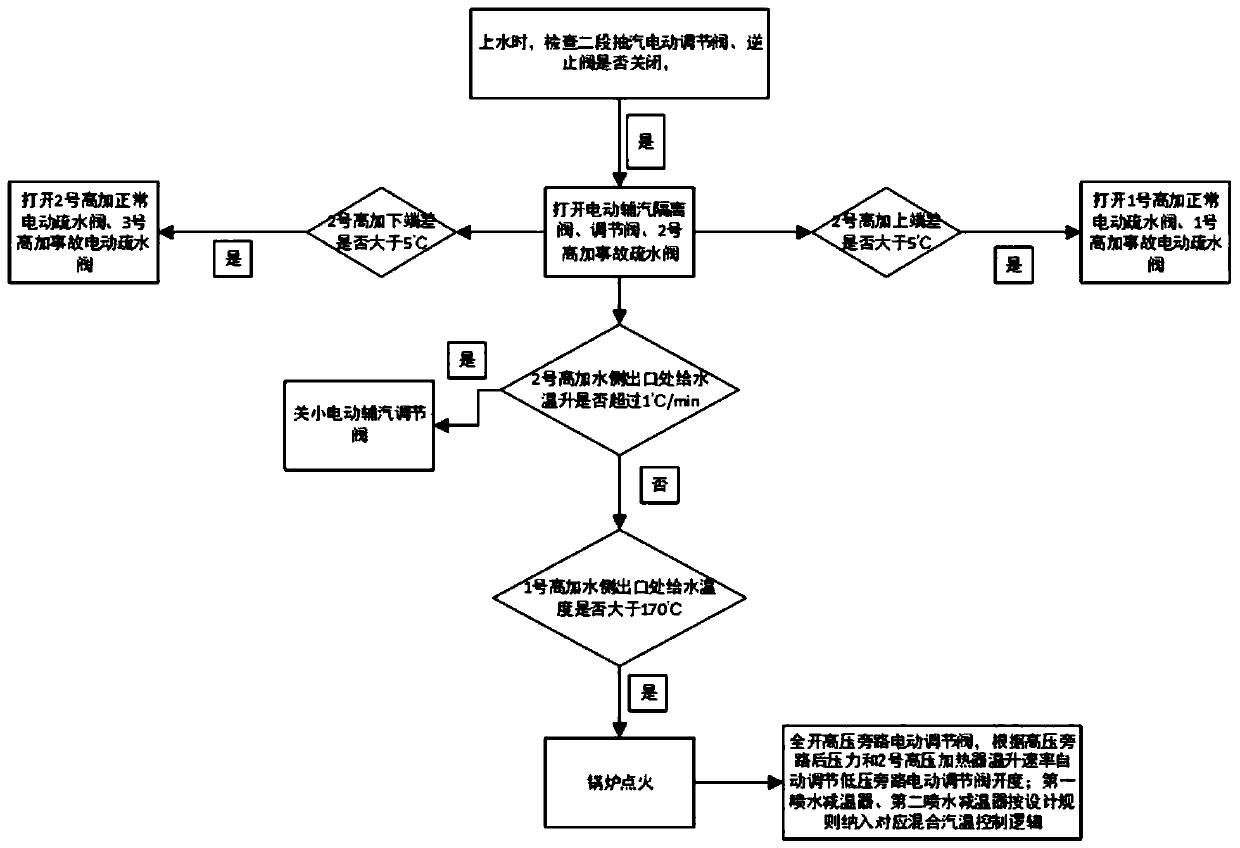

[0072] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

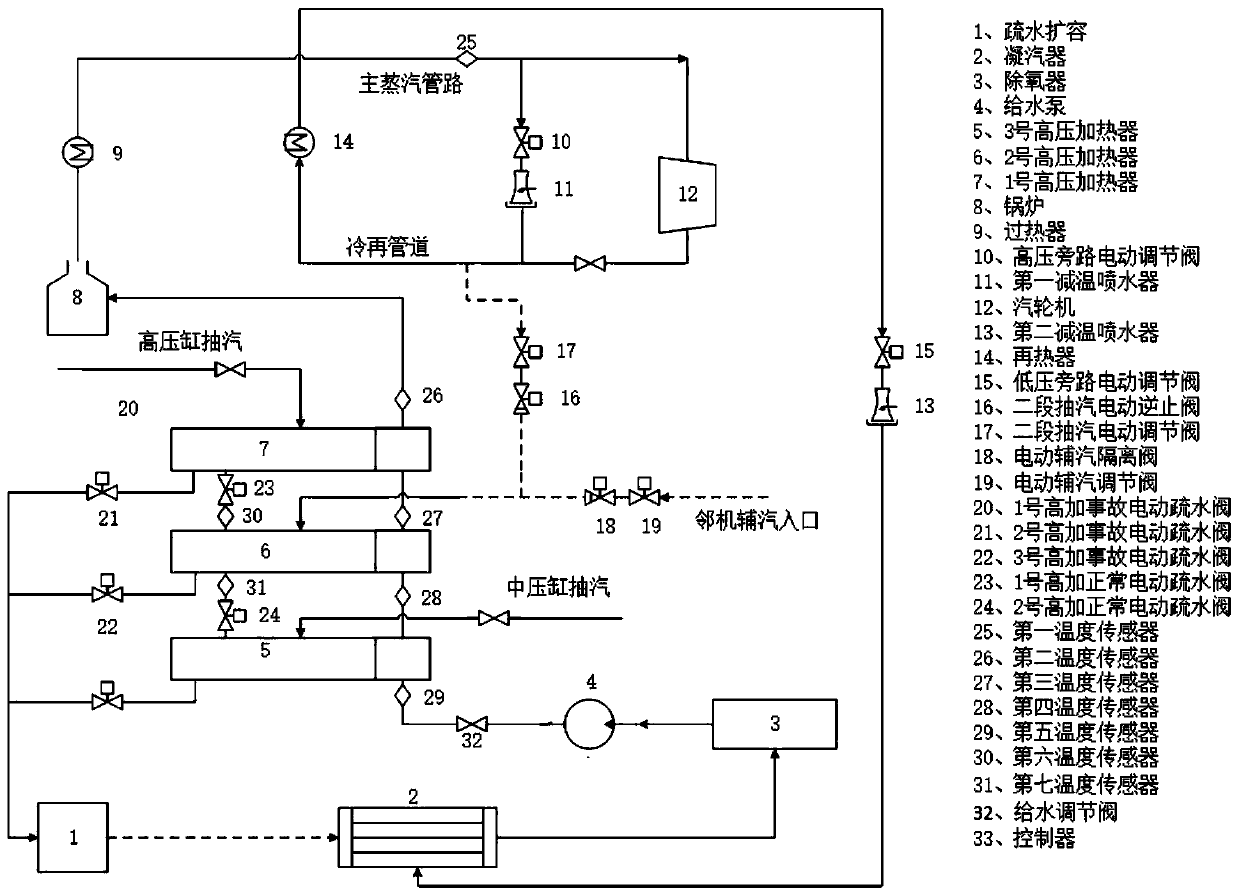

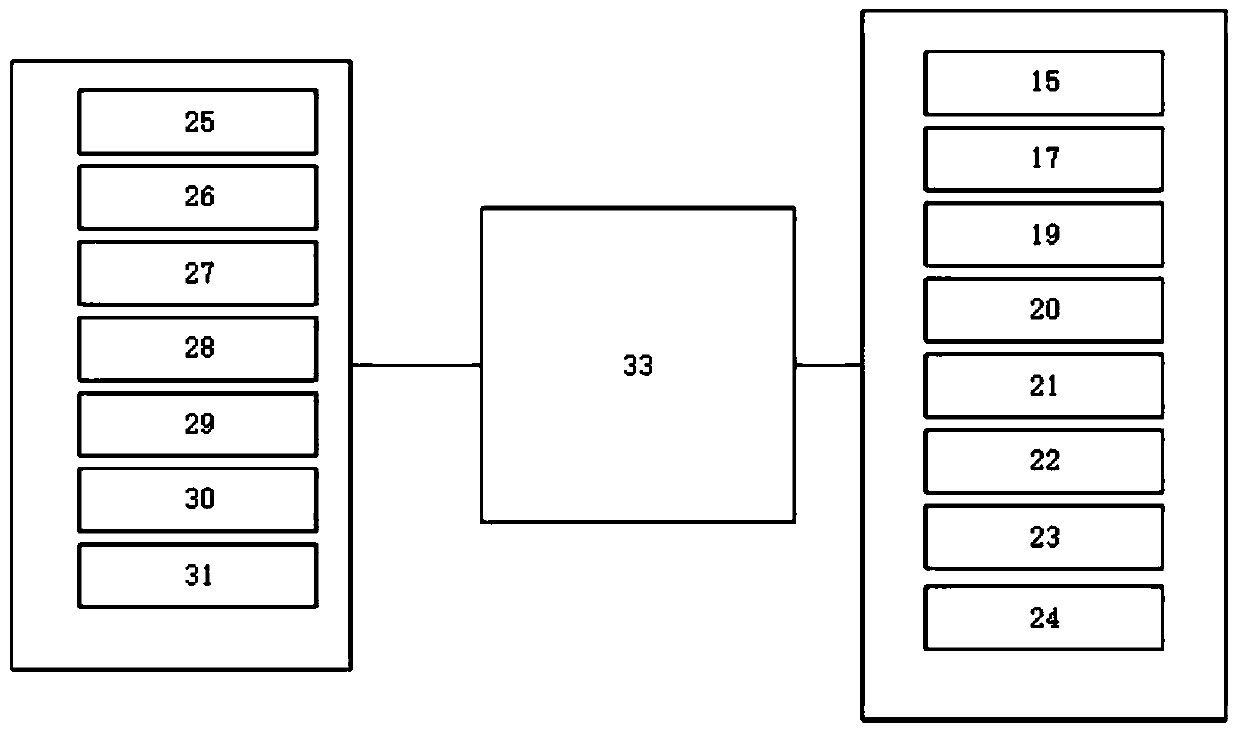

[0073] see figure 1 , figure 1 It shows the block diagram of the control system of the high-pressure heater early start of the present invention. The control system includes high-pressure bypass drainage expansion 1, condenser 2, deaerator 3, feed water pump 4, No. 3 high-pressure heater 5, No. 2 high-pressure heater 6, No. 1 high-pressure heater 7, boiler 8, overheating 9, high pressure bypass electric regulating valve 10, first desuperheating sprinkler 11, steam turbine 12, second desuperheating sprinkler 13, reheater 14, low pressure bypass electric regulating valve 15, second stage steam extraction electric Check valve 16, second-stage steam extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com