Compound water circulation system in corner tube-type hot-water boiler

A hot water boiler and water circulation technology, applied in the field of water circulation system, can solve problems such as large power consumption and low temperature corrosion of hot surface pipes, and achieve the effects of improving operating efficiency, saving manufacturing and installation costs, and improving processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

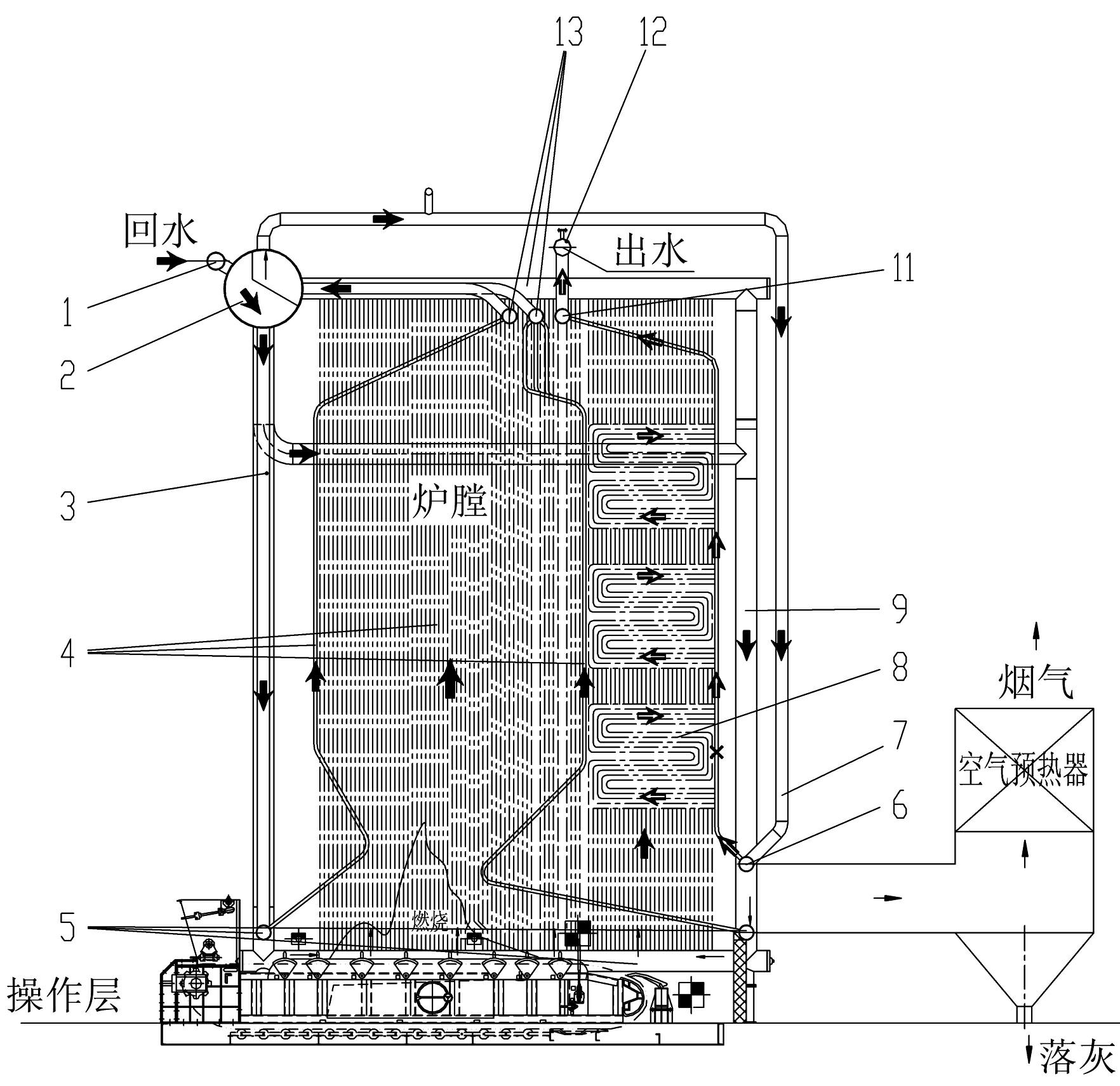

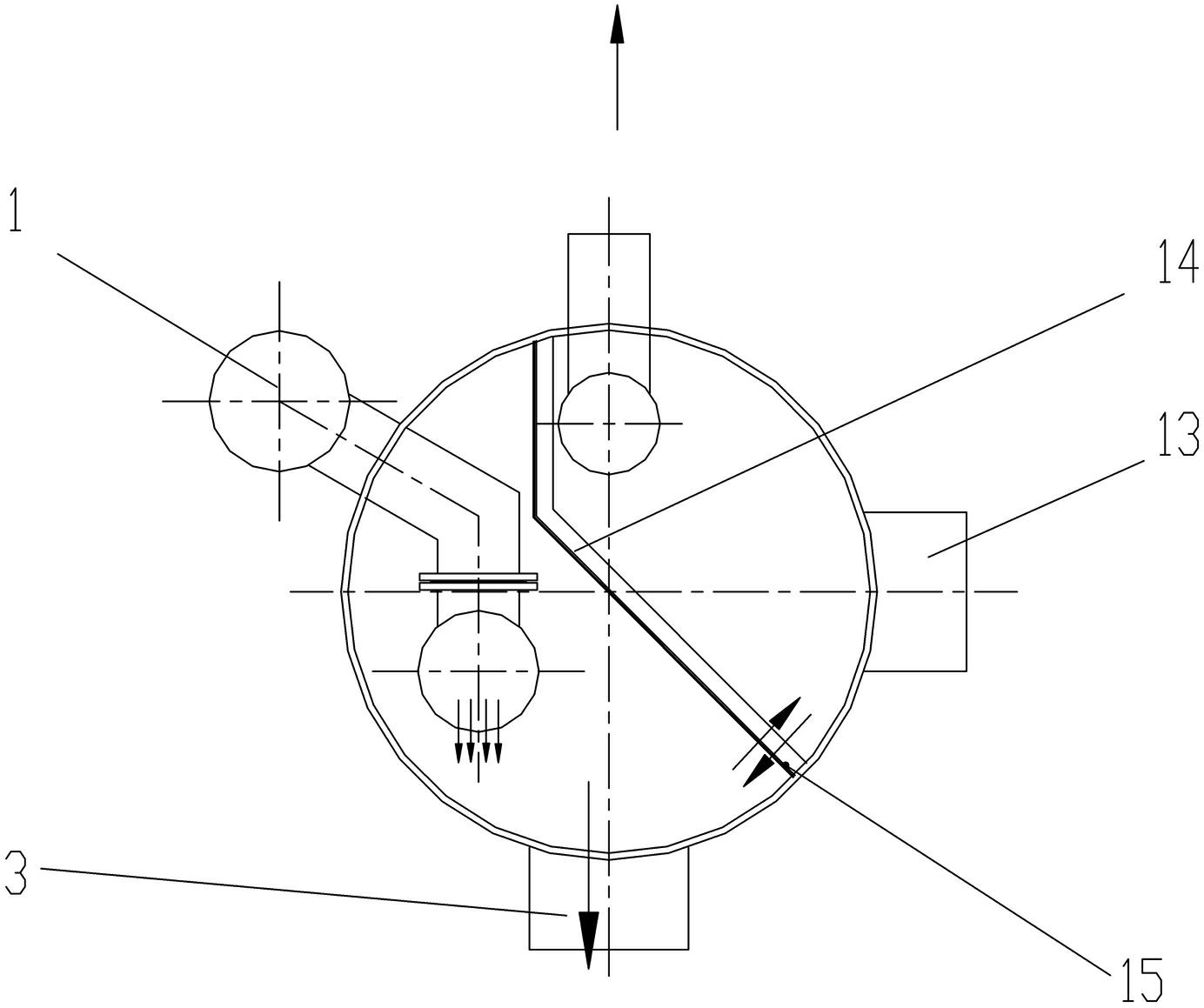

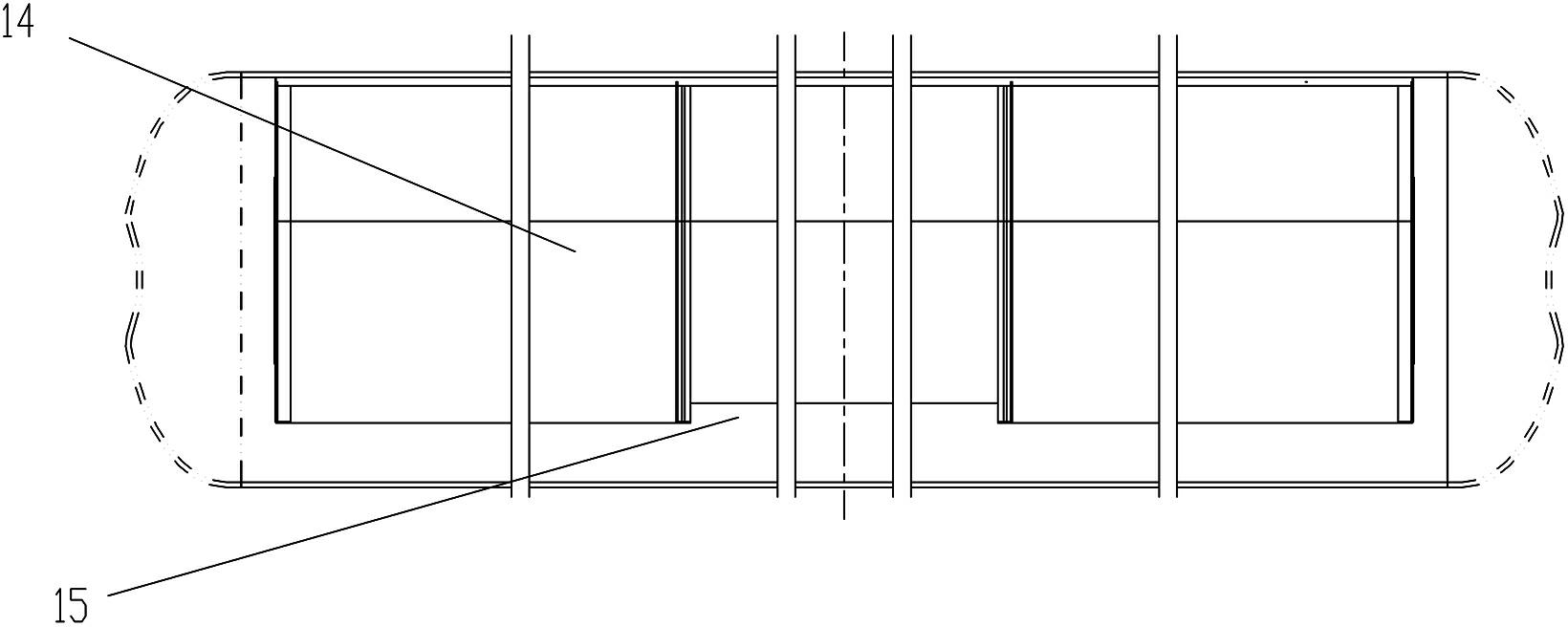

[0014] In the corner tube hot water boiler of the present invention, the composite water circulation system is as follows: figure 1 , figure 2 , image 3 As shown: it is a natural circulation composed of a drum 2, a water baffle 14, a return channel 15 on the water baffle, a front descending pipe 3, a rear descending pipe 9, an ascending pipe 4, and a natural circulation upper header 13 A composite water circulation system that combines the lower header 6, the flag-type heating surface 8, the forced circulation upper header 11 and the water outlet header 12. At the same time, a water baffle 14 with a backflow channel 15 is set in the drum, so that the natural circulation system formed by the drum 2, the downcomer 3 and the downcomer 9, the riser 4 and the natural circulation upper header 13 is in operation. A composite water circulation system that combines natural circulation and forced circulation can be formed when the furnace is shut down. Natural circulation can also e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com