Gas energy pulse soot blower utilizing compressed gas

A technology of compressed gas and soot blower, which is used in the removal of solid residues, combustion products treatment, combustion methods, etc. Remarkable effect, low failure rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

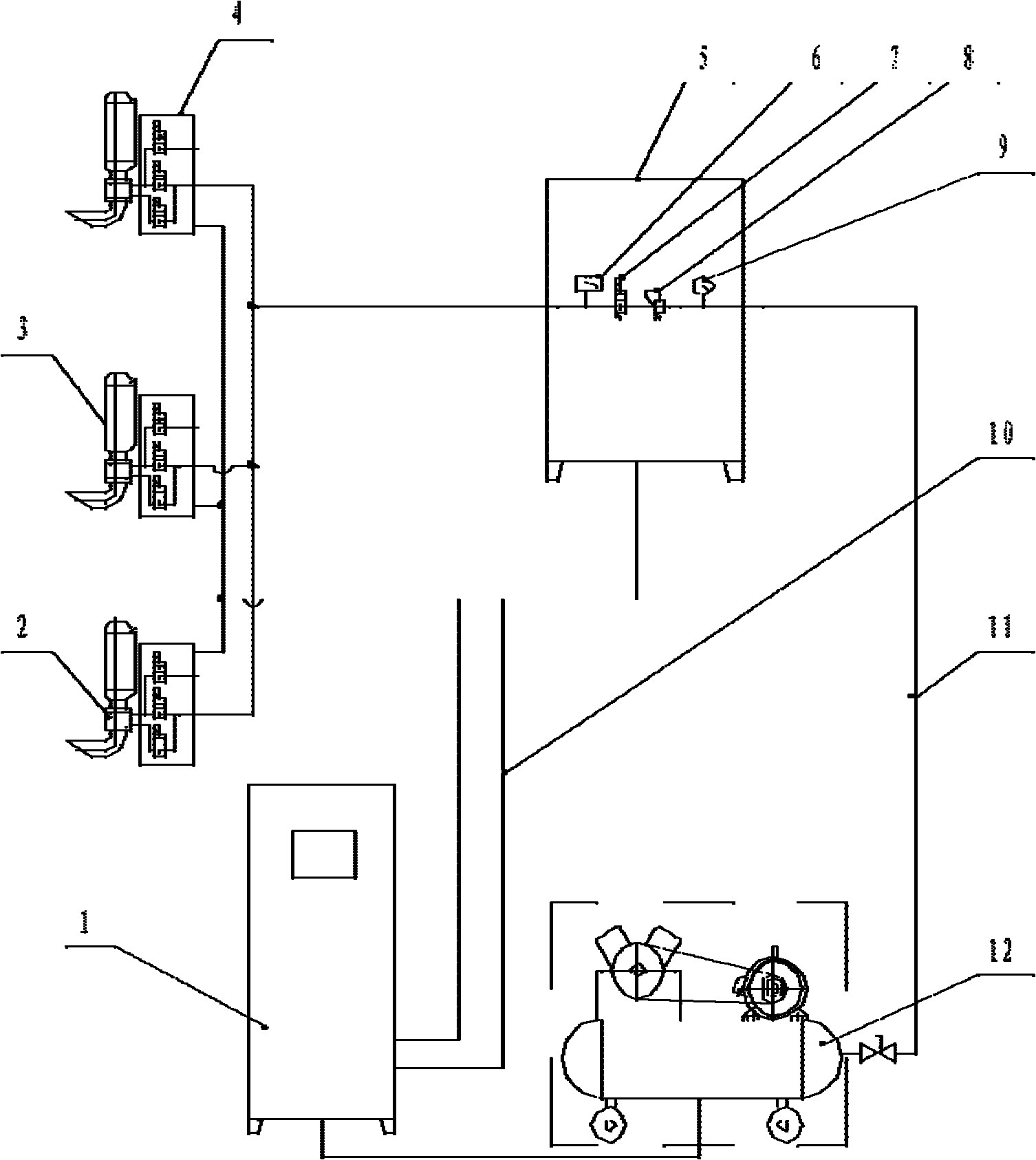

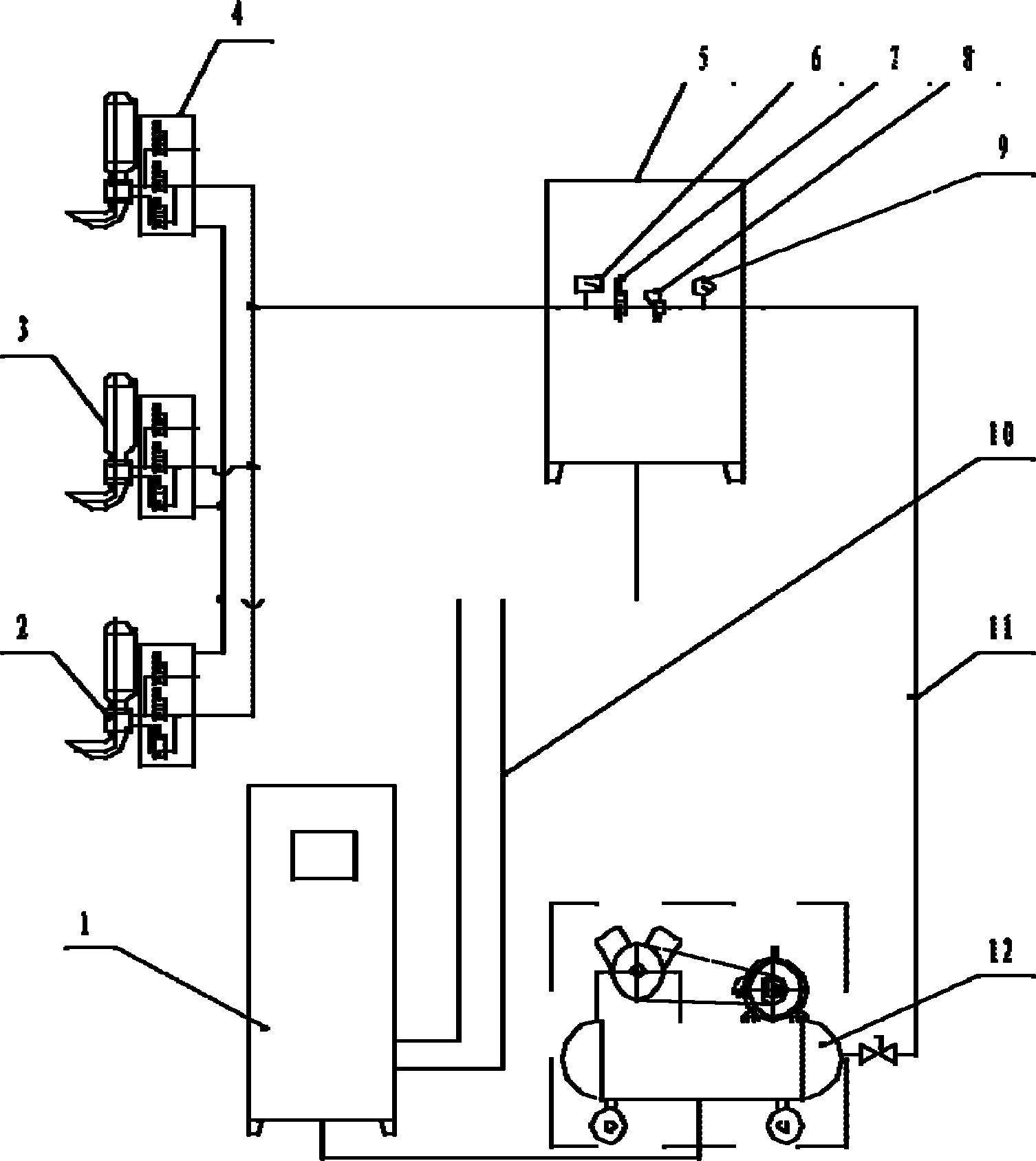

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0016] It is known from aerodynamics that when the high-pressure gas in a confined space contacts the low-pressure gas in a very short period of time, a compression wave will be formed on its front, and in the shock tube, the front compression wave will be continuously strengthened and accelerated. Finally, a shock wave of a certain intensity is generated. The formation and intensity of this kind of shock wave are largely determined by the time of instantaneous contact between high-pressure gas and low-pressure gas, that is, the so-called membrane rupture time. When it reaches a certain critical value, a shock wave can be generated. The shorter the shock wave The greater the intensity.

[0017] The gas energy pulse soot blower of the present invention just utilizes this prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com