Method for blowing soot for waste heat boiler by using waste

A waste heat boiler and waste technology, which is applied to combustion methods, removal of solid residues, lighting and heating equipment, etc., can solve the problems of dead corners of soot blowing, low utilization rate, limited soot blowing range, etc., to achieve convenient technology and improve utilization. High efficiency, good soot blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

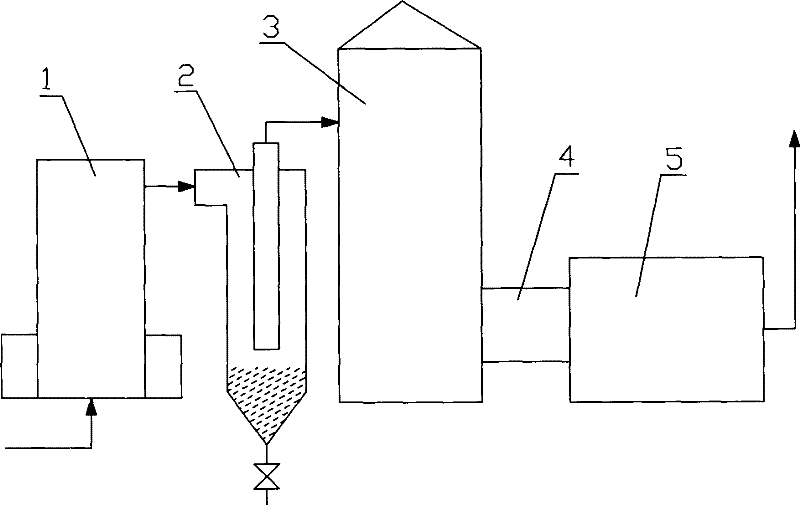

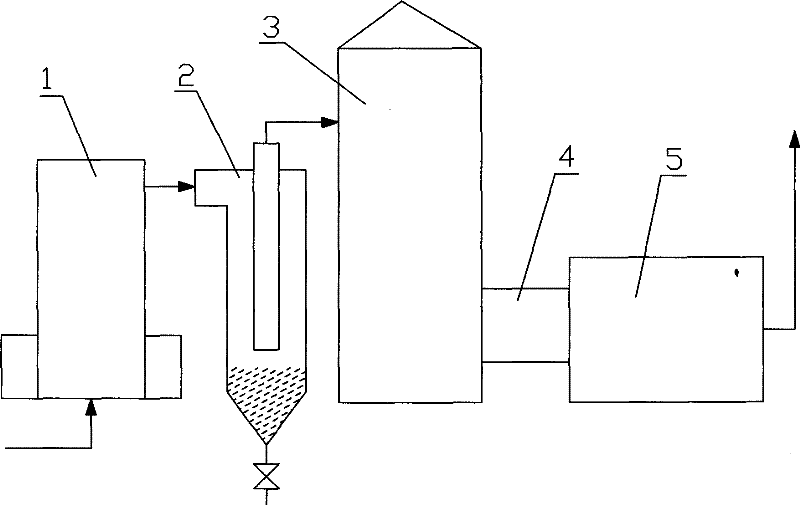

[0011] The first solution of the present invention is: the blowing air from the gas generator enters the cyclone dust collector 2, and the airflow from the exhaust port of the cyclone dust collector 2 enters the exhaust gas waste heat boiler. It is characterized in that: after the cyclone dust collector 2 collects the separated and settled coal powder, When the accumulation height reaches the lower nozzle of the central exhaust pipe adjacent to the cyclone dust collector 2, it is driven by the blowing air to be discharged from the exhaust port of the cyclone dust collector 2, and then introduced into the combustion furnace 3 of the waste heat boiler, and the entrained coarse coal produced by the blowing air after combustion The powder particles enter the boiler body 5 through the flue gas channel 4, and soot blow the heat exchange tube bundle.

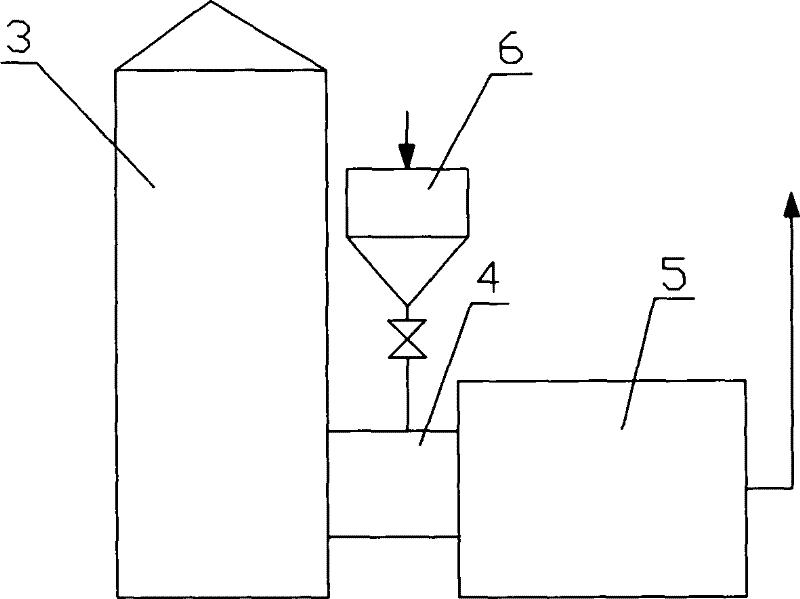

[0012] The second solution of the present invention is: it is characterized in that: the slag of the coal gasifier 1 and the circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com