High-efficiency soot blowing device for SCR (selective catalytic reduction) denitration catalyst

A technology of denitrification catalyst and soot blowing device, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as polluted air, dust, unhealthy health, etc. Effect improvement, effect of soot blowing effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

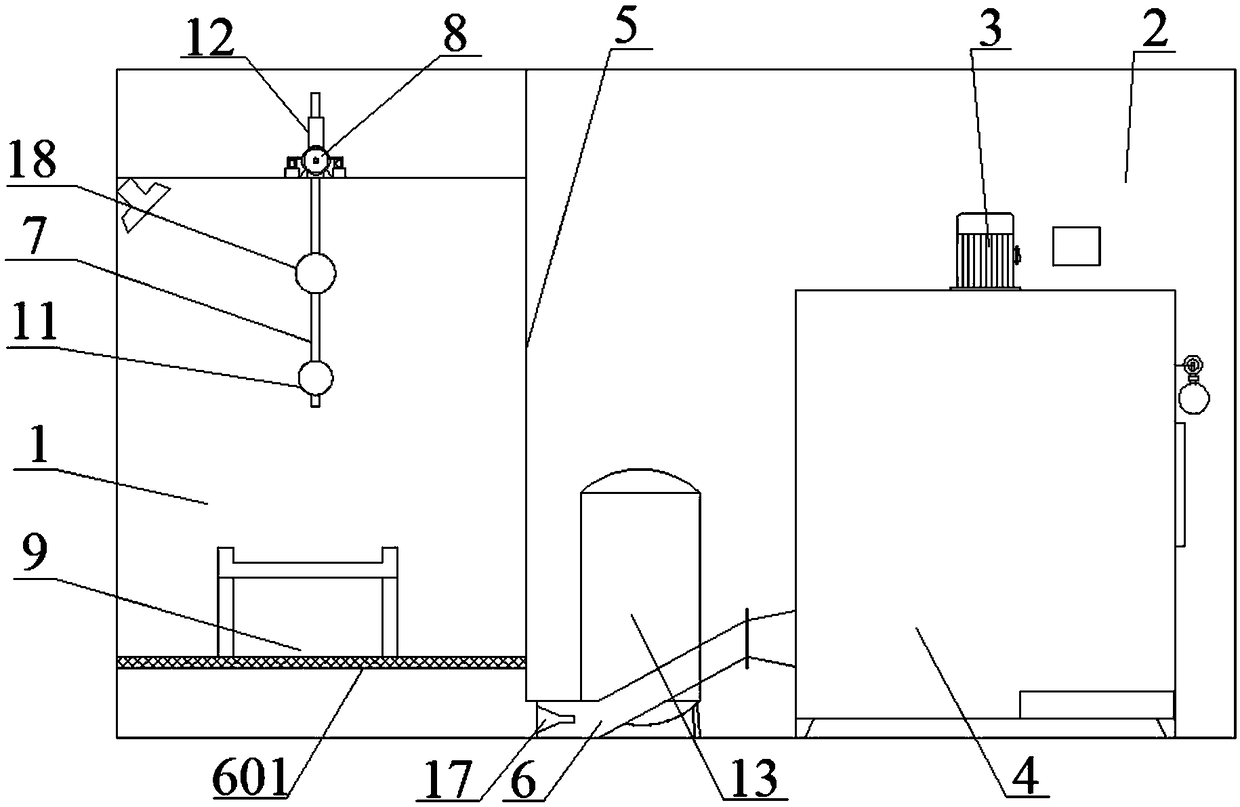

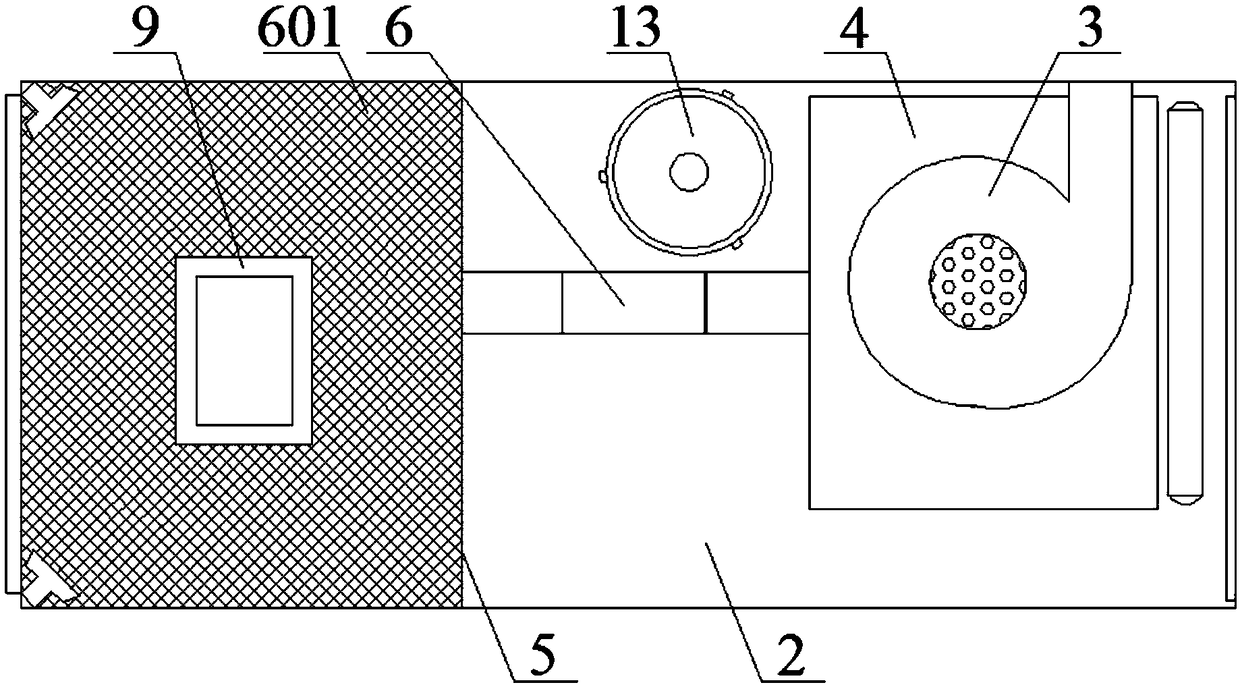

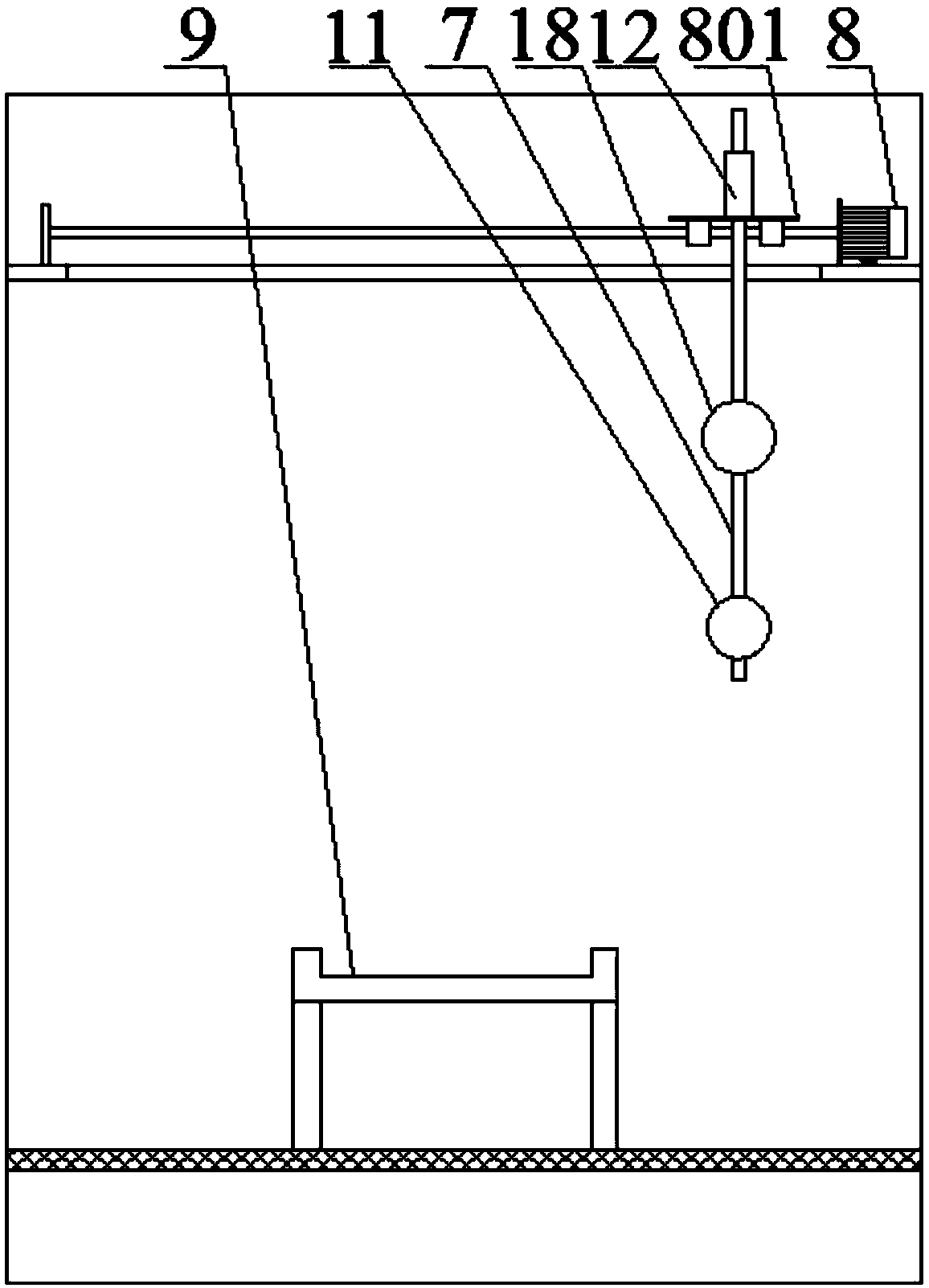

[0023] The present invention relates to a high-efficiency soot blowing device for SCR denitrification catalyst, the device includes a purging unit connected with an air compressor, a catalyst placement platform 9 and a negative pressure unit, the soot blowing device consists of a separator 5 separated purge chamber 1 and dust removal chamber 2, the placement platform 9 is located in the purge chamber 1, and the purge unit is arranged on the top of the purge chamber 1, and the negative pressure unit includes an air inlet upward and located below the placement platform 9 The air suction channel 6 is provided with a mesh plate 601 at the air inlet, and the air suction channel 6 passes through the partition plate 5 and is connected with the negative pressure unit; Sweeping pipe 7, the end of the sweeping pipe 7 is provided with a circular cavity 11, and a turret 14 is arranged in the circular cavity 11, and the circumference of the turret 14 is evenly distributed with sealing rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com