Unit individual type gas impulse ash blower

A soot blowing device and column-type technology, applied in the field of boiler soot blowing devices, can solve the problems of valve body life and reliability, rapid aging of internal gaskets, broken ball valve core, etc., to achieve strong scalability, enhanced Safety, longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

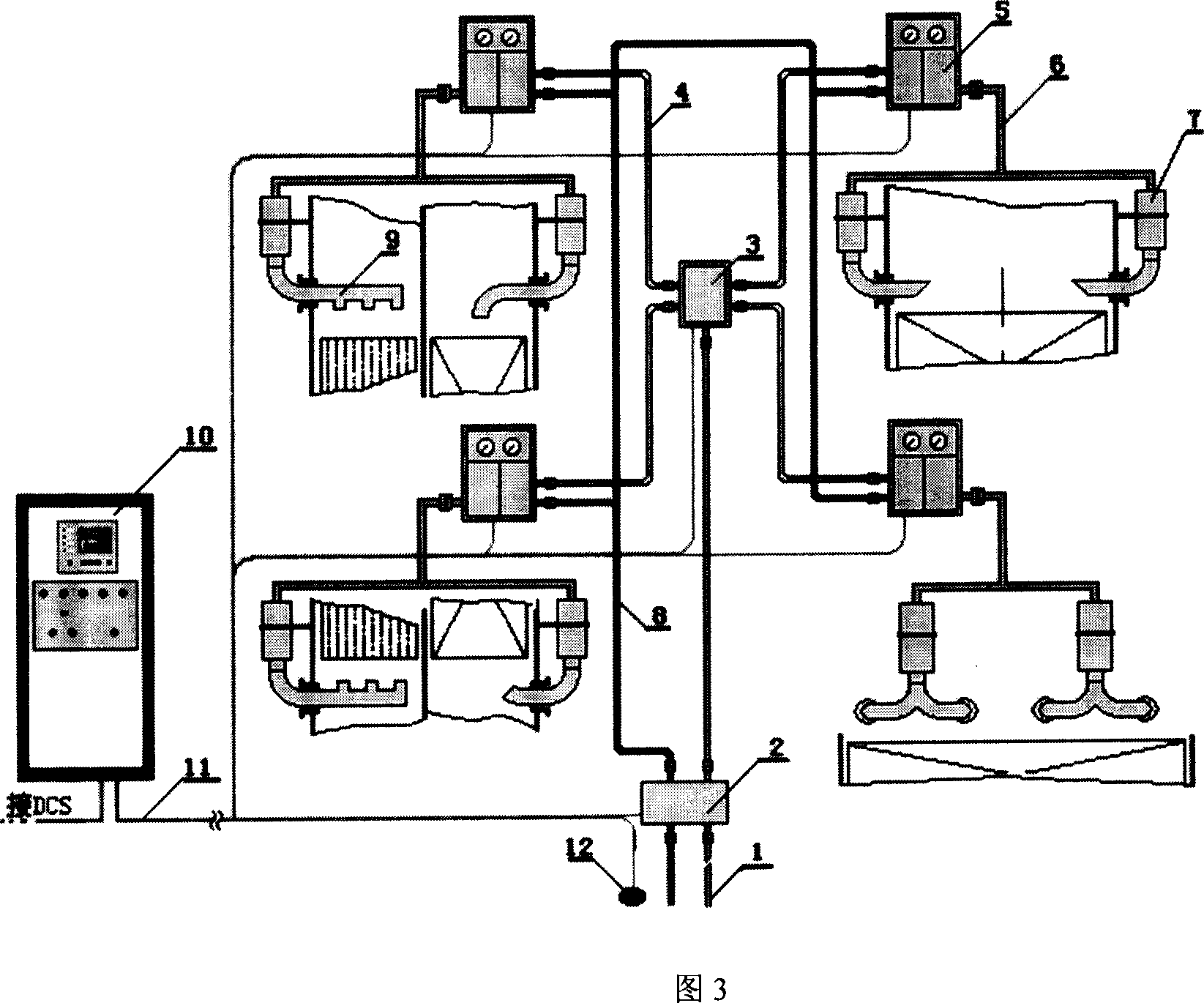

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0022] Referring to Fig. 3, the composition of the unit split type gas pulse soot blowing device includes a gas source allocation unit 2, a gas distributor 3, a pulse initiator 5, a pulse generator 7 and an emission nozzle 9. The gas enters the gas source allocation unit through a pipeline 1, and each One emission nozzle is equipped with a pulse generator to form a soot blowing point, and every two soot blowing points are installed in a group where soot blowing is required in the boiler. The gas is connected to the initiators, and the gas is connected to the gas distributor through the gas pipeline after passing through the gas source adjustment unit. The initiators are connected, and the gas source adjustment unit is connected to the control device 10 through the cable 11 . A gas sensor 12 is arranged at the gas supply station, the pulse initiator, and the gas d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com