Patents

Literature

110results about How to "Maintenance cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

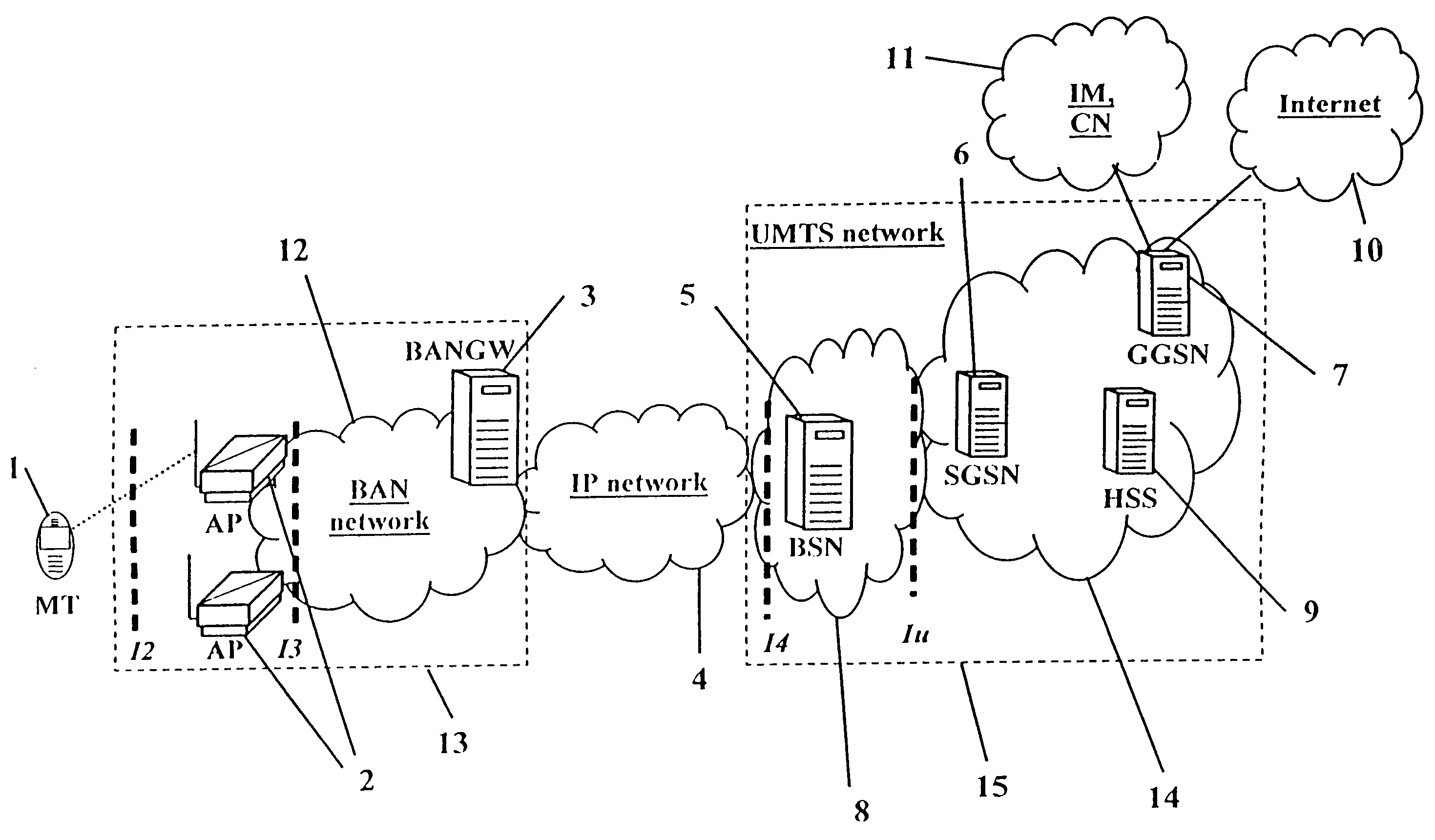

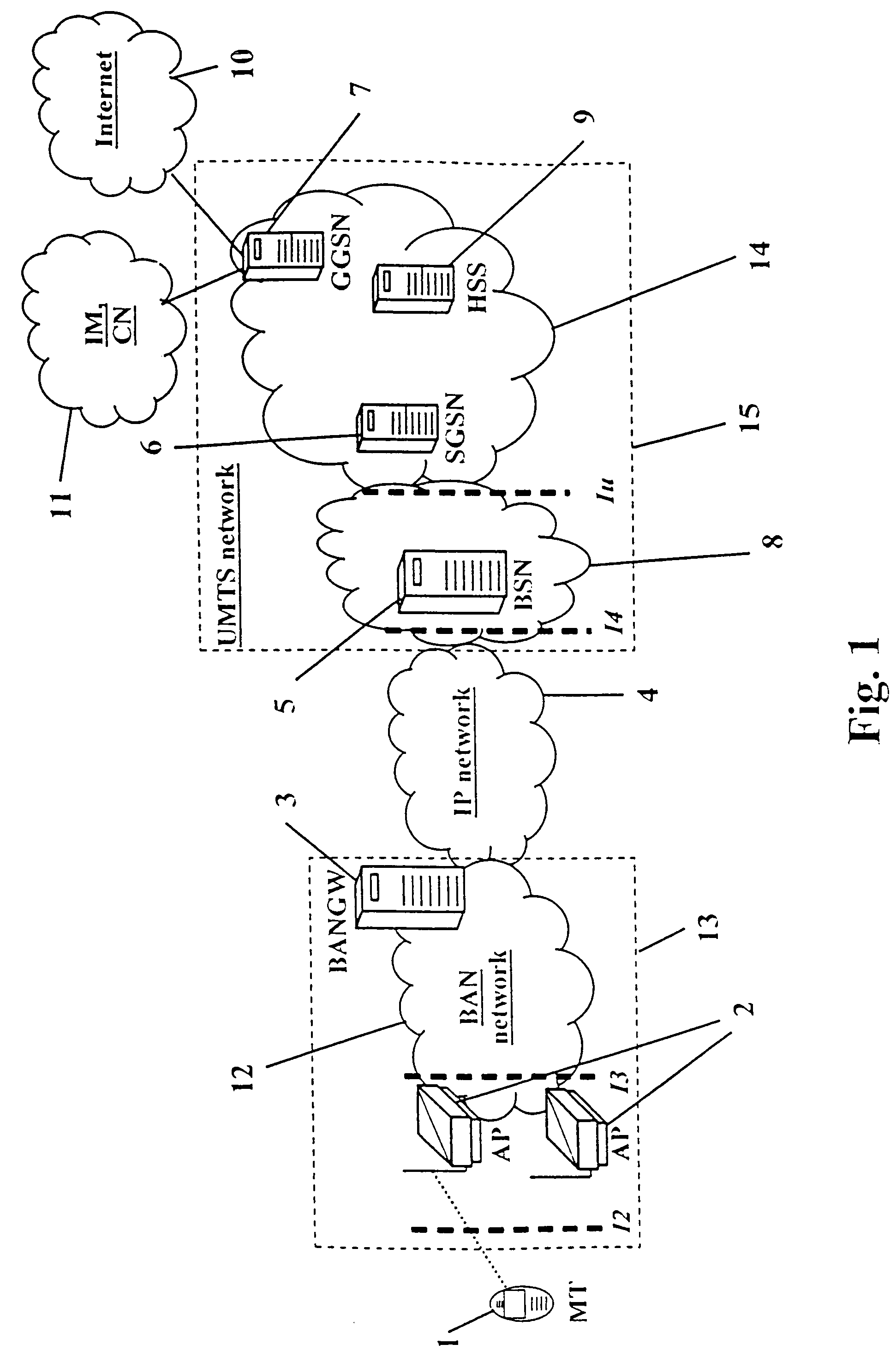

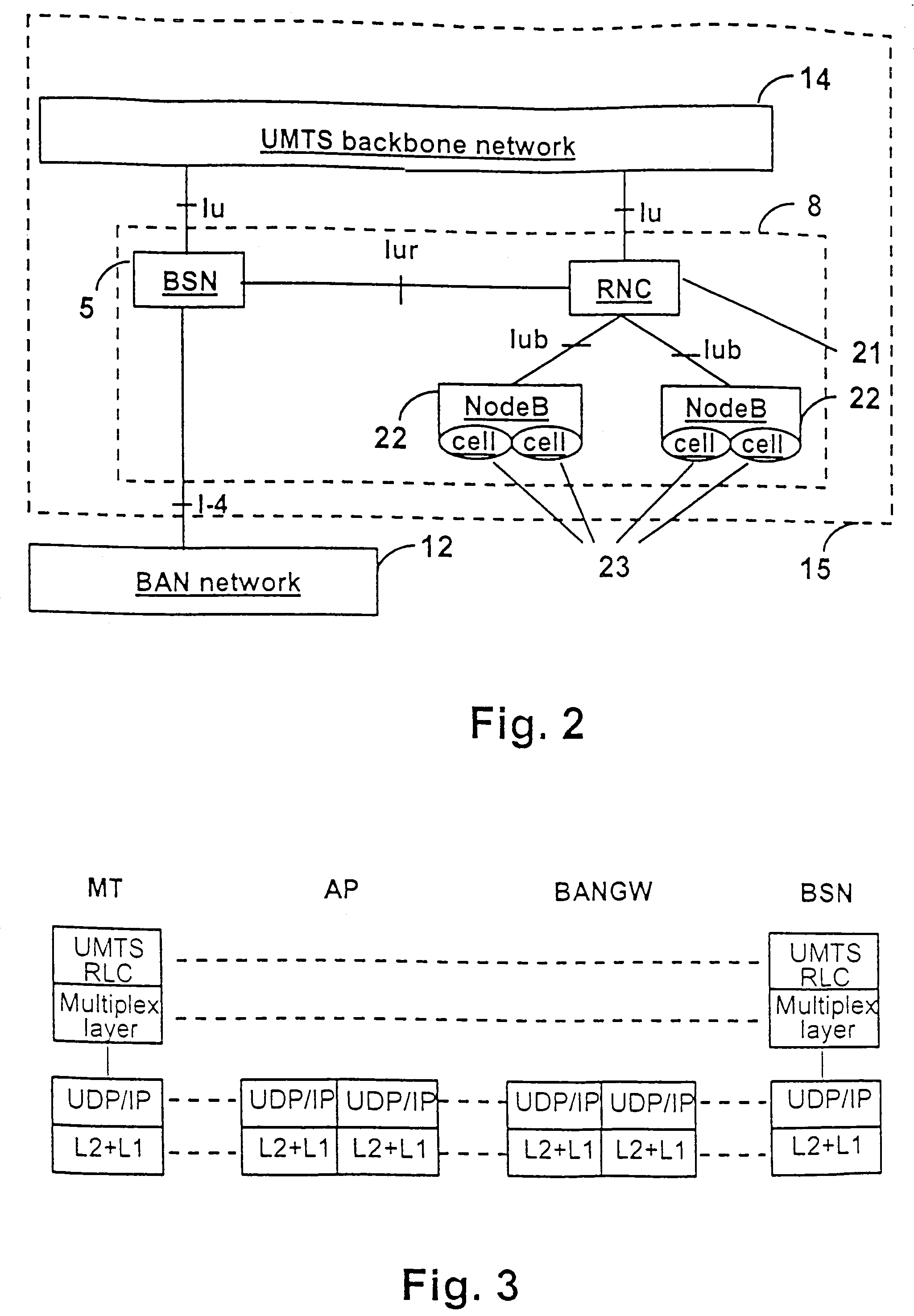

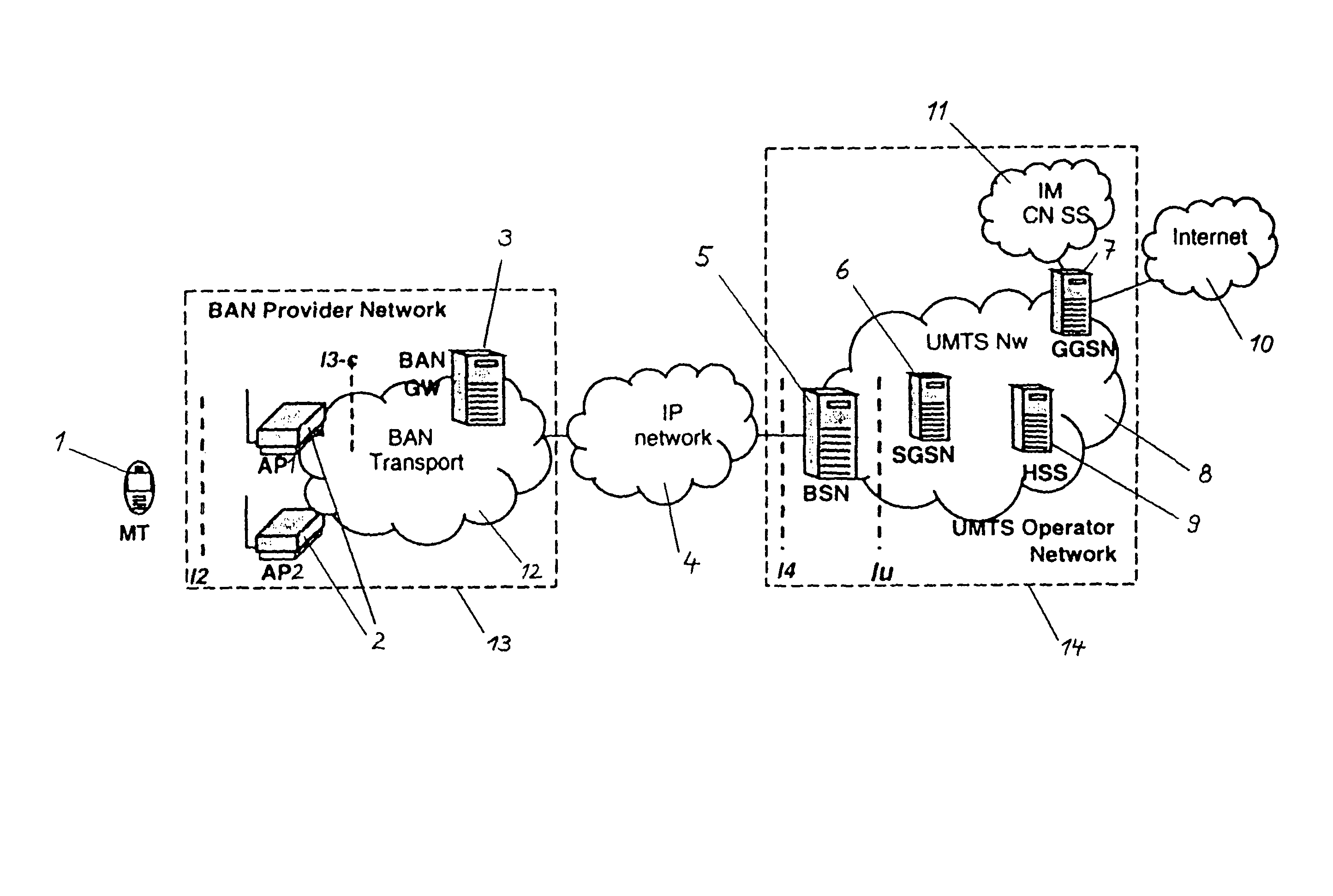

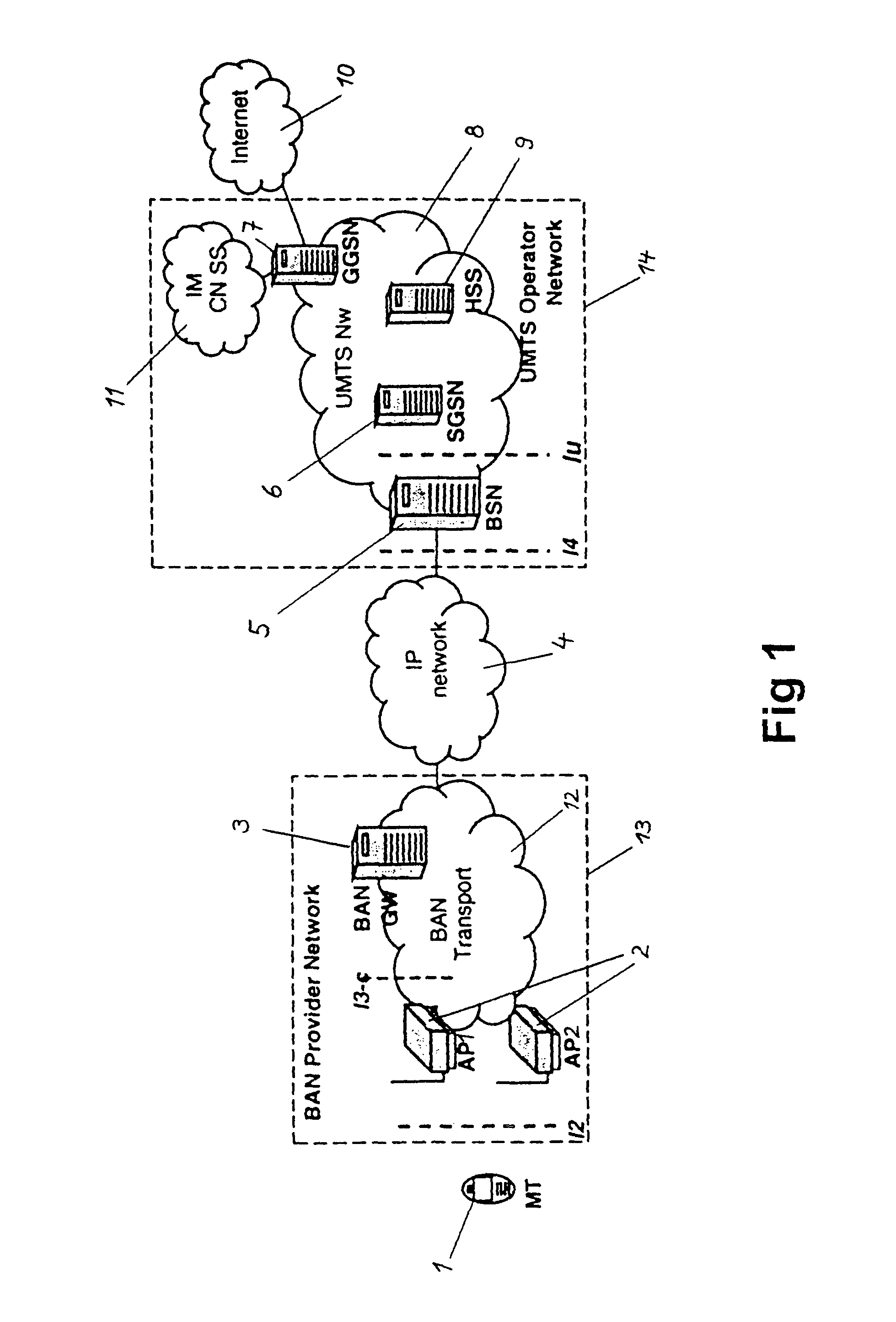

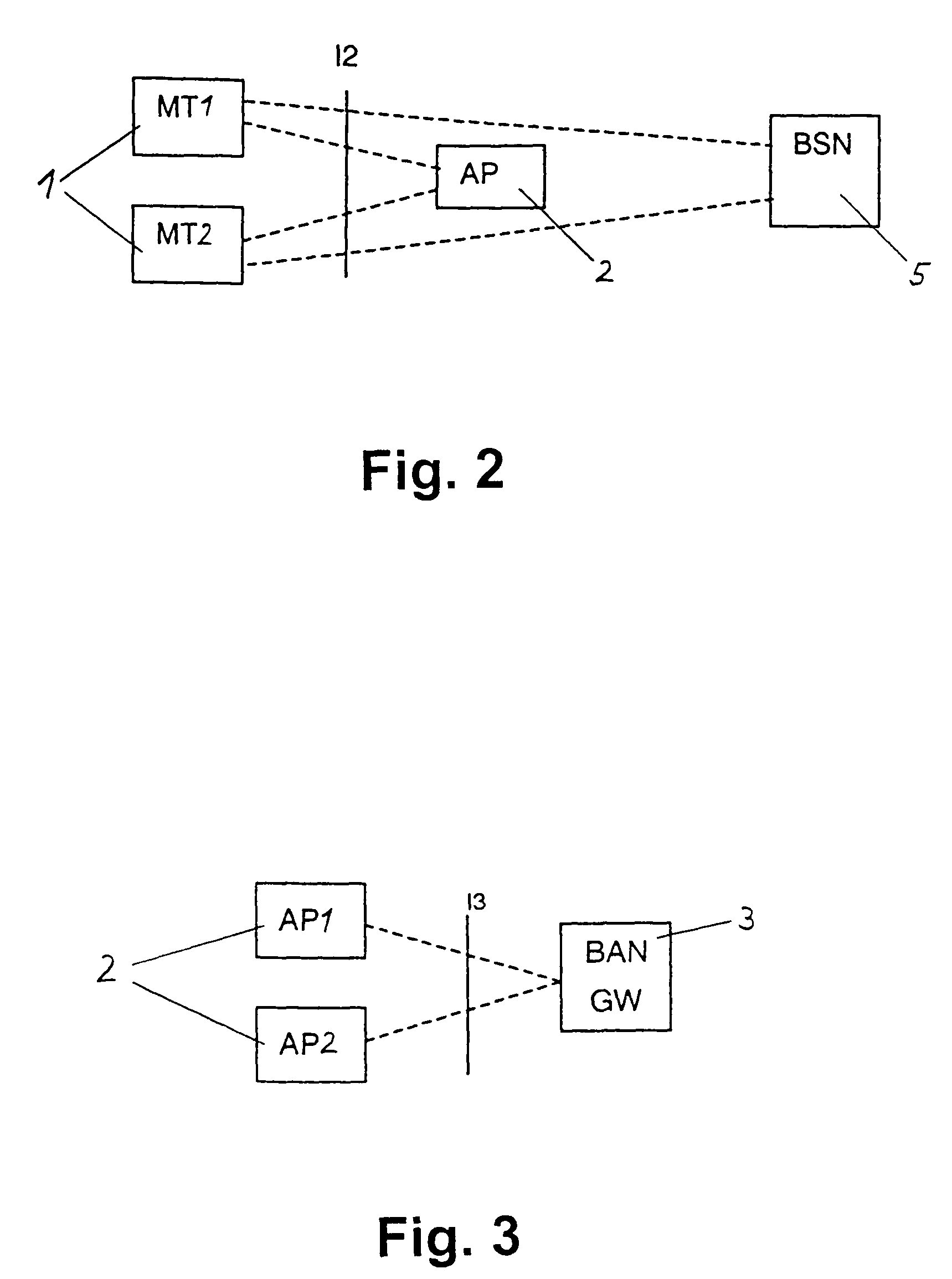

Access system for a cellular network

ActiveUS20050101245A1Improve facilitiesReasonable priceAssess restrictionTelephonic communicationAccess networkTerminal equipment

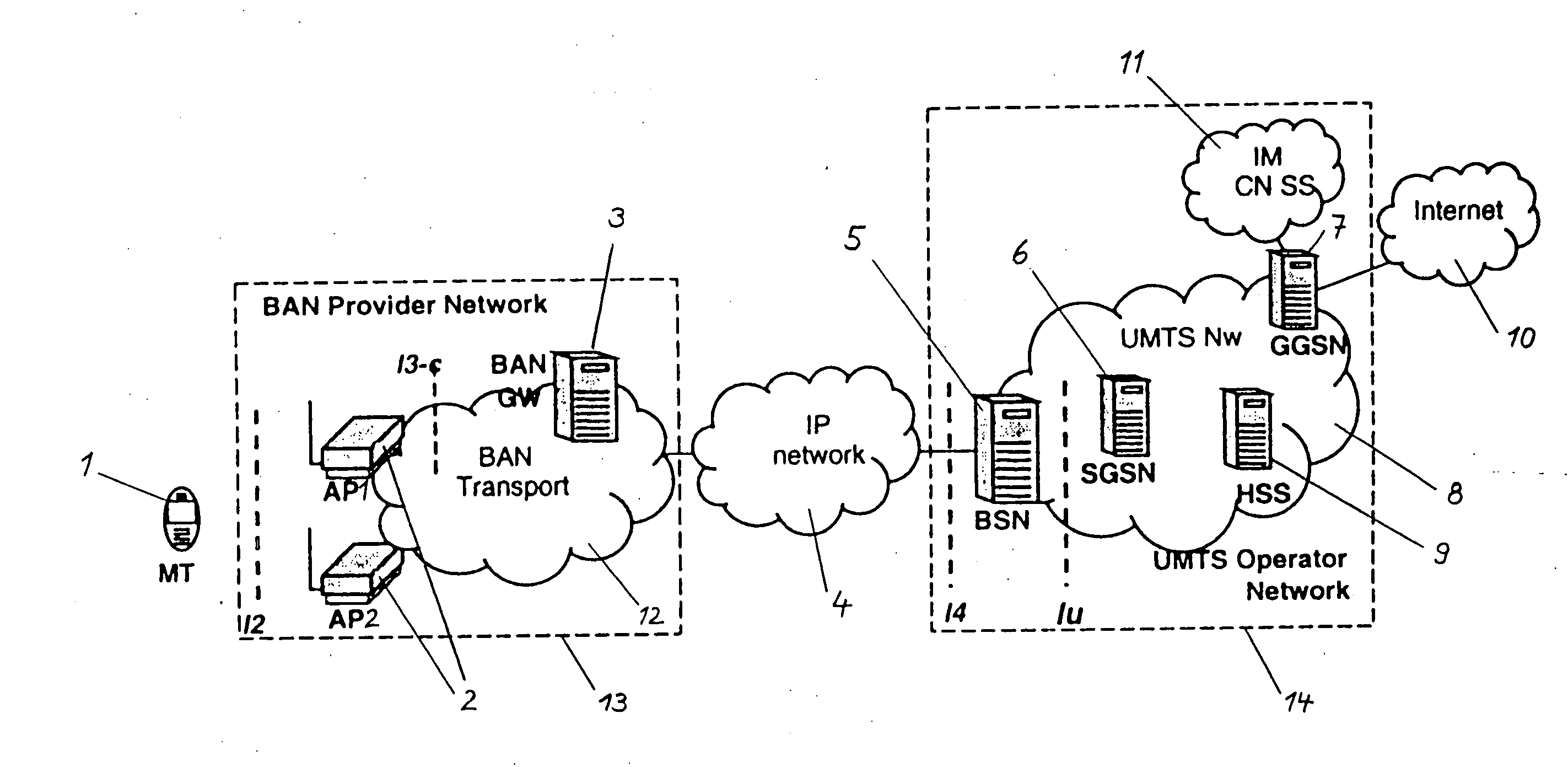

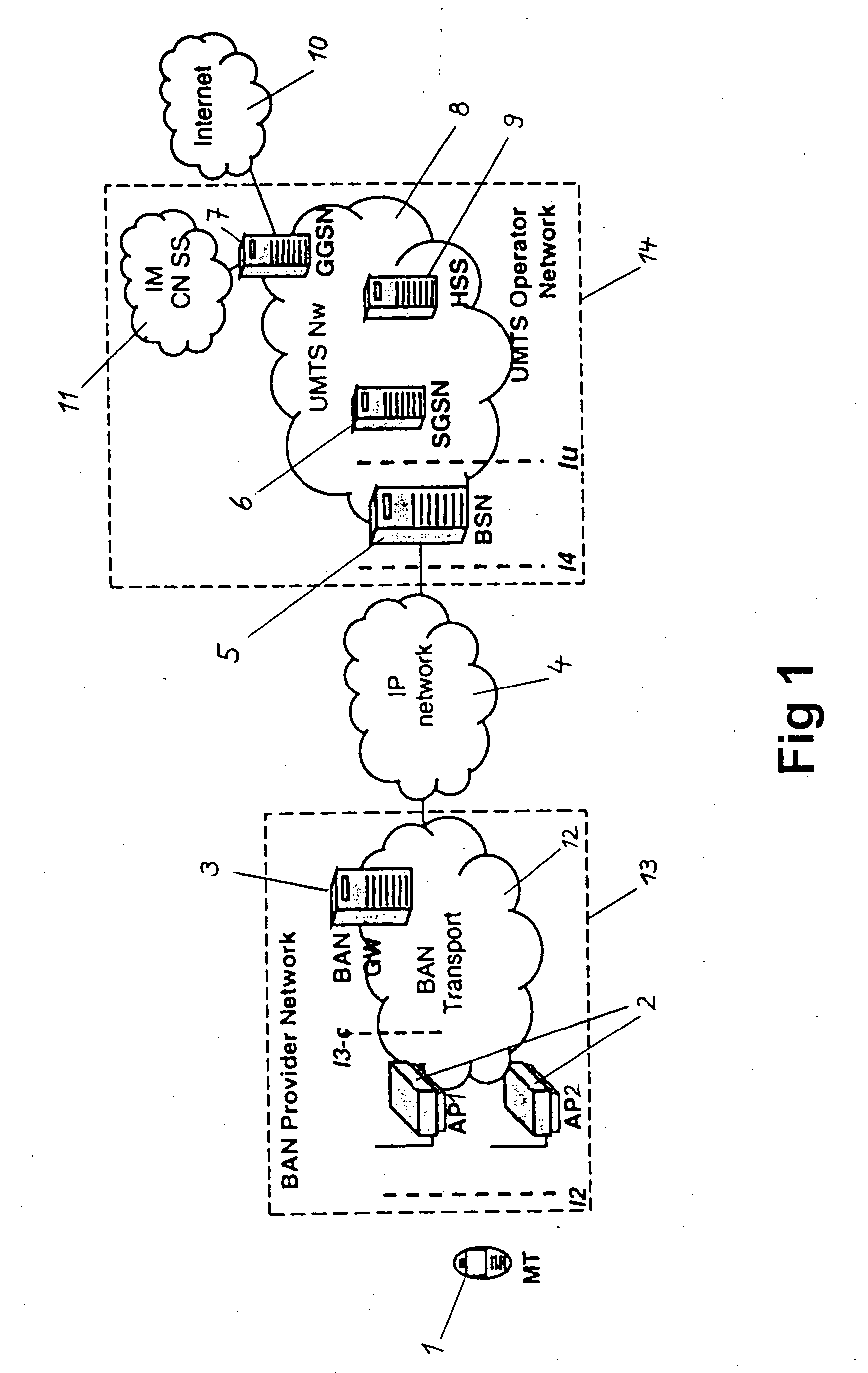

The present invention relates to a method and system for providing access to a cellular network (8), wherein a terminal device (1) is connected to an access device (2) according to access specifications of a broadband access network (12) which is not specifically designed to be used as a part of cellular network (8). The terminal device (1) indicates to the access device (2) that it wishes to be connected to the cellular network (8), and a session or call and a radio bearer is setup between the terminal device (1) and the cellular network (8). To achieve this, a service node (5) provided in the cellular network (8) requests a suitable access bearer from the access network (12) and the access device (2) sets up a corresponding access channel towards the terminal device (1). The terminal device (1) then associates the access channel to the correct radio bearer by using a corresponding identification. Thereby, service functions of the cellular network, e.g. UMTS services, can be distributed via any access network and existing broadband or high-speed access networks can be implemented in new cellular network structures. A huge capacity enhancement can thus be offered to the network operators of the cellular network without any standardization effort or license fee and at very small investment and maintenance costs.

Owner:NOKIA TECHNOLOGLES OY

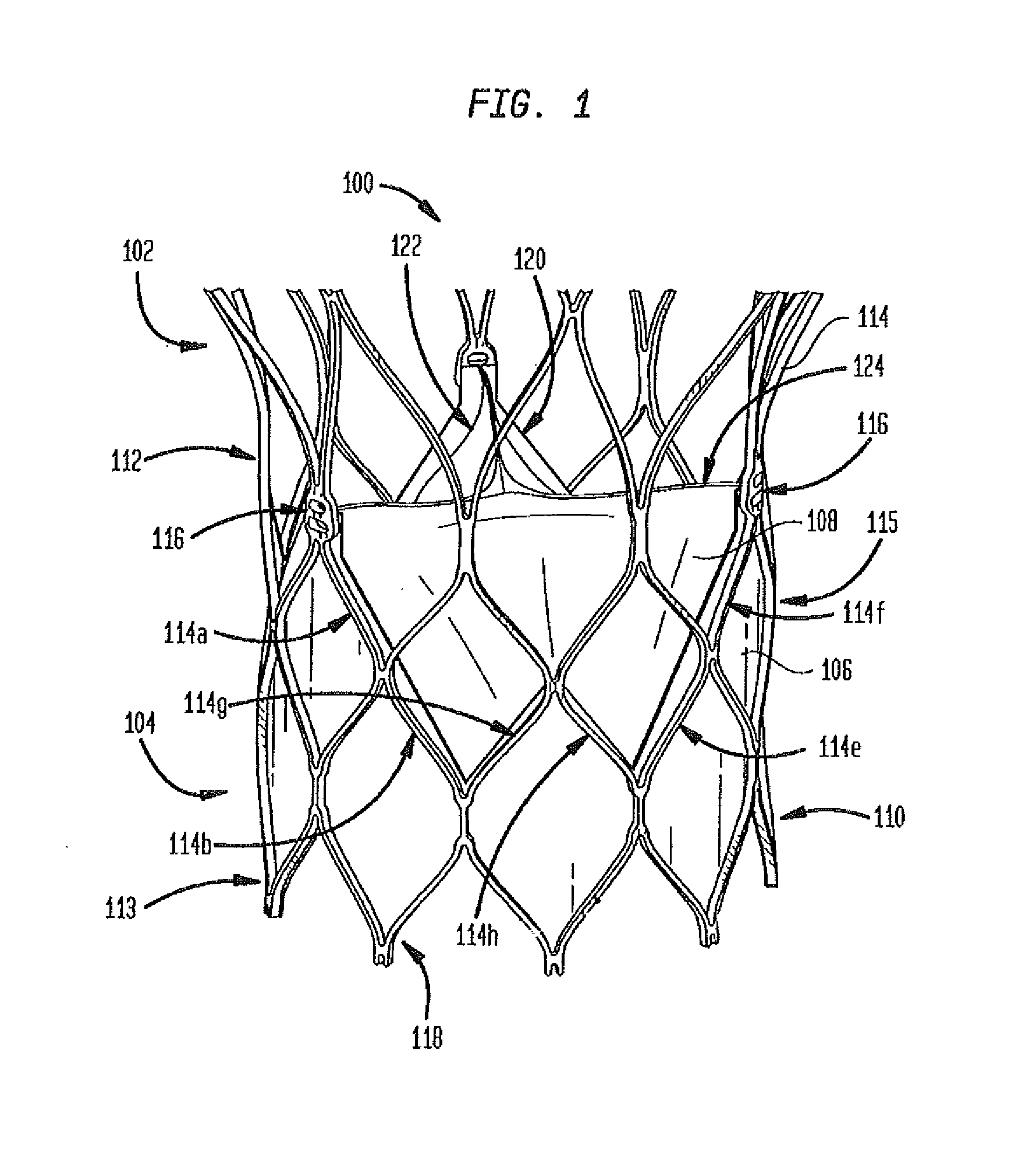

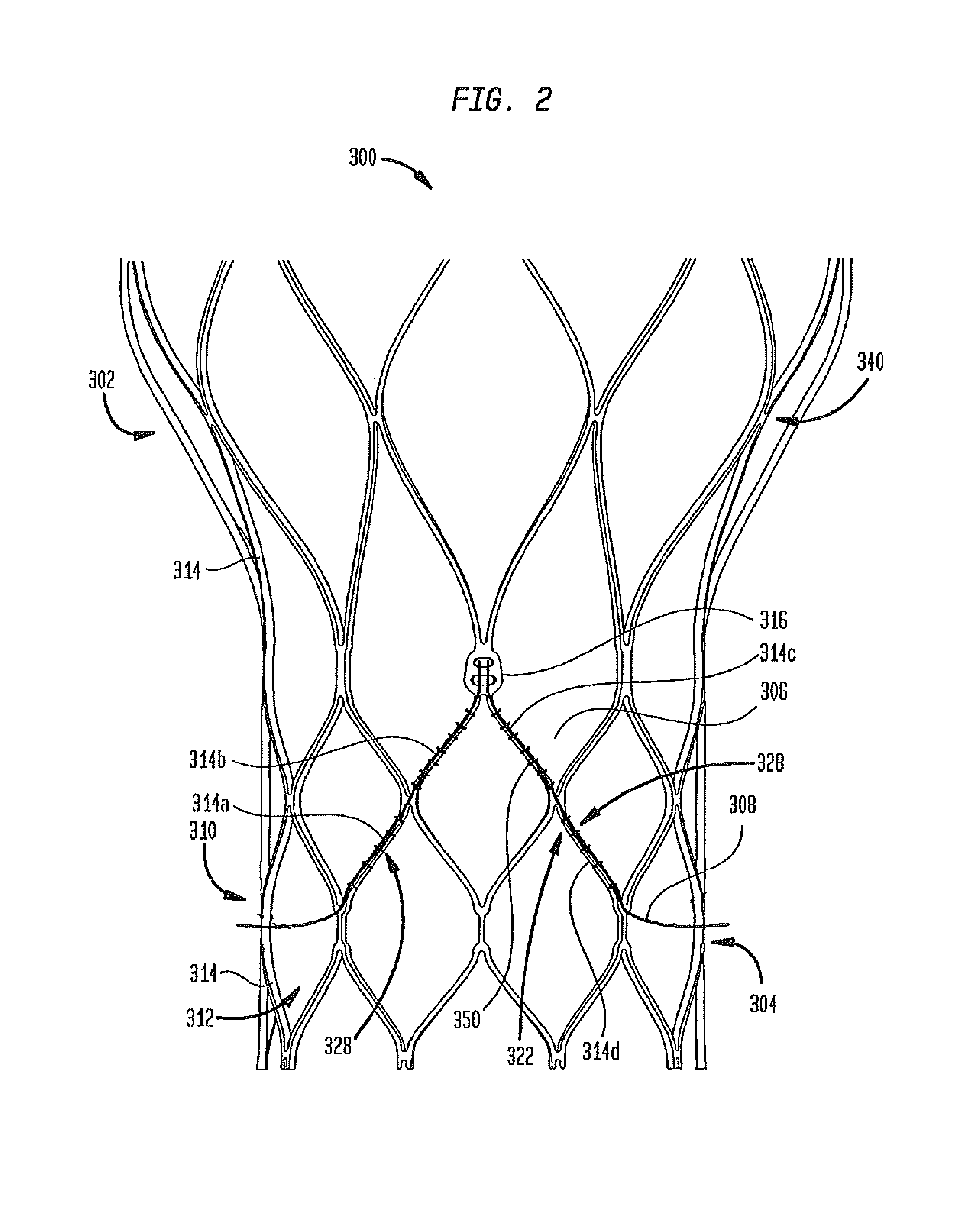

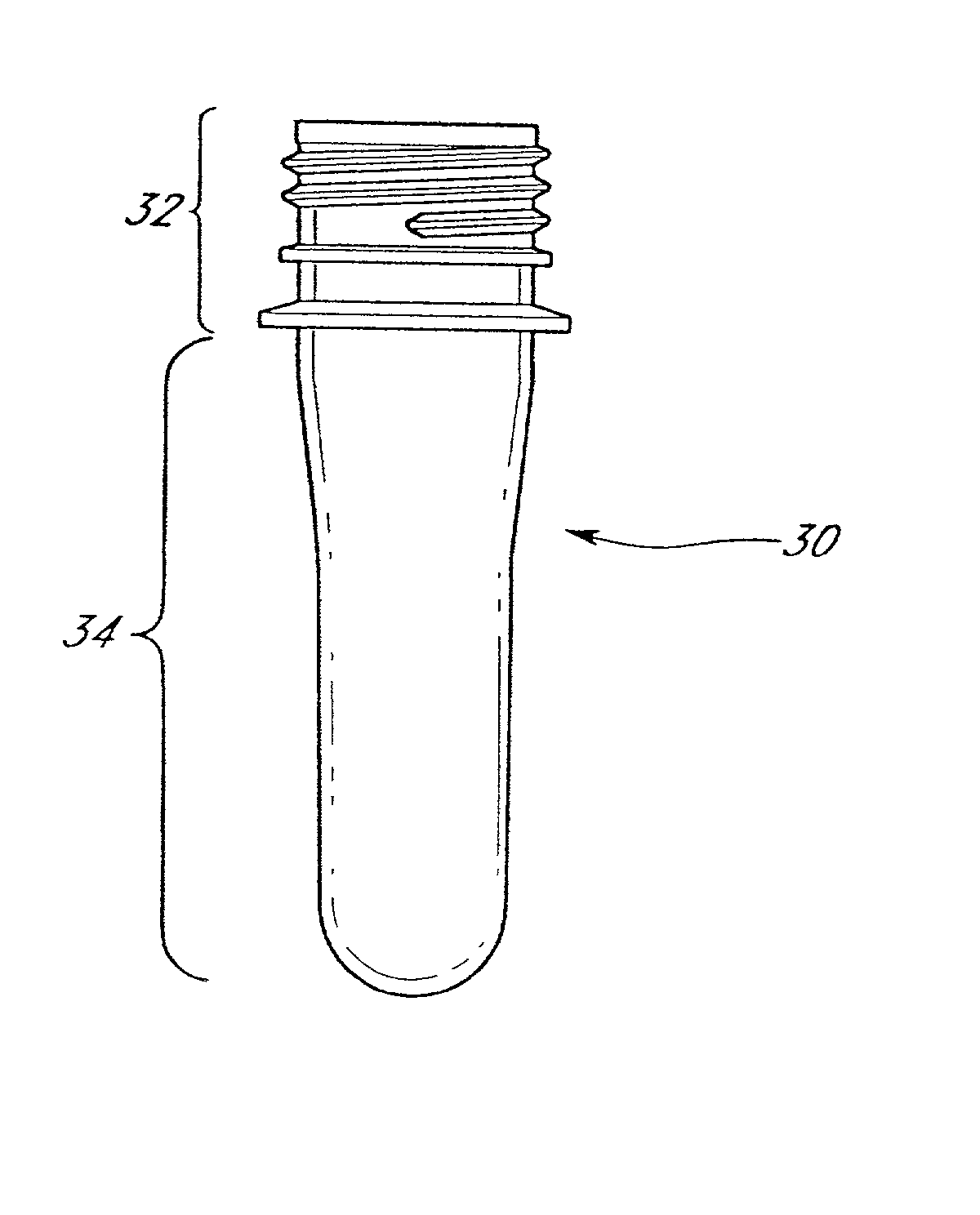

Blunt ended stent for prosthetic heart valve

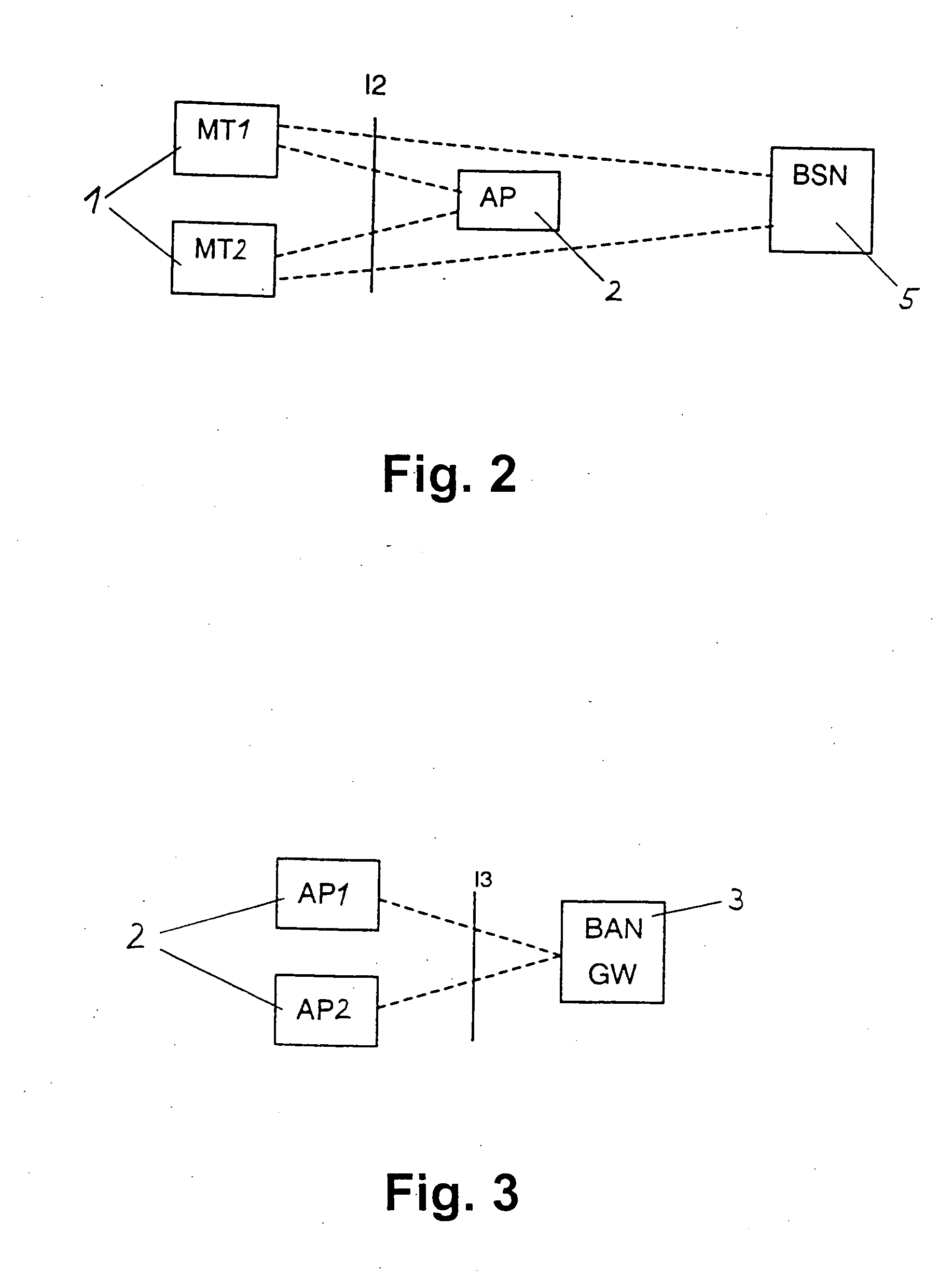

ActiveUS8932343B2Maintain collapsibilityMaintenance costStentsHeart valvesProsthetic valveInsertion stent

A collapsible prosthetic heart valve includes a stent and a valve assembly. The stent has a proximal end and a distal end and includes a plurality of struts. The struts have free ends configured to inhibit tissue penetration. The valve assembly, including a plurality of leaflets, is disposed within the stent.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

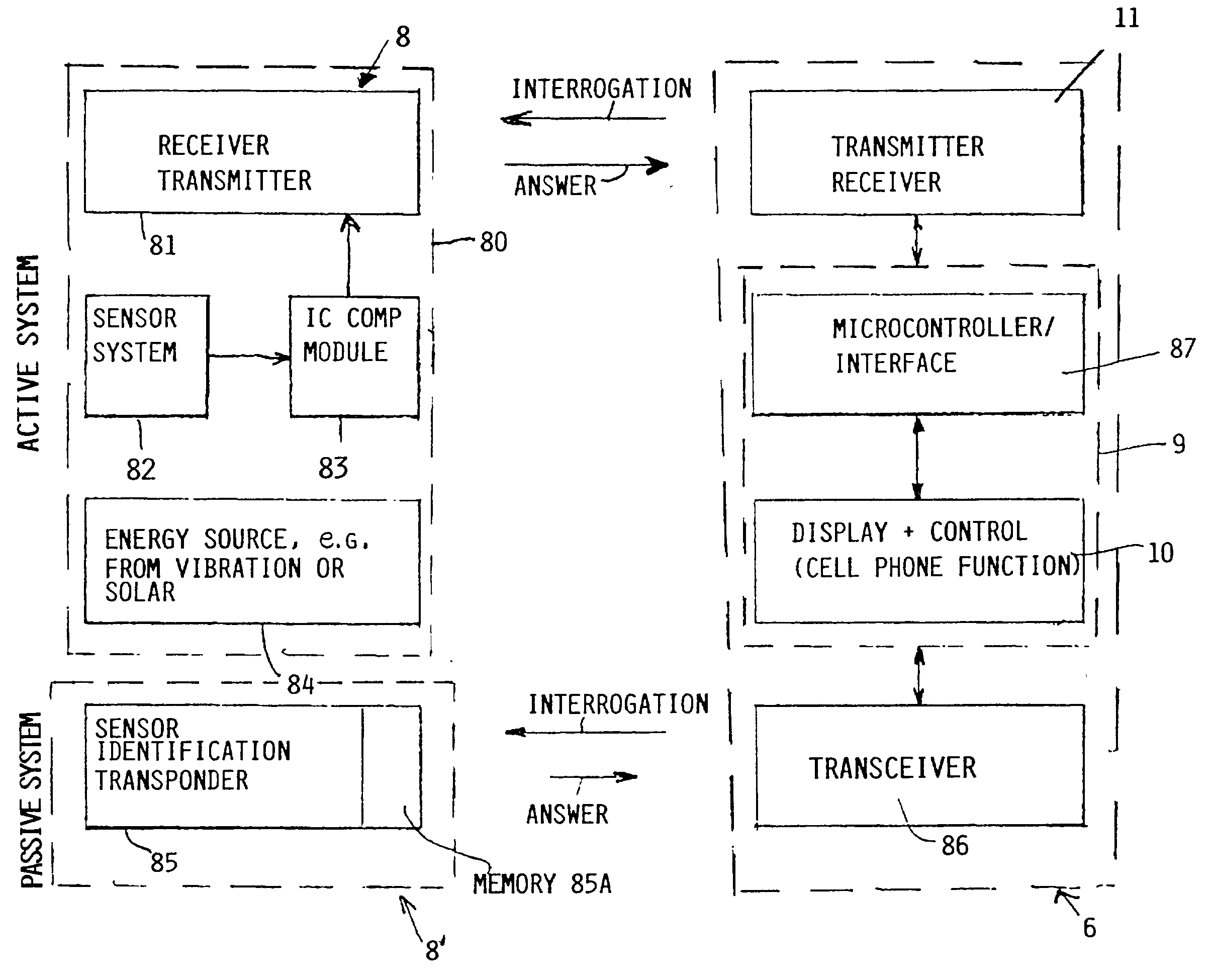

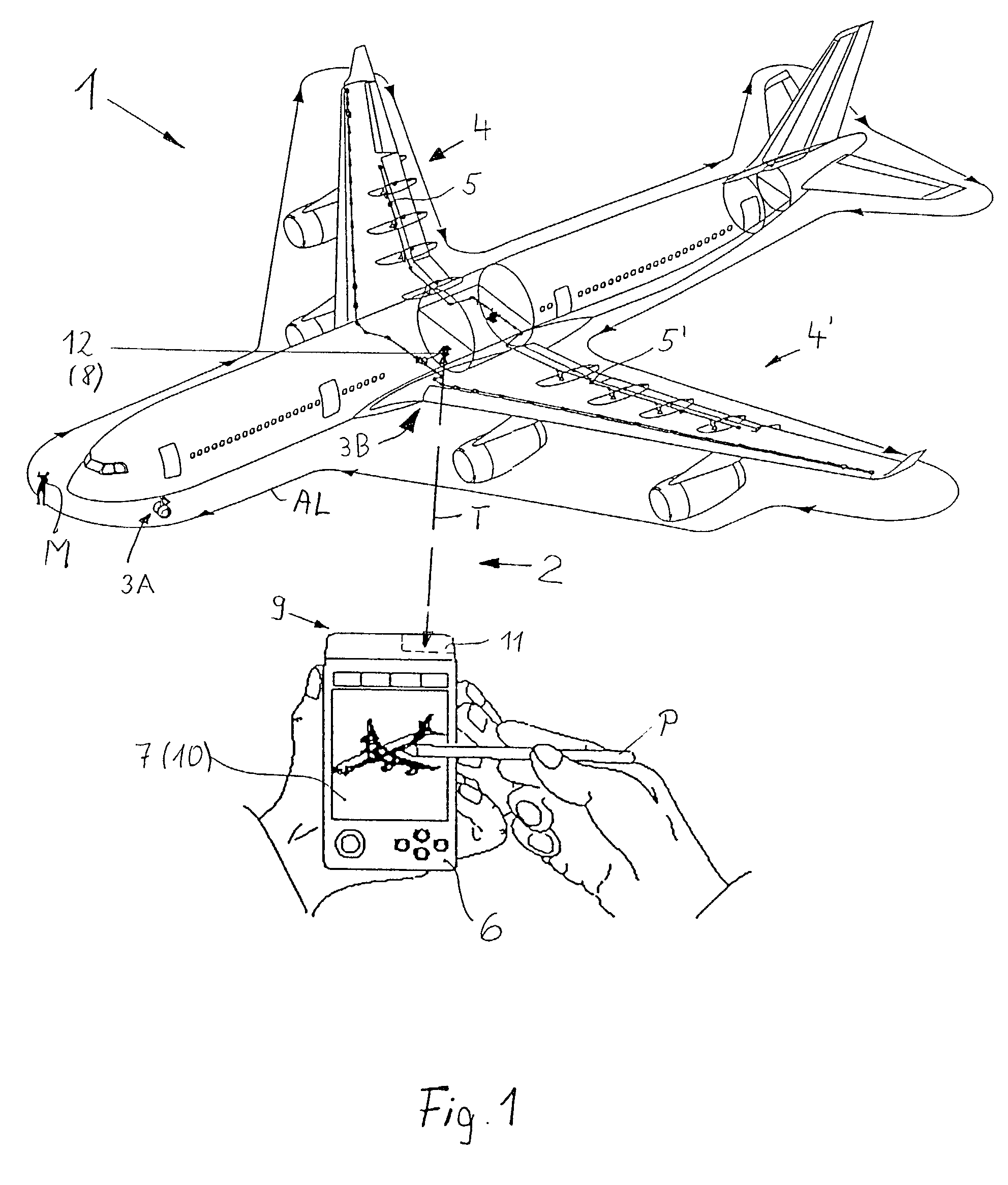

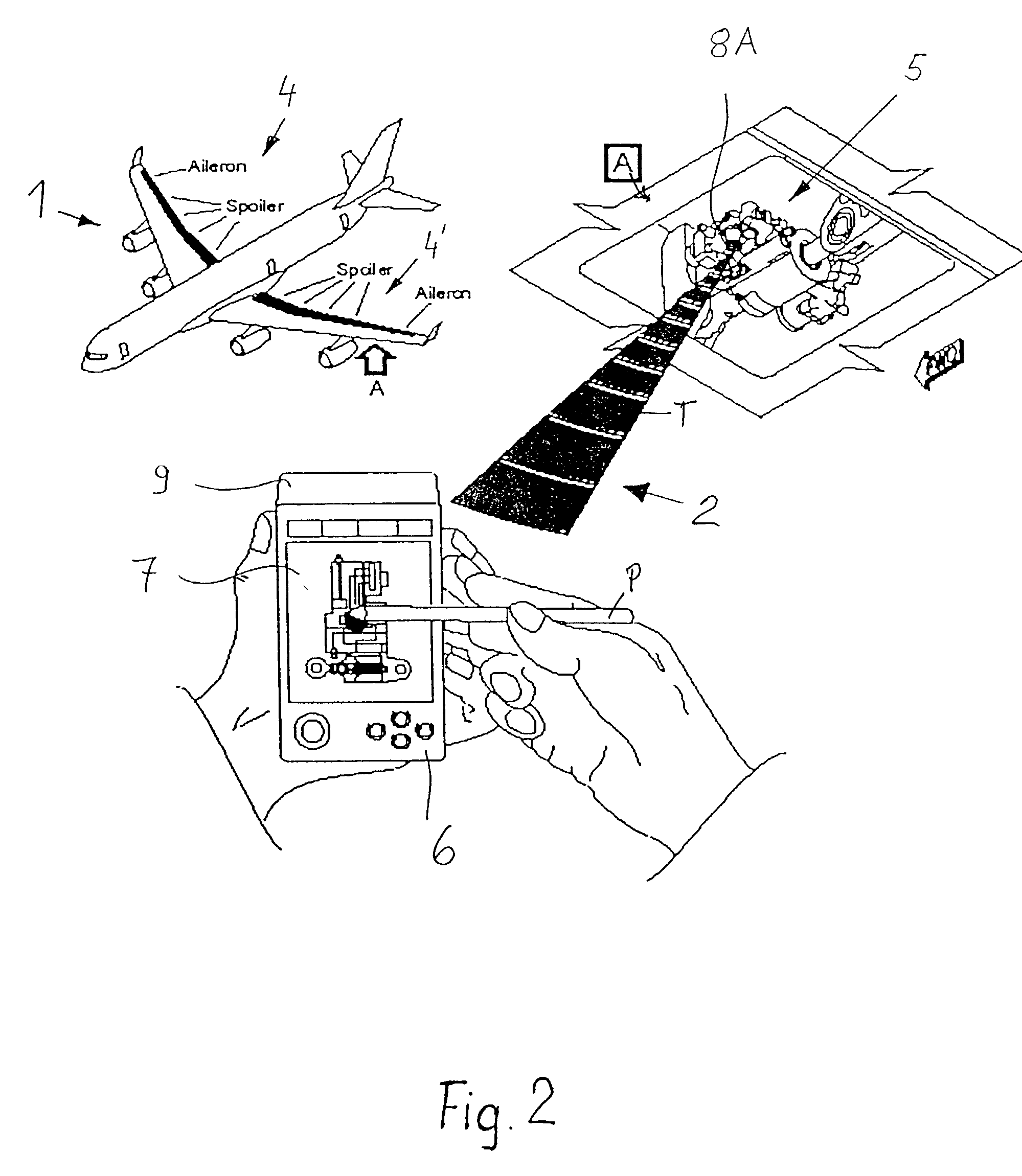

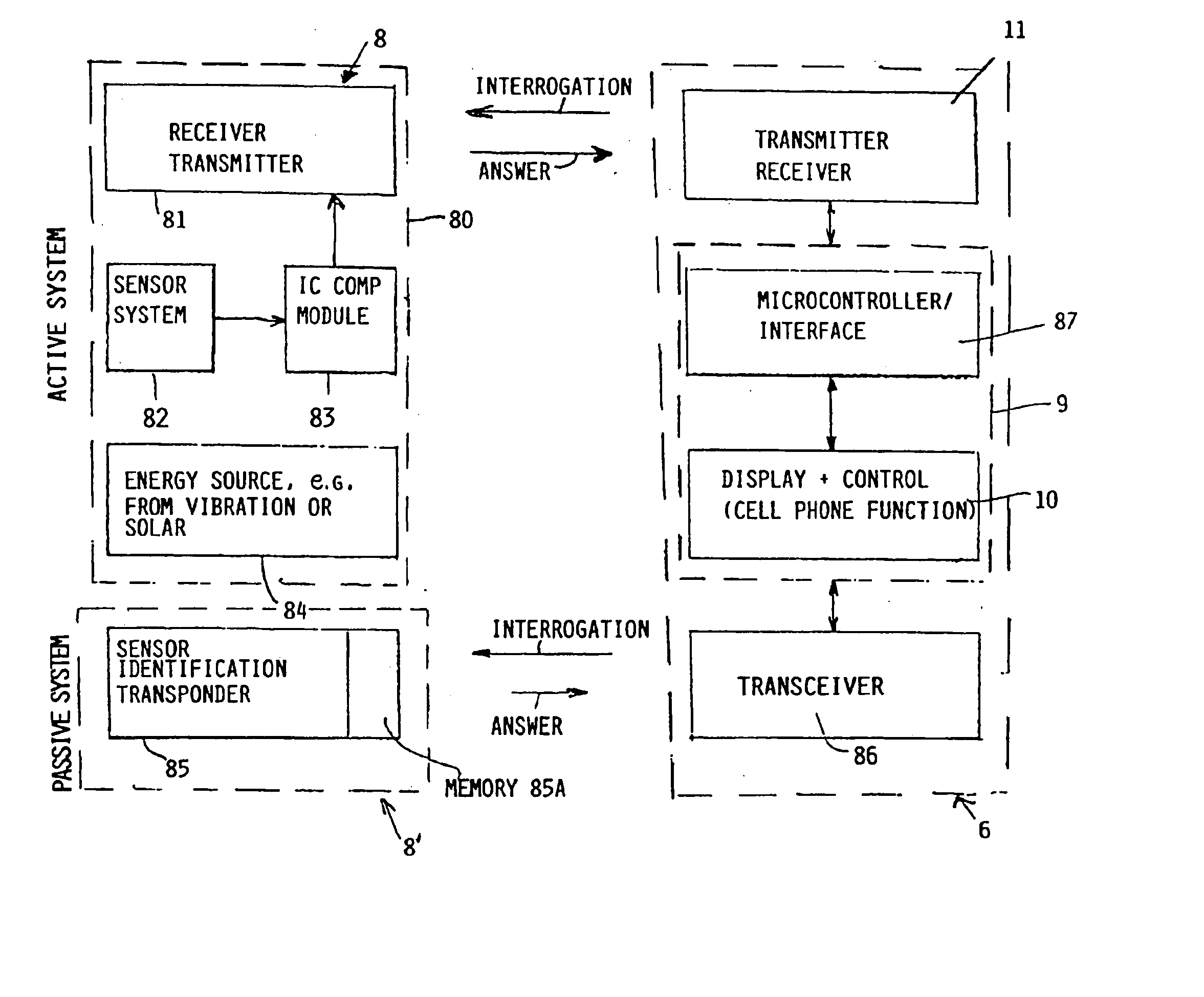

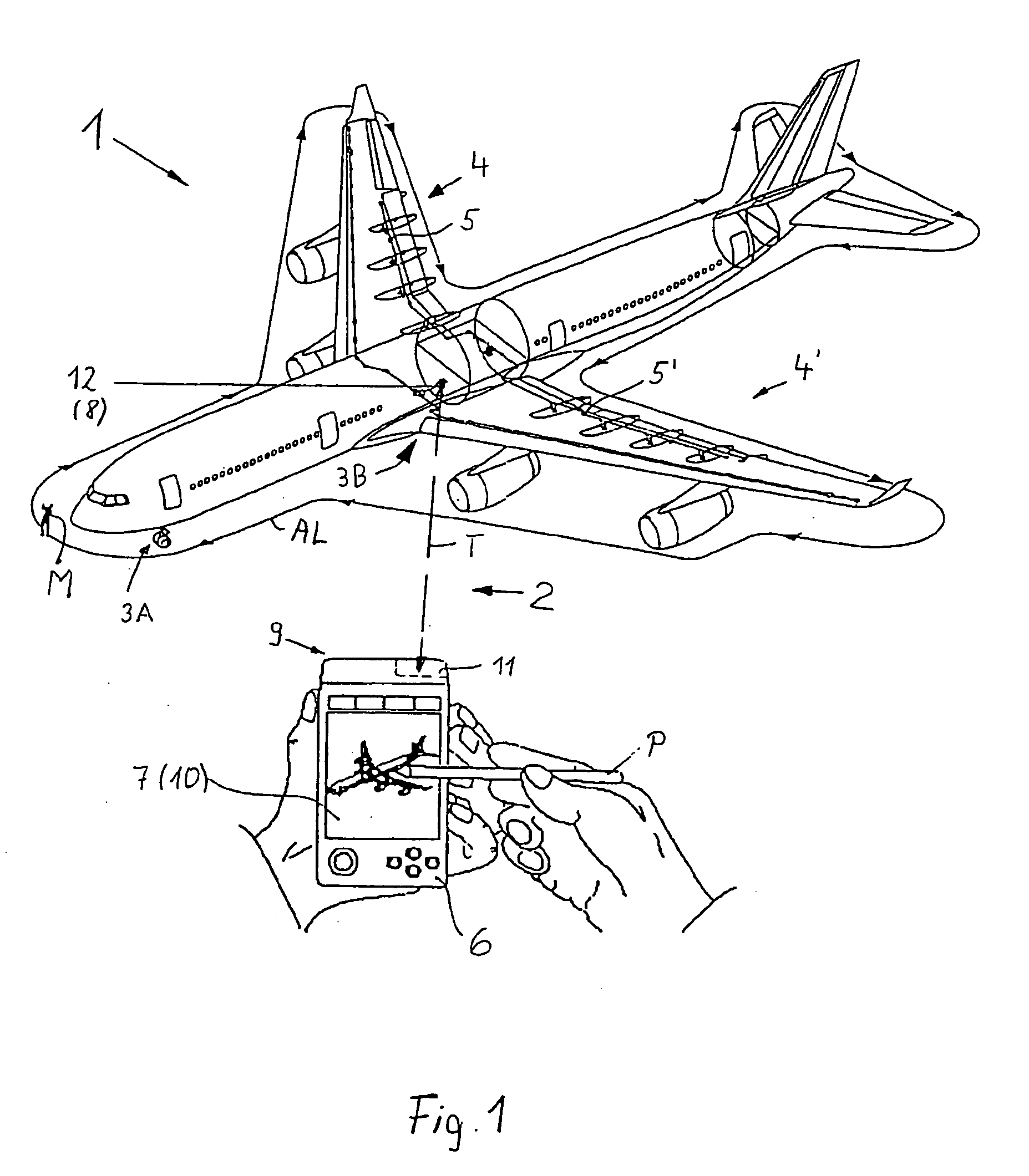

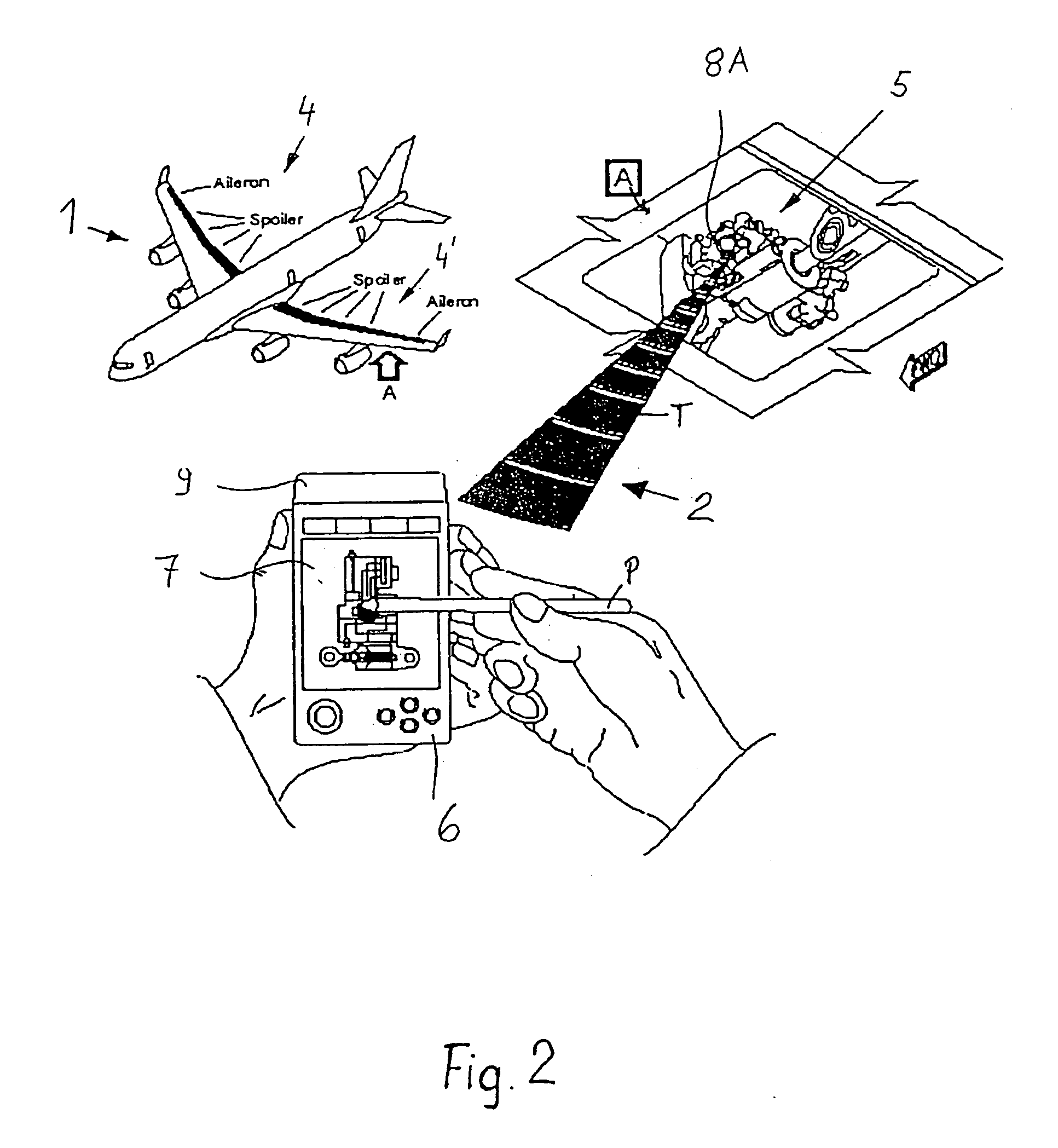

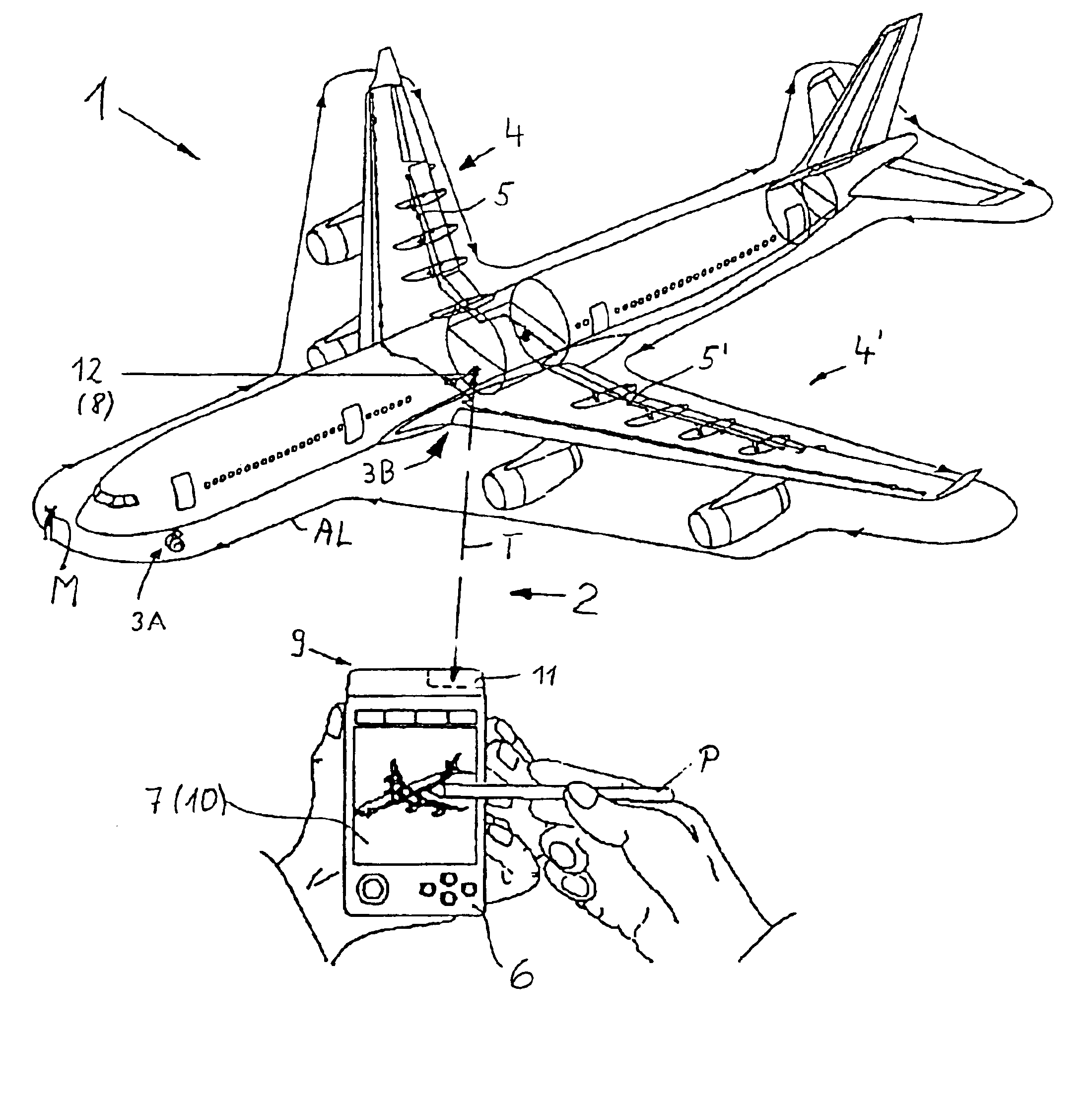

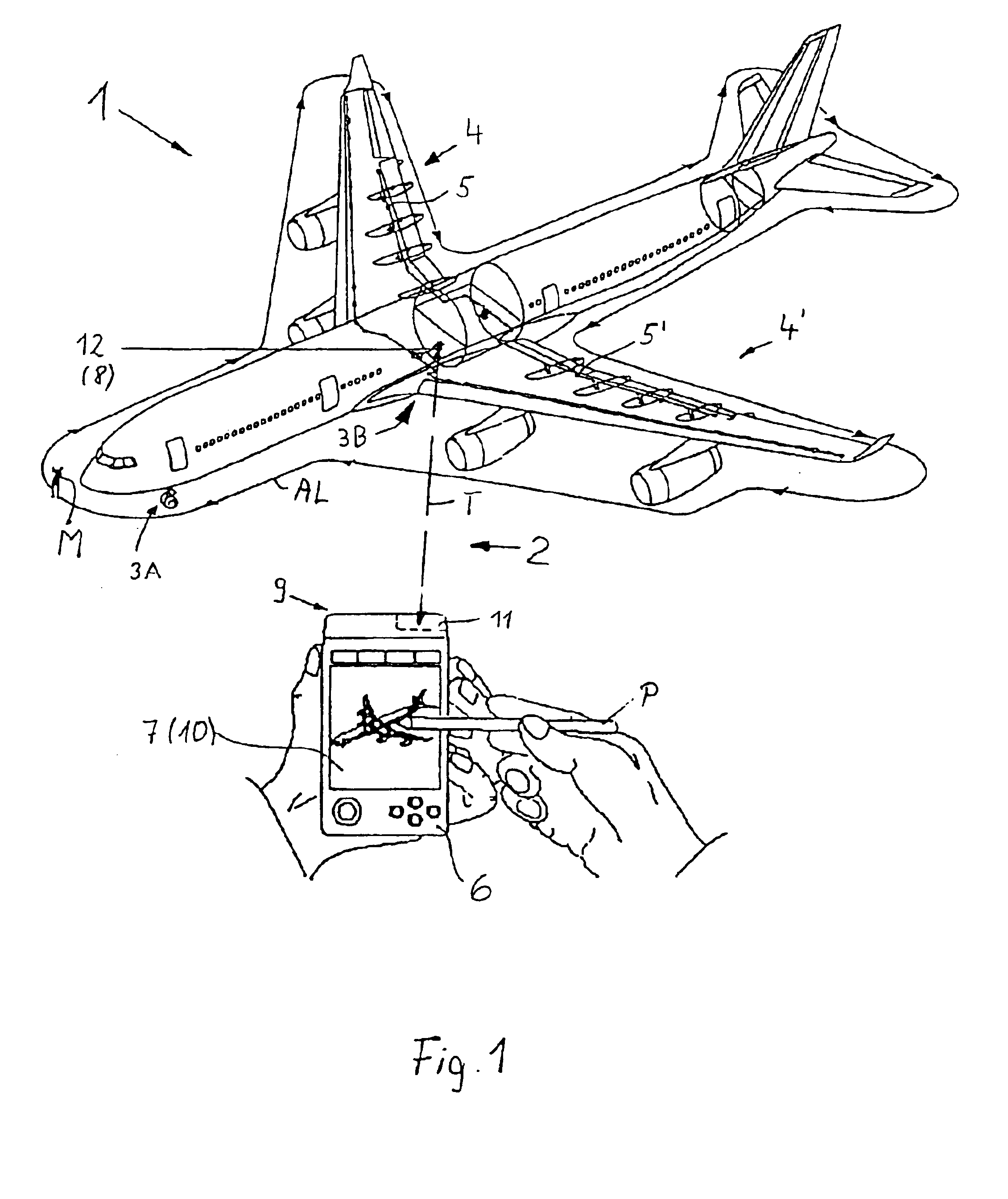

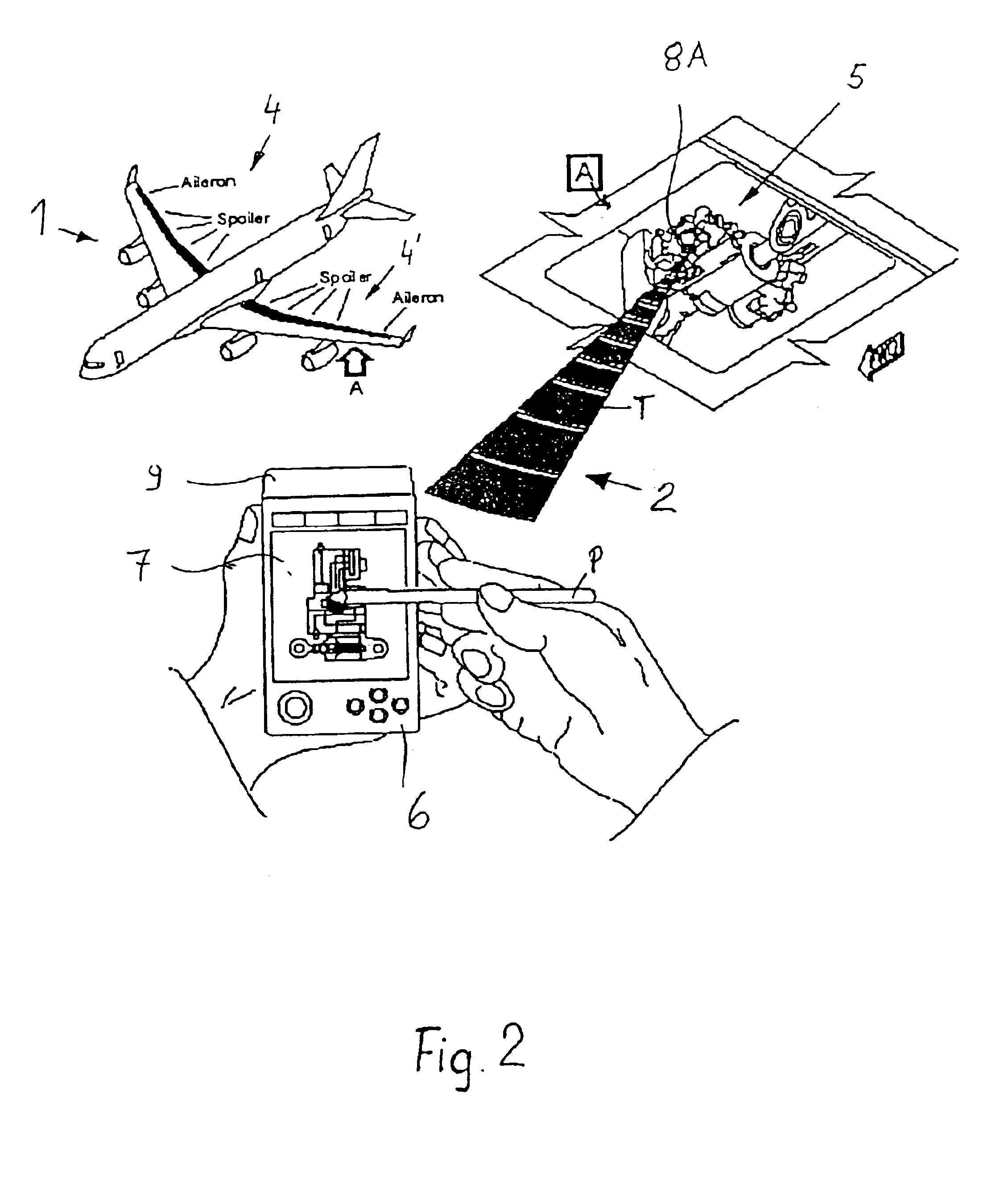

System and method for diagnosing aircraft components for maintenance purposes

InactiveUS20030083794A1Easy maintenanceAvoid replacementVehicle testingRegistering/indicating working of vehiclesDiagnostic systemSignal processing

Aircraft maintenance and repair work is facilitated, especially for a commercial aircraft, by a diagnostic system and method, wherein an aircraft component or assembly of components is monitored by at least one sensor which produces and preferably also stores component status information. Respective status information signals are transmitted, preferably in a wireless manner, from a transmitter of the sensor to a receiver of a signal processing unit which provides status information on a display screen. The status information signals are preferably processed and evaluated with reference to rated maintenance and repair reference information to provide instructions as to what needs to be done where and when for a maintenance or repair. The sensor or sensors may operate during flight and the respective stored information is then processed and used on the ground.

Owner:AIRBUS OPERATIONS GMBH

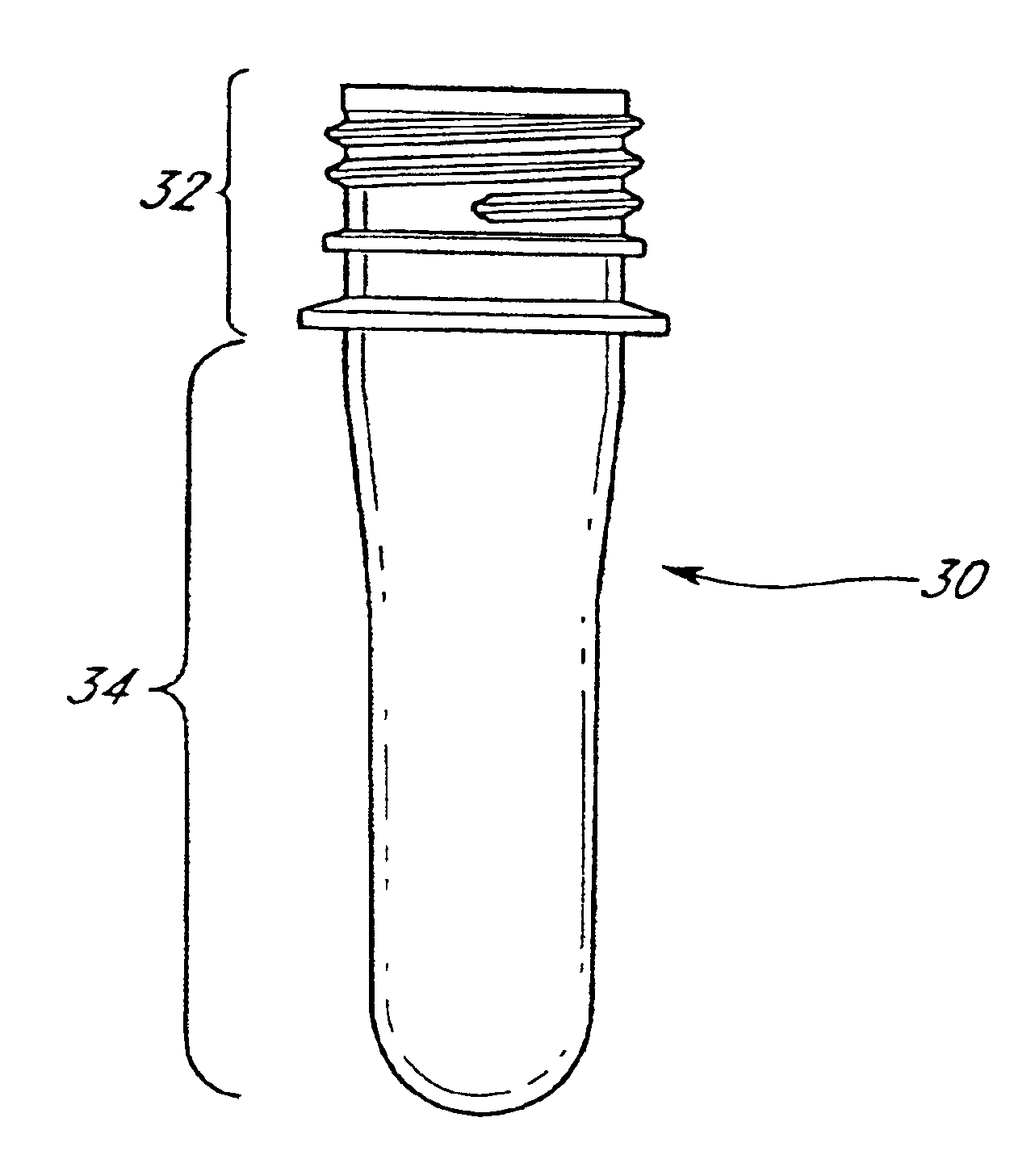

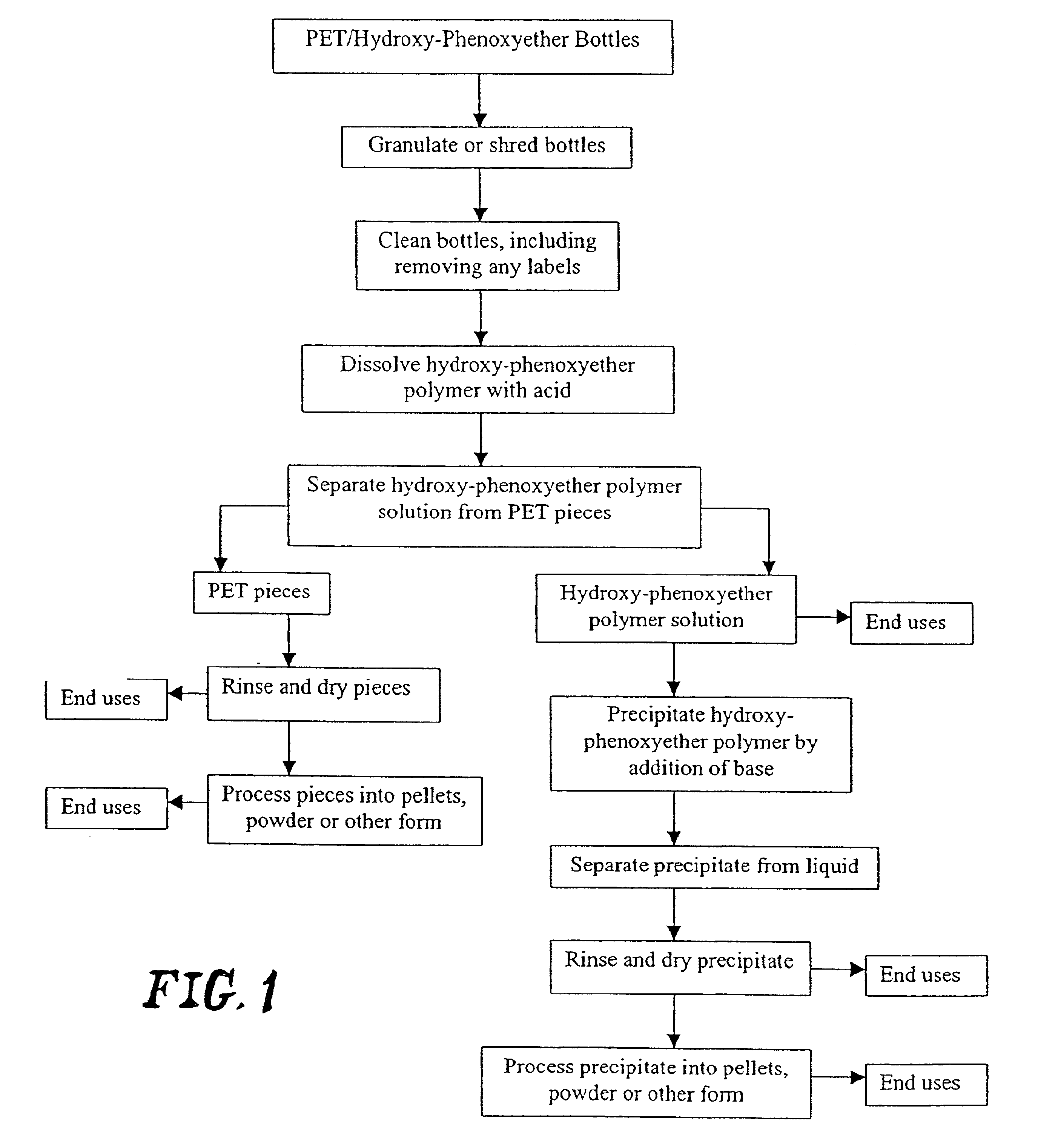

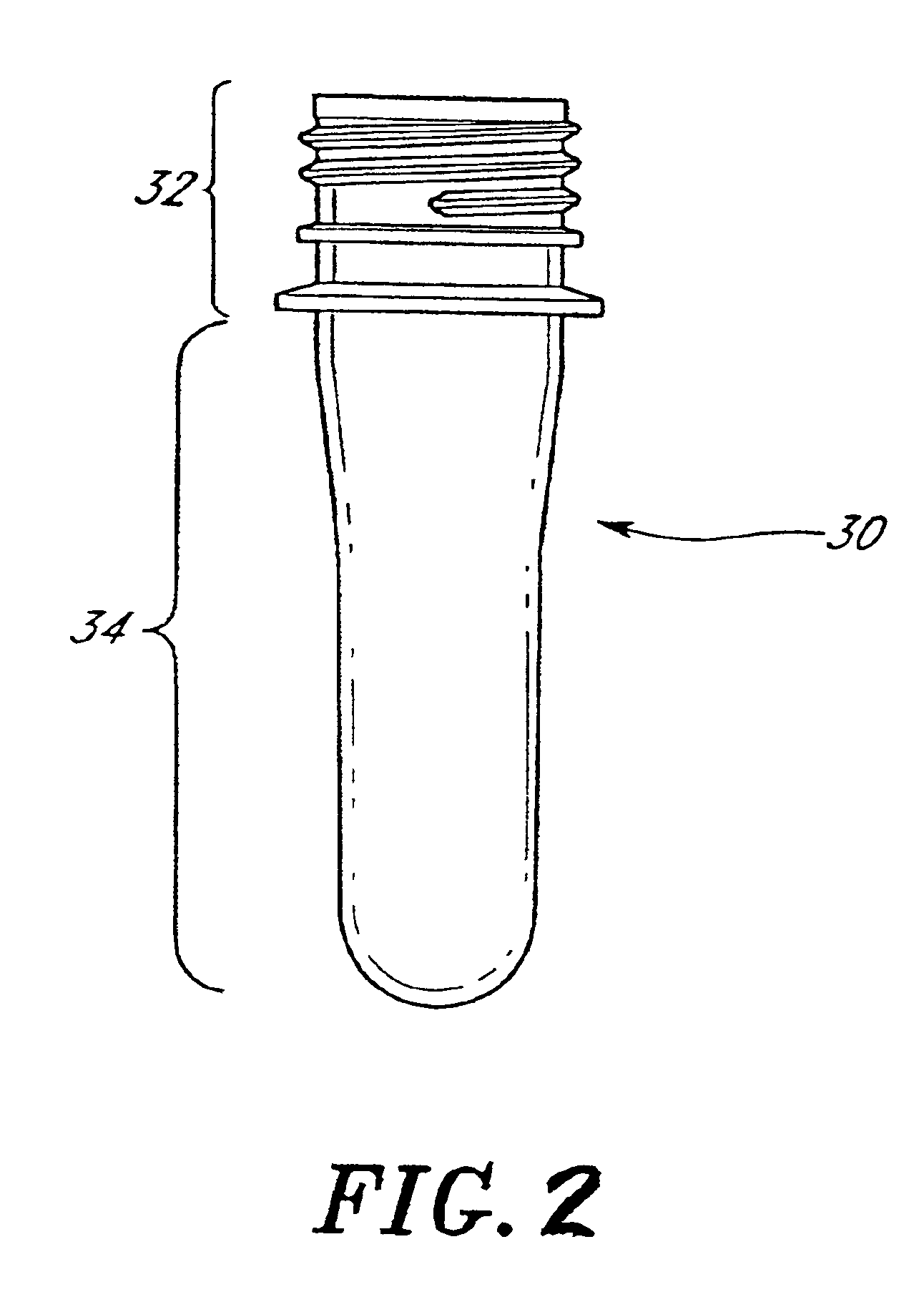

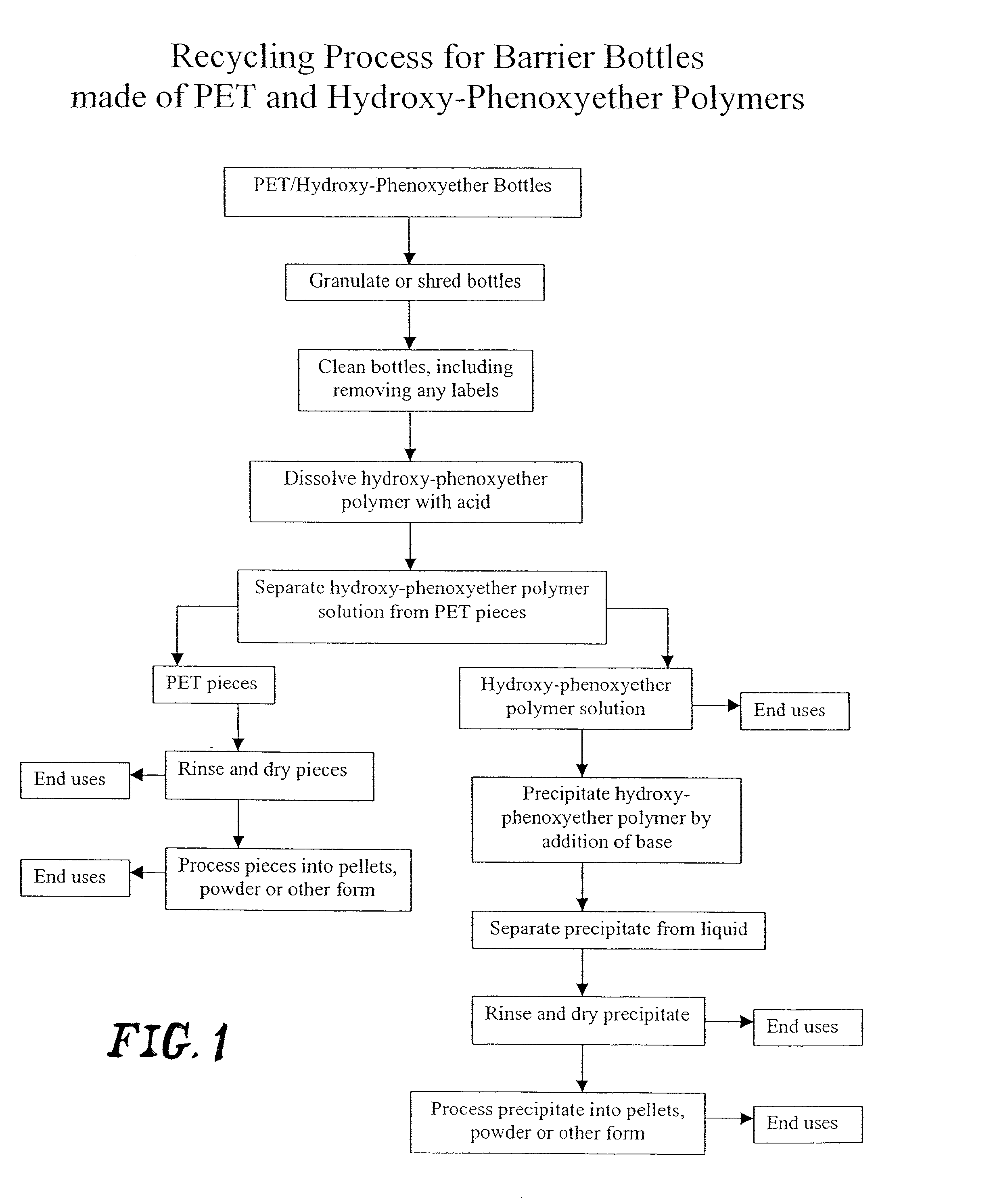

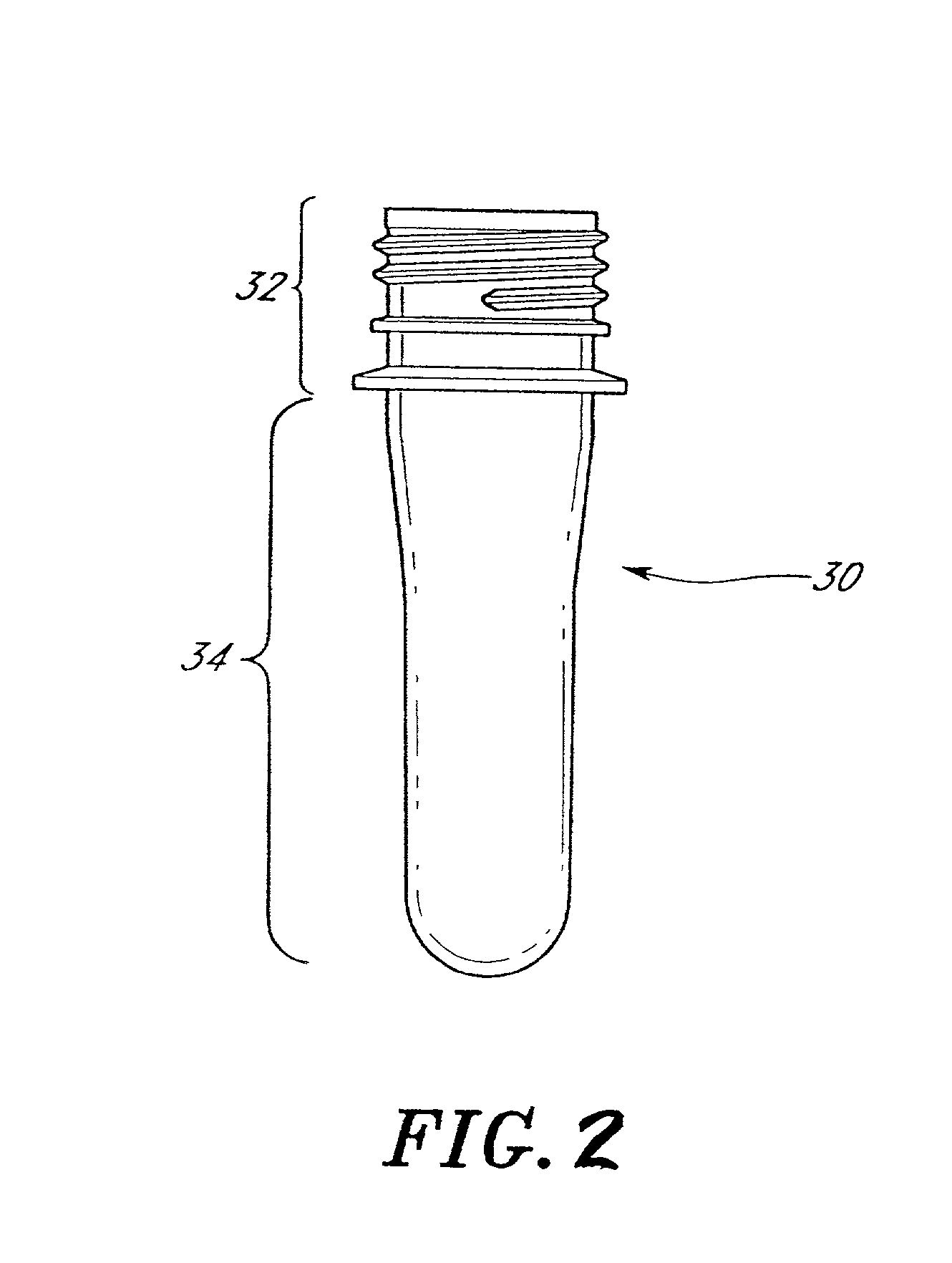

Multilayer containers and preforms having barrier properties utilizing recycled material

InactiveUS6808820B2Reduce the amount requiredMaintain good propertiesSynthetic resin layered productsDomestic articlesPolyesterPolyethylene terephthalate glycol

Preferred embodiments relate to methods and apparatus for making articles made of polyester, preferably virgin polyethylene terephthalate (PET), having coated directly to at least one of the surfaces thereof one or more layers of recycled or post-consumer PET and one or more layers of a material with good gas-barrier characteristics, preferably silicon oxide. Preferably, the recycled PET layer comprises about 25% to about 50% of the entire material content. Preferably the articles take the form of preforms and the containers are blow-molded therefrom and the barrier layer is subsequently applied. The preferred barrier materials have a lower permeability to oxygen and carbon dioxide than PET. In addition, the neck of the preforms and bottles is at least partially in the crystalline state and the body is primarily in the amorphous or semi-crystalline state. This structure in a preform enables the preform to be easily blow molded by virtue of the amorphous material in the body, while being able to have dimensional stability in hot-fill applications.

Owner:CONCENTRATE MFG OF IRELAND

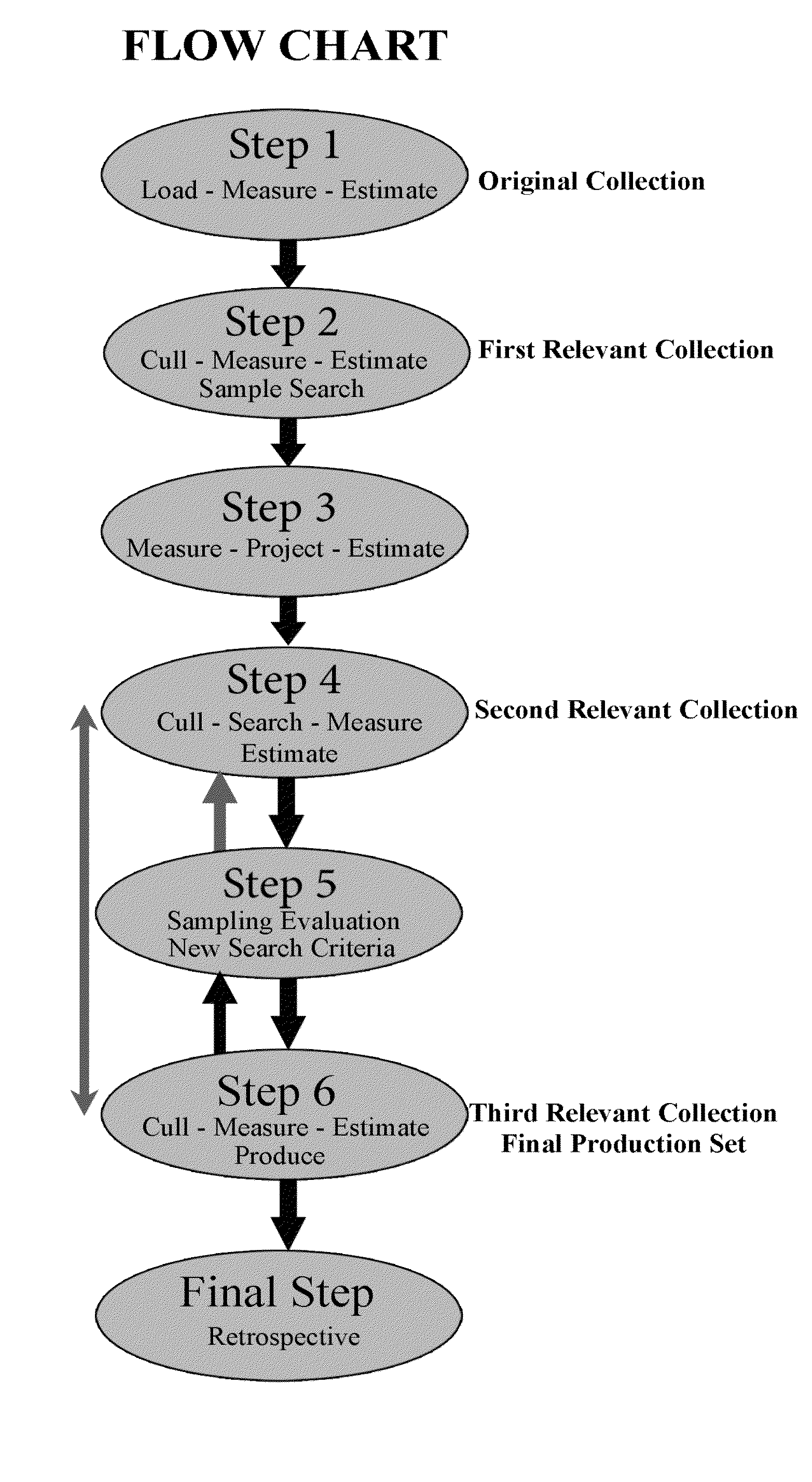

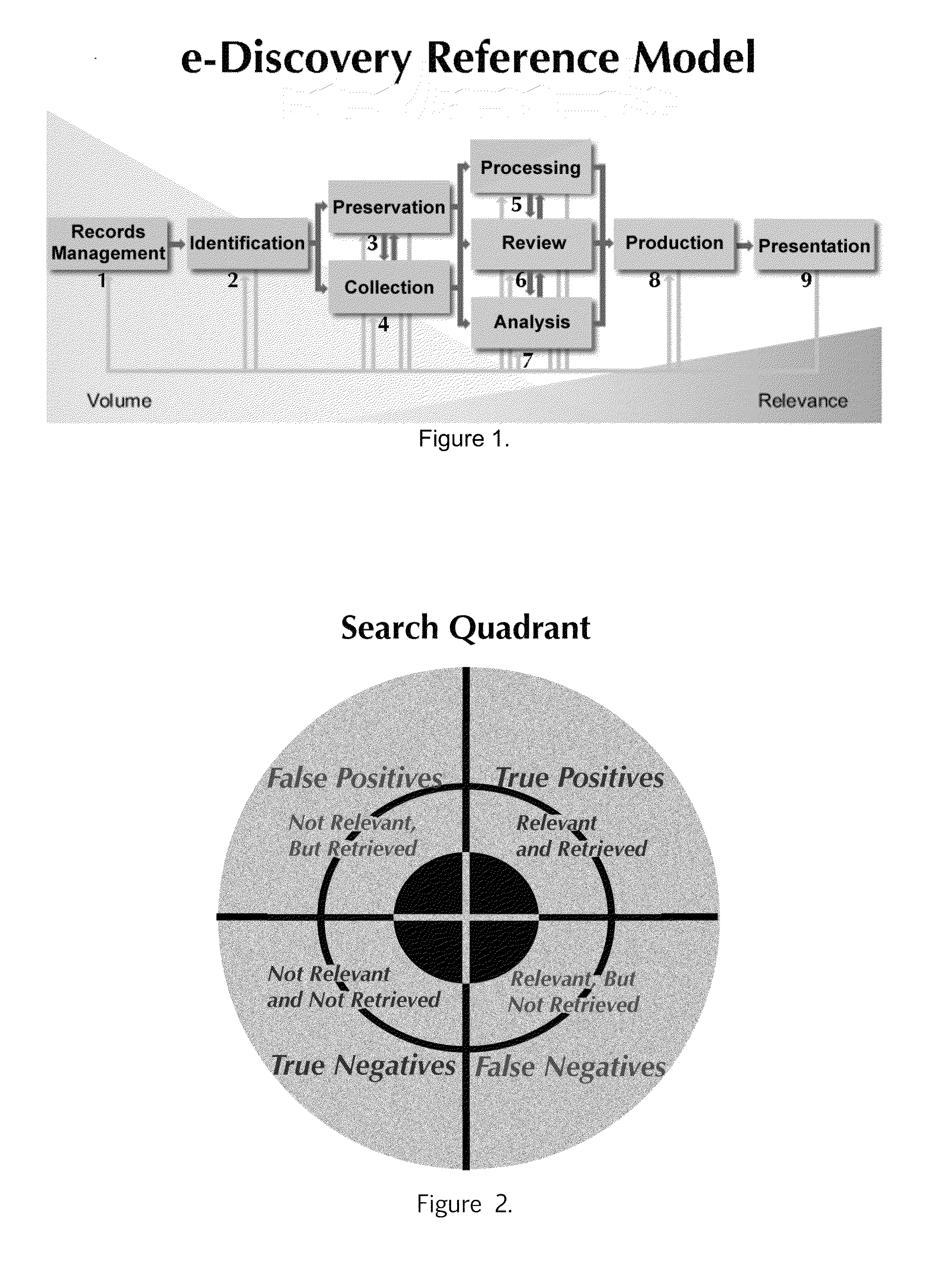

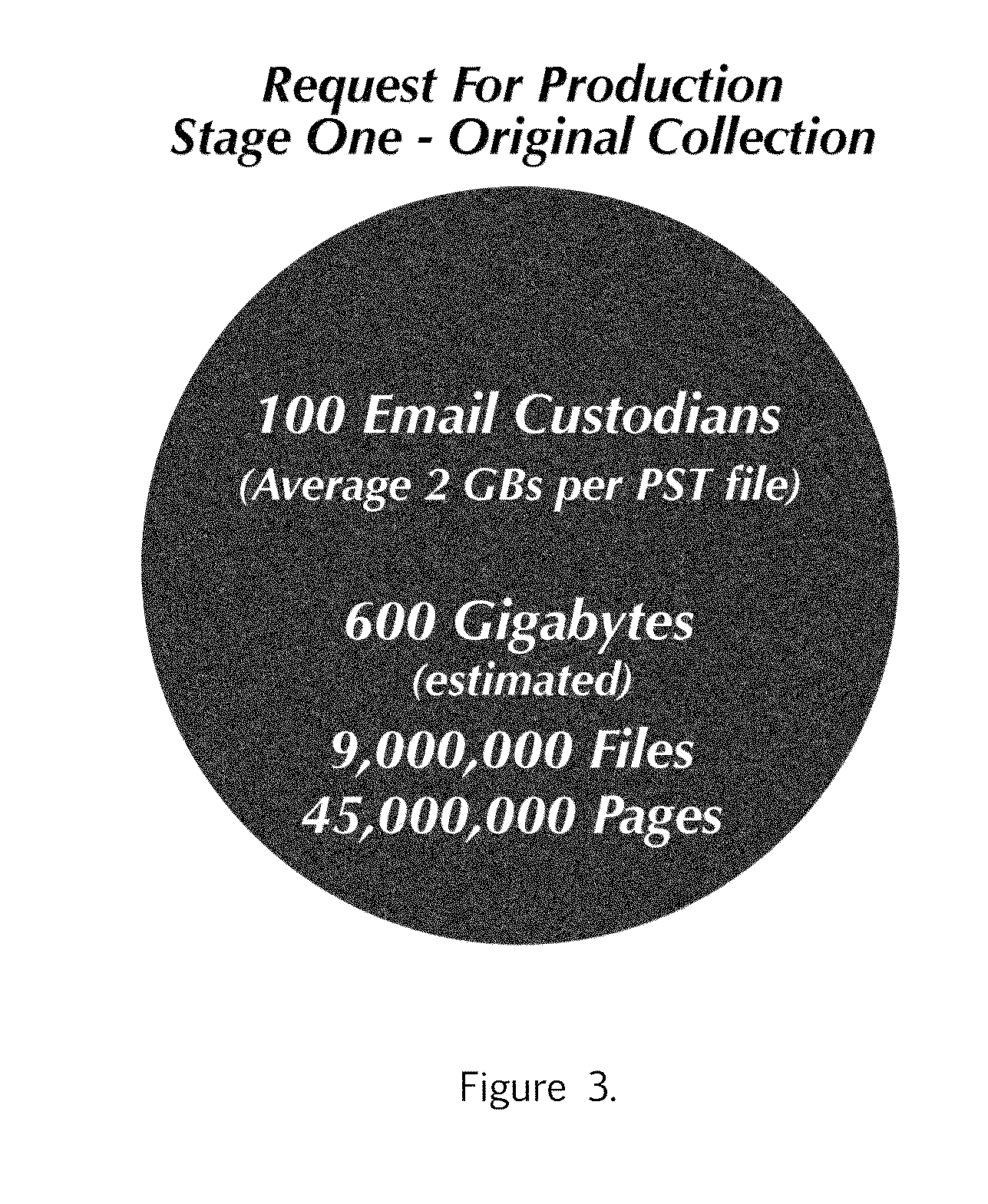

System and method for establishing, managing, and controlling the time, cost, and quality of information retrieval and production in electronic discovery

InactiveUS20100205020A1Reduce the burden onImprove and facilitate protection availablePoint-of-sale network systemsSpecial data processing applicationsRelevant informationElectronic discovery

A cost and quality controlled system for transforming collections of computer files and other electronically stored information by iterative culling and sorting so that production of relevant information can be made within estimated time and costs ranges and precision and recall ratios.

Owner:LOSEY RALPH C

Multilayer containers and preforms having barrier properties utilizing recycled material

InactiveUS20020090473A1Reduce the amount requiredMaintain good propertiesMouldsConfectioneryPolyesterPolyethylene terephthalate glycol

Preferred embodiments relate to methods and apparatus for making articles made of polyester, preferably virgin polyethylene terephthalate (PET), having coated directly to at least one of the surfaces thereof one or more layers of recycled or post-consumer PET and one or more layers of a material with good gas-barrier characteristics, preferably silicon oxide. Preferably, the recycled PET layer comprises about 25% to about 50% of the entire material content. Preferably the articles take the form of preforms and the containers are blow-molded therefrom and the barrier layer is subsequently applied. The preferred barrier materials have a lower permeability to oxygen and carbon dioxide than PET. In addition, the neck of the preforms and bottles is at least partially in the crystalline state and the body is primarily in the amorphous or semi-crystalline state. This structure in a preform enables the preform to be easily blow molded by virtue of the amorphous material in the body, while being able to have dimensional stability in hot-fill applications.

Owner:CONCENTRATE MFG OF IRELAND

System and method for diagnosing aircraft components for maintenance purposes

InactiveUS20040162651A1Easy maintenanceAvoid replacementVehicle testingRegistering/indicating working of vehiclesDiagnostic systemSignal processing

Aircraft maintenance and repair work is facilitated, especially for a commercial aircraft, by a diagnostic system and method, wherein an aircraft component or assembly of components is monitored by at least one sensor which produces and preferably also stores component status information. Respective status information signals are transmitted, preferably in a wireless manner, from a transmitter of the sensor to a receiver of a signal processing unit which provides status information on a display screen. The status information signals are preferably processed and evaluated with reference to rated maintenance and repair reference information to provide instructions as to what needs to be done where and when for a maintenance or repair. The sensor or sensors may operate during flight and the respective stored information is then processed and used on the ground.

Owner:AIRBUS OPERATIONS GMBH

Access system for an access network

ActiveUS7551576B2Improve facilitiesReasonable priceAssess restrictionTelephonic communicationAccess networkRadio access network

The present invention relates to a method, system and device for providing access from a terminal device (1) to a second access network (8). To achieve this an access network device (3) belonging to an first access network (12) stores a second access network information comprising information of second access network(s) (8) accessible from the first access network (12). Communication means between the terminal device and and the first access network are established and the second access network information is delivered to the terminal device (1). The terminal device (1) accesses the second access network (8) via the first access network (12). The accessing is done based on the second access network information delivered to said terminal device (1). Thereby, service functions of the second access network, e.g. UMTS services, can be distributed via any other access network and existing broadband or high-speed access networks can be implemented in new cellular network structures. A huge capacity enhancement can thus be offered to the network operators of the cellular network without any standardization effort or license fee and at very small investment and maintenance costs.

Owner:NOKIA TECHNOLOGLES OY

Biaxially oriented polylactic acid film with improved heat seal properties

ActiveUS20100323196A1Lower heat seal initiation temperatureHeat seal rangeSynthetic resin layered productsLaminationPolybutylene adipate co-terephthalatePolylactic acid

Multi-layer biaxially oriented polylactic acid (BOPLA) film with a novel formulation improves the heat seal initiation temperature and heat seal performance of BOPLA films while maintaining good optical clarity. The film may include a core layer including polylactic acid base polymer resin, and a heat sealable layer including amorphous polylactic acid base polymer and a modifier comprising polycaprolactone or poly(butylene-adipate-co-butylene terephthalate).

Owner:TORAY PLASTICS AMERICA

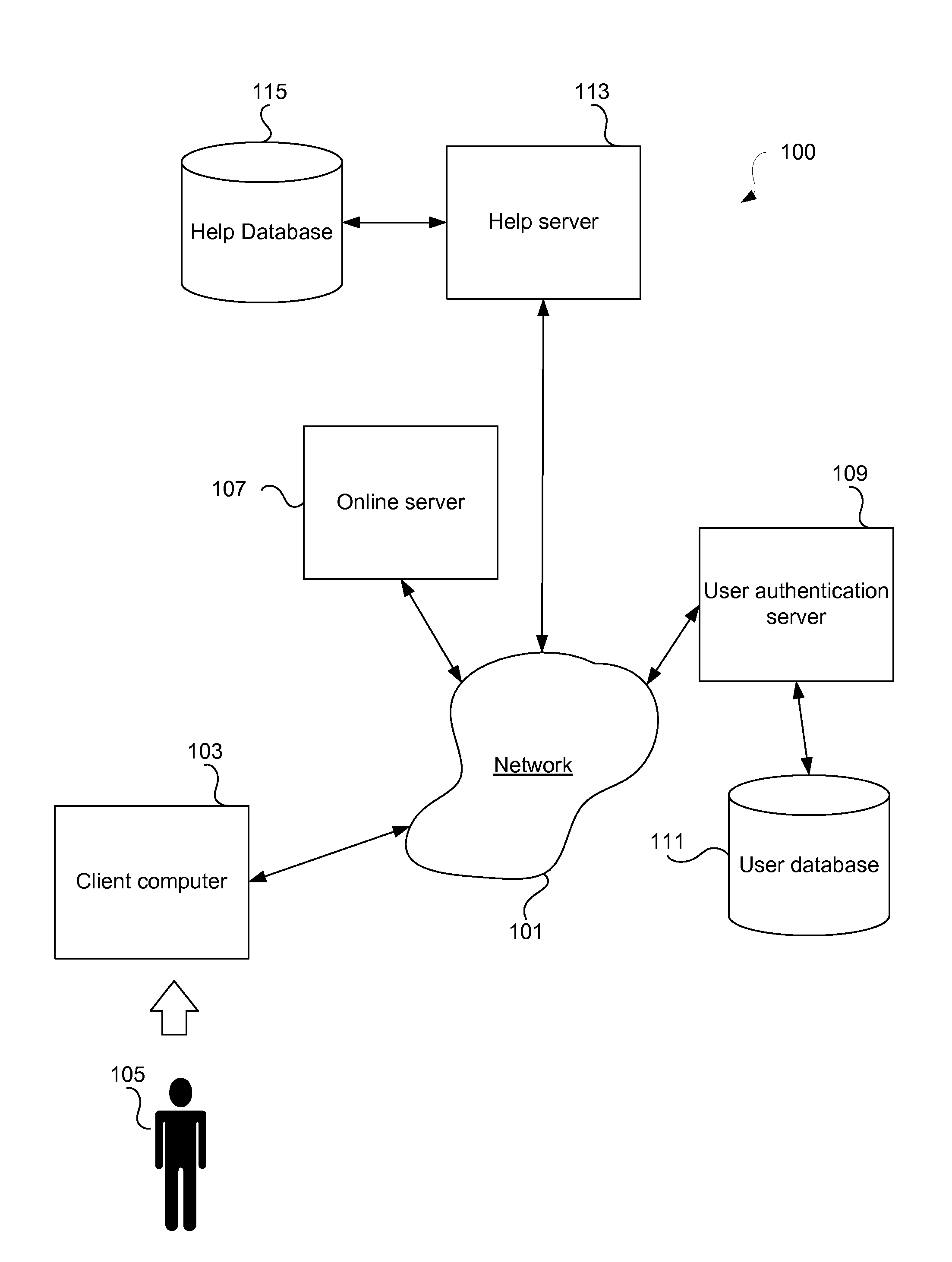

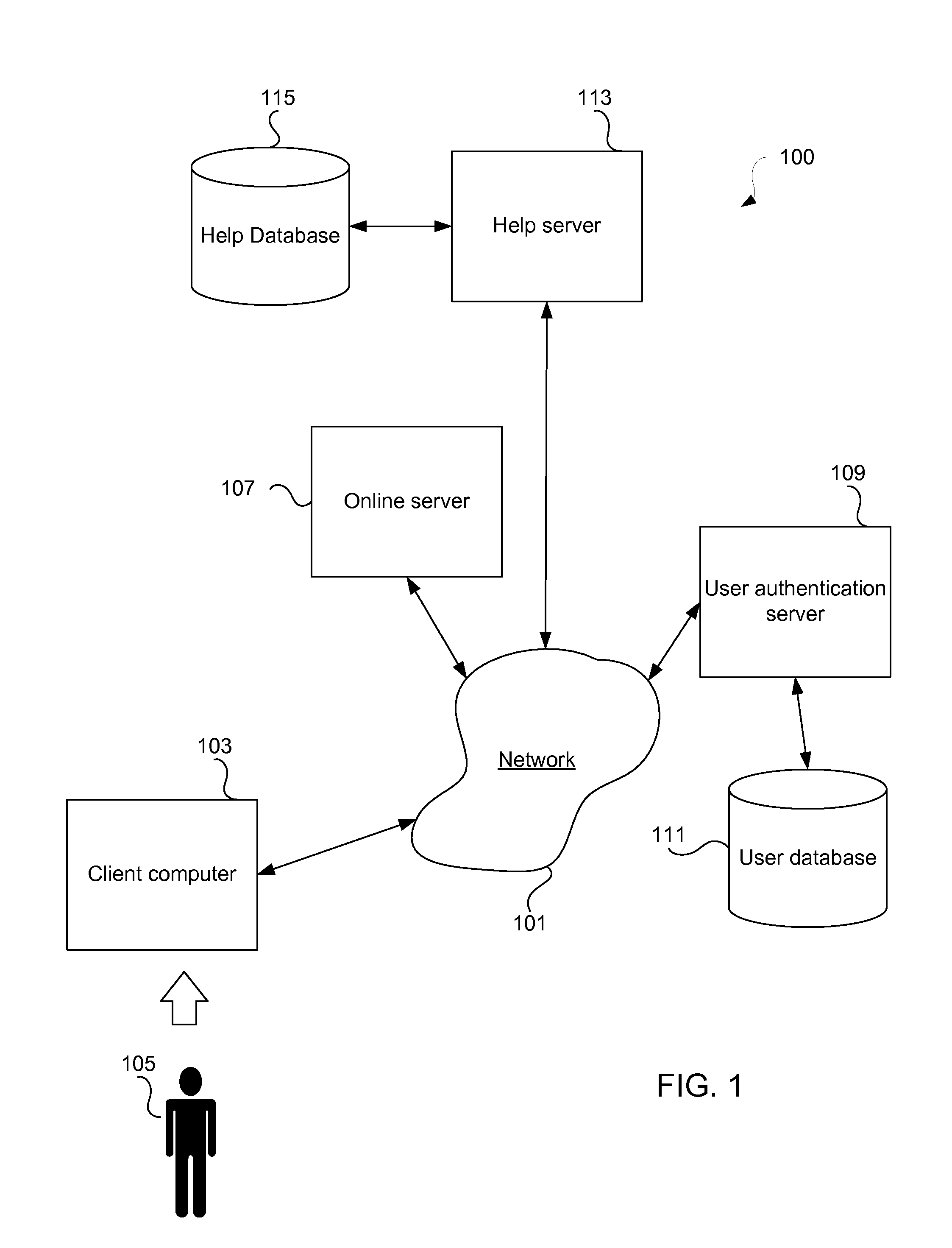

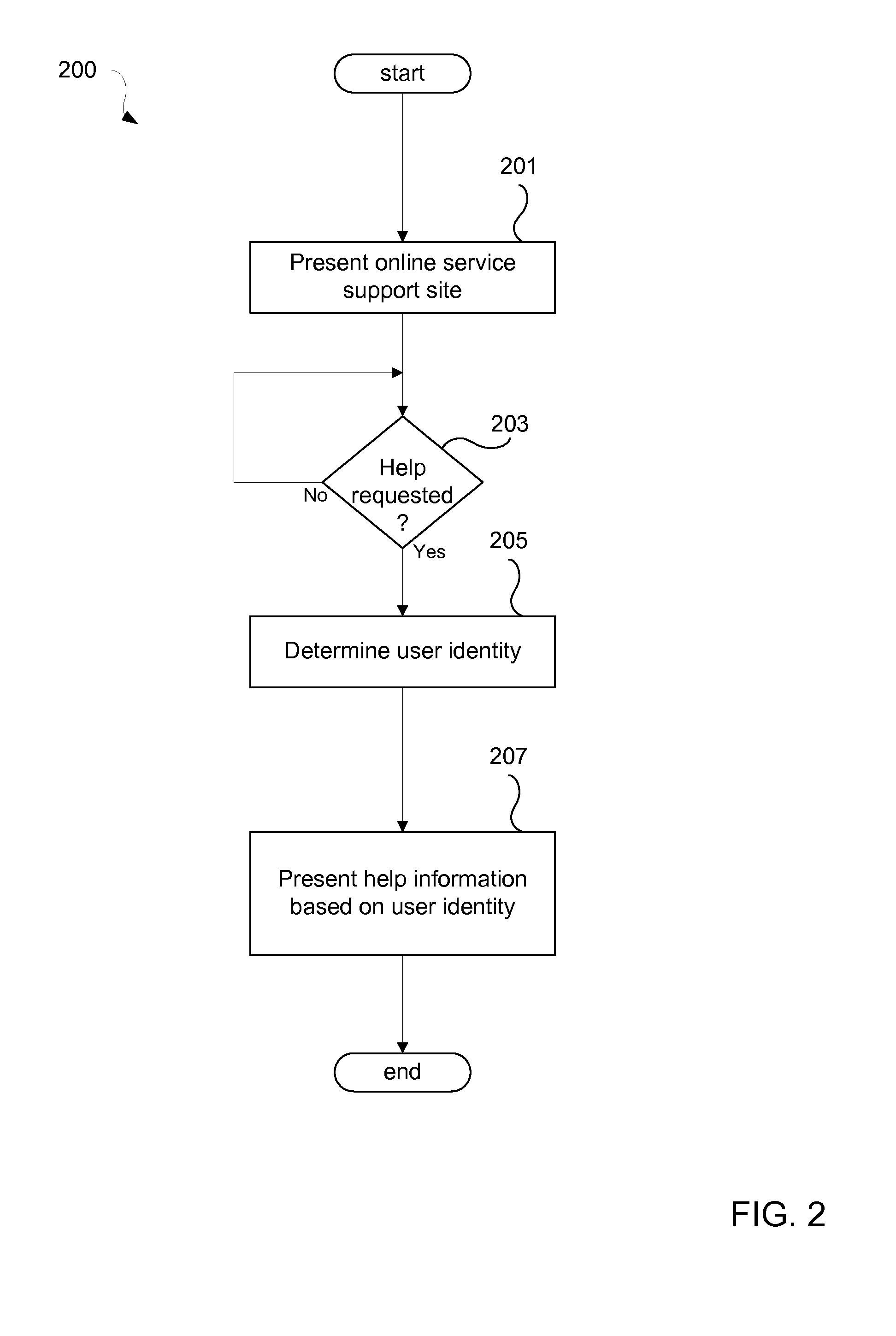

Contextual and customized help information

InactiveUS20090183237A1Easy to createMaintenance costDigital data processing detailsUser identity/authority verificationGraphicsGraphical user interface

Improved methods, systems, computer readable media and graphical user interfaces for automated customer support are disclosed. Automated customer support can be computer-implemented and can provide help information to users. The help information can be context sensitive and / or customized. For example, the help information can be dependent on (i) context of a help request and / or (ii) a particular user. Further, if a user requires more help than the automated customer support can provide, then the user can be provided with the opportunity to contact a customer support agent for additional assistance.

Owner:APPLE INC

System and method for diagnosing aircraft components for maintenance purposes

InactiveUS6941204B2Maintenance costLow costVehicle testingRegistering/indicating working of vehiclesDiagnostic systemSignal processing

Owner:AIRBUS OPERATIONS GMBH

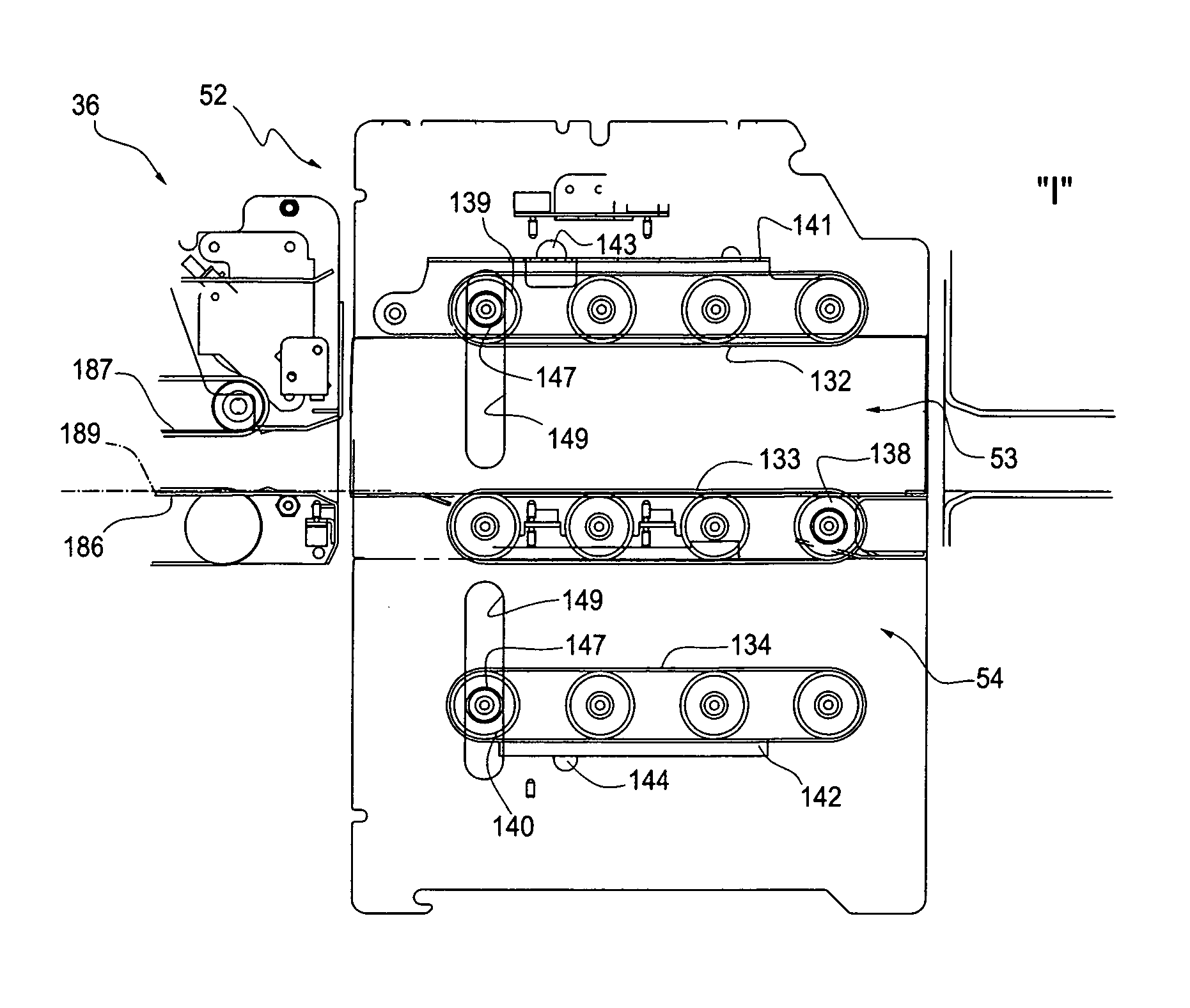

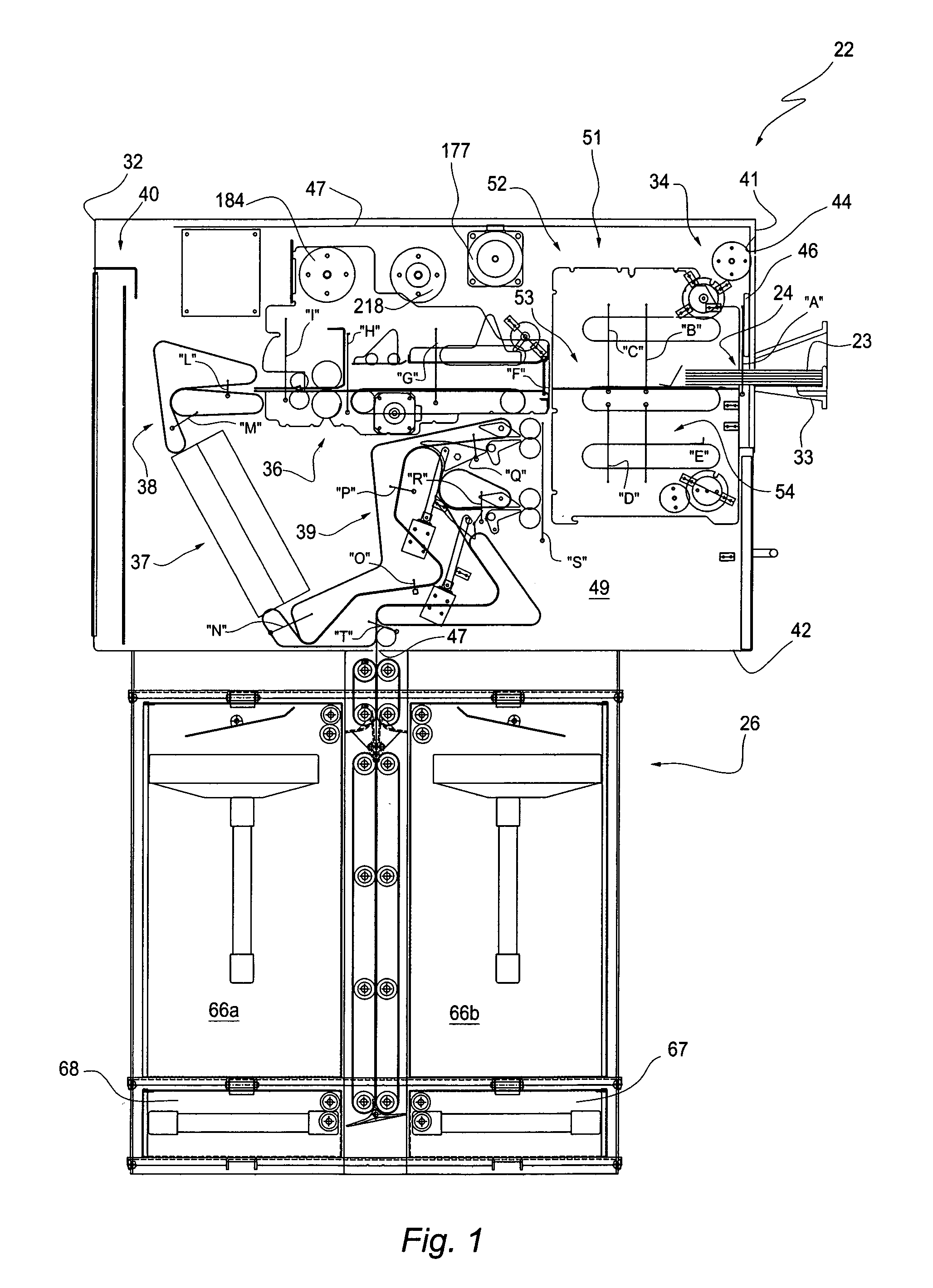

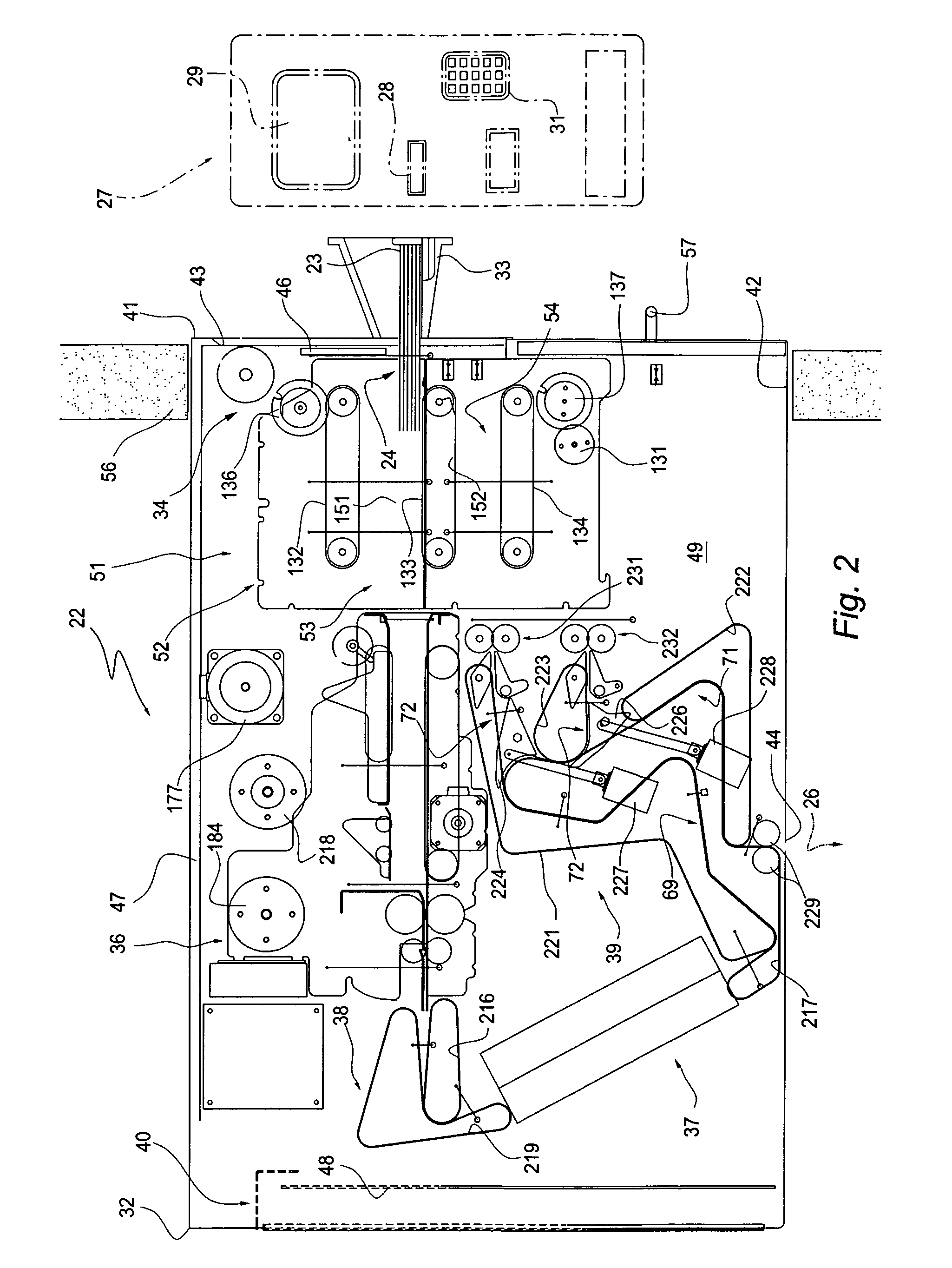

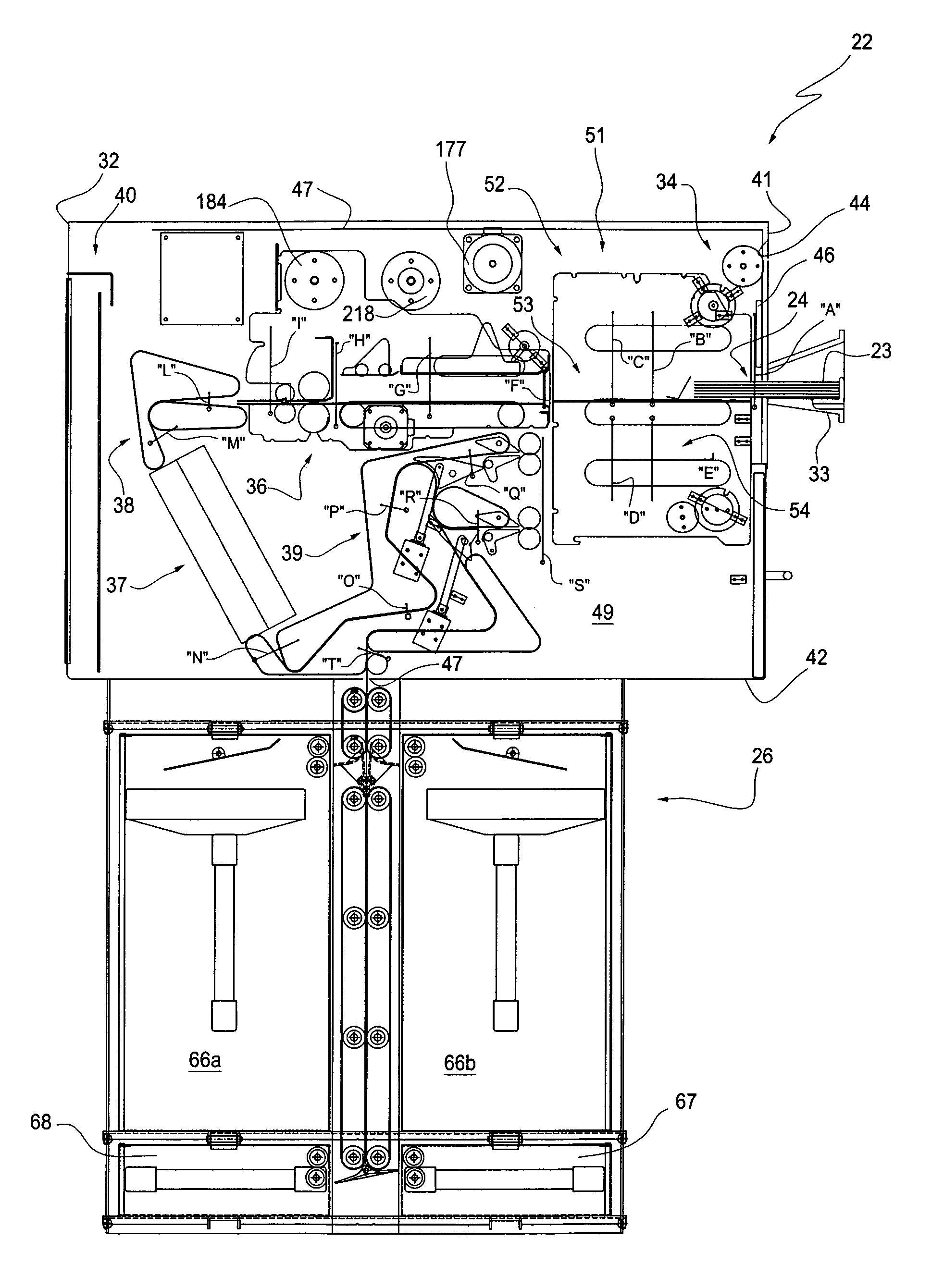

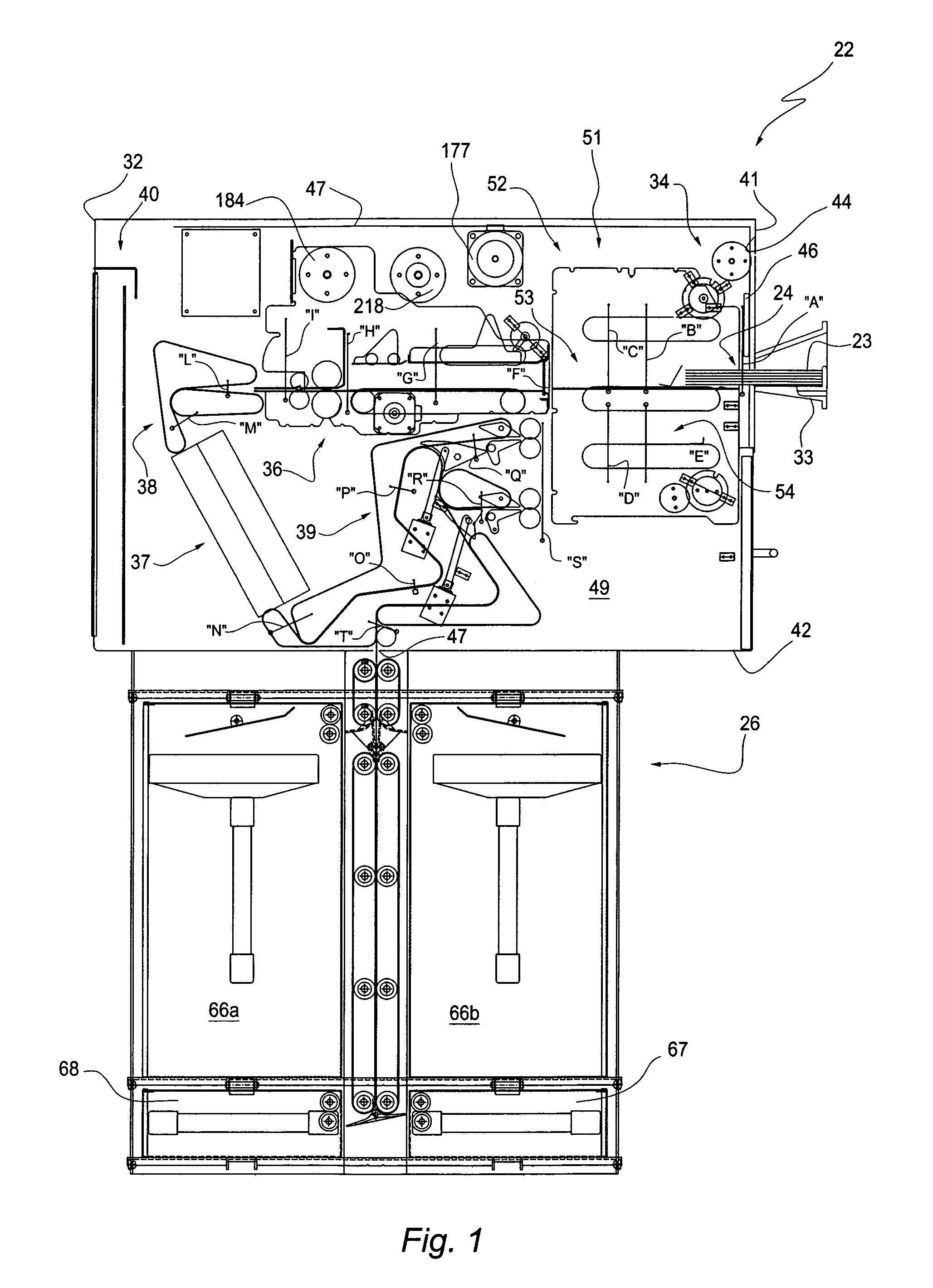

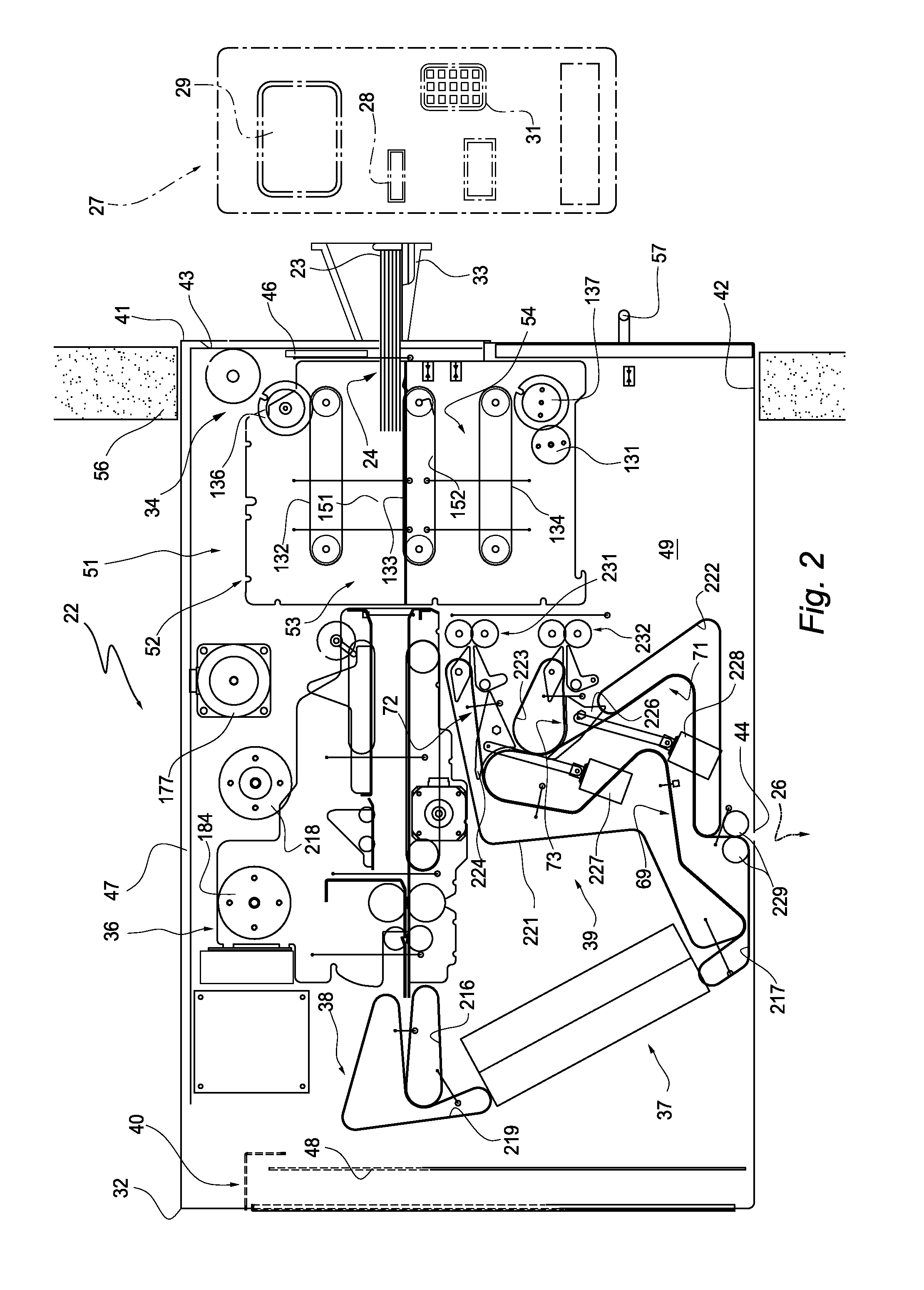

Equipment for the automatic deposit of banknotes

ActiveUS20050127590A1Low costEasy to addFunction indicatorsCoin/currency accepting devicesEngineering

An equipment (22) for the automatic deposit of banknotes (23) comprising a transaction port (33) for receiving a stack (24) of banknotes, a separating device (36) for separating the constituting sheets of the stack (24), a validation device (37) for discriminating the constituting sheets as recognized banknotes and constituting sheets not recognized, a transport mechanism (38, 39) servo-dependent on the validation device to drag said constituting sheets along differentiated paths (72, 73) for the recognized banknotes and the constituting sheets not recognized, and a box assembly (51) adjacent to the transaction port. The box assembly (51) includes two storage boxes (53, 54) and is shiftable among at least three different positions. The three positions are associated with predetermined conditions of communication of the storage boxes (53, 54) with the transaction port (33), the separating device (36) and the transport mechanism (38, 39) to receive the stack, transfer the stack to the separating device, temporarily store as banknote sub-stack and as discard sub-stack the recognized banknotes and, respectively, the constituting sheets not recognized and to return, by request, the discard sub-stack and the banknote sub-stack.

Owner:CTS CASHPRO

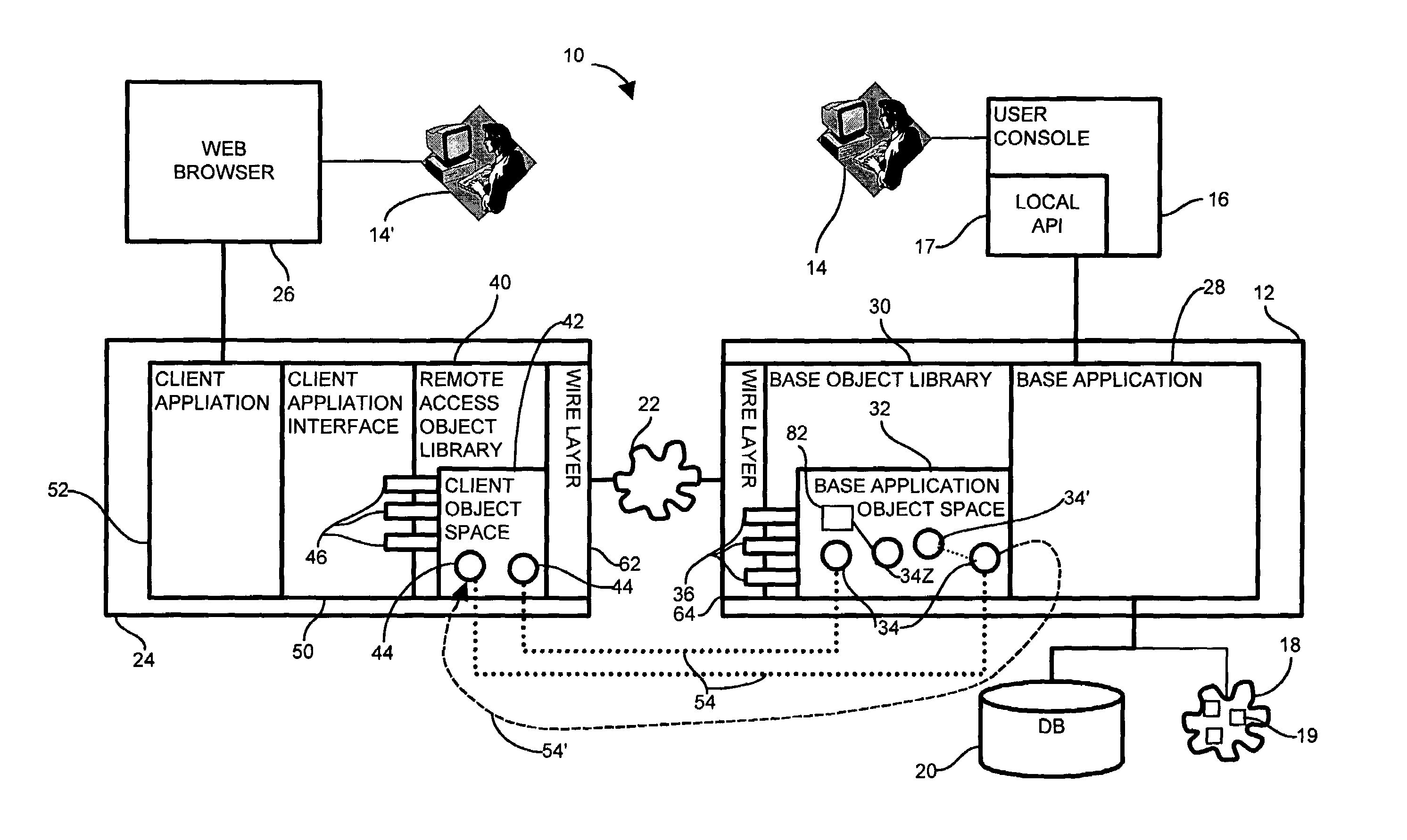

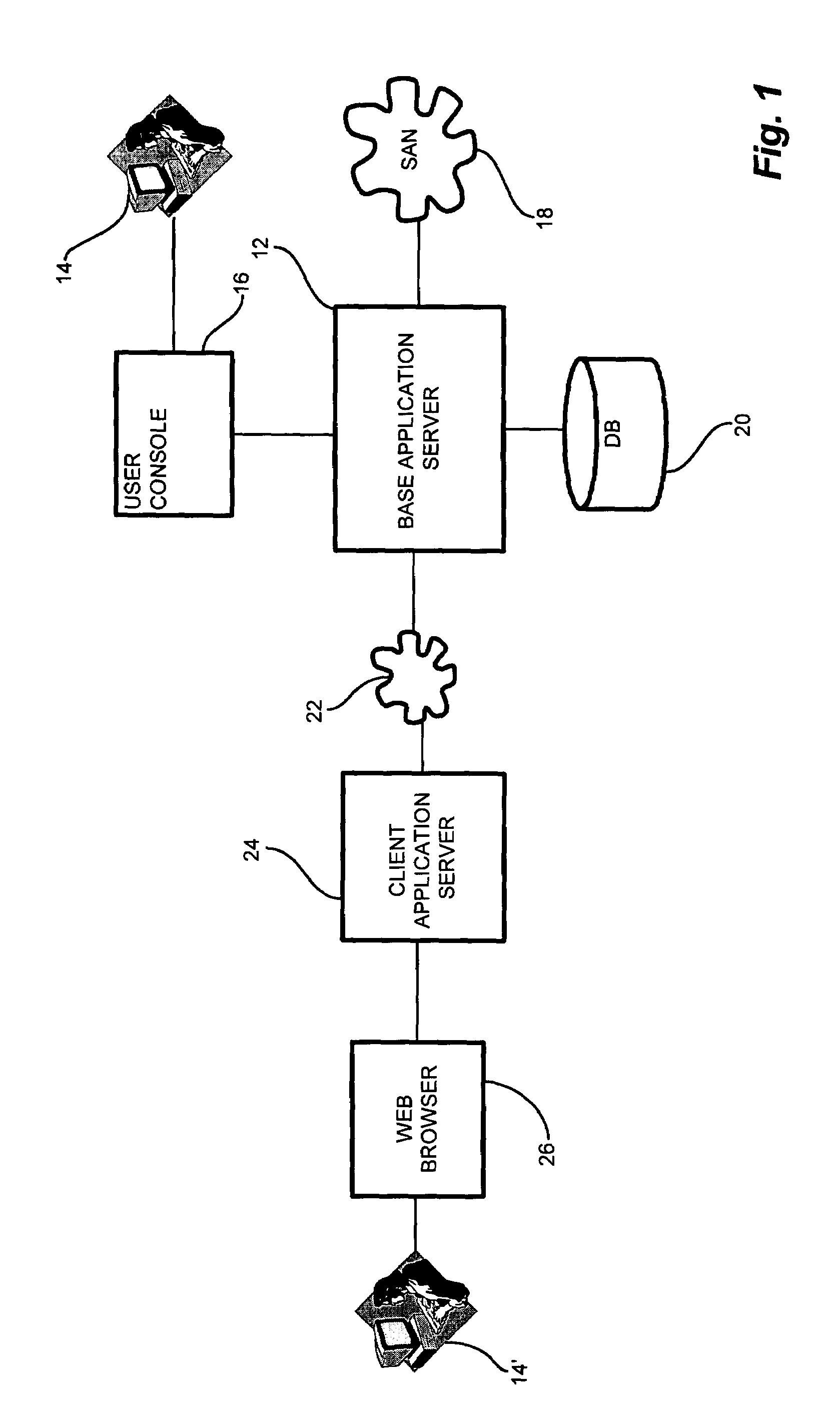

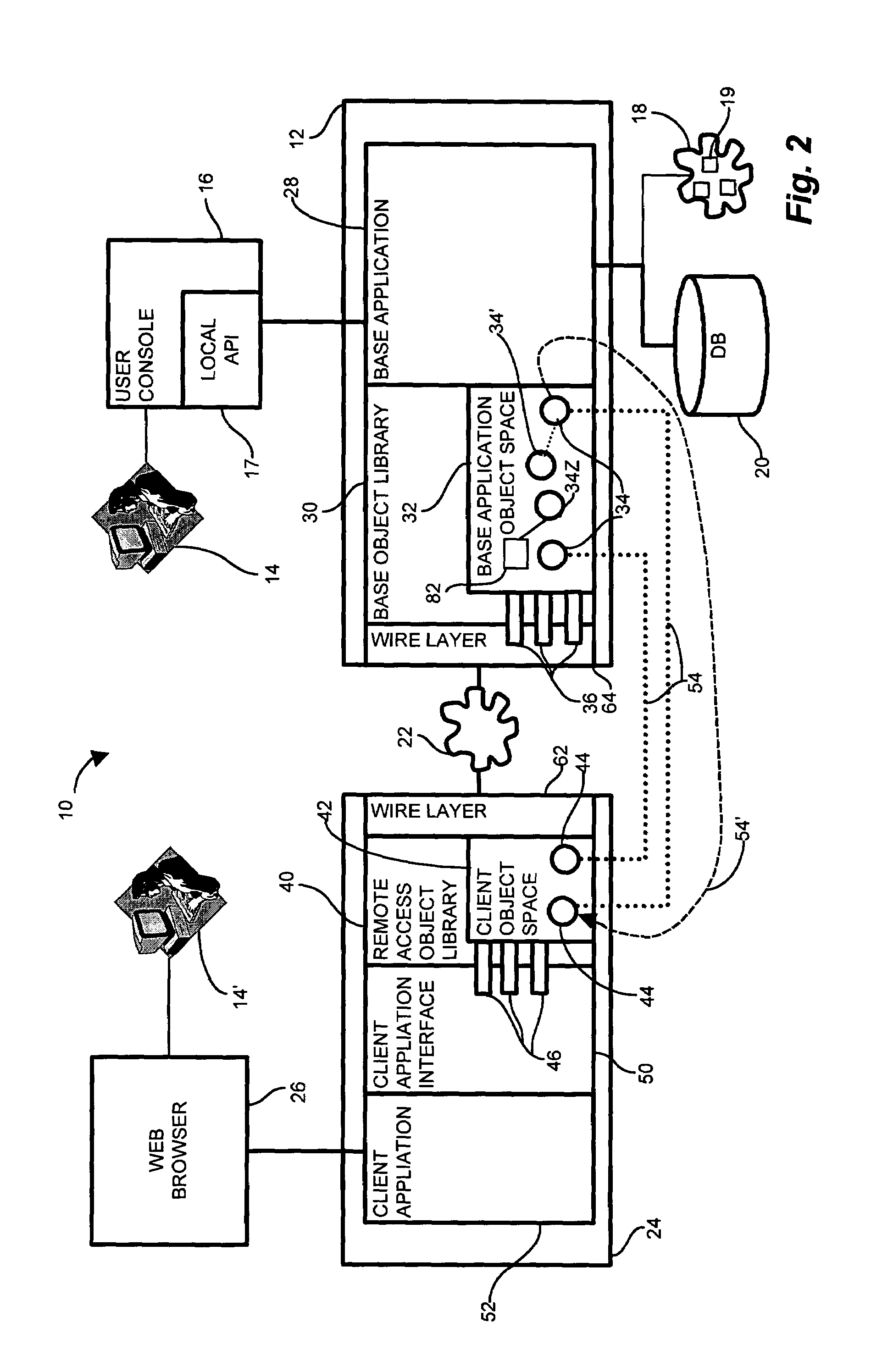

System and methods for deploying and invoking a distributed object model

ActiveUS7340747B1Limited accessExposure was also limitedInterprogram communicationMultiple digital computer combinationsPublic interfaceDistributed object

A client application interface, or toolkit, provides a specified, exposed set of software components, or objects, for external user access. Development of a common interface for external user applications allows a remote access object model to define the interface corresponding to a base object model. The remote access object model, therefore, defines a generic toolkit upon which a user builds a custom application to suit individual remote access needs. Development of a single remote access object model limits regressive testing and provides a known baseline of tested functionality for the remote interface without compromising the existing base object model. Limited exposure of the objects in the client application interface avoids security, integrity, and inconsistency breaches. Therefore, the client application interface is operable to support the client application to emulate a specified exposure of a network administration and management application operations and functions via the remote access object model, or library.

Owner:EMC IP HLDG CO LLC

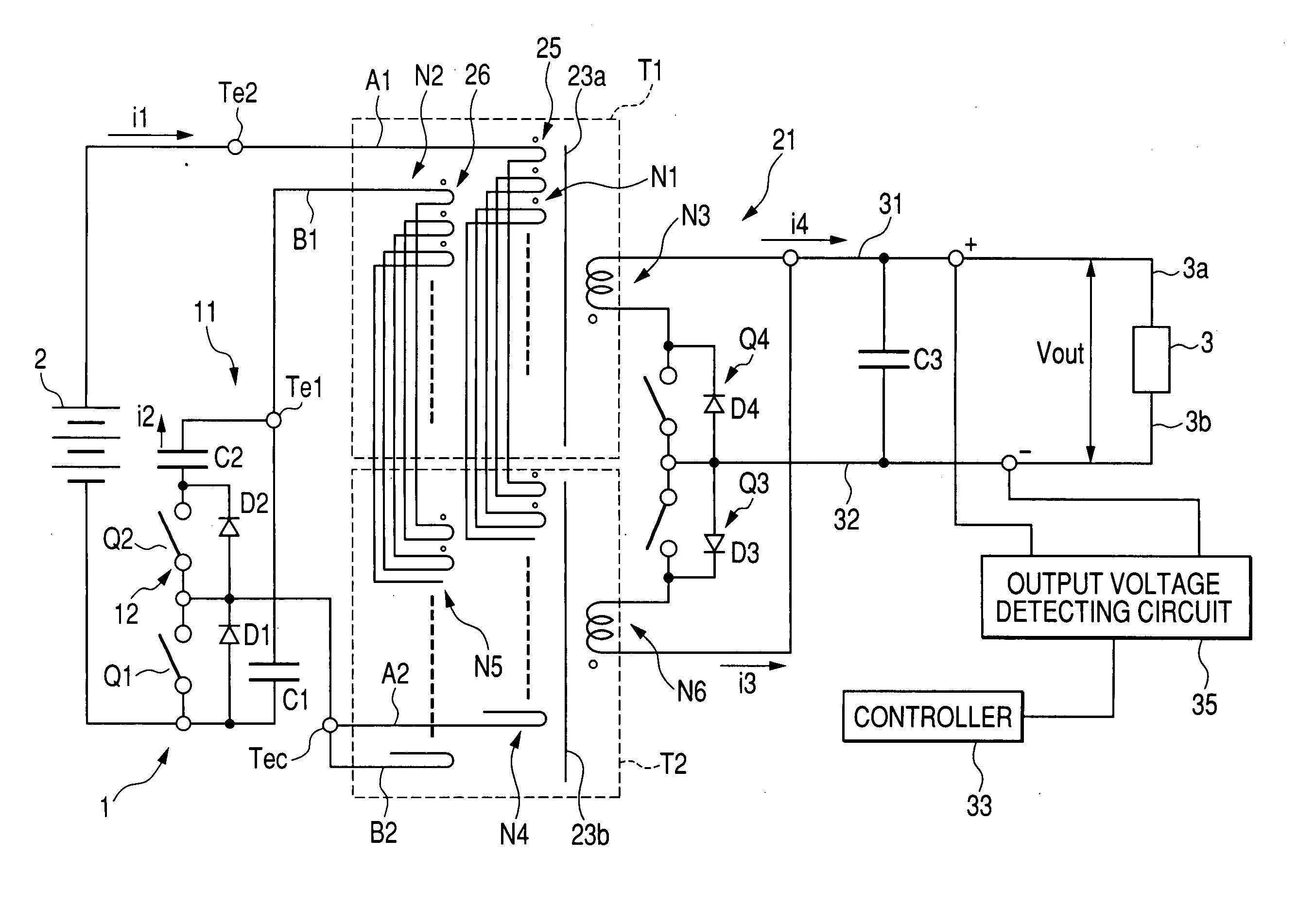

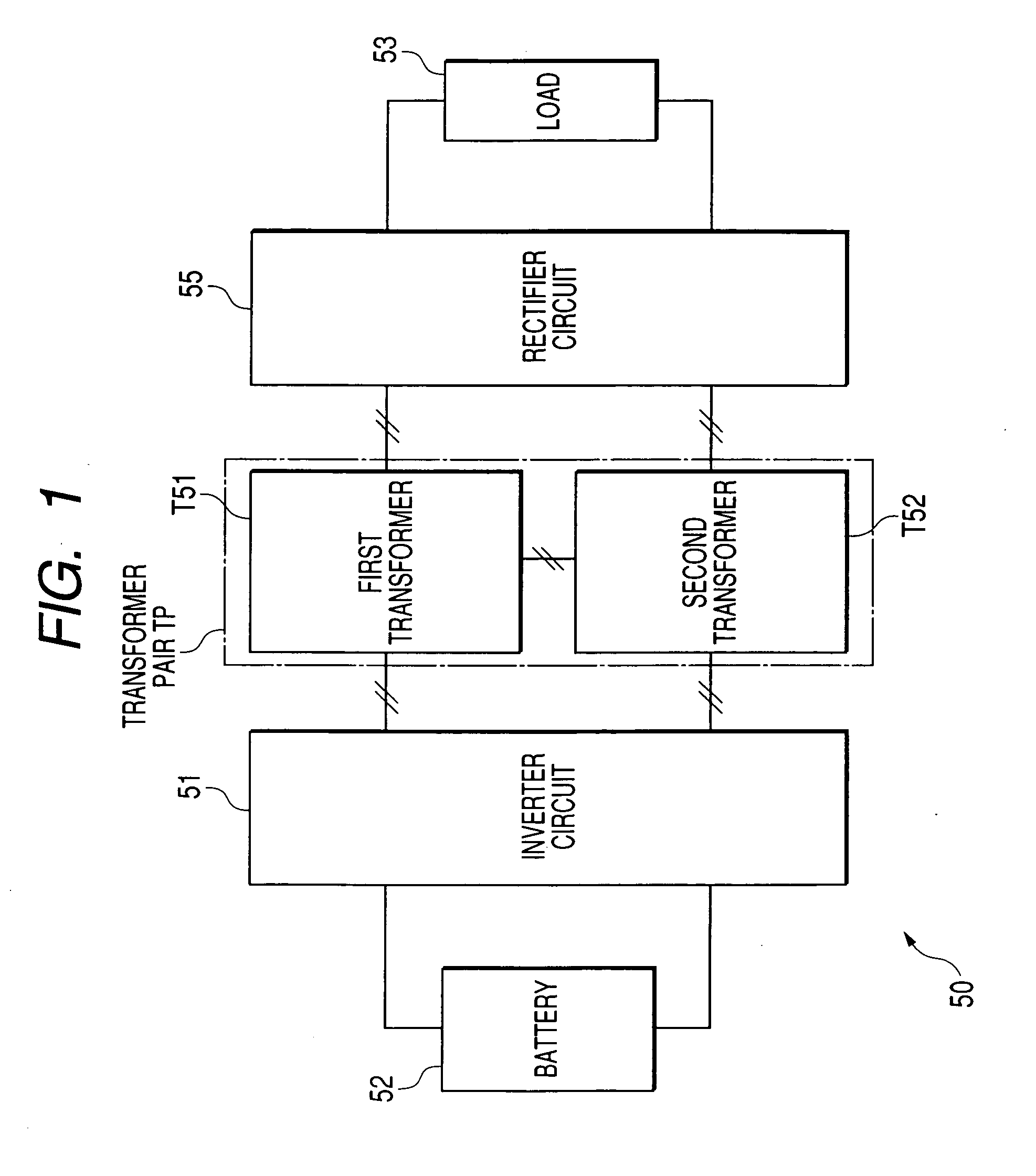

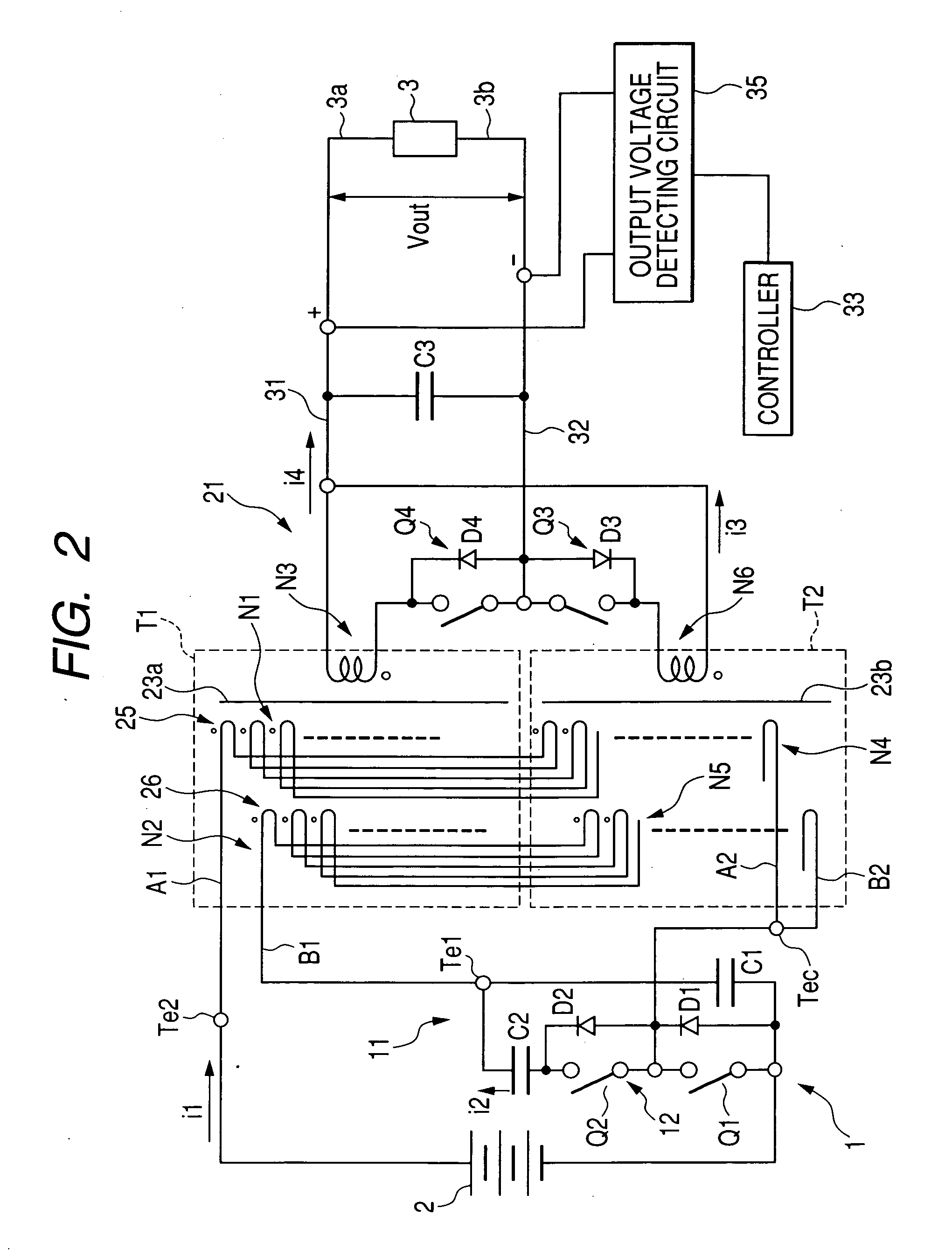

Dc-dc converter with integrated transformer assembly composed of transformer pair

InactiveUS20080101097A1Reduce component countReduce in quantityConversion constructional detailsDc-dc conversionDc dc converterTransformer

In an integrated transformer assembly, a common coil member has a first portion alternately wound, for each one electromagnetic turn, around the first core member and around the second core member. The first portion of the common primary coil member wound around the first core member is magnetically linked to the first magnetic path thereof so as to constitute a first primary coil. The first portion of the common primary coil member wound around the second core member is magnetically linked to the second magnetic path thereof so as to constitute a second primary coil. The first and second primary coils are connected in series. A secondary coil member has first and second secondary coils. The first and second secondary coils are arranged to be magnetically linked to the first and second primary coils of the common primary coil member, respectively.

Owner:DENSO CORP +1

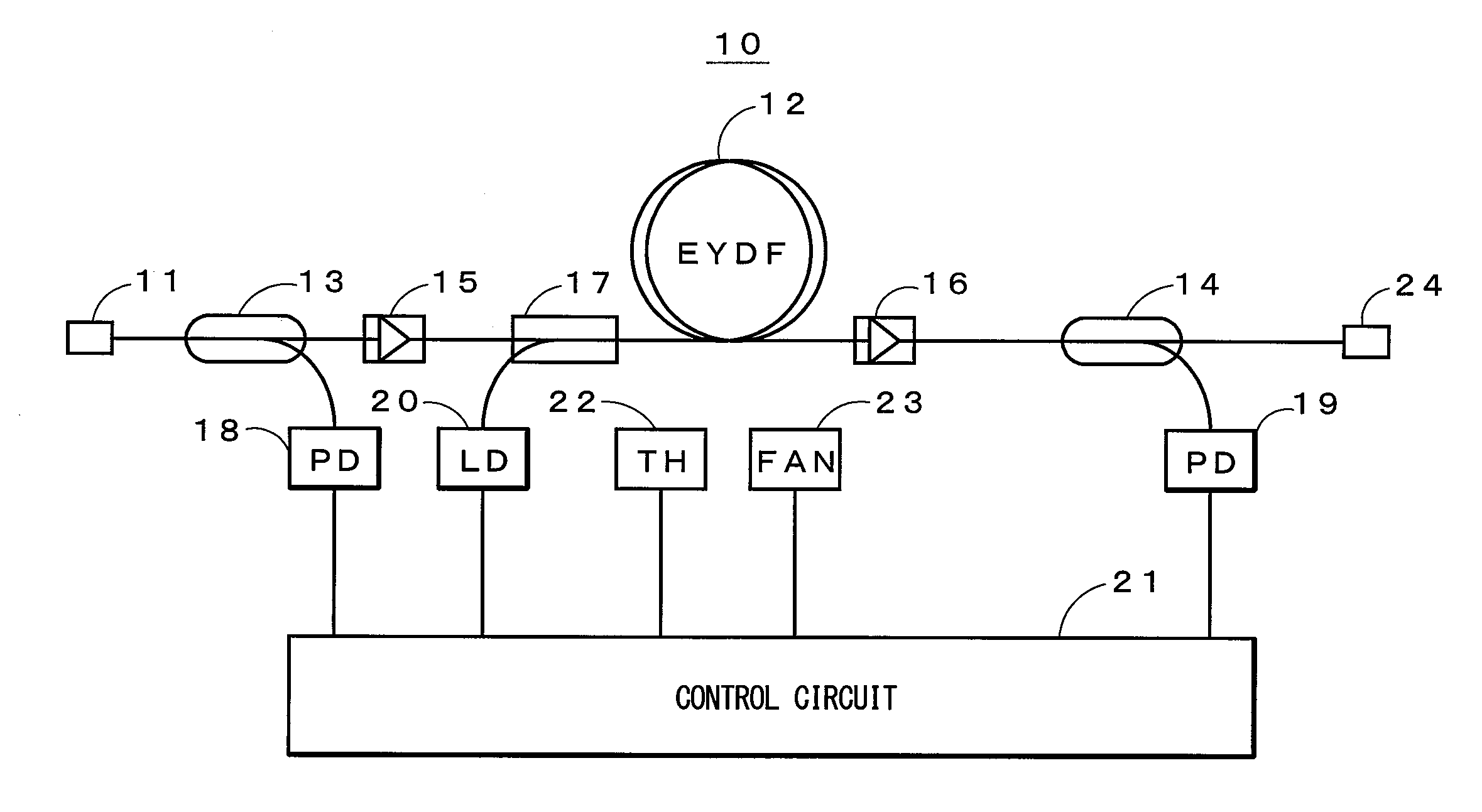

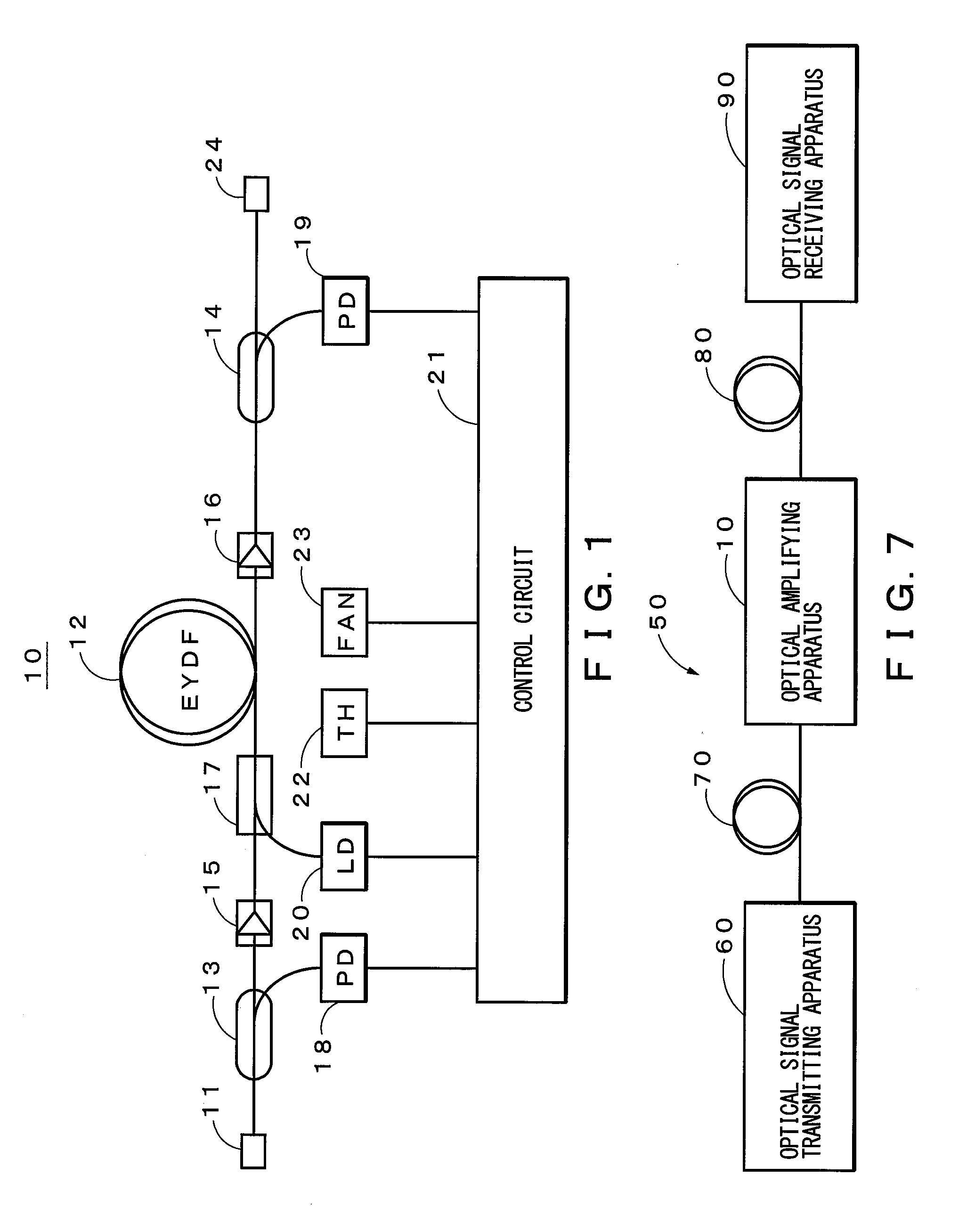

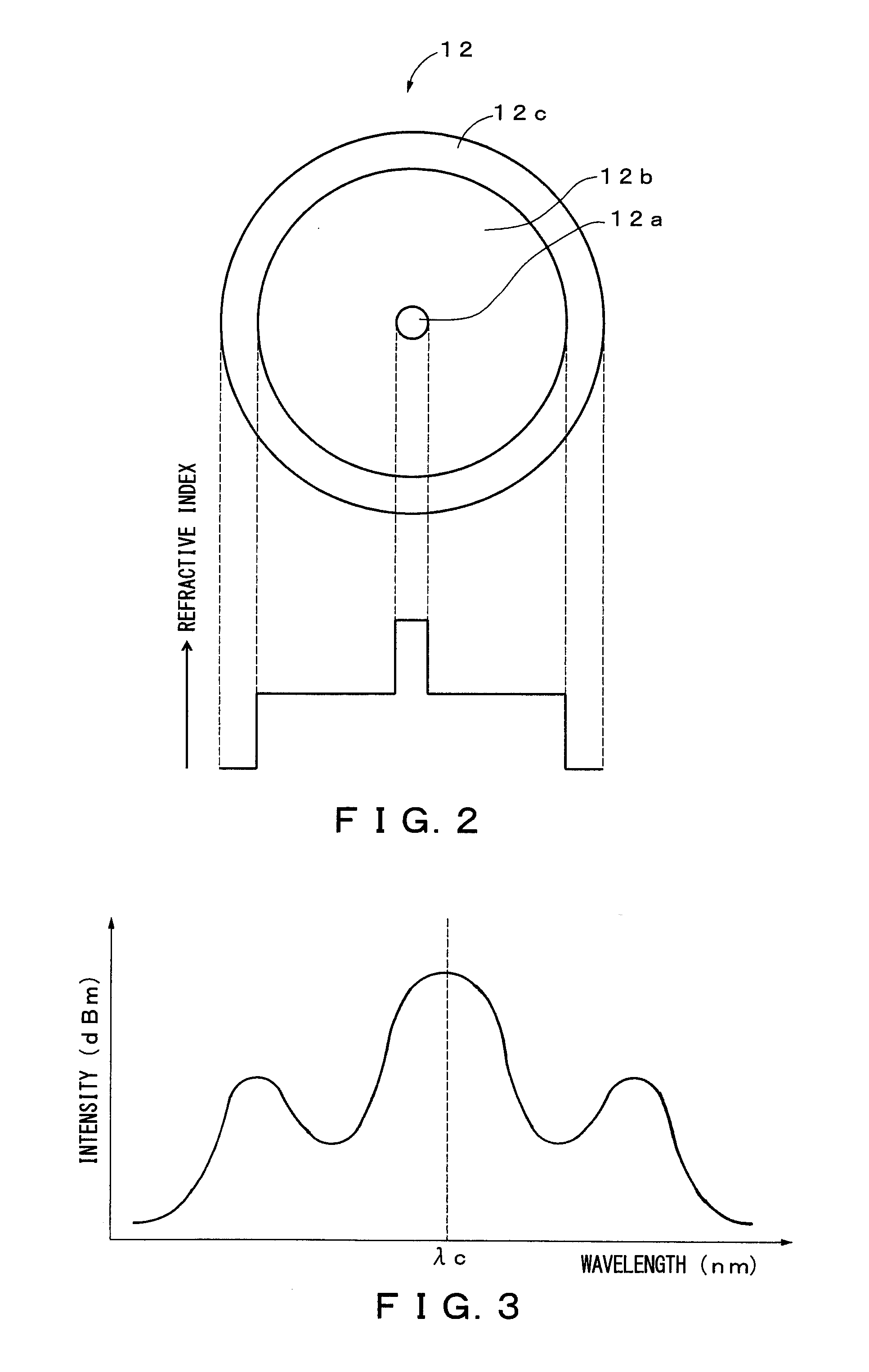

Optical Amplifier and Optical Transmission System

InactiveUS20130235449A1Improve communication qualityReduce power consumptionLaser output parameters controlFibre transmissionStimulated emissionLaser light

An optical amplifying apparatus that amplifies an optical signal, including an input section whereto the optical signal is inputted, a laser light source that generates laser light, the laser light source including an uncooled semiconductor laser device, an optical fiber that amplifies the optical signal by a stimulated emission based on the laser light from the laser light source, an output section that outputs the optical signal amplified by the optical fiber, and a passive optical component disposed between the optical fiber and the output section. The laser light source is thermally coupled to the optical fiber and / or the passive optical component via a thermally conductive medium. An oscillating wavelength of the laser light source is varied by increasing a temperature of the laser light source with heat generated by the optical fiber and / or the passive optical component.

Owner:FURUKAWA ELECTRIC CO LTD

Equipment for the automatic deposit of banknotes

An equipment (22) for the automatic deposit of banknotes (23) comprising a transaction port (33) for receiving a stack (24) of banknotes, a separating device (36) for separating the constituting sheets of the stack (24), a validation device (37) for discriminating the constituting sheets as recognized banknotes and constituting sheets not recognized, a transport mechanism (38, 39) servo-dependent on the validation device to drag said constituting sheets along differentiated paths (72, 73) for the recognized banknotes and the constituting sheets not recognized, and a box assembly (51) adjacent to the transaction port. The box assembly (51) includes two storage boxes (53, 54) and is shiftable among at least three different positions. The three positions are associated with predetermined conditions of communication of the storage boxes (53, 54) with the transaction port (33), the separating device (36) and the transport mechanism (38, 39) to receive the stack, transfer the stack to the separating device, temporarily store as banknote sub-stack and as discard sub-stack the recognized banknotes and, respectively, the constituting sheets not recognized and to return, by request, the discard sub-stack and the banknote sub-stack.

Owner:CTS CASHPRO

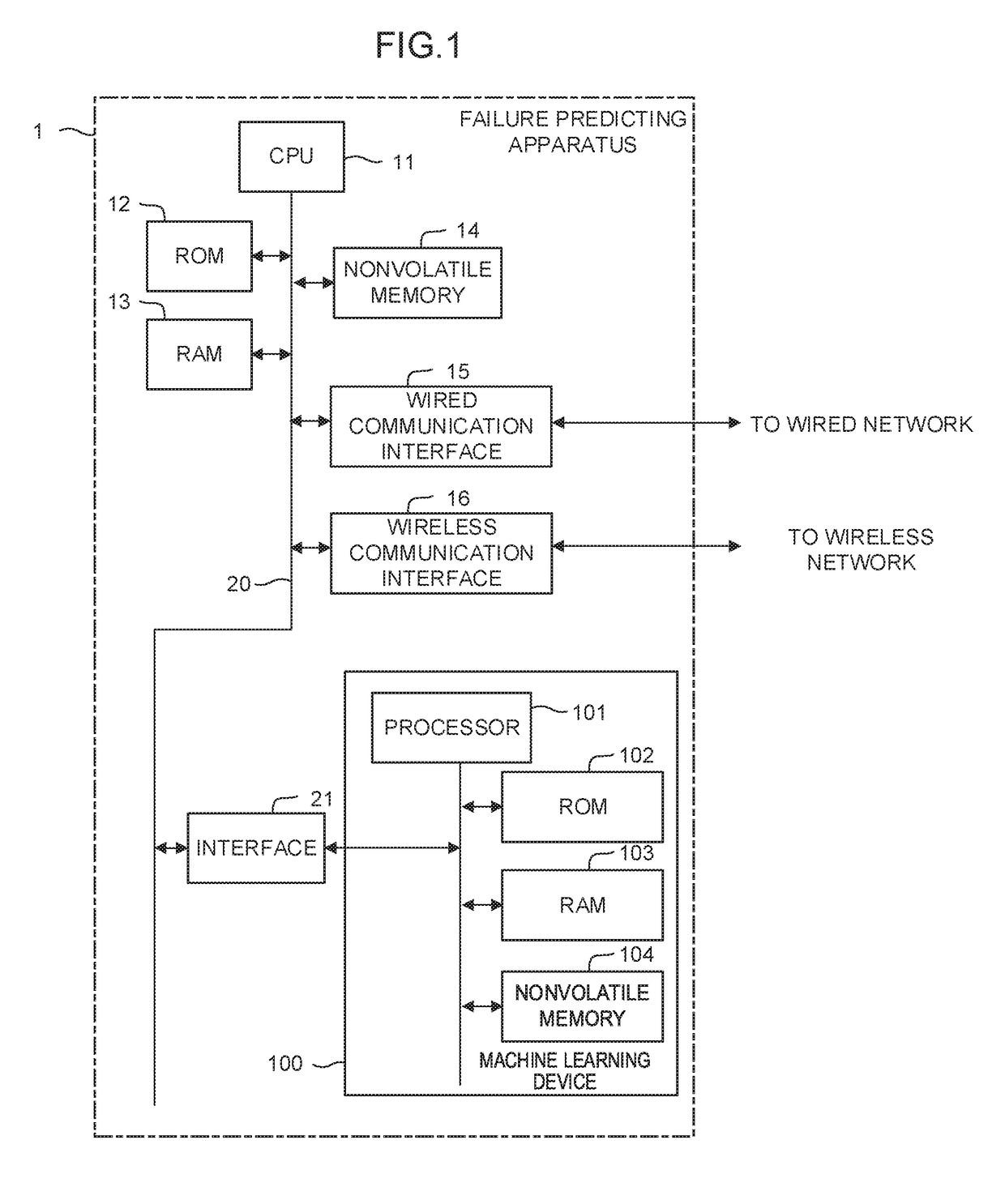

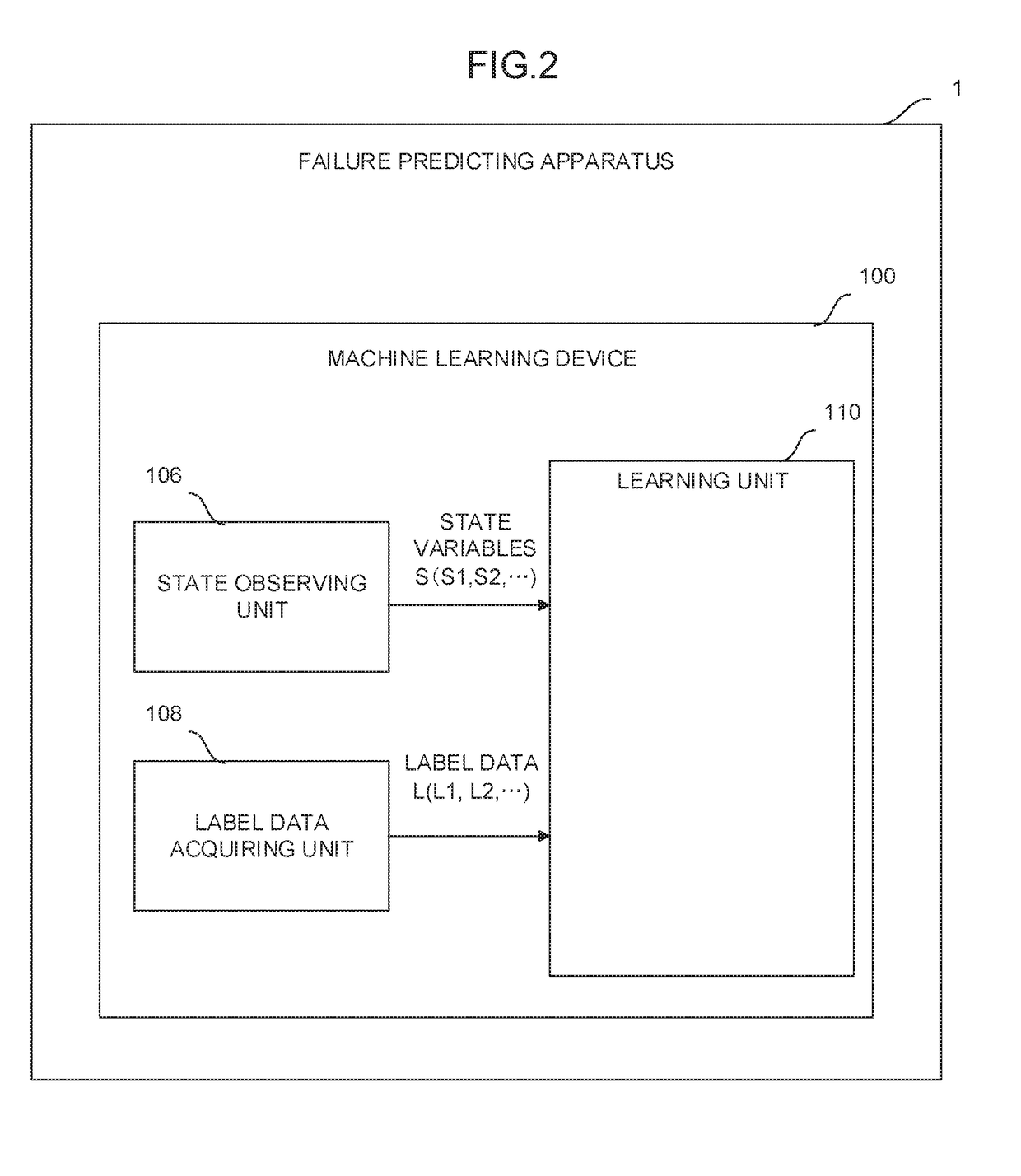

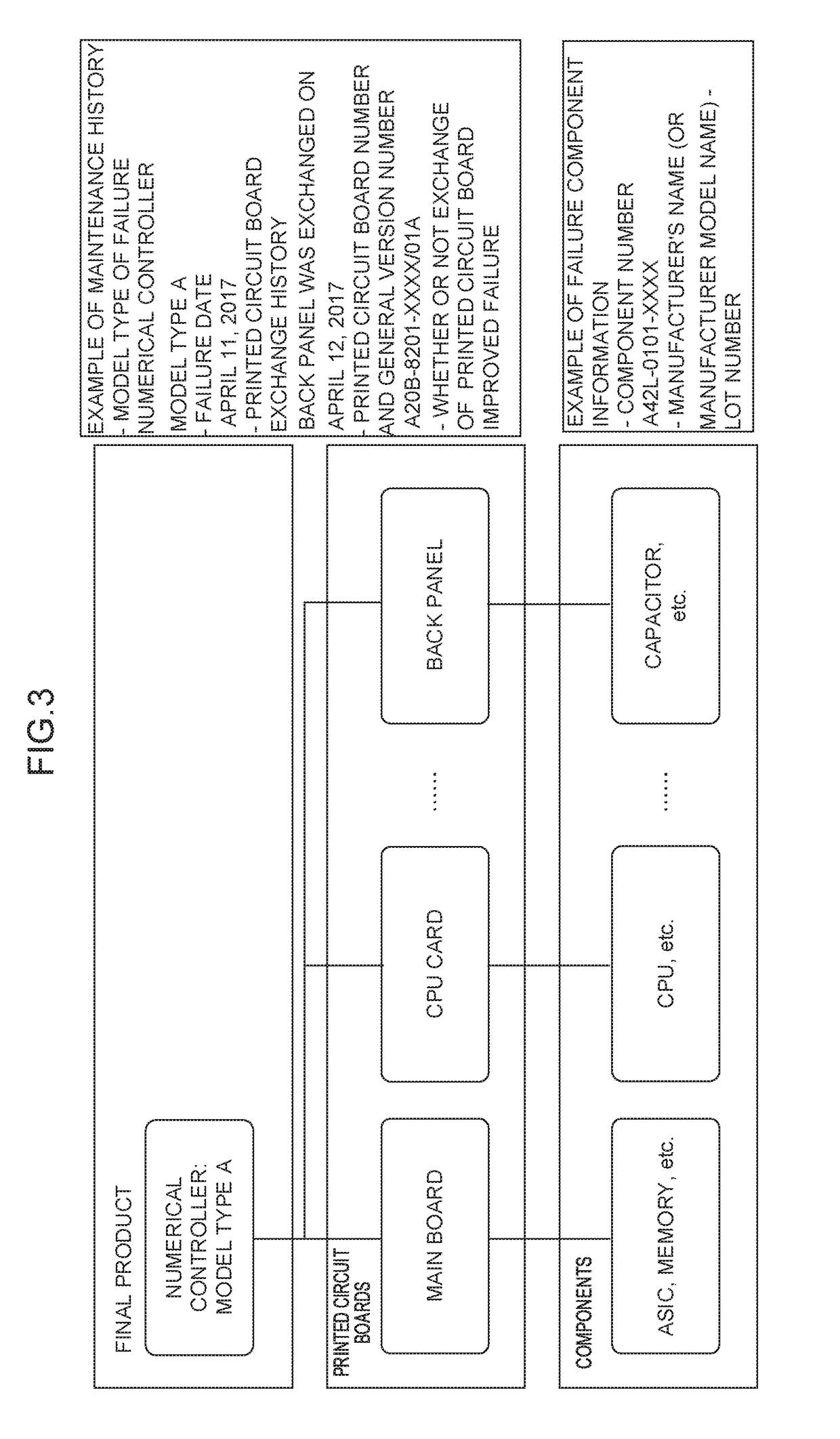

Failure predicting apparatus and machine learning device

InactiveUS20180373233A1Accurate predictionMaintenance costProgramme controlSimulator controlPrinted circuit boardState variable

A machine learning device included in a failure predicting apparatus includes a state observing unit that observes, as state variables indicating a current environmental state, operating state data indicating an operating state of the management target device and device configuration data indicating a device configuration of the management target device, a label data acquiring unit that acquires, as label data, maintenance history data indicating a maintenance history of the management target device, and a learning unit that, by using the state variables and the label data, learns a failure timing of a printed circuit board included in the management target device, the operating state data, and the device configuration data such that the failure timing is associated with the operating state data and the device configuration data.

Owner:FANUC LTD

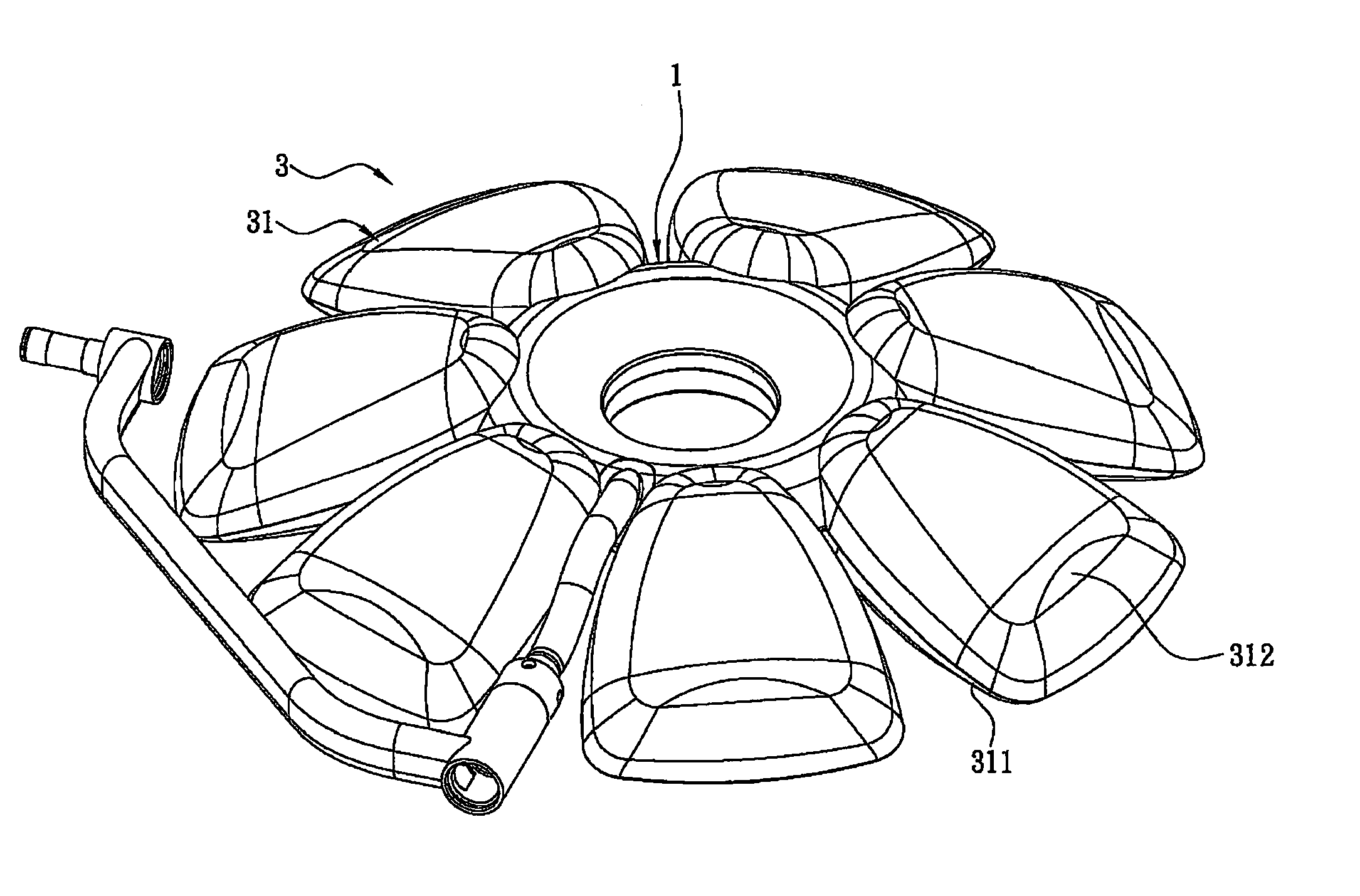

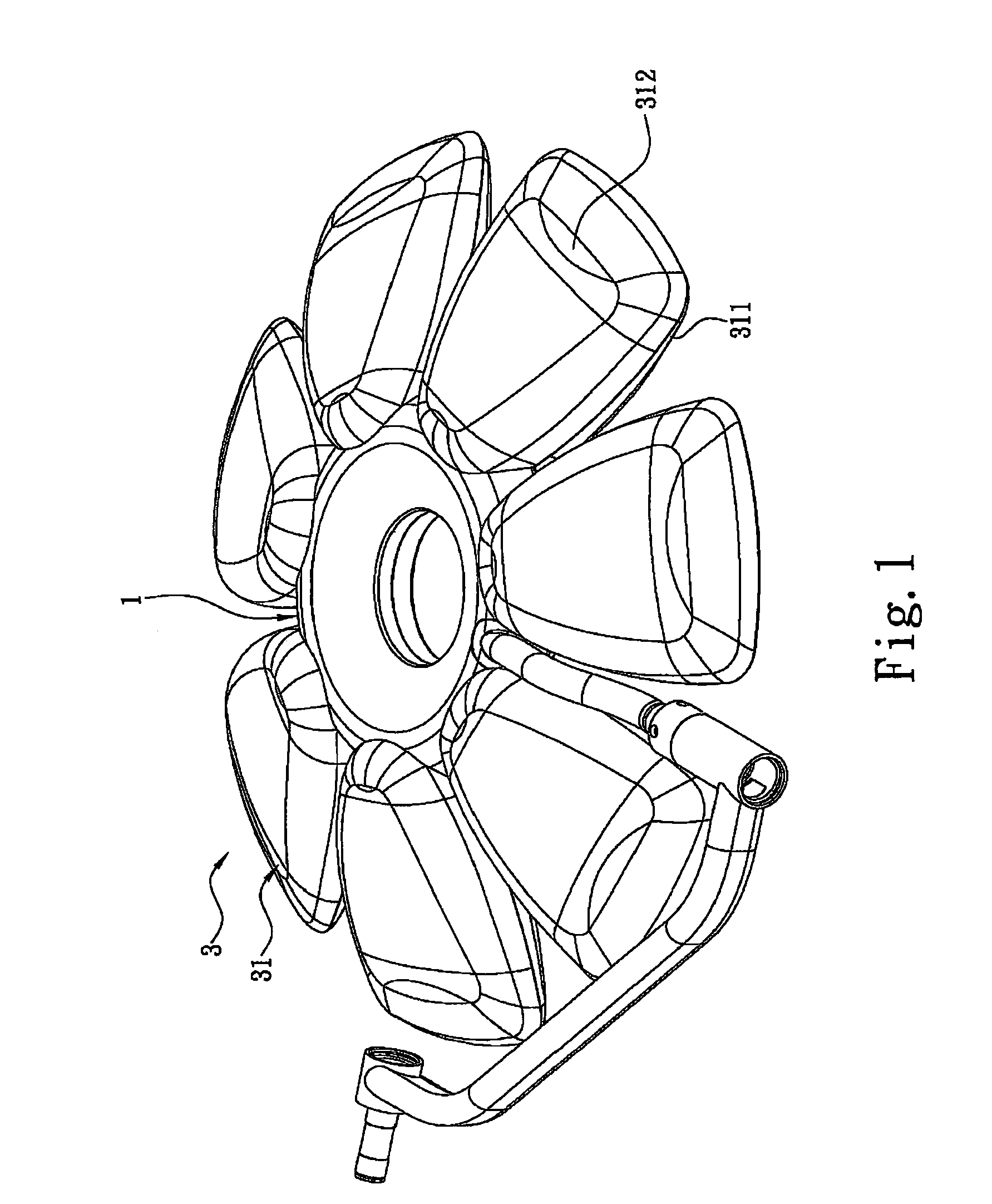

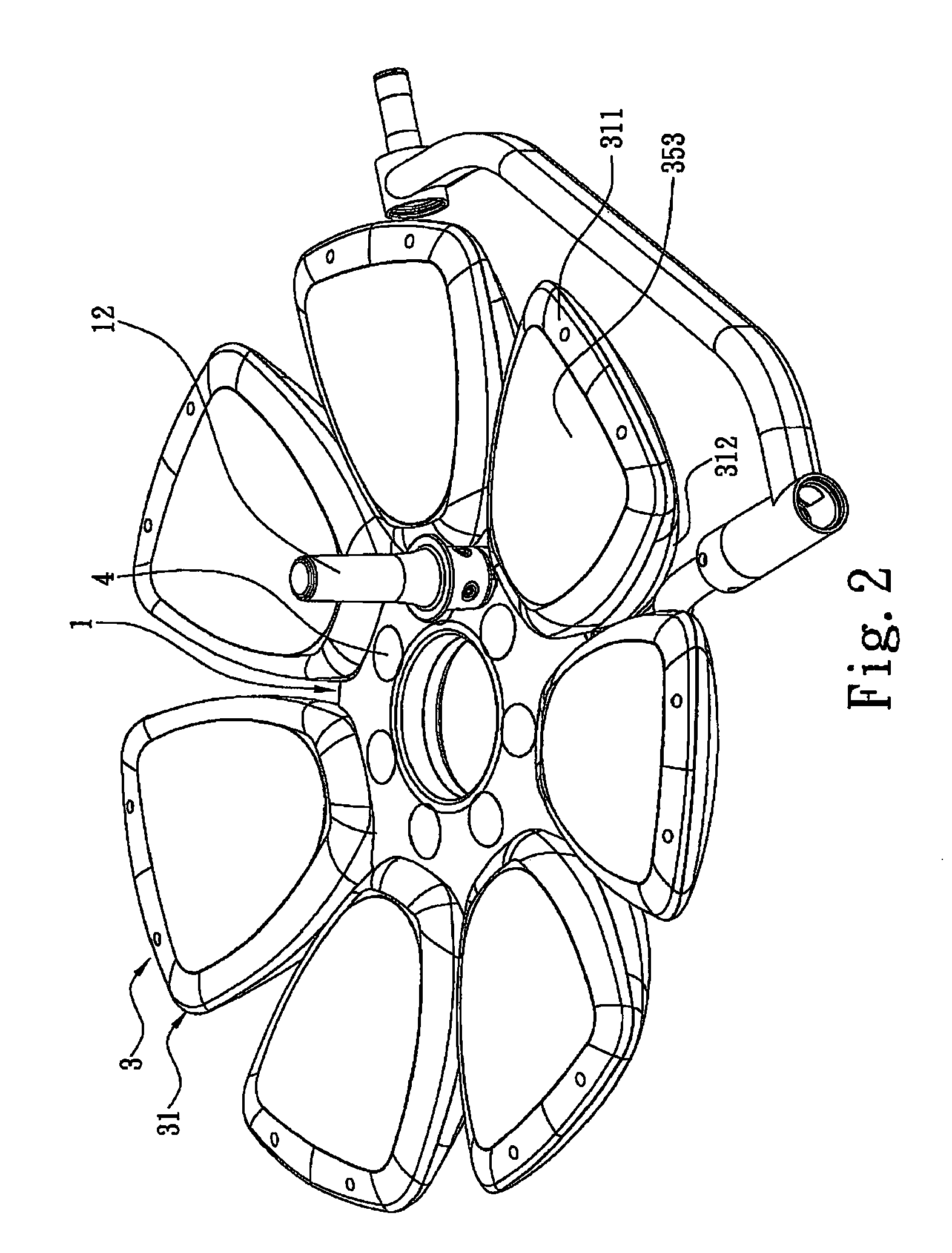

Multi-source shadowless operating lamp

InactiveUS7980738B2Avoid dustMaintenance costMechanical apparatusPoint-like light sourceOptoelectronicsLamp shell

A multi-source shadowless operating lamp is disclosed, which includes a central base, a link element received in the central base, and a plurality of spotlights mounted on a peripheral of the central base and spaced a distance apart from each other. A light field is defined below the central base and extends perpendicular to the central base. Each spotlight defines a light focus spot through the light field. The focus spots exactly pass the same height in the light field. Each spotlight includes a lamp shell connecting with the central base, a dissipation substrate accommodated in the lamp shell, and a plurality of LED sets. The LED sets at different positions respectively cast light to the focus spot of the spotlight. An angle between the dissipation substrate and the light shell is adjustable to change position of the focus spot of the spotlight relative to the light field.

Owner:MEDILAND ENTERPISE

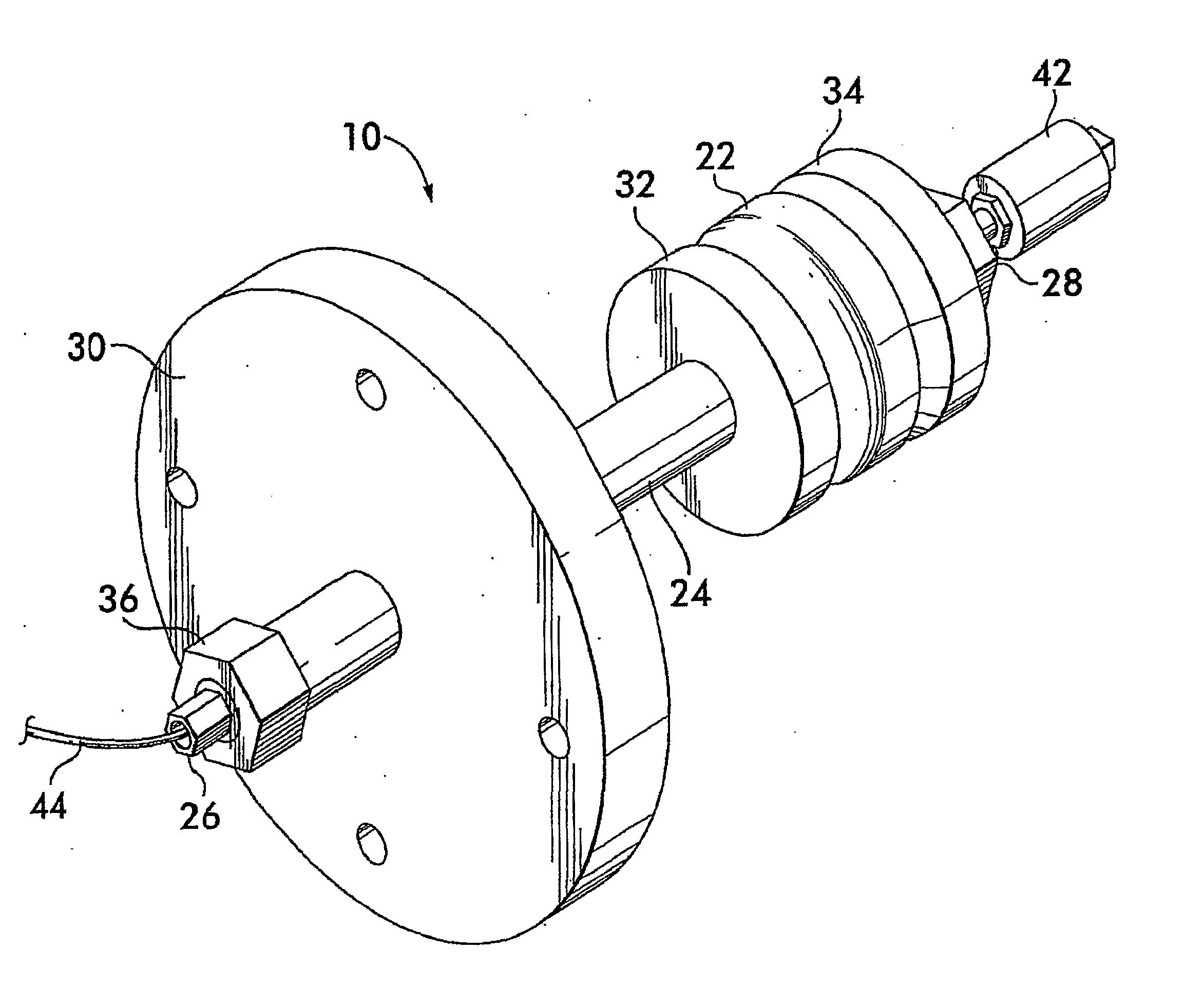

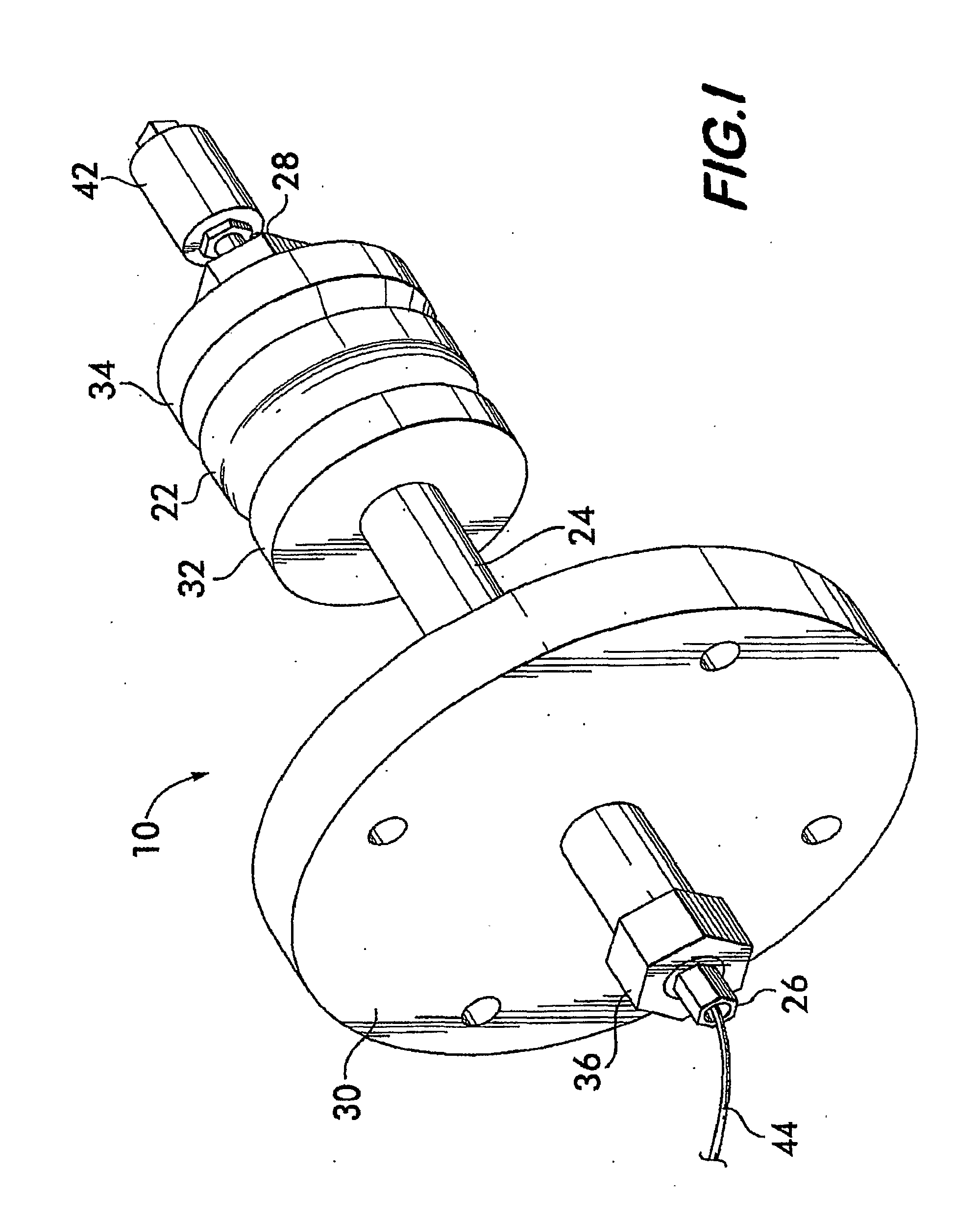

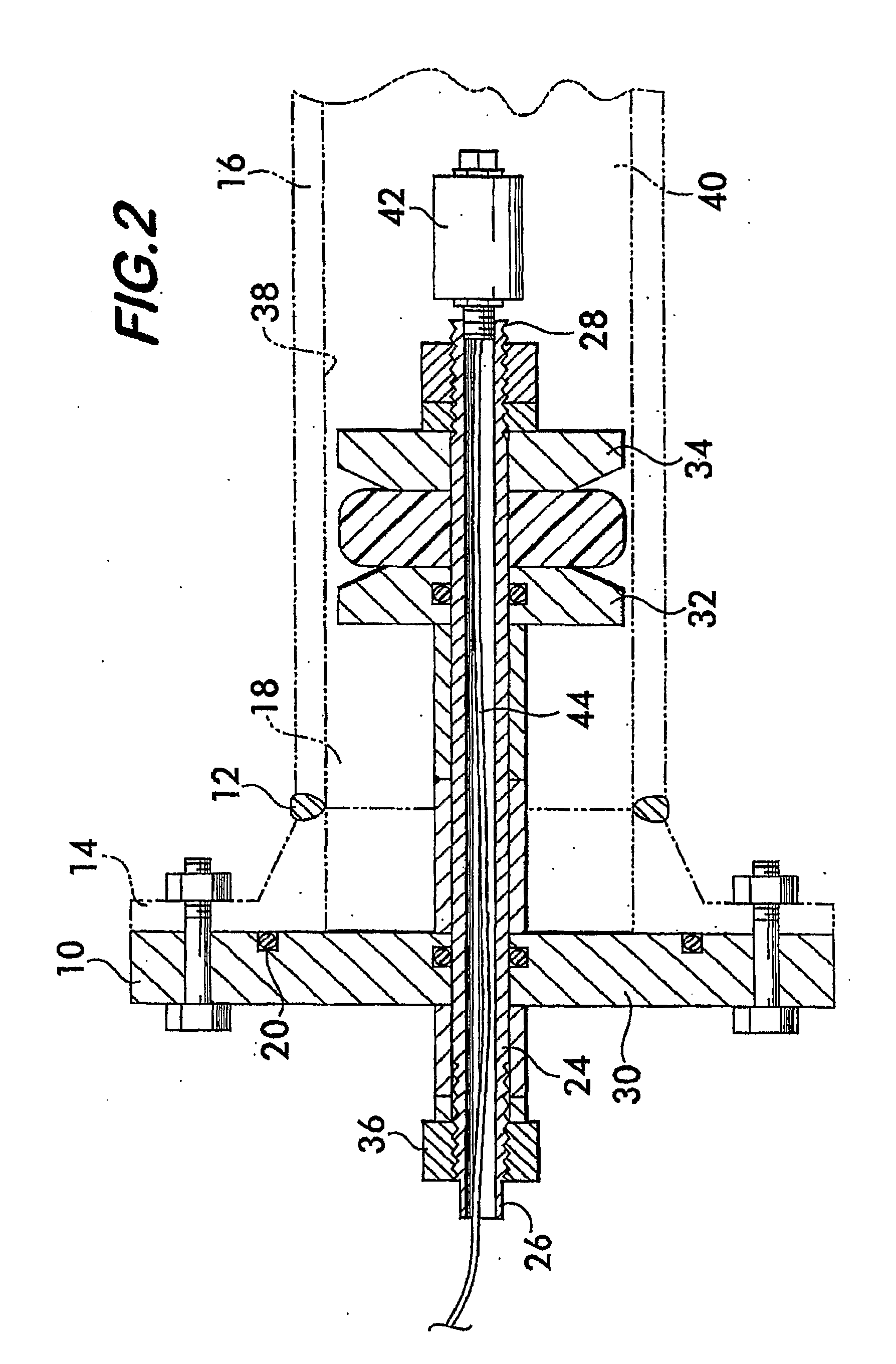

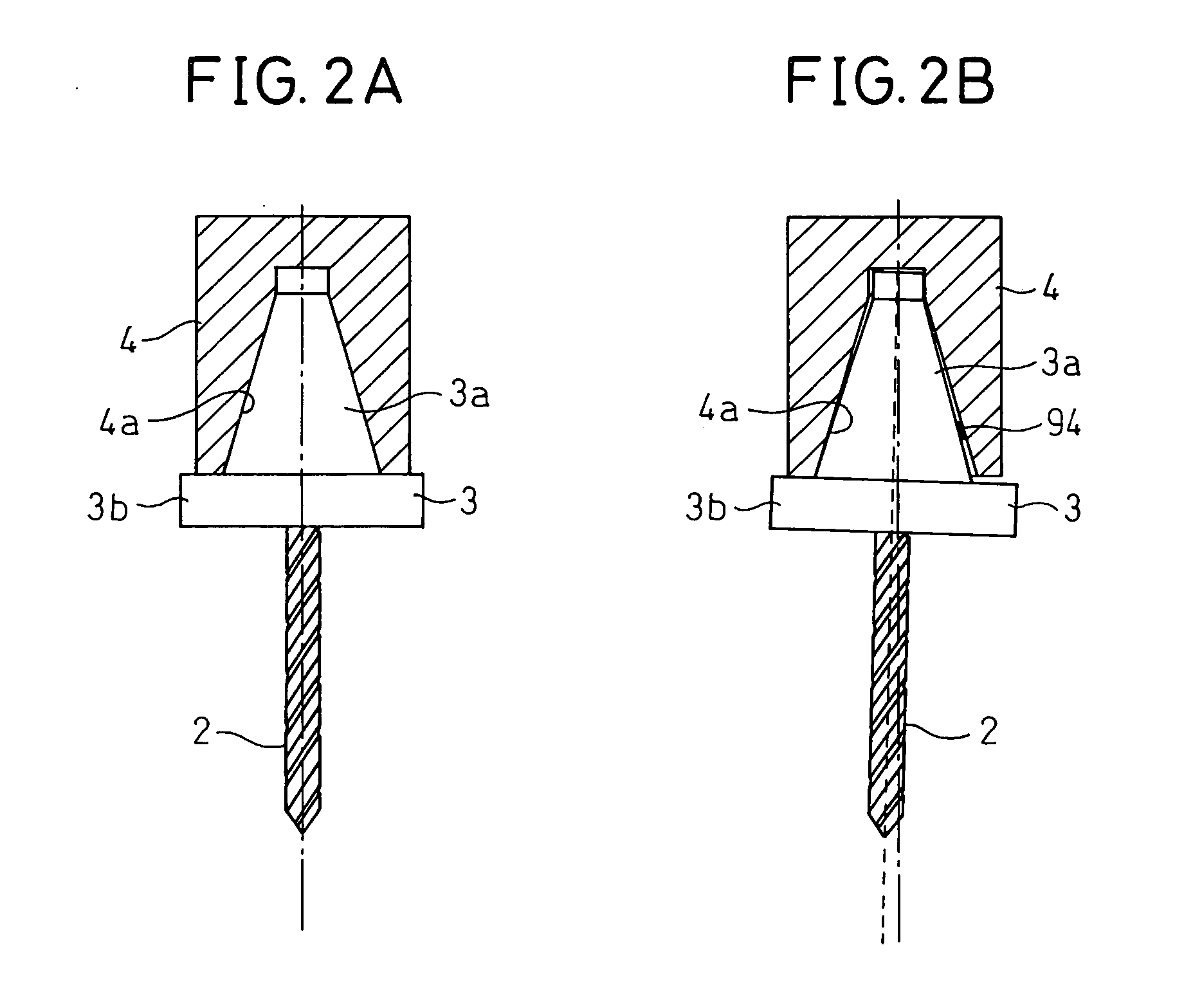

Test Plug and Method for Monitoring Downstream Conditions

InactiveUS20100083738A1Reduces required time and complexityReduce the possibilityDetection of fluid at leakage pointTransducerEngineering

A test plug assembly (10, 50, 90) includes a shaft (24, 56, 100) on which an annular elastic seal (22, 68, 94) and compression elements (32, 34, 62, 106, 110) are mounted. The compression elements (32, 34, 62, 106, 110) confront opposite axial sides of the annular seal (22, 68, 94) and are movable relative to one another for axially compressing and radially expanding the seal (22, 68, 94) into fluid-tight sealing engagement with an inner peripheral wall (38, 70, 96) of a pipe (16, 52, 92). A transducer (42, 80, 122) is mounted on the distal end of the shaft (24, 56, 100) and measures a condition within the pipe (16, 52, 92) at a location beyond the seal (22, 68, 94). As one example, the transducer (42, 80, 122) is a temperature compensation pressure transducer for obtaining pressure measurements within the downstream portion of the pipe (16, 52, 92) beyond the test plug (10, 50, 90). The transducer (42, 80, 122) produces electrical signals and is in communication with a control unit (982) located externally of the pipe (16, 52, 92). The control unit (982) converts the electronic signals of the transducer (42, 80, 122) for driving a display apparatus (983) to provide visible or audible information and / or warning signals concerning the measurements. The control unit (982) is responsive to transducer signals for automatically terminating welding of a pipe when the signals indicate that pressure at the distal end of the shaft (24, 56, 100) beyond the seal (22, 68, 94) is at a prescribed undesired level.

Owner:EST GROUP

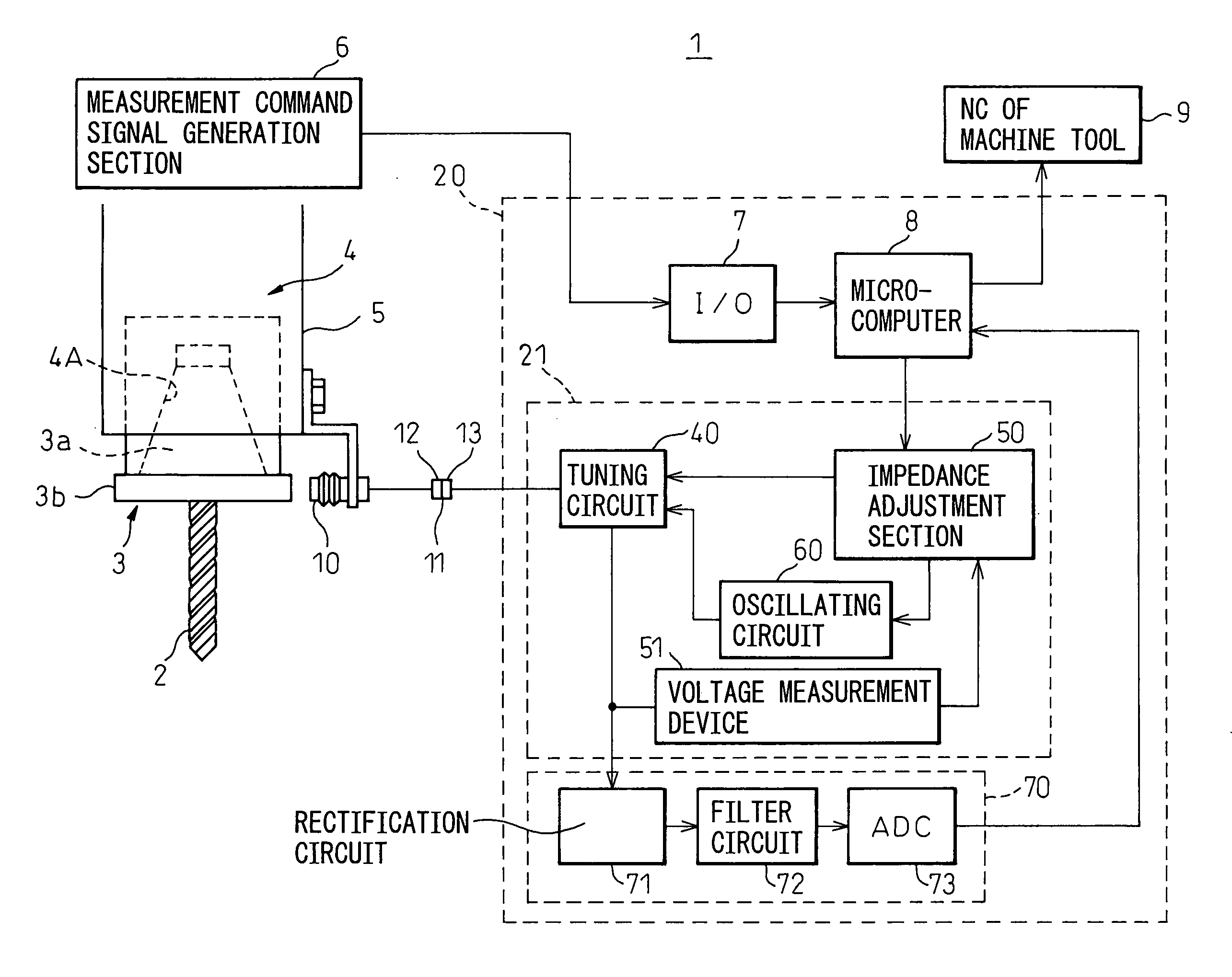

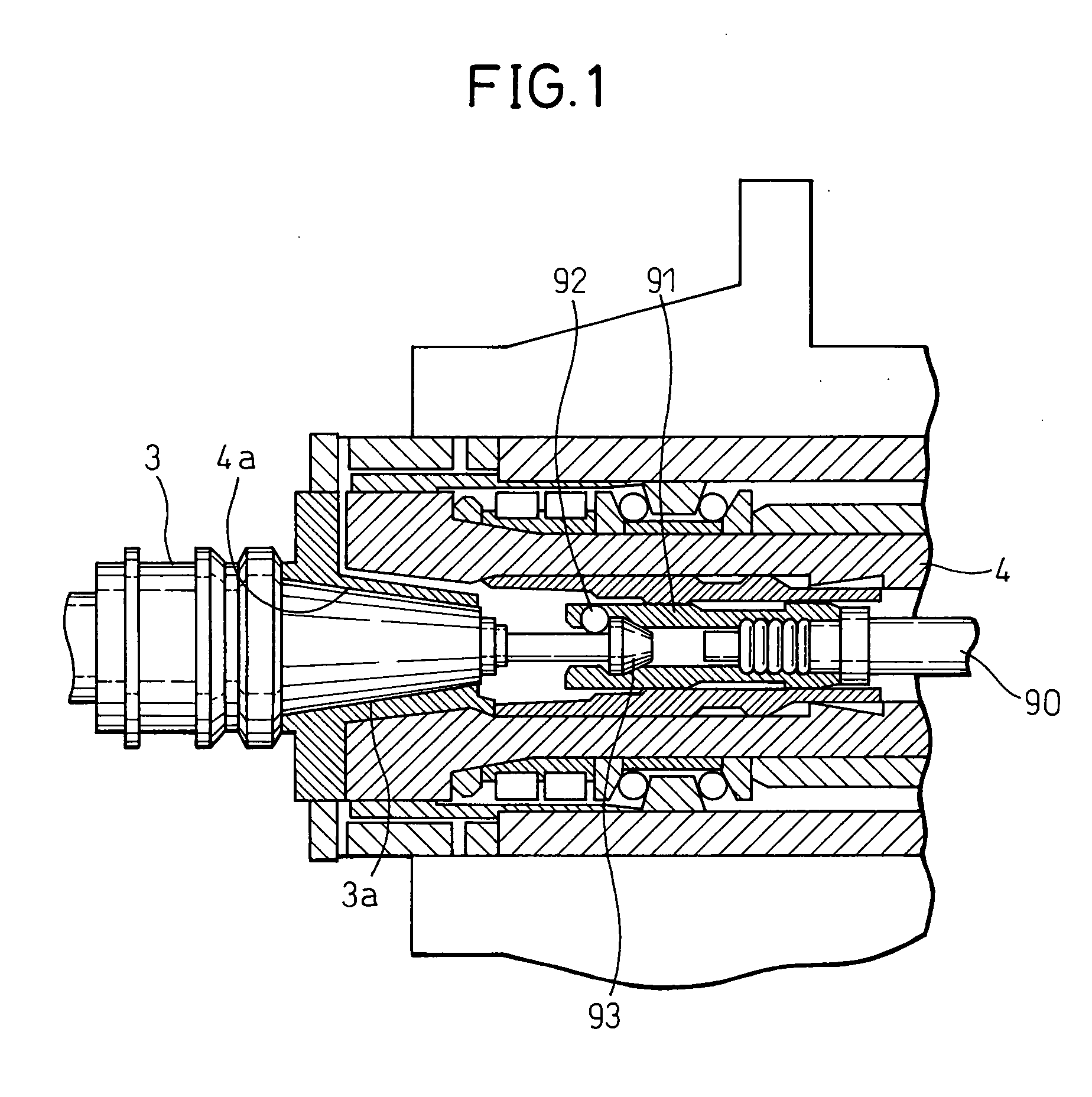

Machine tool

InactiveUS20060261969A1Easy to optimizeMaintenance costMeasurement of torque/twisting force while tighteningWork measurementResonanceEngineering

A machine tool in which a tool holder having a tool is attached to a main spindle and the main spindle is rotated to conduct machining on a workpiece, comprises: a displacement sensor, the impedance of which is changed according to a distance from the displacement sensor to the tool holder, an AC signal being impressed upon the displacement sensor from an amplifying unit, wherein an abnormality of a state, in which the tool holder is attached to the main spindle, is judged from a signal level appearing in the displacement sensor. The machine tool further comprises: a tuning circuit connected to the displacement sensor, the tuning circuit composing a resonance circuit together with the displacement sensor; and an impedance adjustment circuit for adjusting an internal impedance constant of the tuning circuit.

Owner:TOKYO SEIMITSU +1

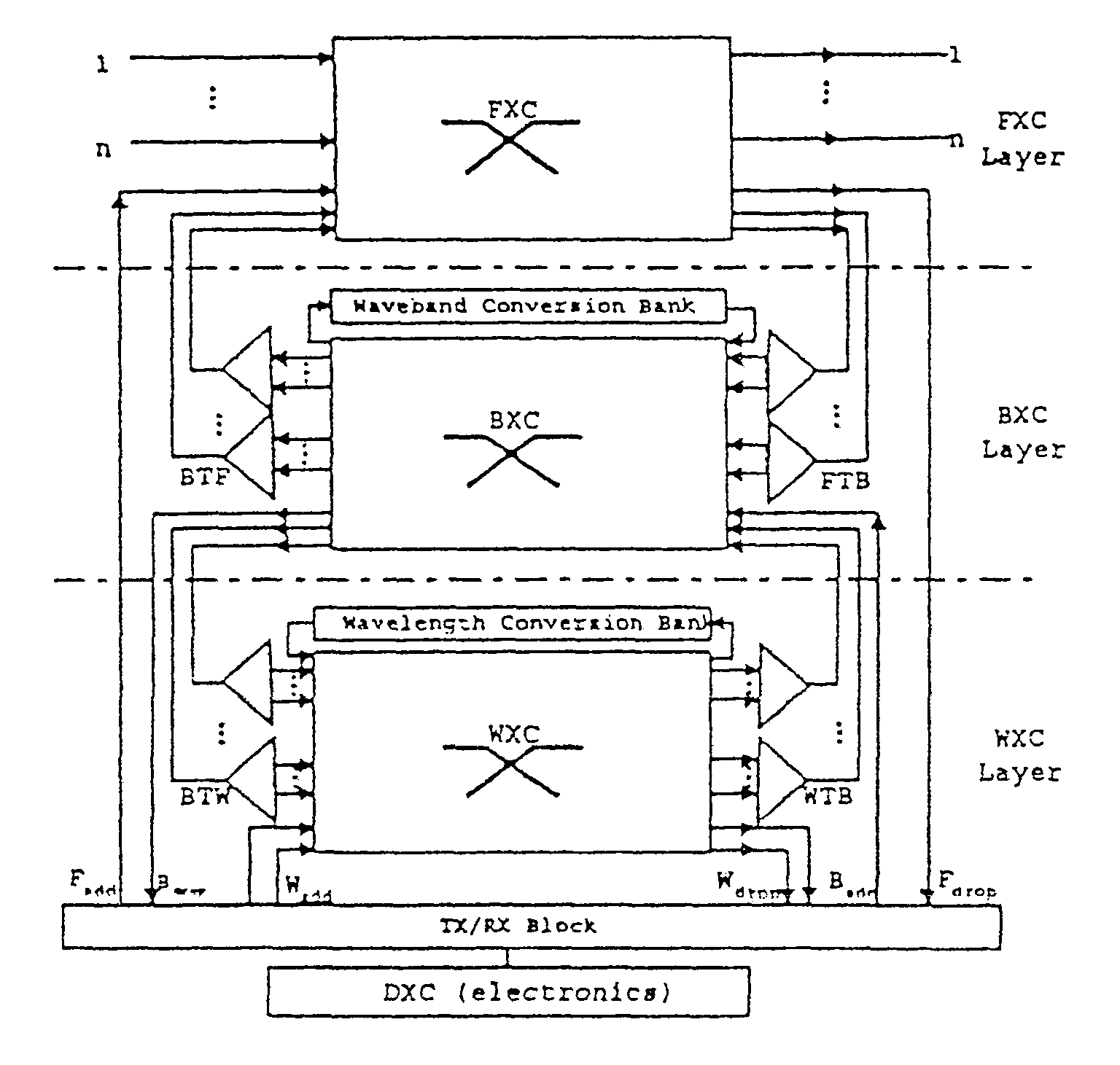

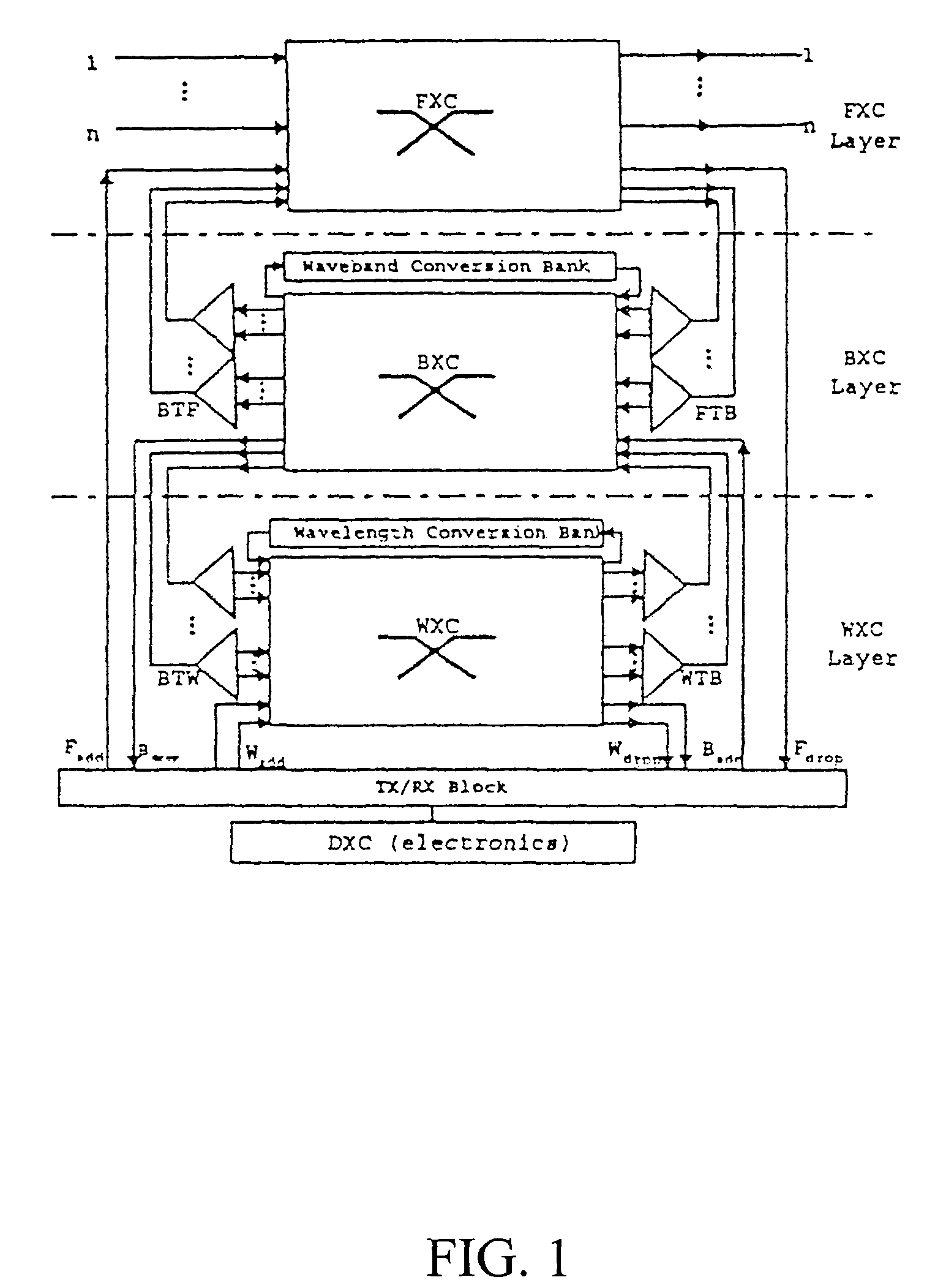

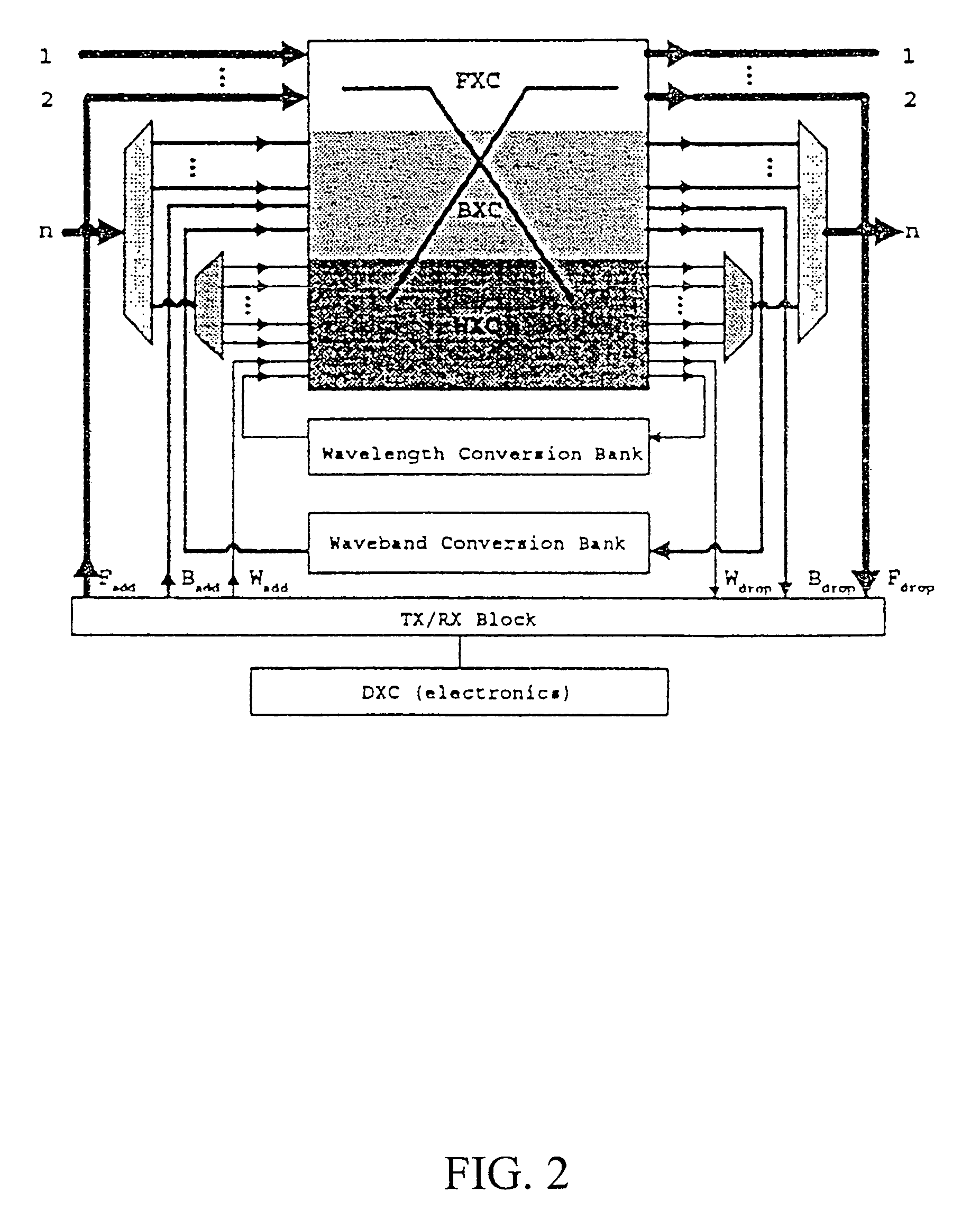

Efficient optical network design using multi-granular optical cross-connects with wavelength band switching

InactiveUS7162632B2Near optimal resultRun fastMultiplex system selection arrangementsWavelength-division multiplex systemsCross connectionData traffic

A method for managing static data traffic of at least one light path in an optical network, comprising the steps of achieving load balanced path routing for the at least one light path, assigning wavelengths to demands of the at least one light path, and, switching the at least one light path according to its assigned wavelength. A method for managing dynamic data traffic of at least one light path in an optical network, comprising the steps of routing the K-shortest path, which has the largest interference length (L), and, assigning waveband with a First-Fit network topology based on band / port number restriction and minimum weight.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

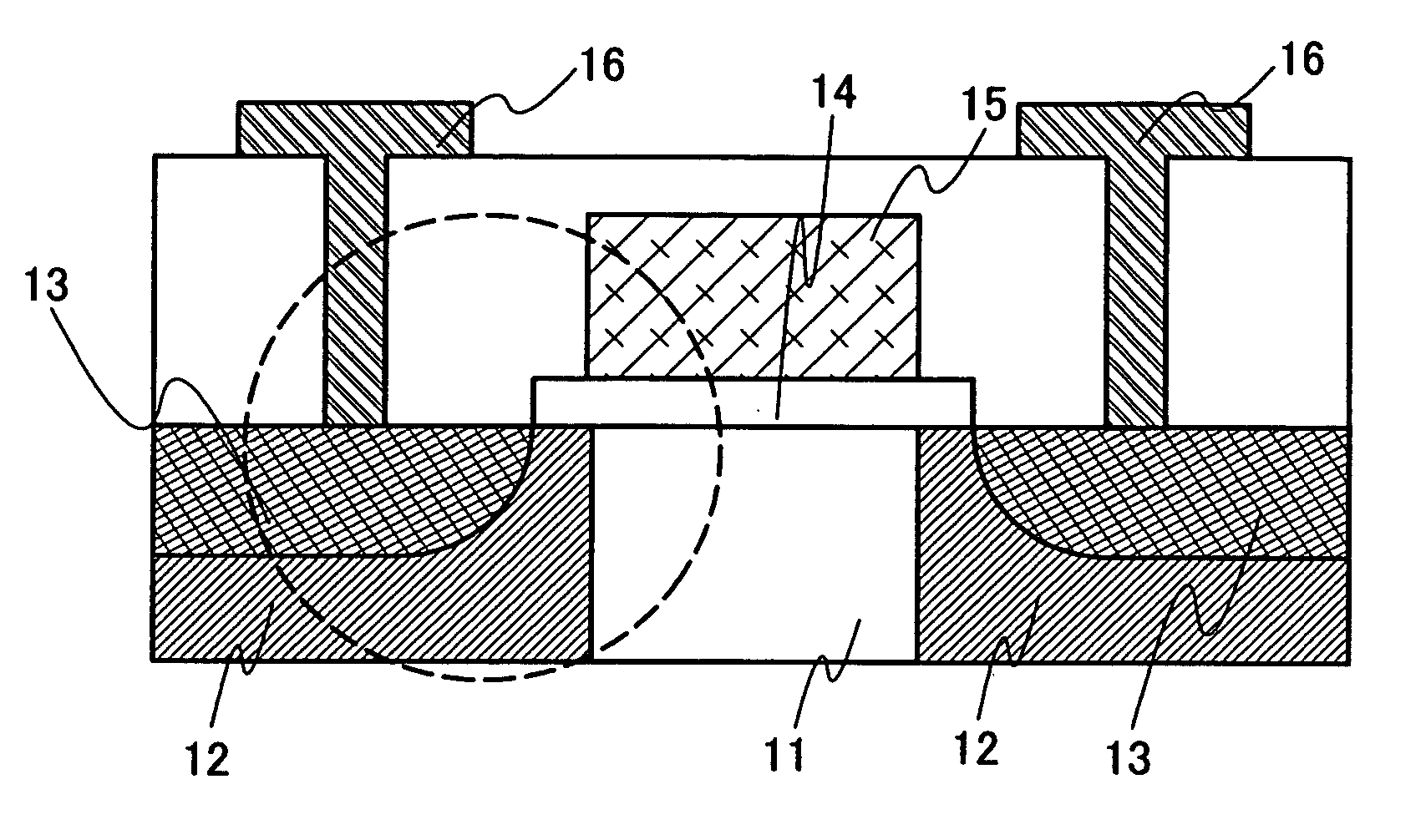

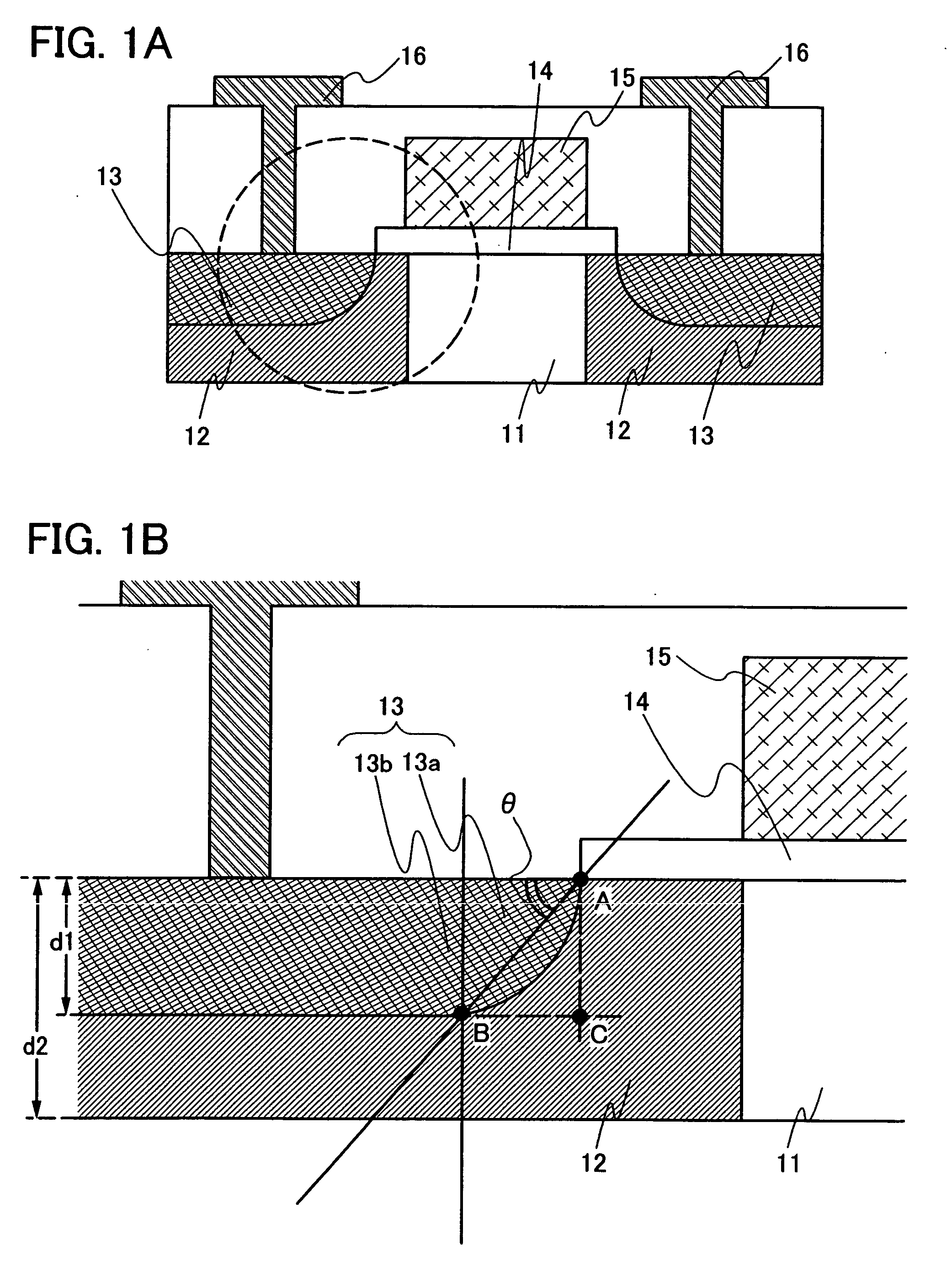

Semiconductor device and manufacturing method thereof

InactiveUS20070126058A1High currentReduce sheet resistanceTransistorSolid-state devicesSiliconCondensed matter physics

It is an object of the present invention to obtain a transistor with a high ON current including a silicide layer without increasing the number of steps. A semiconductor device comprising the transistor includes a first region in which a thickness is increased from an edge on a channel formation region side and a second region in which a thickness is more uniform than that of the first region. The first and second region are separated by a line which is perpendicular to a horizontal line and passes through a point where a line, which passes through the edge of the silicide layer and forms an angle θ (0° <θ<45°) with the horizontal line, intersects with an interface between the silicide layer and an impurity region, and the thickness of the second region to a thickness of a silicon film is 0.6 or more.

Owner:SEMICON ENERGY LAB CO LTD

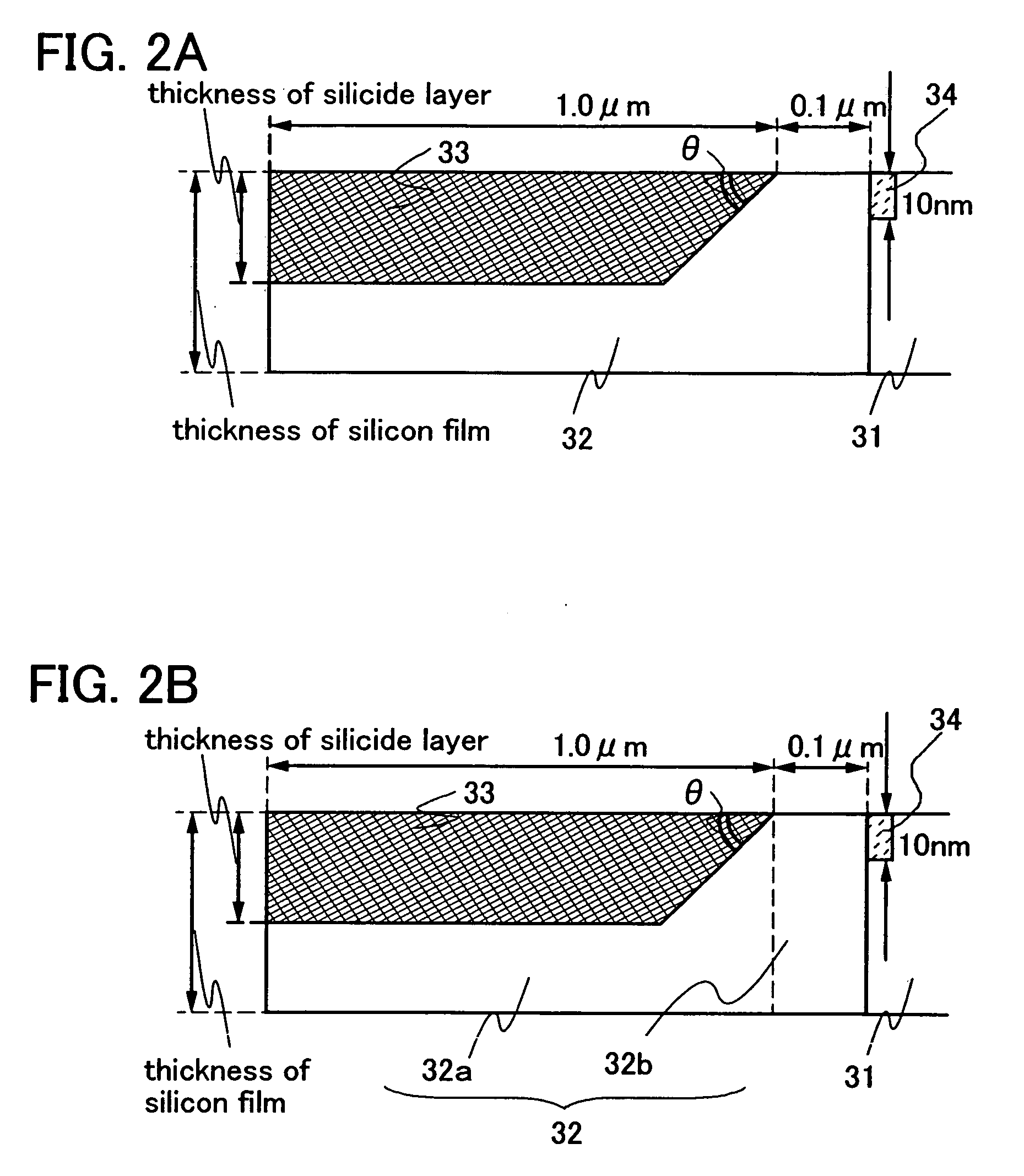

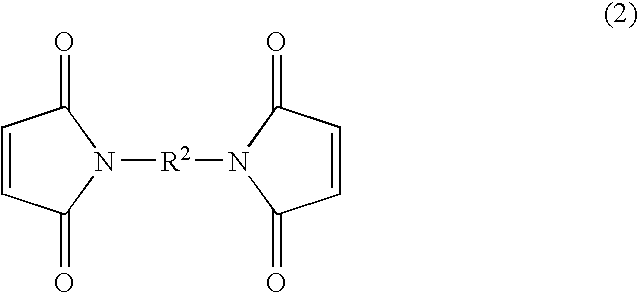

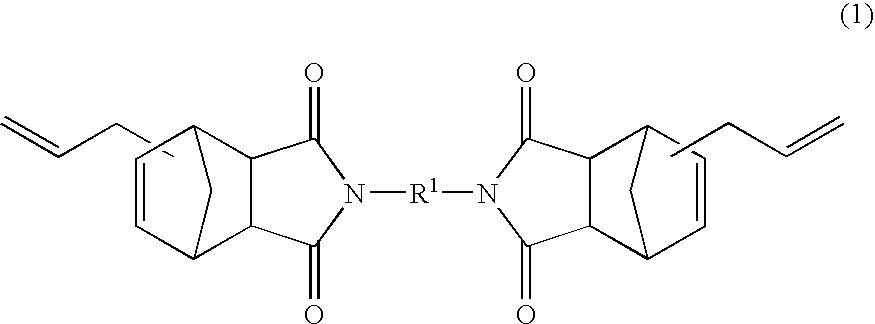

Curable resin composition for ink jet printer, cured product thereof, and printed wiring board using the same

InactiveUS20070270568A1Low viscosityImprove heat resistanceInksNon-metallic protective coating applicationImideAryl

A curable resin composition for an ink jet printer containing: (A) a bis-allyl-nadi-imide compound defined by the following general formula (1): wherein R1 represents an alkyl group having 2 to 18 carbon atoms, an aryl group, or an aralkyl group; (B) a bismaleimide compound defined by the following general formula (2): wherein R2 represents an alkyl group having 2 to 32 carbon atoms, an aryl group, or an aralkyl group, and (C) a diluent, and having a viscosity of 150 mPa·s or lower at 25° C.

Owner:TAIYO INK MFG CO LTD

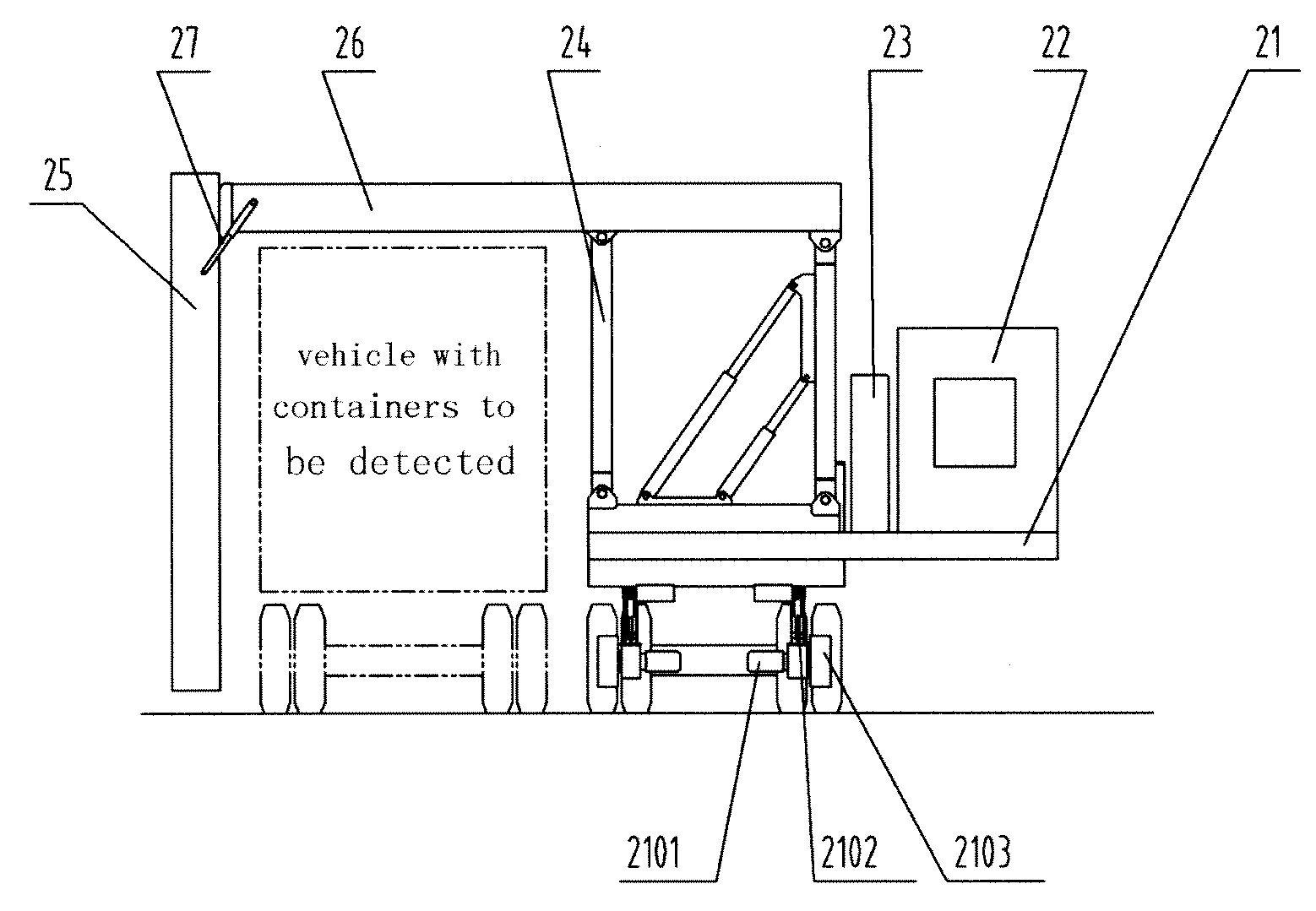

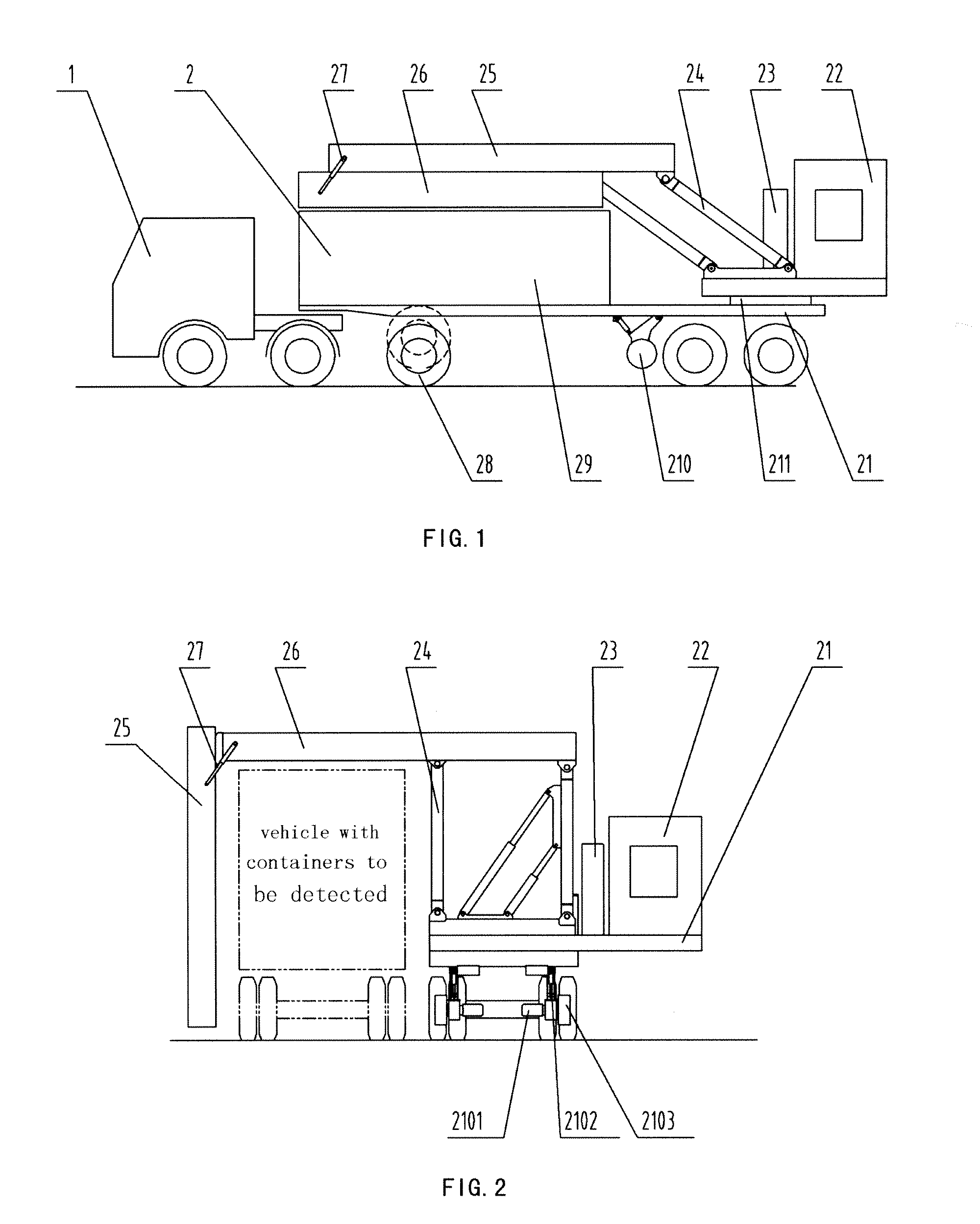

Detection Apparatus

ActiveUS20090271068A1Low failure rateMaintenance costDigital data processing detailsItem transportation vehiclesFailure rateEmission standard

A detection apparatus comprises a freely-movable integral framework provided with front wheels and rear wheels, characterized in that, a control portion and a scan portion, and a driving mechanism driving said framework to move are provided on said framework, wherein said framework is provided with a first interface for connecting to external power, so that said detection apparatus is driven by external power via the driving mechanism to perform detection while conducting detection on site, and wherein the semitrailer for mounting the framework is provided with a second interface connectable to a traction apparatus so as to connect the detection apparatus and the traction apparatus while carrying out site-changing transportation. Said detection apparatus is not affected by the alteration of the emission standards, has low failure rate and maintenance cost, has zero emission in the detection state, and is pollution-free.

Owner:NUCTECH CO LTD

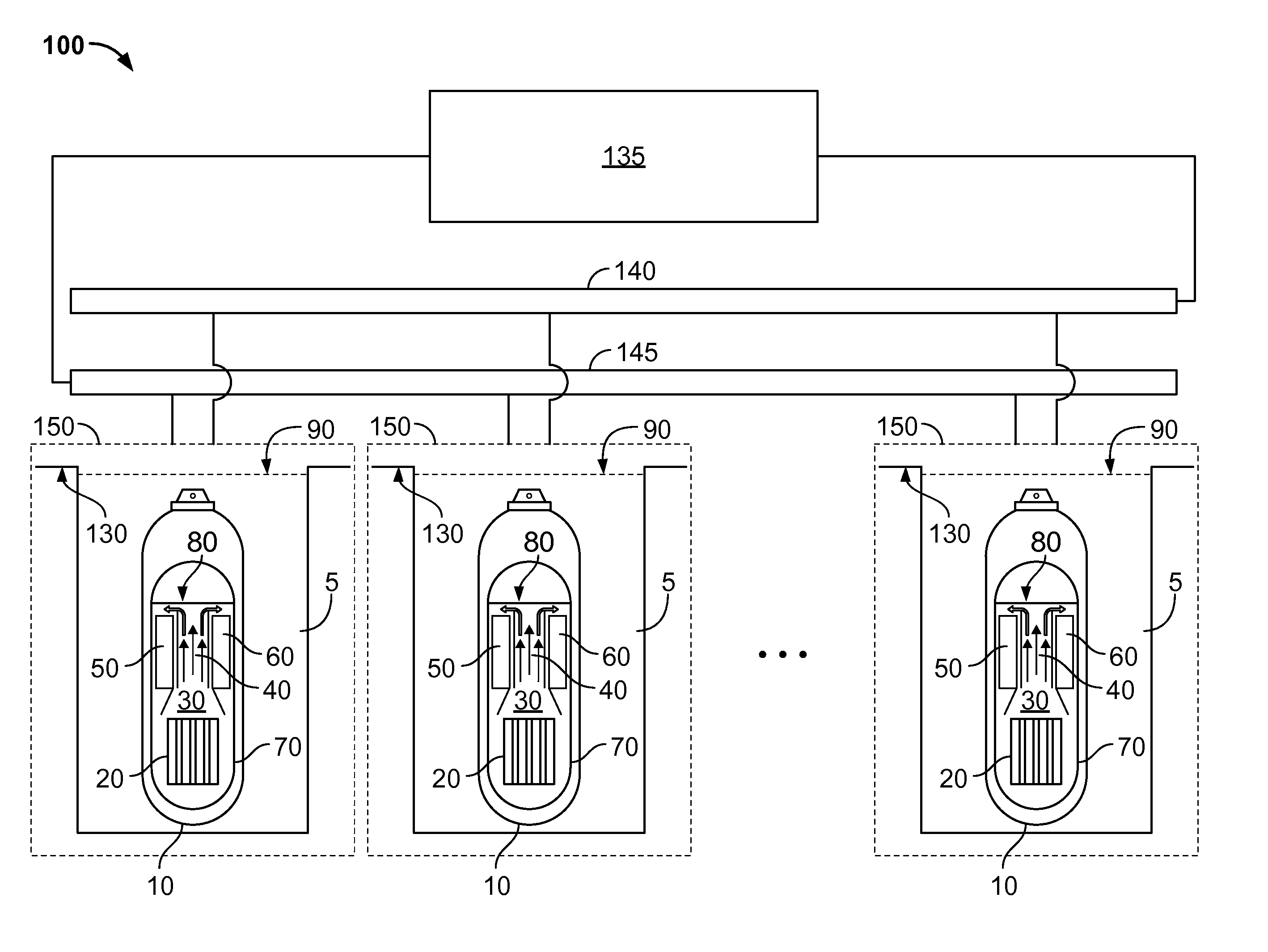

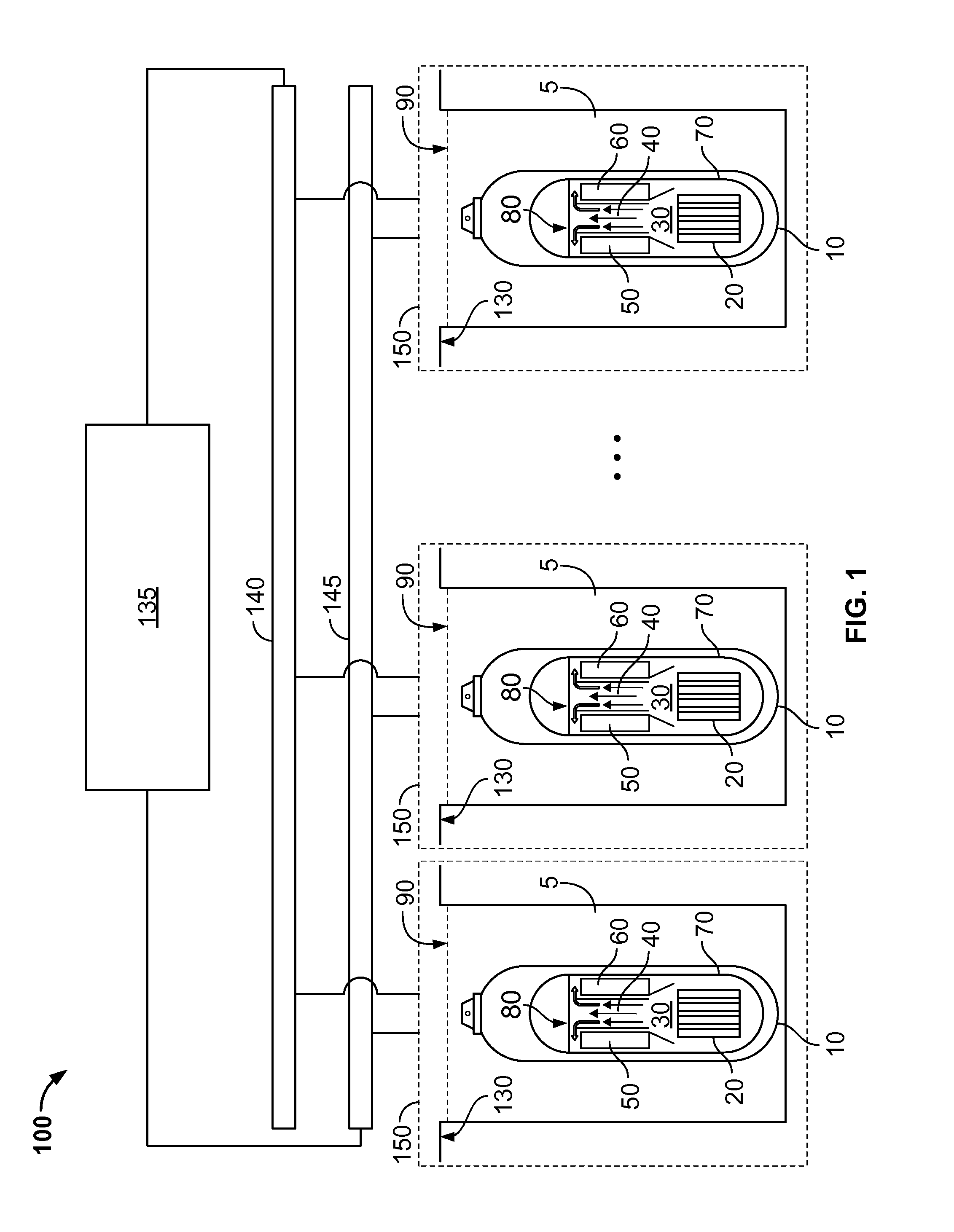

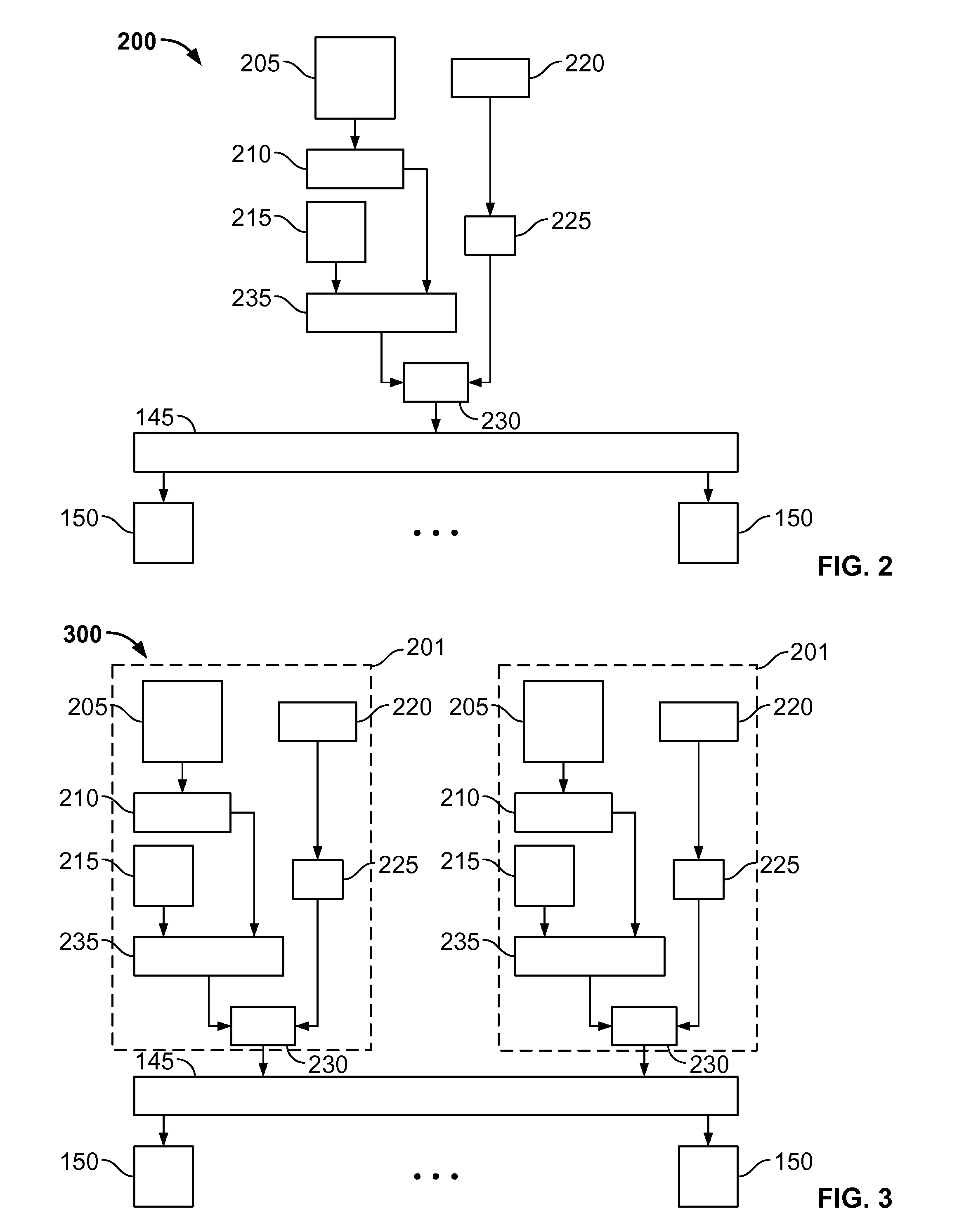

Managing Electrical Power for a Nuclear Reactor System

ActiveUS20140152098A1Maintenance costLow costPower plant safety arrangementNuclear energy generationElectricityNuclear reactor

An electrical power system for a nuclear power facility includes an active alternating current (AC) power bus configured to be electrically coupled to a plurality of engineered safety feature (ESF) loads of a plurality of nuclear power systems, each of the ESF loads configured to fail to a safe position upon loss of primary AC power; a critical battery system electrically coupled to the active AC bus, the critical battery system comprising a plurality of valve regulated lead acid (VRLA) batteries; and a primary AC power source electrically coupled to the active AC bus.

Owner:NUSCALE

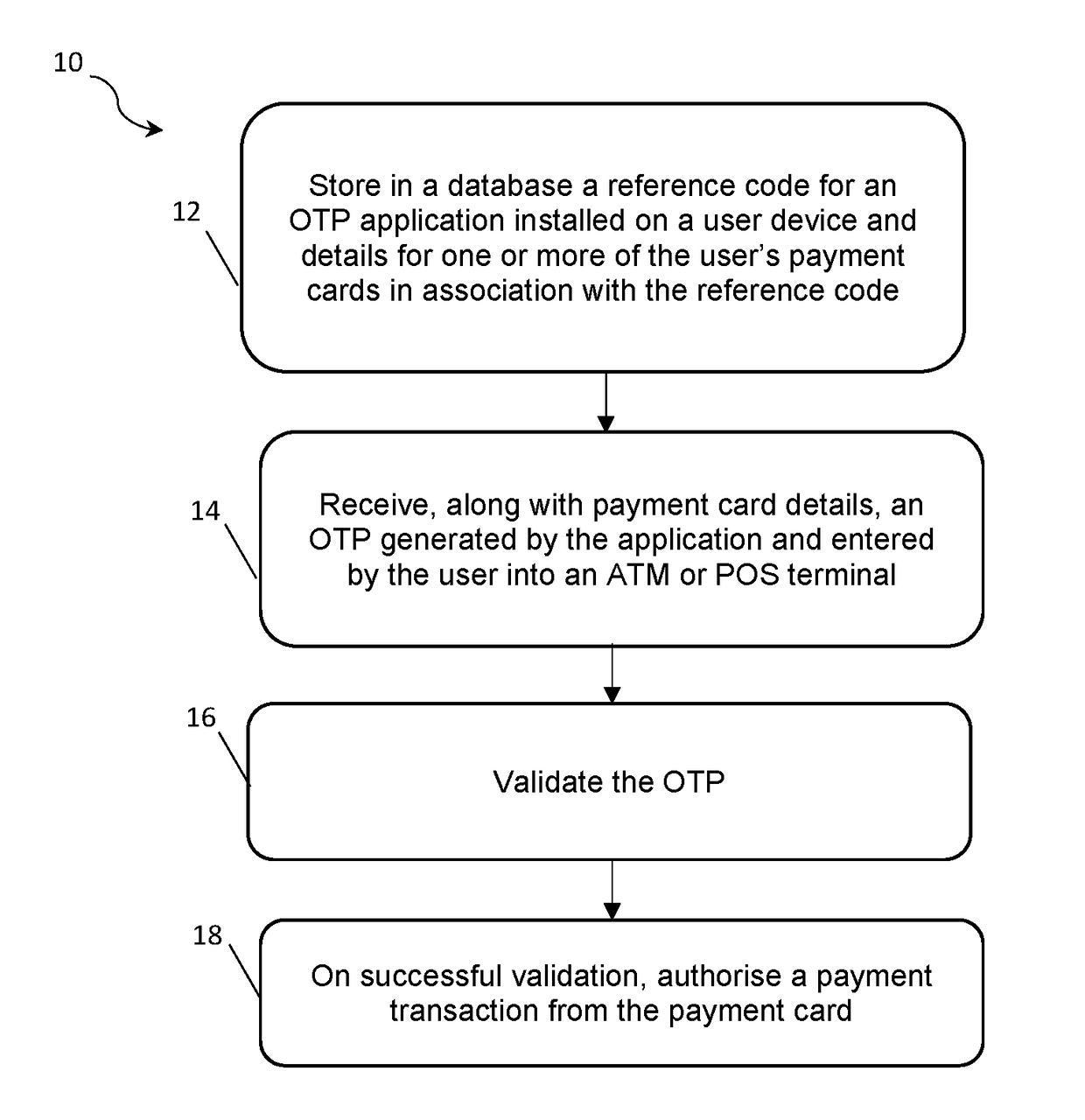

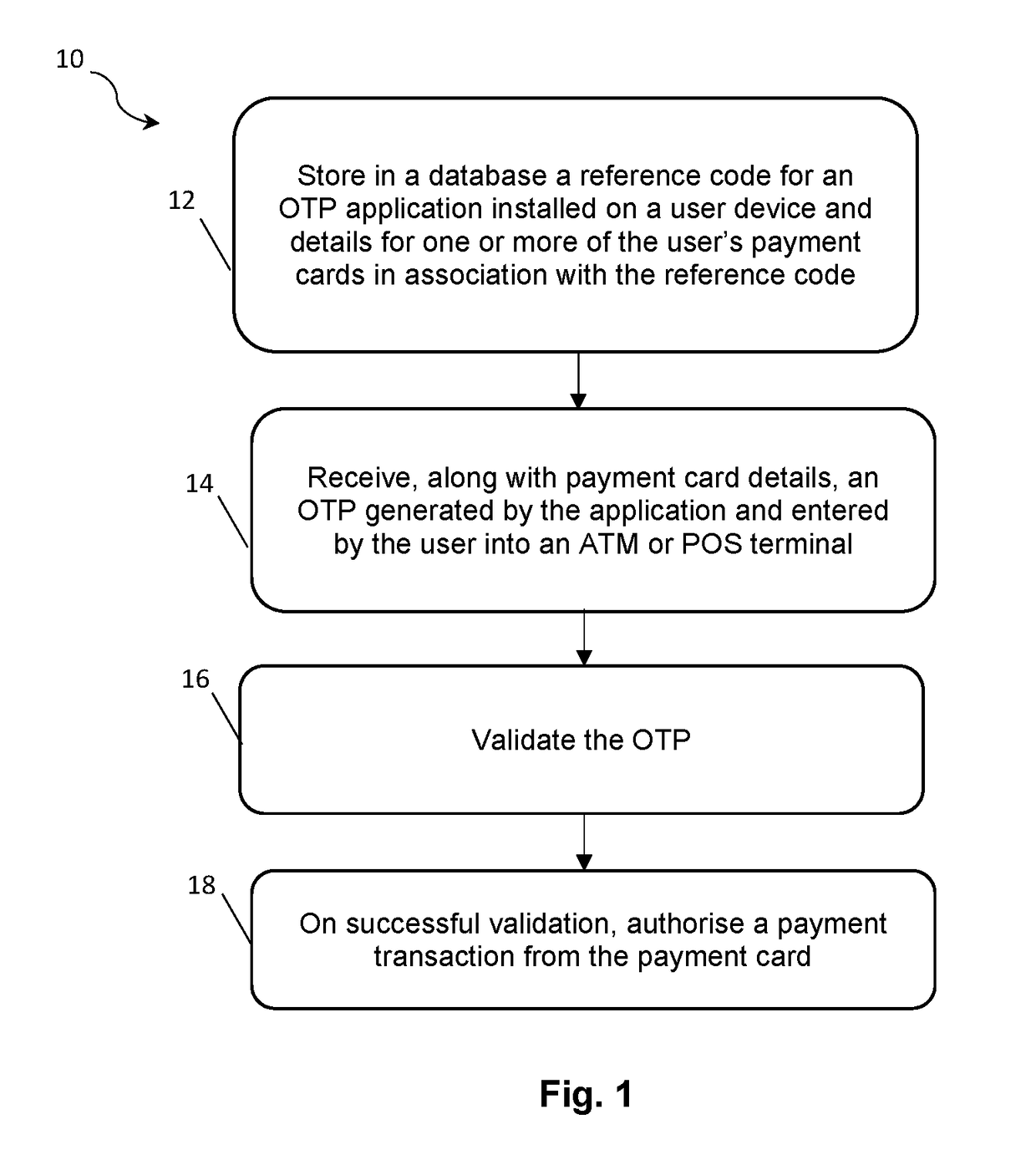

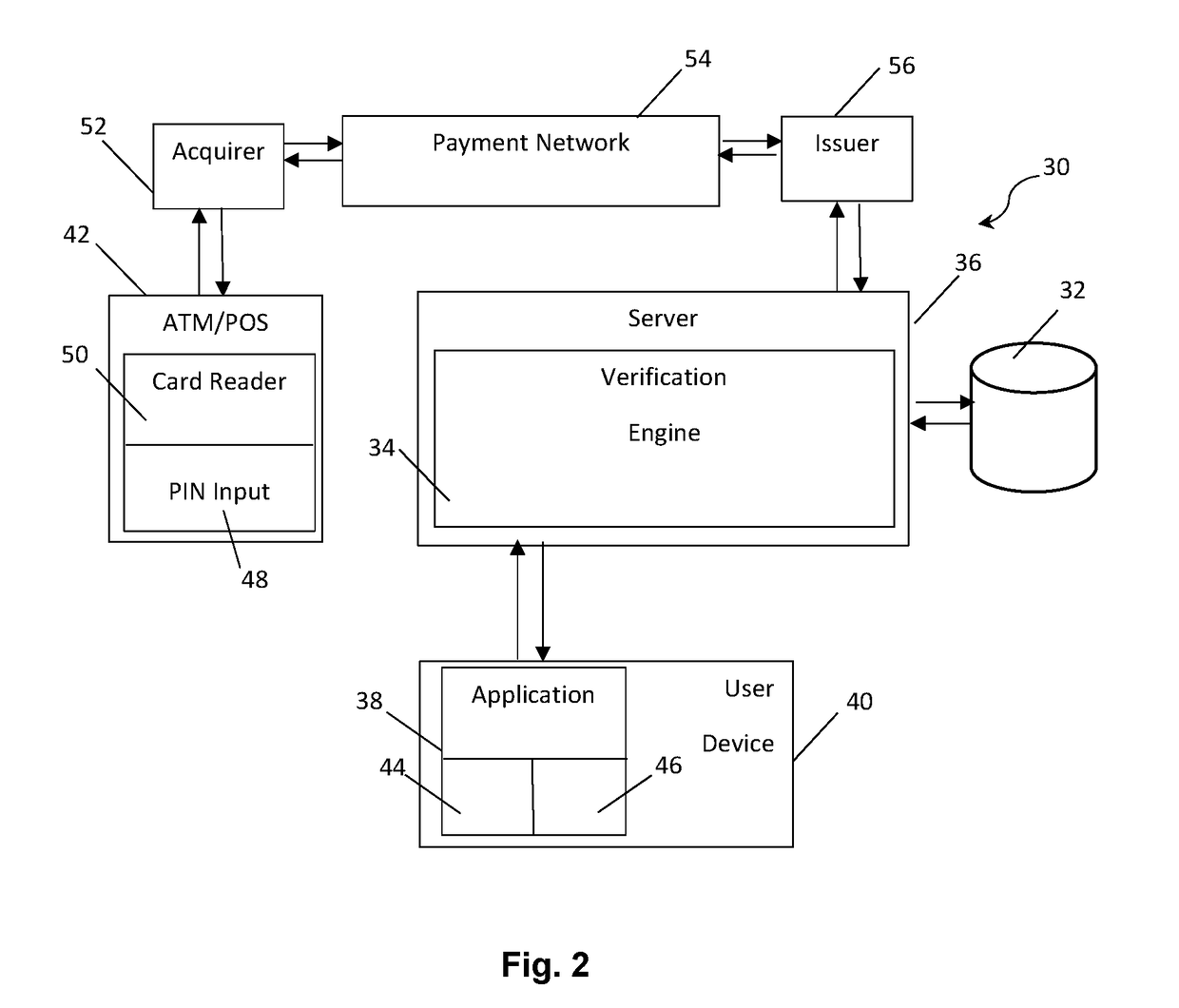

Method and system for dynamic pin authorisation for ATM or POS transactions

InactiveUS20170091730A1Negate needSecure in useDigital data authenticationPoint-of-sale network systemsPayment transactionApplication software

A computer-implemented method is proposed for OTP authorisation for ATM or POS transactions. The method comprises: a) storing in a database a reference code for an OTP application installed on a user device and details for one or more of the user's payment cards in association with the reference code; b) receiving, along with payment card details, an OTP generated by the application and entered by the user into an ATM or POS terminal; c) validating the OTP; and d) on successful validation, authorising a payment transaction from the payment card.

Owner:MASTERCARD INT INC

Access system for a cellular network

ActiveUS8144728B2Improve facilitiesReasonable priceAssess restrictionTelephonic communicationAccess networkStructure of Management Information

The present invention relates to a method and system for providing access to a cellular network (8), wherein a terminal device (1) is connected to an access device (2) according to access specifications of a broadband access network (12) which is not specifically designed to be used as a part of cellular network (8). The terminal device (1) indicates to the access device (2) that it wishes to be connected to the cellular network (8), and a session or call and a radio bearer is setup between the terminal device (1) and the cellular network (8). To achieve this, a service node (5) provided in the cellular network (8) requests a suitable access bearer from the access network (12) and the access device (2) sets up a corresponding access channel towards the terminal device (1). The terminal device (1) then associates the access channel to the correct radio bearer by using a corresponding identification. Thereby, service functions of the cellular network, e.g. UMTS services, can be distributed via any access network and existing broadband or high-speed access networks can be implemented in new cellular network structures. A huge capacity enhancement can thus be offered to the network operators of the cellular network without any standardization effort or license fee and at very small investment and maintenance costs.

Owner:NOKIA TECH OY

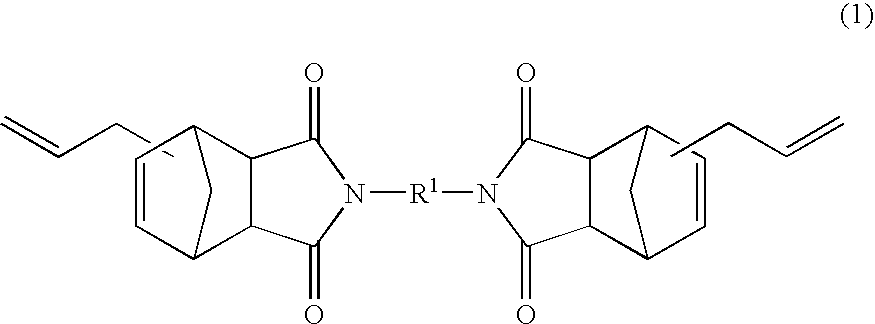

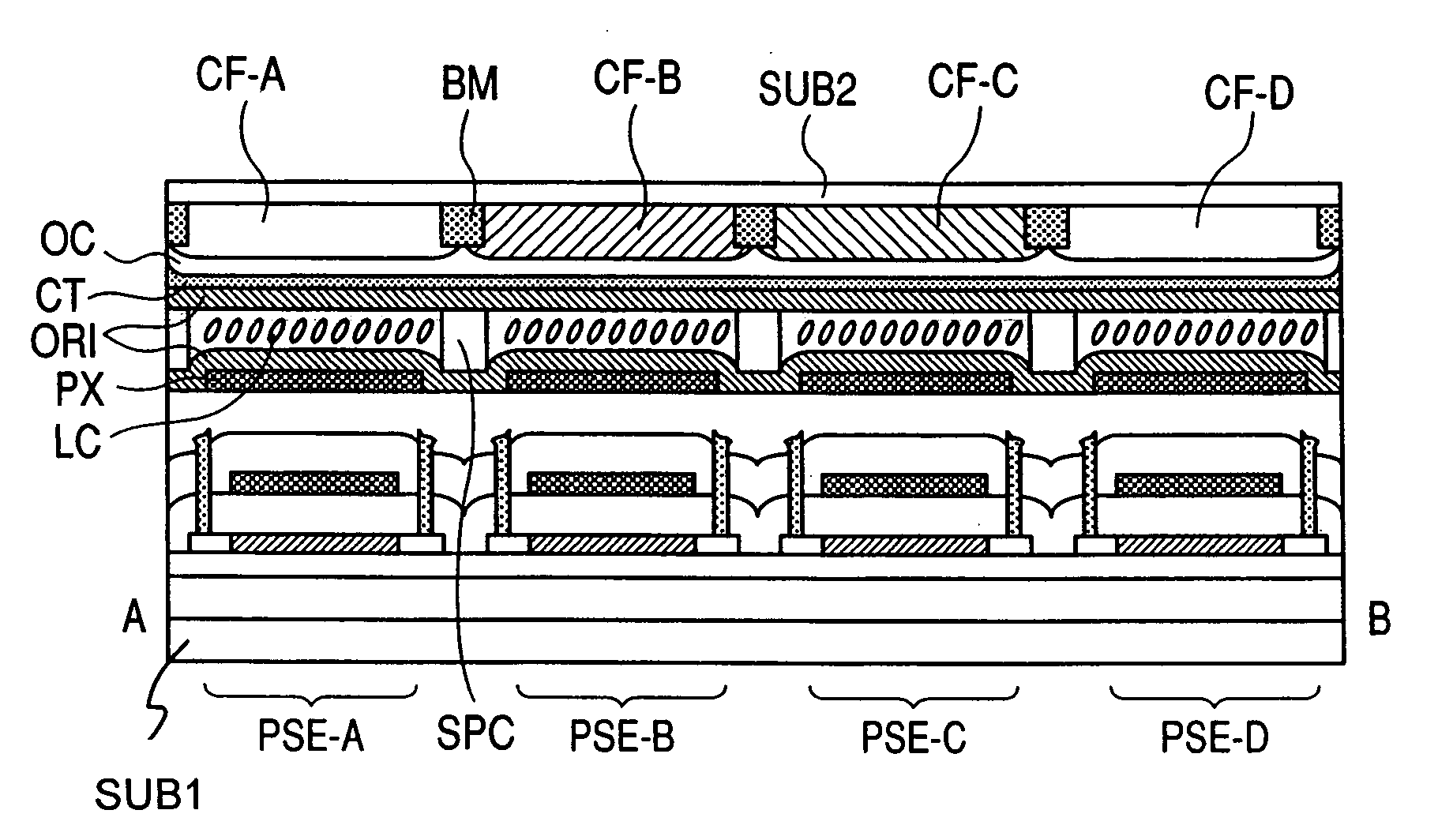

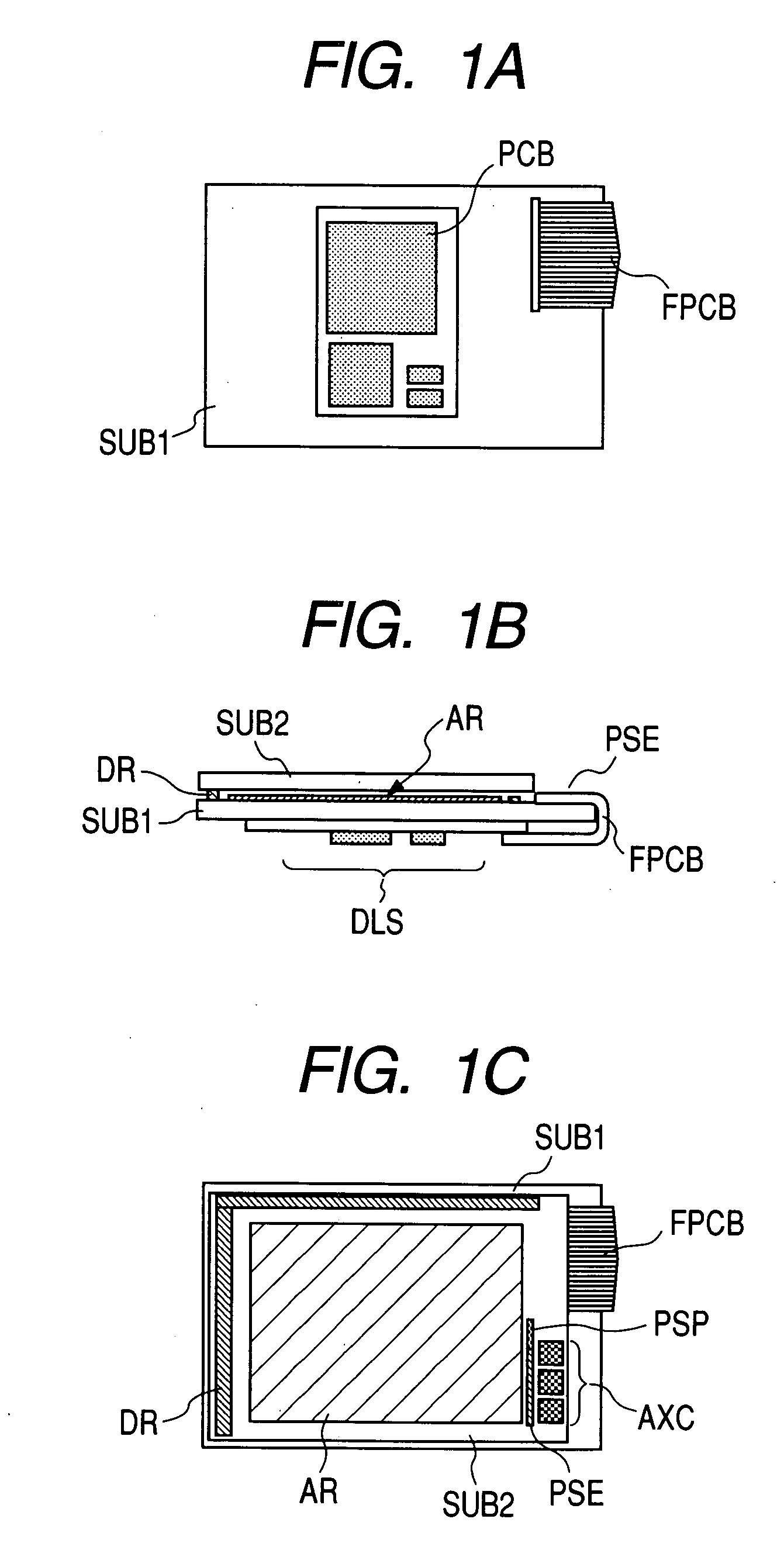

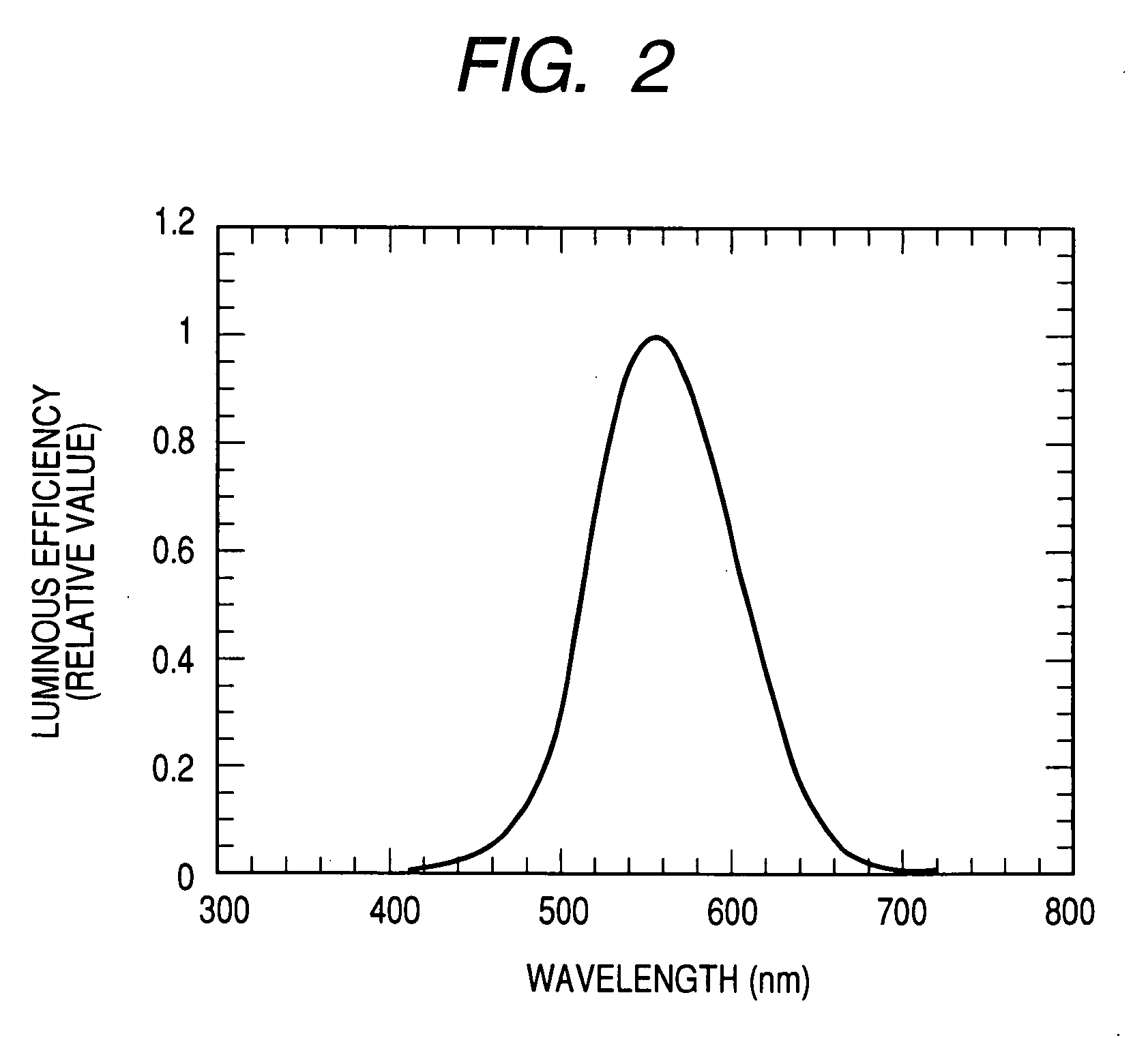

Image display apparatus with ambient light sensing system

InactiveUS20080164481A1Maintenance costLow costStatic indicating devicesFinal product manufactureSignal processing circuitsLight energy

An image display apparatus with an illuminance sensor, where the packaging cost, mechanical reliability due to packaging, and product yield are maintained. In the same semiconductor film as a thin-film-transistor (TFT) consisting of a pixel formed over an insulating substrate constituting a pixel, plural photo-sensors composed of a TFT for detecting light which has different detecting wavelength bands, and a signal processing circuit for generating a signal which controls the brightness of the pixel on the basis of the output of the photo-sensor are formed. The photo-sensor detects light energy of different wavelength bands by using a filter having a different film thickness of the semiconductor film or a different light transmission band. Ambient illuminance is detected by processing the output of each sensor in the signal processing circuit. The detected signal is fed back to the brightness control of the pixel.

Owner:JAPAN DISPLAY INC

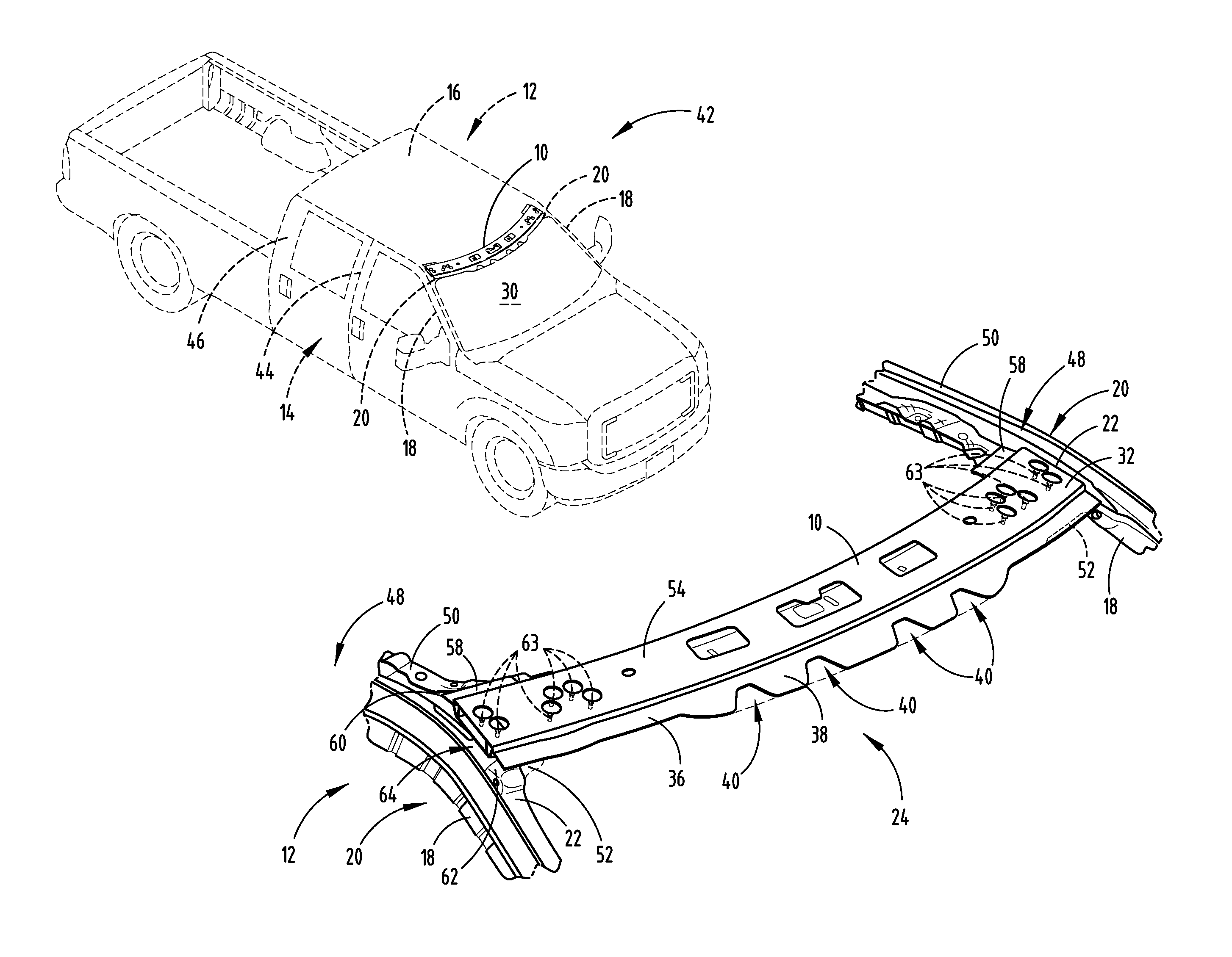

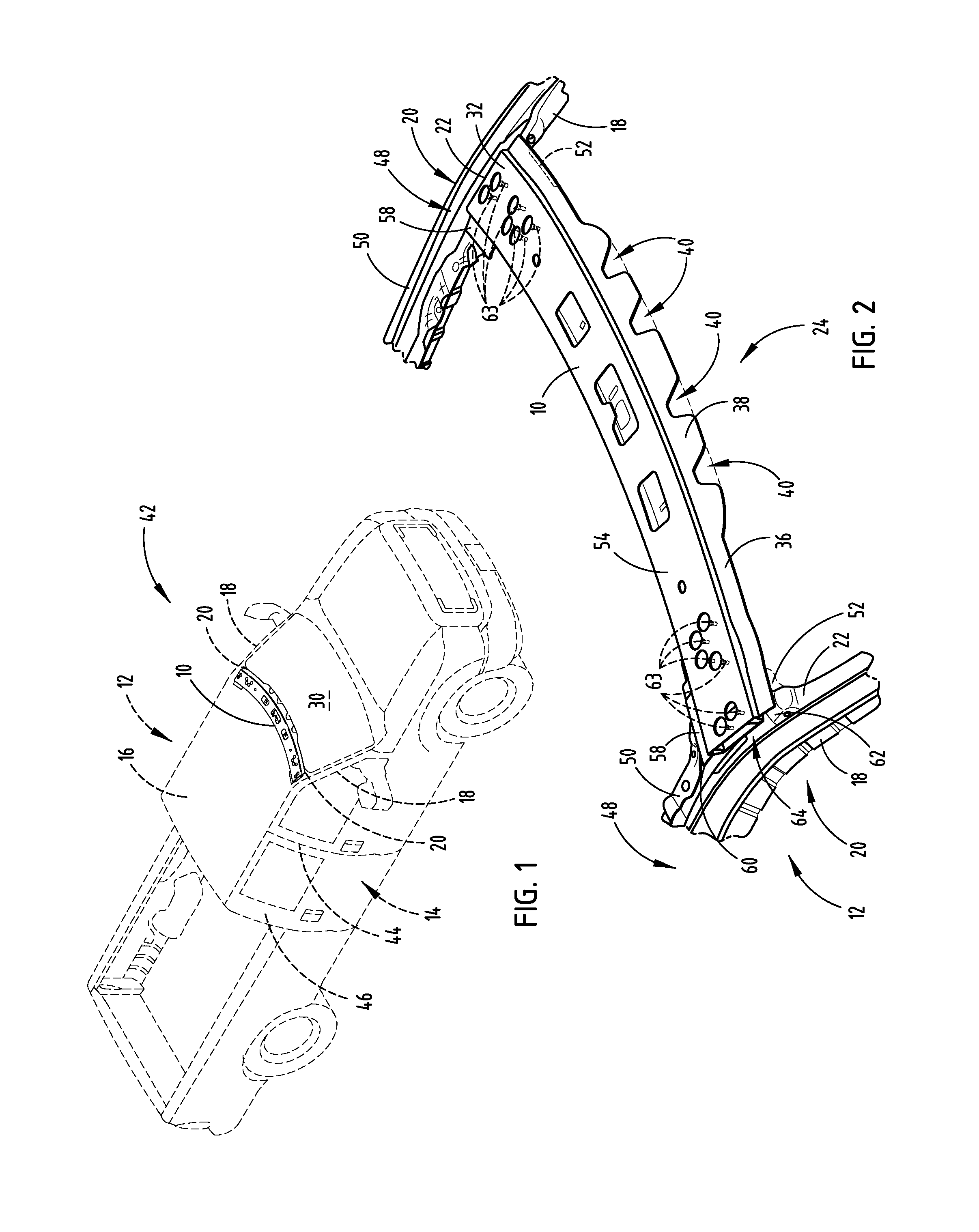

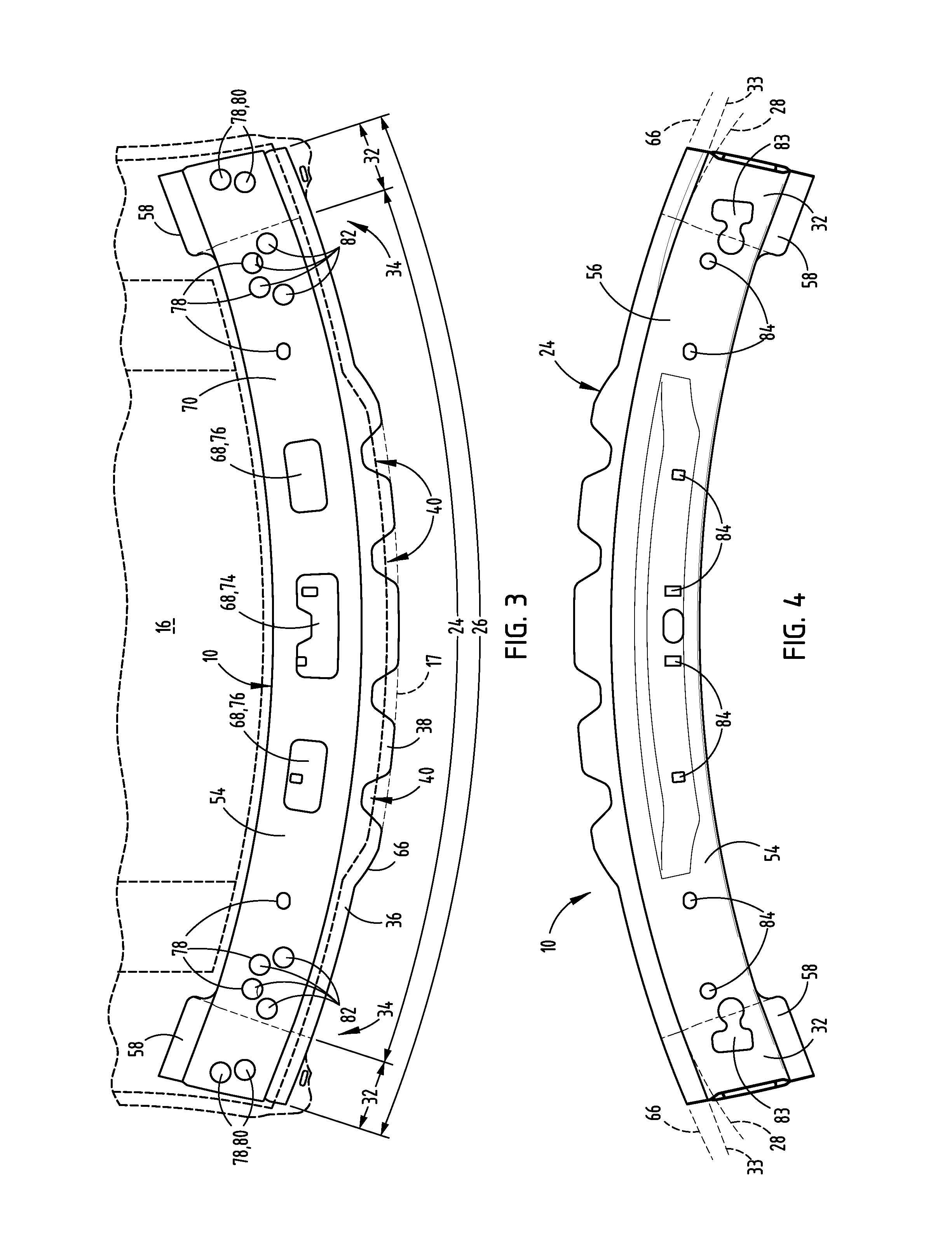

Header beam of a vehicle frame and method of forming the same

ActiveUS8998307B1Consistent curvatureReduced integrityVehicle seatsSuperstructure subunitsVehicle frameEngineering

A header beam couples between A-pillars of a vehicle frame. The header beam is formed from a generally straight beam segment that is extruded to have a hollow body portion with supportive legs extending within the hollow interior along the length of the beam segment, defining uninterrupted forward and rearward box sections for supporting continuous load paths on the header beam. The end portions of the beam segment are clamped and the beam segment is stretch bent to form a curvature between the end portions that remain generally straight. A front flange extends forward along the body portion and is struck proximate the end portions to form an edge that is parallel to the curvature formed between the end portions. The end portions are attached to the A-pillars and the edge of the front flange is attached to a windshield.

Owner:FORD GLOBAL TECH LLC

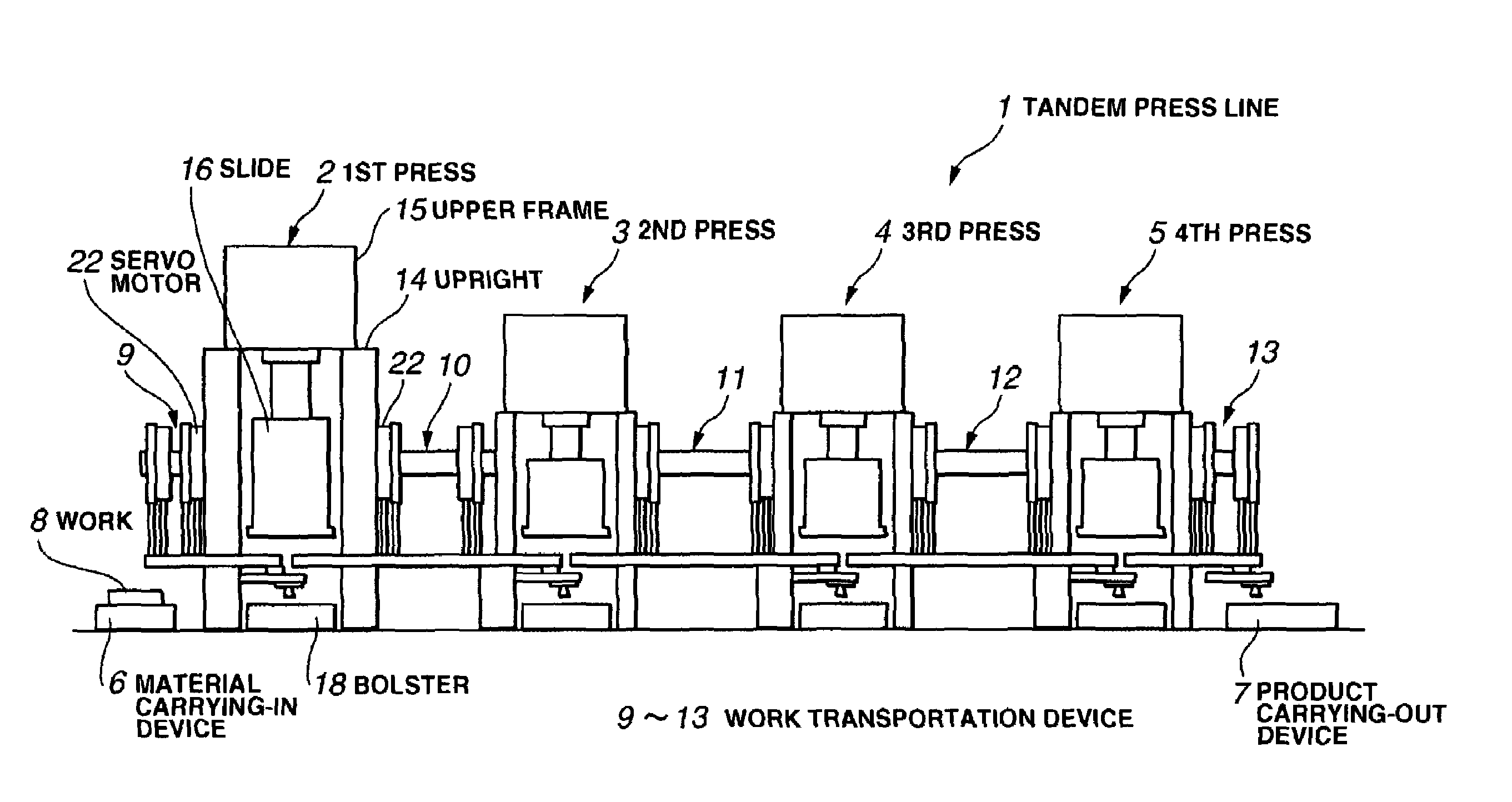

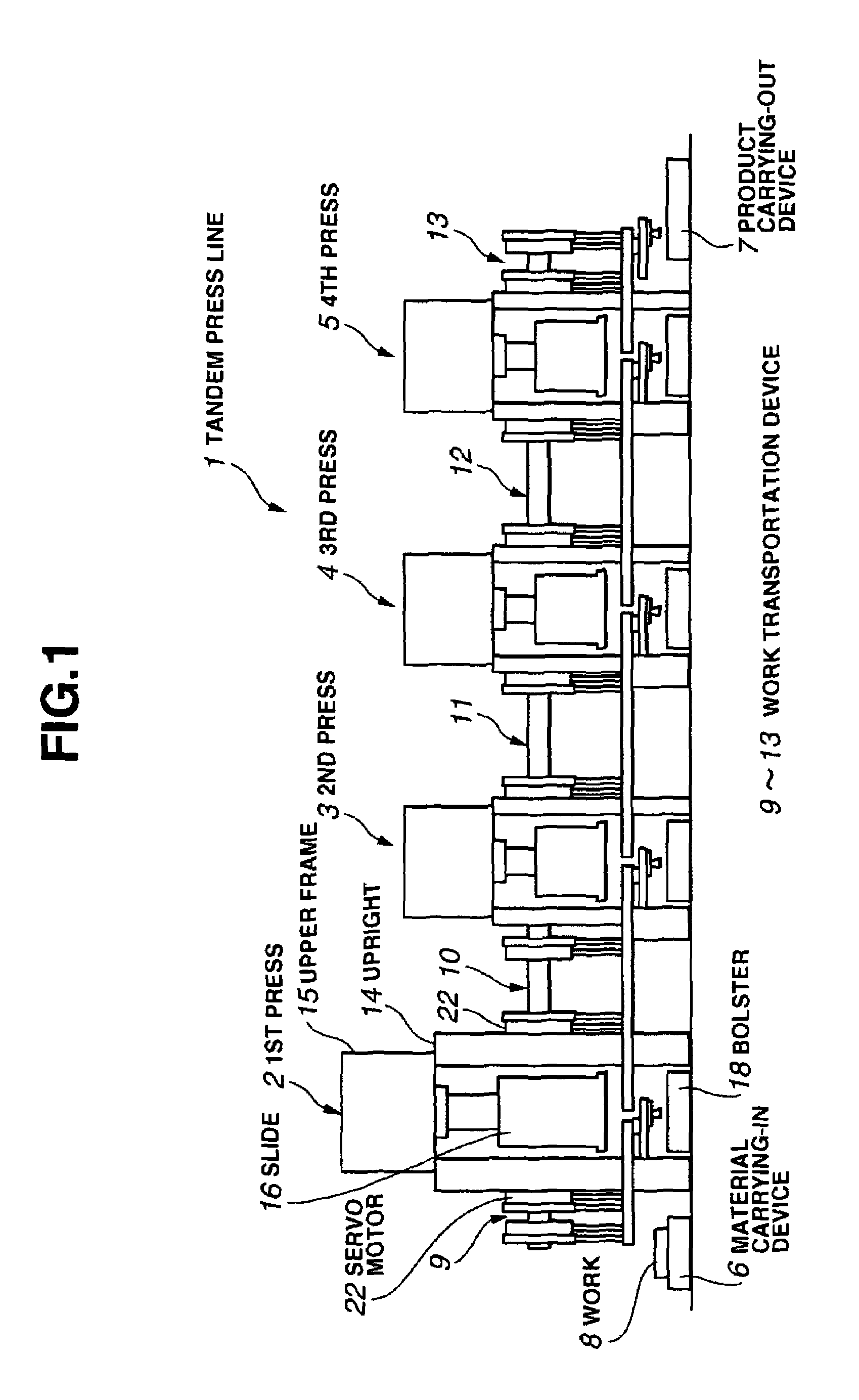

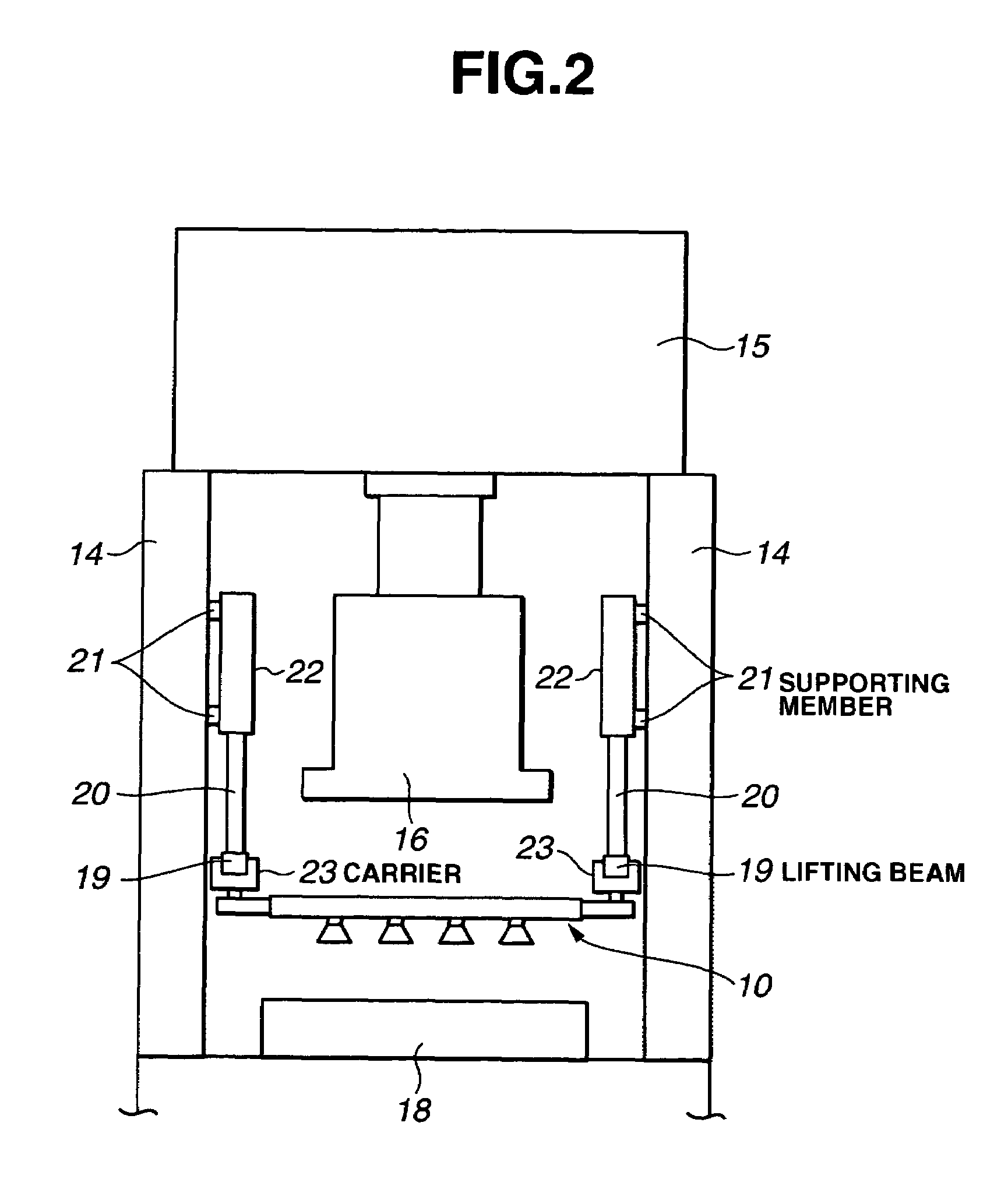

Tandem press line, operation control method for tandem press line, and work transportation device for tandem press line

ActiveUS7428837B2Stable controlEfficient press formingMetal-working feeding devicesForging hammersAngular differenceMachine press

Owner:KOMATSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com