Soot blowing method of heating furnace

A technology of heating furnace and soot blower, which is applied in the field of heating furnace soot blowing, and can solve problems such as failure to blow, under-blowing, blindness of soot blowing operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

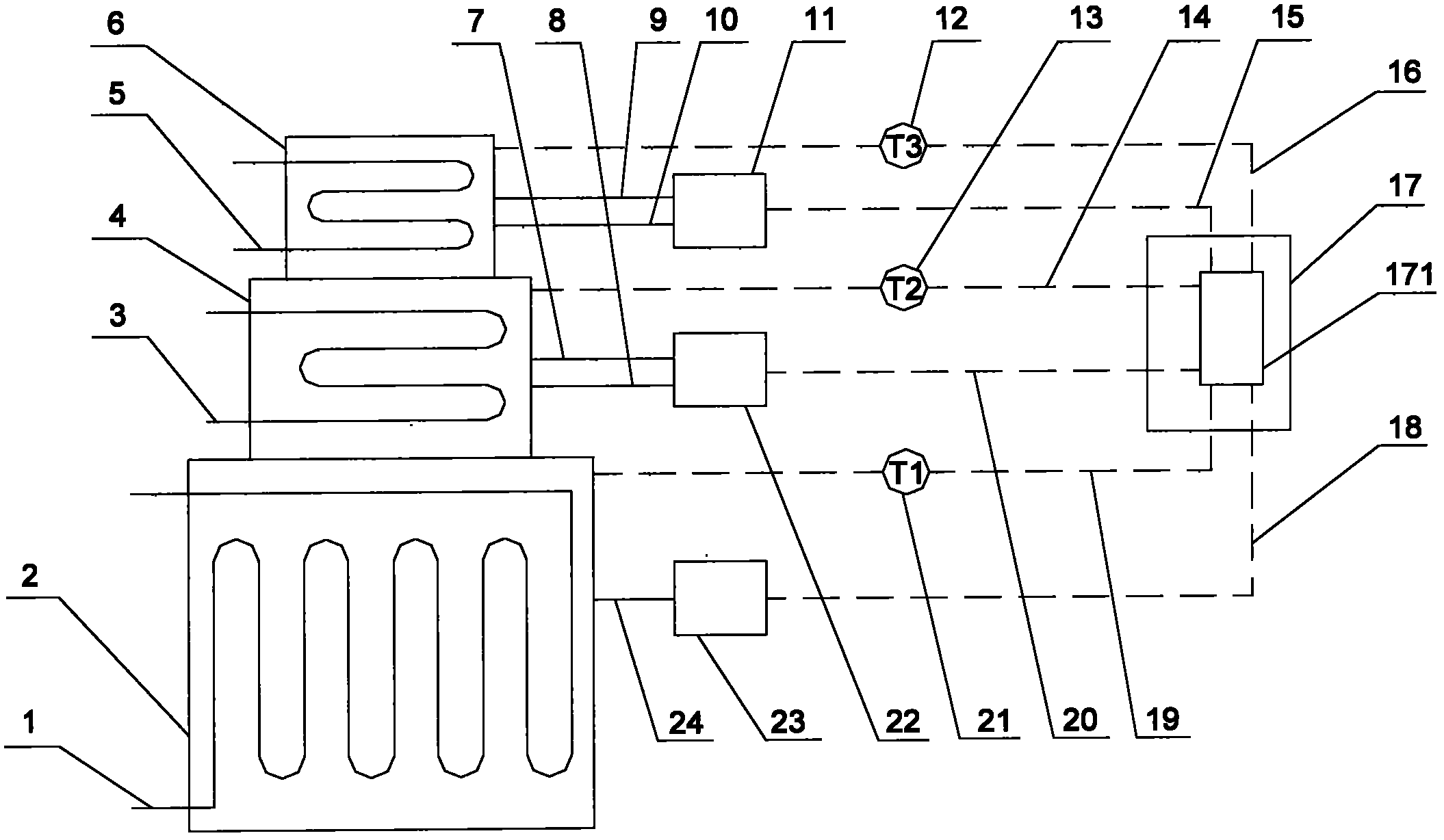

[0019] figure 1 The present invention is applied to a tubular heating furnace. This type of tubular heating furnace is currently the most widely used in refining and chemical enterprises. It includes three parts: radiation section 2, convection section 4 and air preheater 6. The radiation furnace tube 1 is set in the section 2, the convection furnace tube 3 is set in the convection section 4, and the heat exchange tube 5 is set in the air preheater 6. The radiation furnace tube 1 can only be cleaned with a soot cleaning agent due to structural reasons, and the convection furnace The tube 3 and the heat exchange tube 5 can use a combination of steam and soot cleaning agent cleaning technology.

[0020] Each area of the heating furnace is equipped with a flue gas outlet temperature measuring device: a radiation section temperature measuring device 21 a convection section temperature measuring device 13 and an air preheater section temperature measuring device 12, and the flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com