Device for improving fullness of combustible gas in shock wave generation tank

A technology for generating tank and fullness, which is applied in the field of boiler soot blowing, which can solve the problems of insufficient deflagration, insufficient mixing of gas and air, etc., and achieve the effects of increasing gas utilization rate, improving soot blowing effect, and ensuring correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

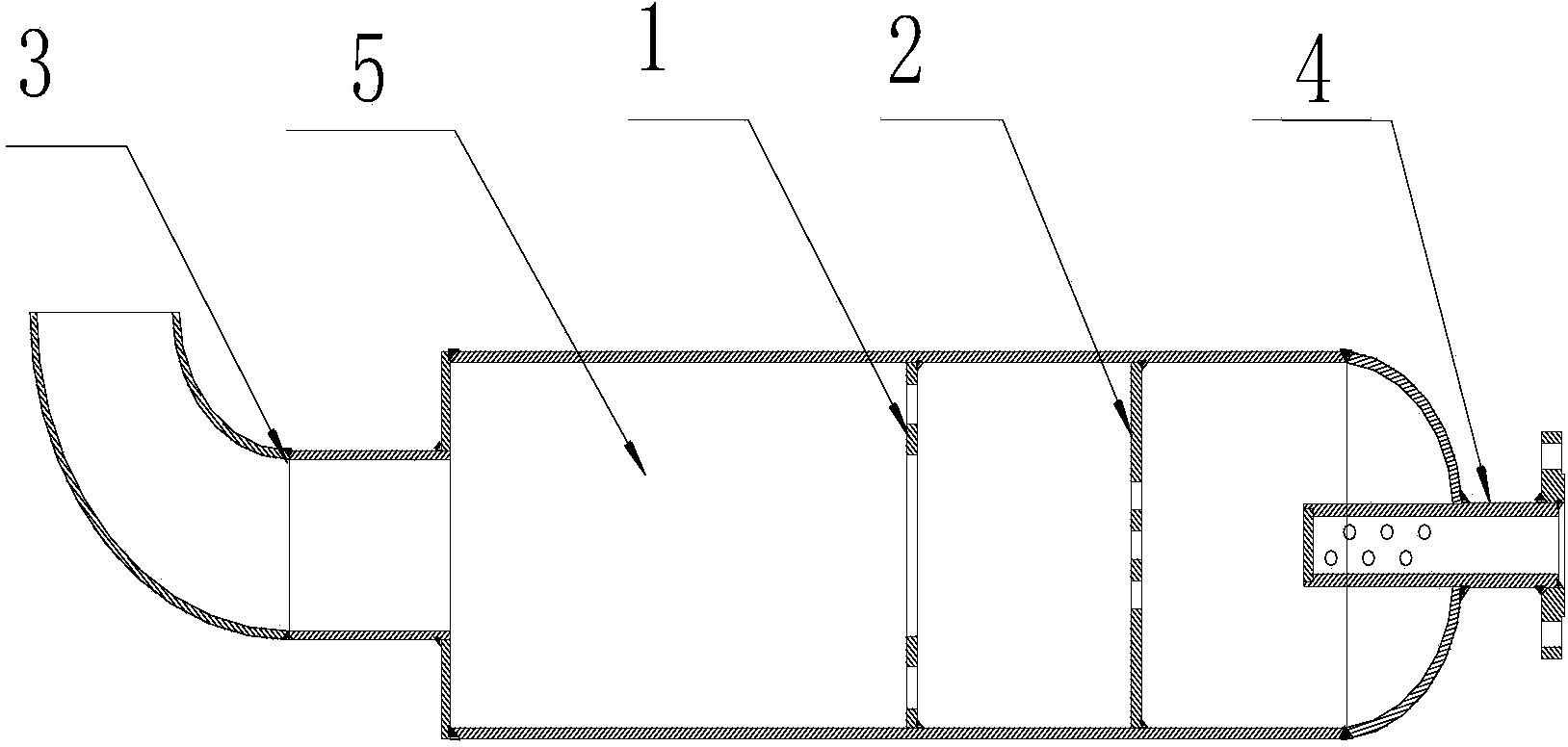

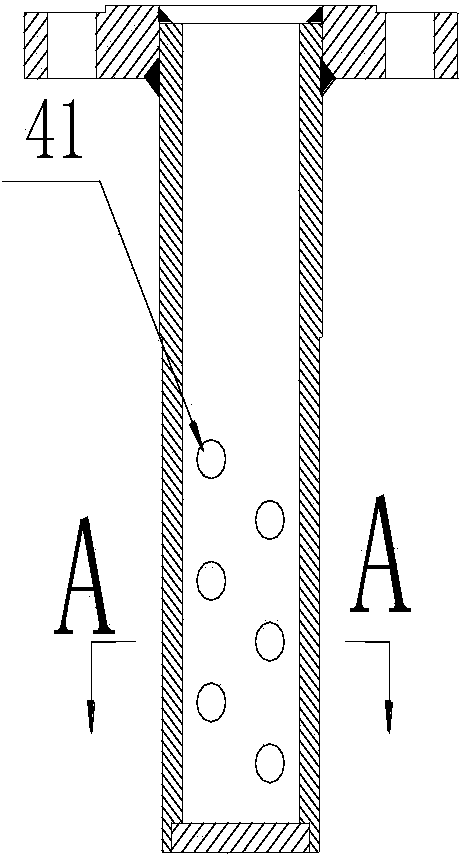

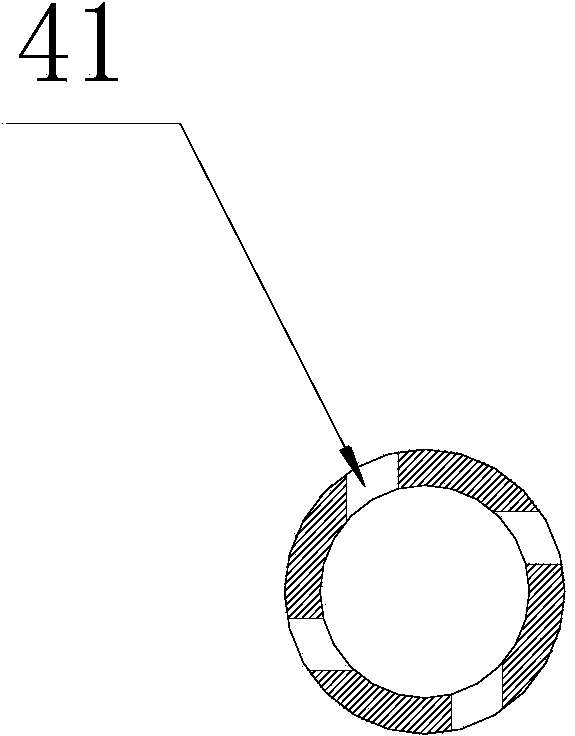

[0020] see Figure 1 to Figure 7 , the embodiment of the present invention provides a device for improving the fullness of combustible gas in a shock wave generating tank, including an air inlet port 4, a head, a first baffle 1, a second baffle 2, a generator tank 5 and a spout 3. Among them, the air inlet 4 is welded with one end of the generator tank body 5 through the head, and the other end of the generator tank body 5 is welded with the nozzle 3; In the generator tank 5 adjacent to the end of the air inlet port 4, and the second partition plate 2 and the first partition plate 1 are arranged in parallel at preset intervals; The plate 1 is provided with a central through hole 11 and oblique holes 12 evenly distributed along the circumference around the central through hole 11; the second partition plate 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com