Injection mold for filter screen

A technology for injection molds and filter screens, applied in the direction of coating, etc., can solve problems such as cumbersome processes and affect product quality, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

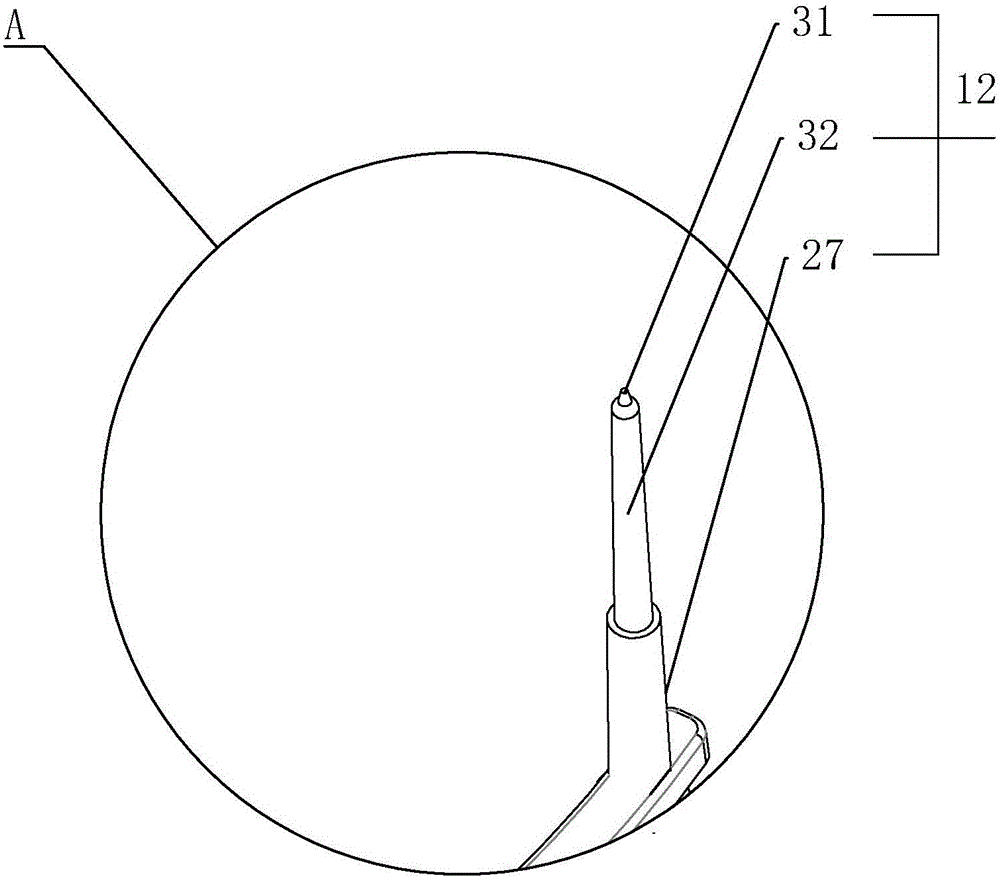

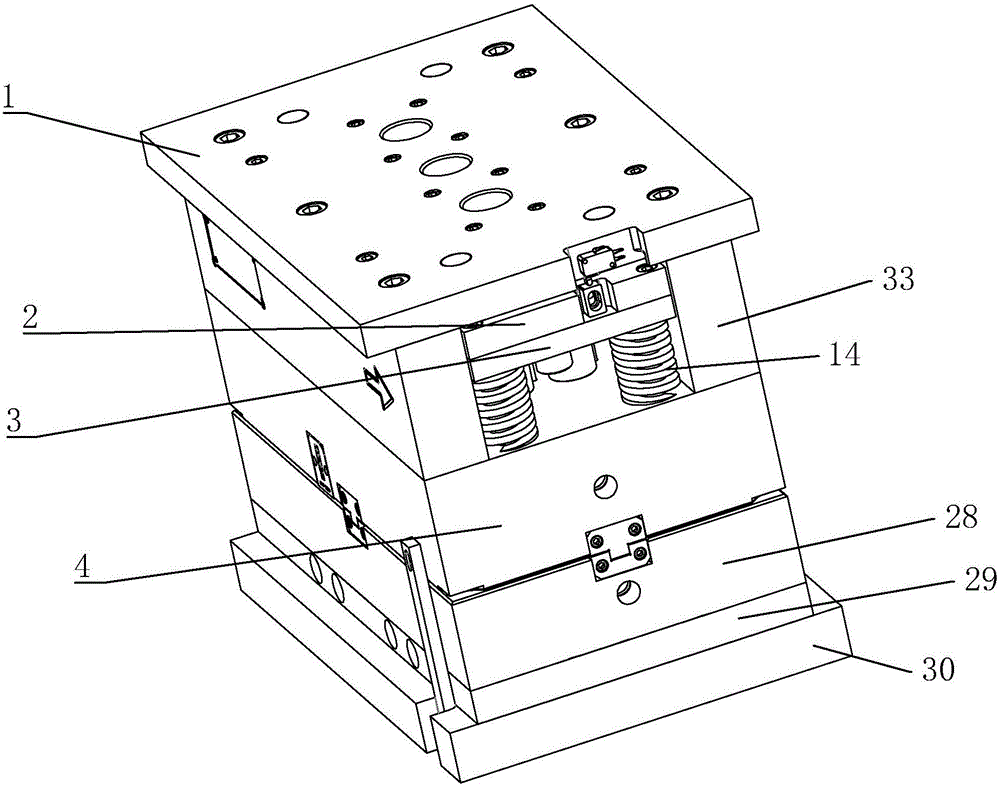

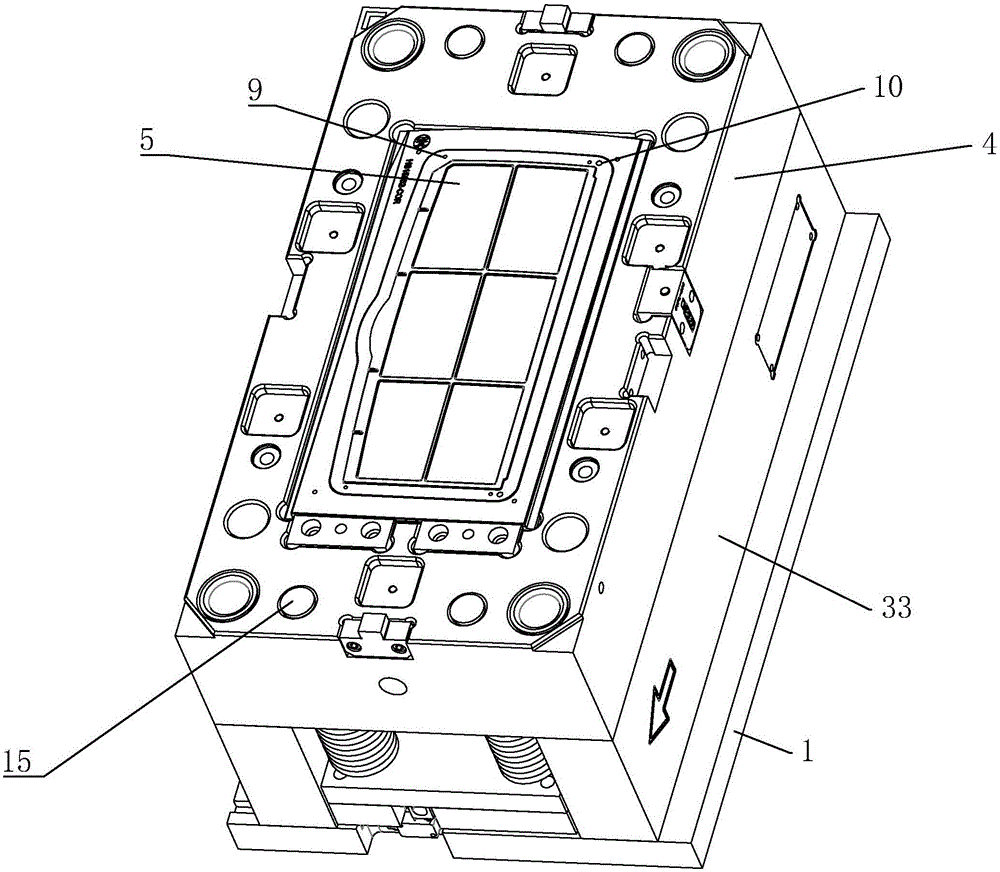

[0025] combined with Figure 1 to Figure 5 The present invention is described in further detail.

[0026] A kind of filter net injection mold, comprises moving die, middle plate 28 and fixed die successively, described moving die comprises die fixed plate 4, and described fixed die comprises backing plate 29, and described die fixed plate 4 is provided with the first A die 5, the side of the middle plate 28 facing the die fixing plate 4 is provided with a second die 6 that cooperates with the first die 5, and the side of the middle plate 28 away from the second die 6 is provided with There is a runner, and the runner is provided with a secondary runner 12 perpendicular to the middle plate 28 to the inside of the middle plate 28, and the middle plate 28 is provided with several vertical channels on the side facing the first die 5. A fixing rod 8 for hanging the filter screen, and a first fixing hole 9 matched with the fixing rod 8 is provided on the die fixing plate 4 . The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com