Condensate water preventing type efficient kit drying device

A technology for preventing condensation water and drying equipment, which is applied to drying, drying machines, lighting and heating equipment, etc. The effect of saving consumption, extending relative time and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

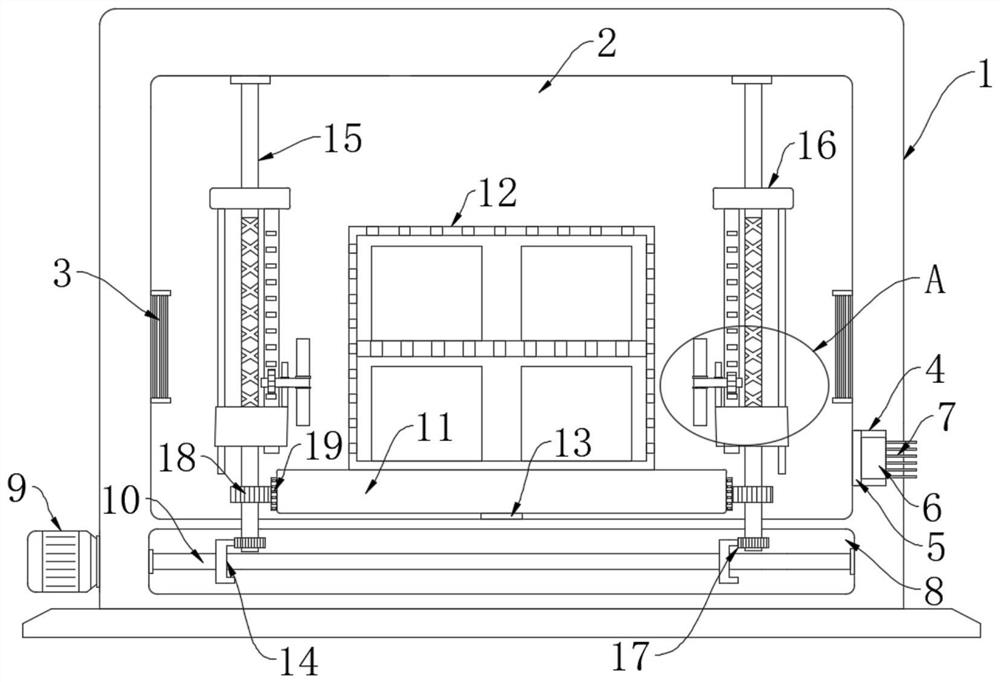

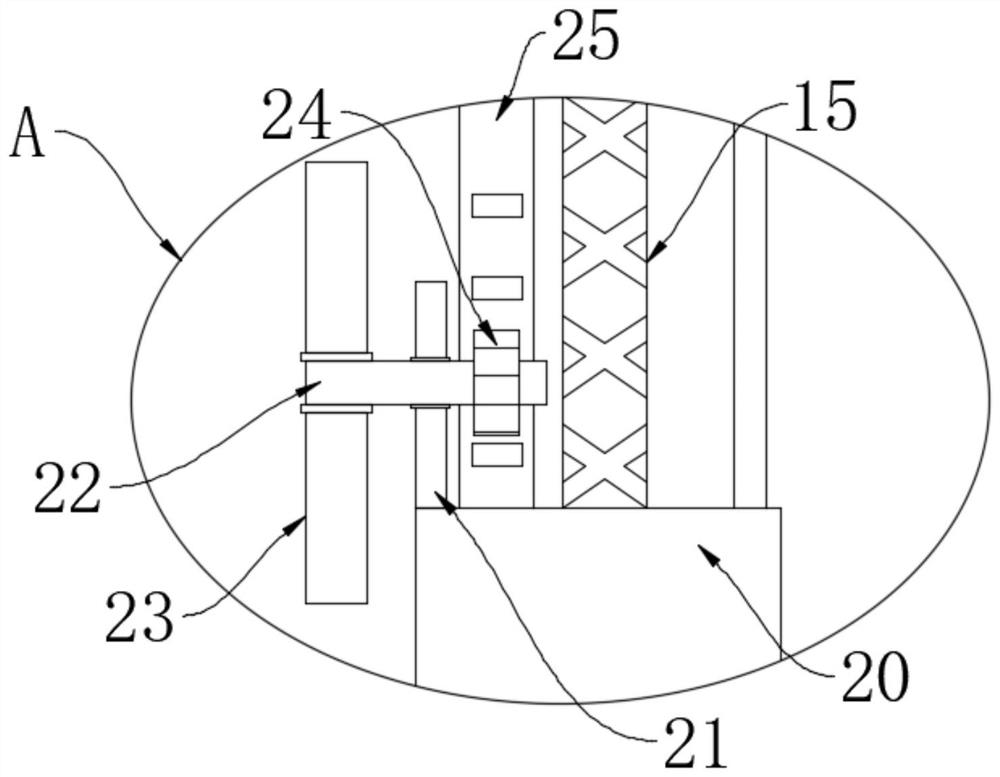

[0024] refer to Figure 1-2 , an anti-condensation water type high-efficiency kit drying equipment, comprising a drying box 1, a drying chamber 2 and a rotating chamber 8 are provided in the drying chamber 1, the rotating chamber 8 is located below the drying chamber 2, and the drying chamber 2, both sides inner wall is all equipped with heating resistance wire 3, heating resistance wire 3 is prior art, generates heat after electrification, is provided with placement frame 12 in drying chamber 2, placement frame 12 is made up of a plurality of perforated plates, each The manufacturing materials of each porous plate are heat-conducting materials, which are convenient to quickly transfer heat to the test kits, and multiple test kits are placed in the placement frame 12;

[0025] The energization mechanism, the energization mechanism includes a power generation tank 4 provided on the inner wall of one side of the drying chamber 2, a heat conduction plate 5 is fixedly connected to...

Embodiment 2

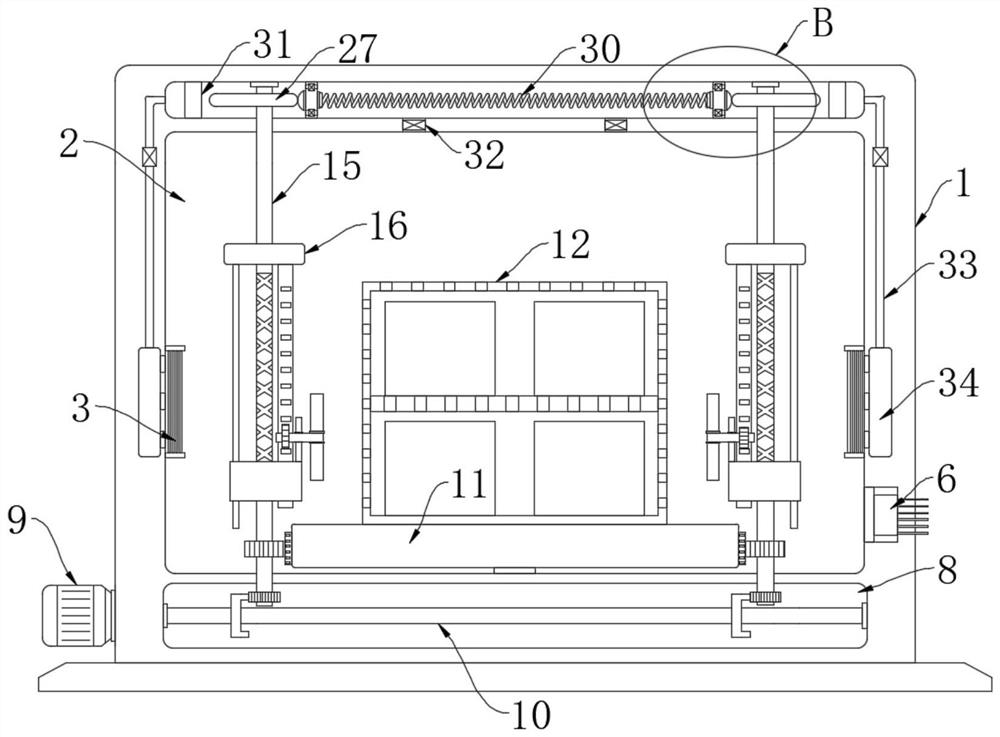

[0032] refer to Figure 3-4 , The difference between this embodiment and Embodiment 1 is that a movable cavity 26 is provided in the drying box 1, and the movable cavity 26 is located above the drying chamber 2, and the upper ends of the two vertical rods 15 all extend into the movable cavity 26 , the parts of the two vertical rods 15 located in the movable chamber 26 are provided with cams 27, and the movable chamber 26 is symmetrically provided with two baffles 28 for sliding left and right, and the two baffles 28 are located between the two cams 27 , the opposite ends of the two baffles 28 are elastically connected by springs 30, the opposite ends of the two baffles 28 are matched with the corresponding cams 27, the opposite ends of the two baffles 28 are fixedly connected with bumps, and the bumps Offset with the cam 27, the movable chamber 26 communicates with the drying chamber 2 through two inlet pipes 32, so as to absorb the gas in the drying chamber 2 into the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com