Method and apparatus for cleaning ash on surface of denitrification catalyst through fuel gas impact

A technology of denitrification catalyst and soot cleaning device, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of reduced service life, damage to boiler tubes, and increased maintenance frequency, so as to avoid damage and ensure the effect of soot blowing , The effect of reducing investment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

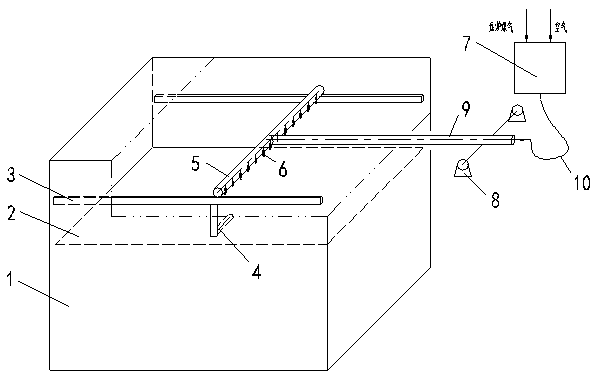

[0022] Such as figure 1 As shown, the denitrification catalyst surface gas soot cleaner of the present invention includes a slide rail 3 , an igniter 4 , a sliding arm 5 , a burner 6 , a mixer 7 and a driving device 8 . The slide rail 3 is installed on the inner wall of the denitrification reactor housing 1, and the slide arm 5 is installed on the slide rail 3 through a pulley. The burner 6 that spouts fire below, the burner 6 adopts the high-speed burner of the pre-mixed burner type, and has a combustion chamber itself. After the fuel and air are mixed, the complete combustion (85%) is basically achieved in the combustion chamber The gas is ejected from the converging port at a high speed by the gas combustion expansion pressure, and the speed is 90-120m / s, and the highest can reach 300m / s.

[0023] A gas inlet pipe 9 is fixedly connected to the sliding arm 5 , and the sliding arm 5 communicates with the gas inlet pipe 9 . The gas inlet pipe 9 is connected to the air-gas mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com