SMC molded air cylinder double molding production method

A production method and secondary molding technology, which is applied in the field of cooling towers, can solve the problems of environment and personnel influence, excessive dust, long production cycle, etc., and achieve the effect of improving strength, ensuring structural strength and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

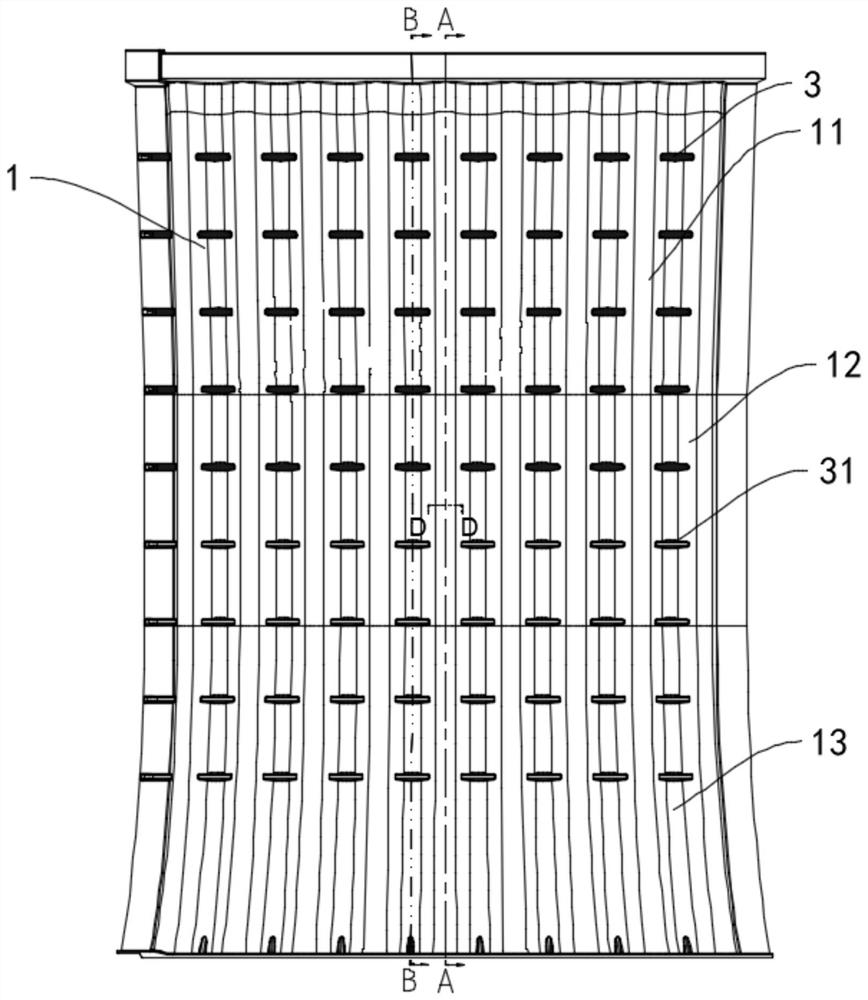

[0028] Please combine figure 1 , 2 , Shown in 5 and 6, a kind of SMC molded blower cylinder twice molding production method, its steps are:

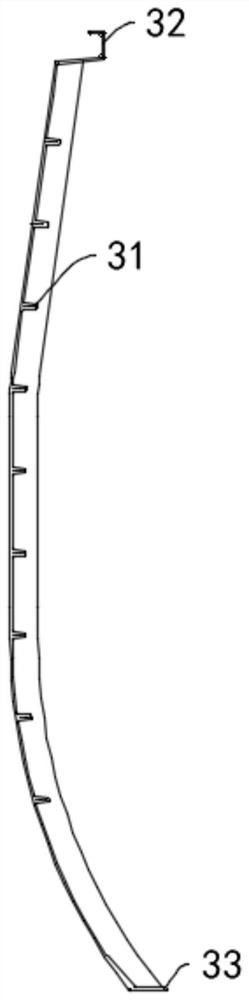

[0029] Filler primary molding: place the filler 2 on the filler mold, the surface of the filler 2 is covered with a certain thickness of SMC sheet, and molded by a press to obtain the primary molded filler 2; wherein, the filler mold is Filler mold reinforcing rib grooves are provided for molding positioning reinforcing ribs 4, and the positioning reinforcing ribs 4 are located on both sides of the obtained primary molded filling 2; the shape of the filling 2 at this time is Image 6 structure shown.

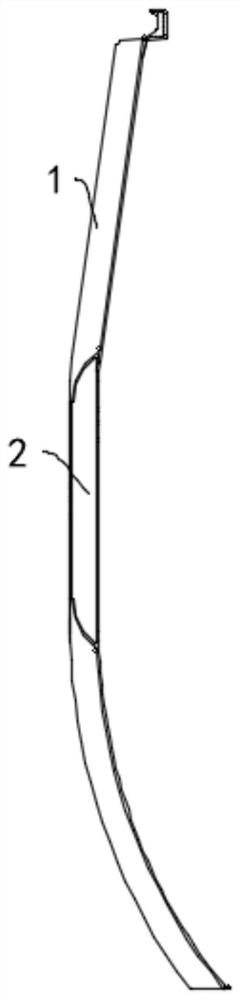

[0030] Secondary molding of the filler: place the filler 2 obtained by the primary molding on the fan cylinder mold, and accurately position and pave the The SMC material is subjected to secondary molding with a press to obtain an SMC molded air duct. The shape of the formed SMC molded air duct is figure 1 As shown in the structure, a...

Embodiment 2

[0037] Such as Figure 1-6 As shown, a SMC molded air cylinder is formed by connecting and combining several air cylinder bodies 1. The cross section of the air cylinder body 1 is in the shape of a sine wave. The air cylinder body 1 includes a diffuser section 11 from top to bottom, a rotating plane 12 and contraction section 13; wherein, the sine wave groove on the side of the air cylinder body 1 at the rotation plane 12 is provided with a filling 2, and the outside of the filling 2 is provided with the air cylinder at the rotation plane 12 The body 1 is integrally connected to the filling plane 20; the air duct body 1 and the filling plane 20 are molded structures of sheet molding compound, and the filler 2 is insert molded and fixed between the air duct body 1 and the filling plane 20 between.

[0038] Further, the filler 2 is surrounded by an inner liner 29 .

[0039] Further, each side and four corners of the air duct body 1 are provided with rounded corners.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com