Single-sheet type riveting device

A single-piece, riveting technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problem of labor-intensive, not necessarily removal, etc., to reduce labor costs, avoid inconvenience, and increase friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention patent will be described in detail below with reference to the accompanying drawings.

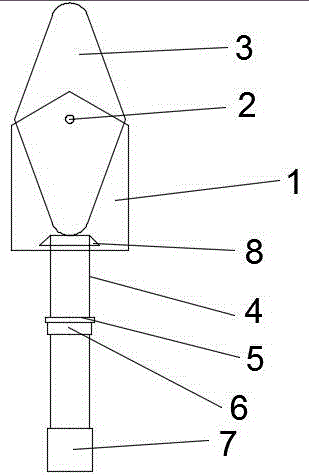

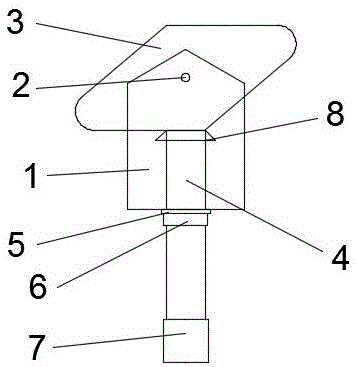

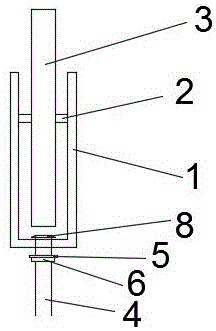

[0016] like Figure 1 to Figure 3 As shown, drill holes in the wall in advance, and rotate the threaded shaft 4 until the baffle 8 contacts the inner side of the slot 1, so that it will not come out of the slot, so as to achieve the integrity of the device and avoid inconvenience caused by falling off parts during carrying or installation. Manually rotate the riveting piece 3 until the long axis is in a straight line with the threaded shaft 4, insert the device into the pre-drilled hole, and start to screw the threaded shaft 4 after inserting it to the limit position. Both ends of the long axis of the fixing piece 3 are arc-shaped, which is convenient for inserting into the wall. After the threaded shaft 4 applies force to the riveting piece 3, the direction of the force is deflected, so that the long axis of the riveting piece 3 is close to the horizontal direction. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com