Screw tap used for stretching threads

A technology of taps and threads, which is applied in the field of taps for stretching threads, can solve the problems of single function, etc., and achieve the effects of ingenious structure of the tap, improved life, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

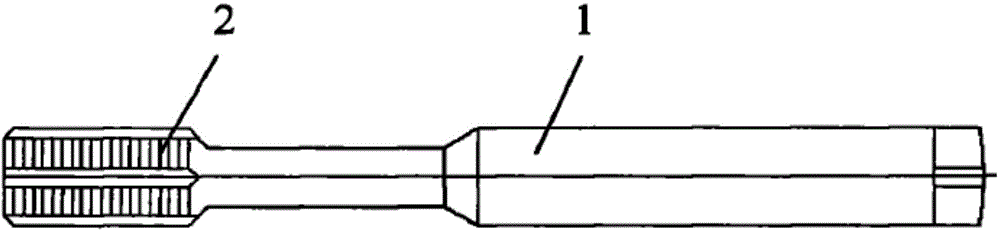

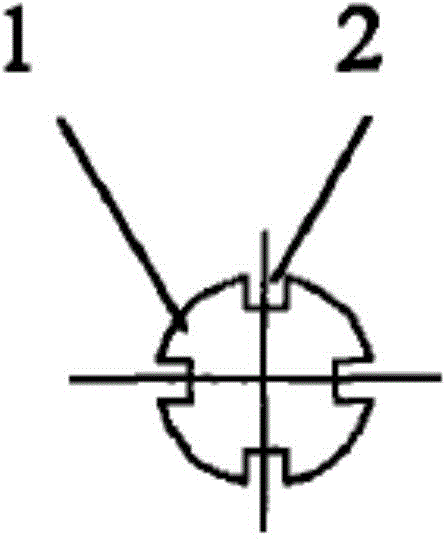

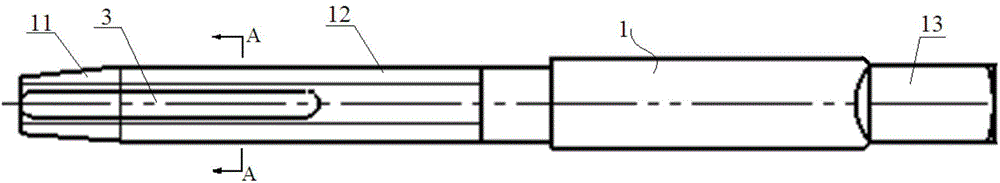

[0026] A tap for drawing threads, such as image 3 , Figure 4 As shown, it includes a tap main body 1. The front end of the tap main body 1 is a thread cutting part 11, and the tail end is a clamping part 13. Screw teeth are provided on the thread cutting part 11. Between the thread cutting part 11 and the clamping part 13 is The extrusion part 12, the thread cutting part 11 is a conical structure, the extrusion part 12 is a cylindrical structure, the bottom end of the thread cutting part 11 is the same diameter as the extrusion part 12, and extends from the top end of the thread cutting part 11 to the extrusion part 12 An oil tank 3 is provided. Wherein, the oil grooves 3 are arranged along the axial direction parallel to the tap main body 1 , and there are four oil grooves 3 in total, which are evenly distributed along the axial direction of the tap main body 1 . The length of the oil groove 3 is 8-9 pitch lengths, and the depth of the oil groove 3 between the 7th and 8th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com