Dust removal device for closed corridor of suspension type belt conveyor

A technology of belt conveyor and dust cleaning device, which is applied in the direction of conveyors, transportation and packaging, cleaning machinery, etc., and can solve the problems of automatic cleaning of closed corridors that have not yet been established

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

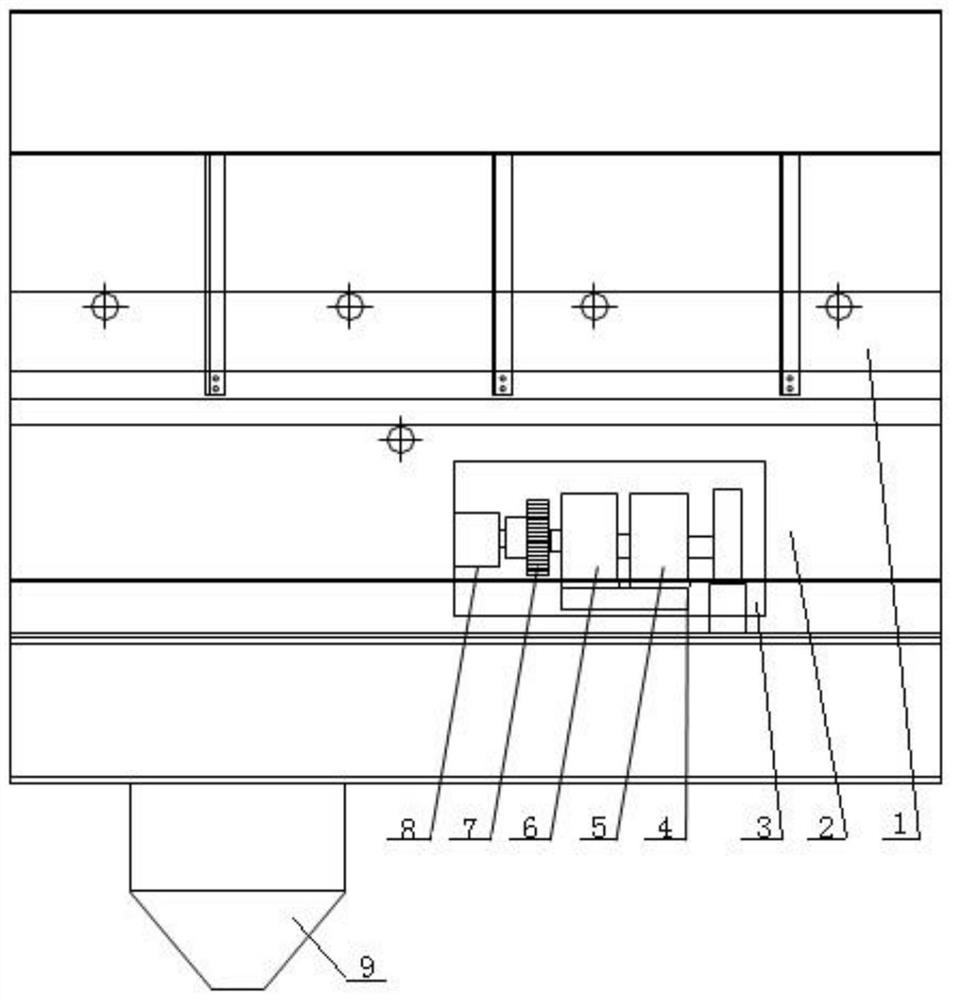

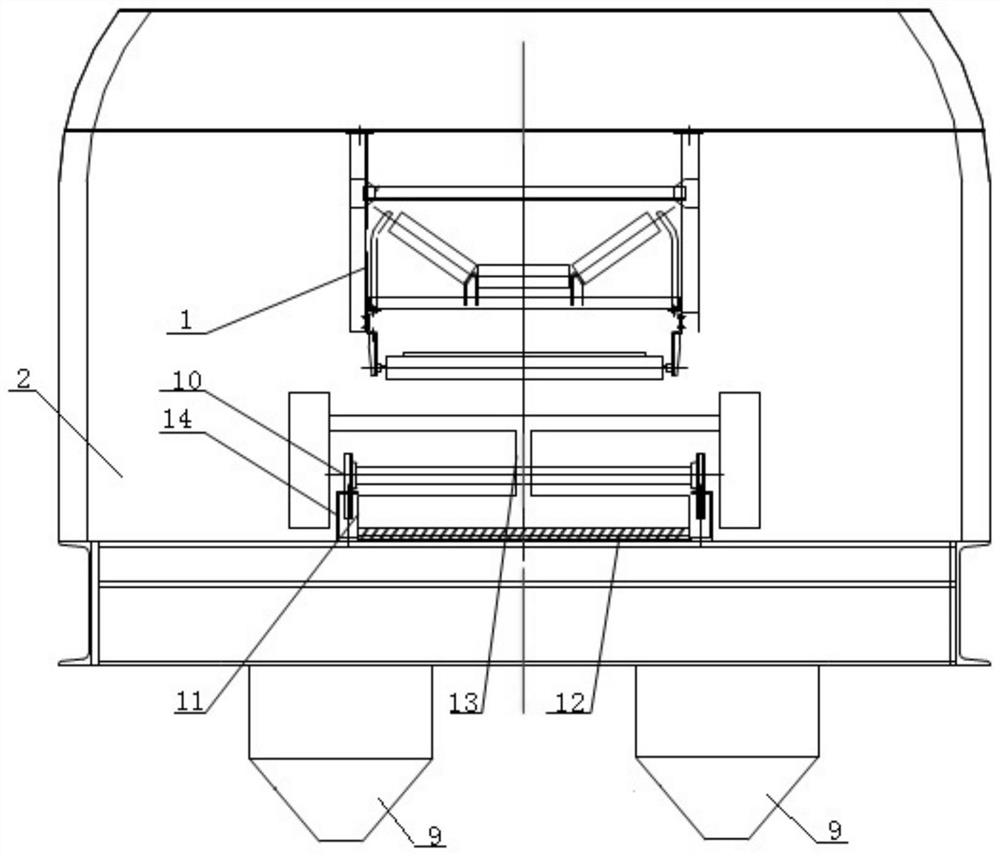

[0027] Such as figure 1 , figure 2 As shown, a kind of ash cleaning device of a suspended belt conveyor closed corridor according to the present invention includes a running track 14, a walking trolley 3, a dust collection cover 11, a rolling brush 12, a connecting pipe 13 and a dust processing device; The running track 14 is located in the closed corridor 2 and below the suspended belt conveyor 1, and is composed of 2 parallel tracks; the running trolley 3 can move along the running track 14; corresponding to the running trolley between the 2 tracks 3. A dust collection cover 11 is arranged at the bottom, and the suction port of the dust collection cover 11 is respectively provided with rolling brushes 12 on both sides of the moving direction of the traveling trolley 3, and the rolling brushes 12 are in rolling contact with the ground of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com