Patents

Literature

45results about How to "Adapt to various working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

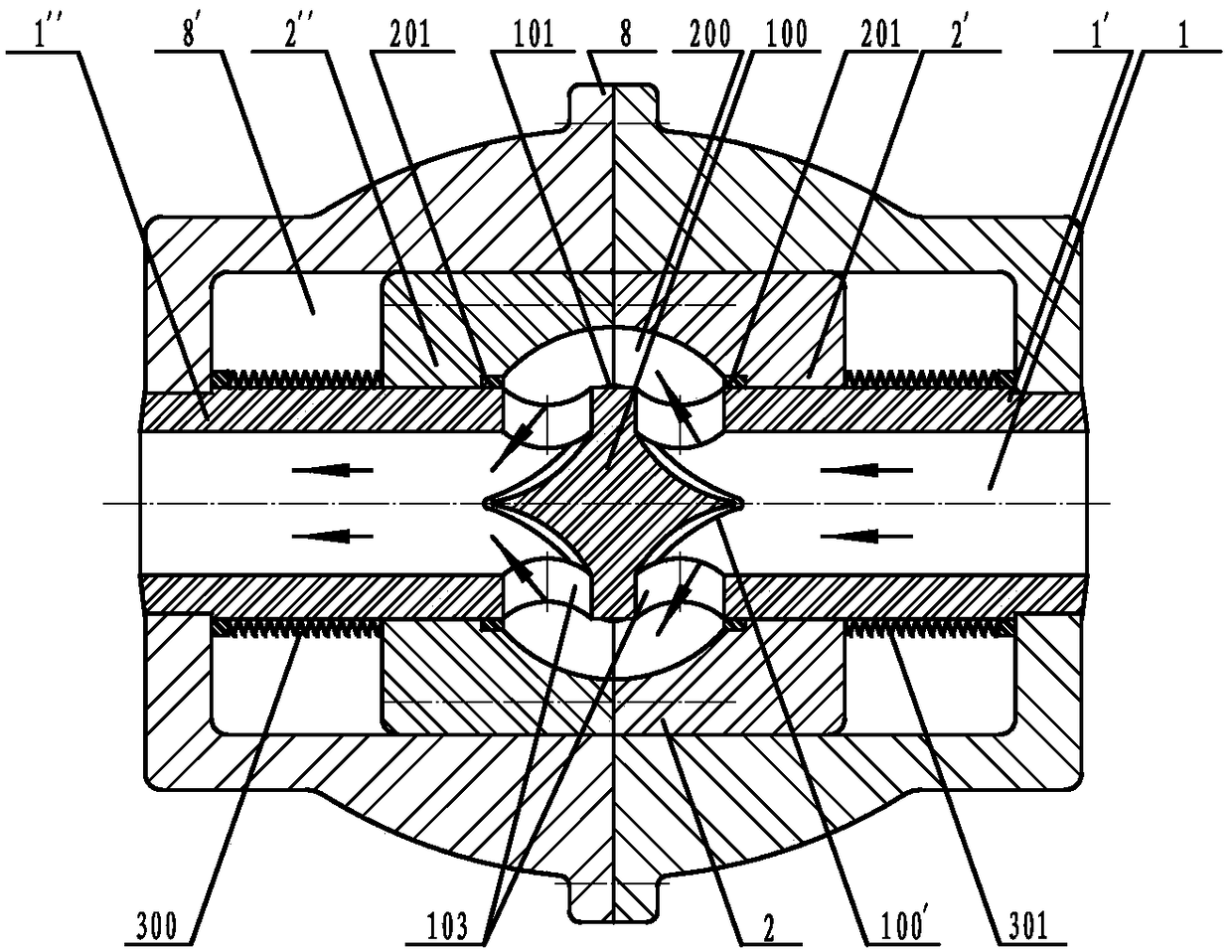

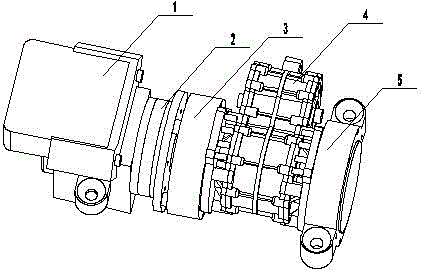

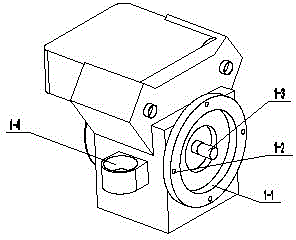

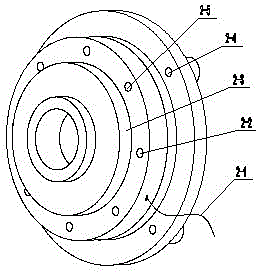

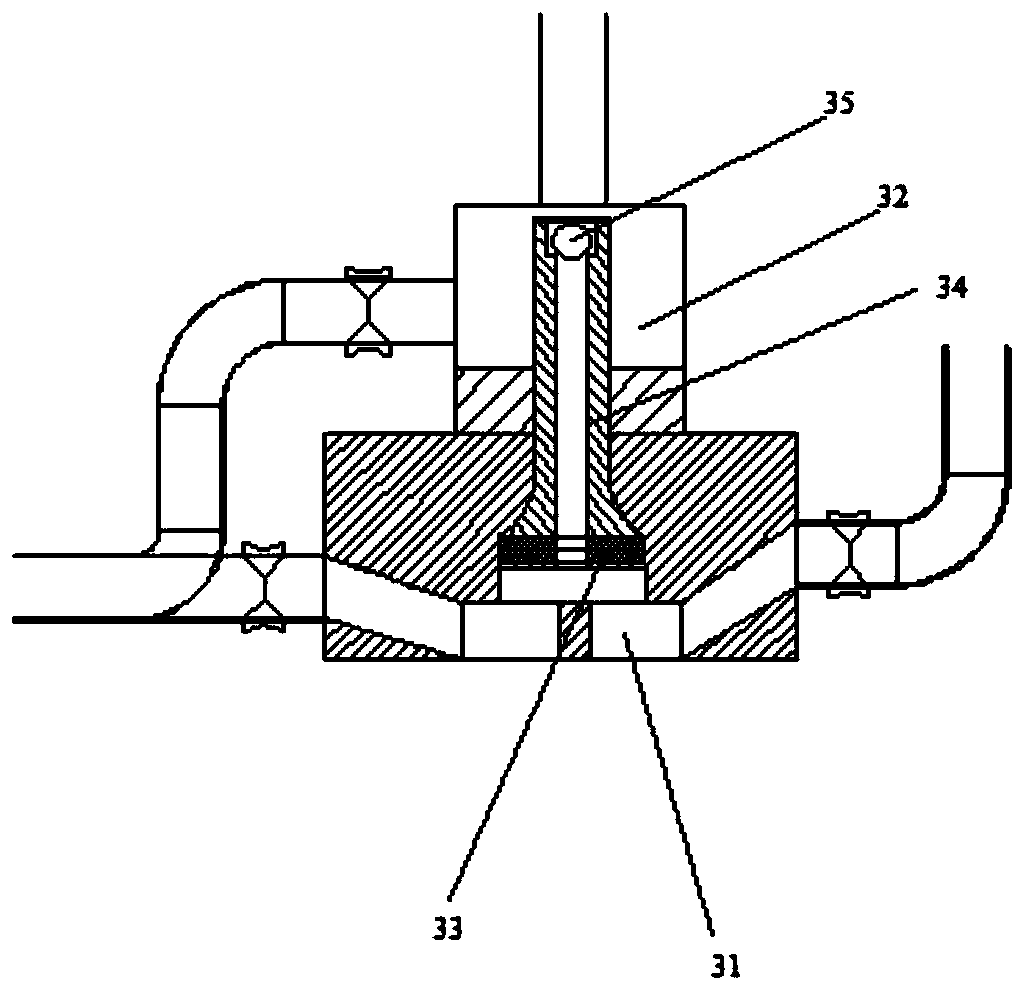

Core pipe valve

ActiveCN108488403AFacilitate smart manufacturingSmart manufacturing benefitsOperating means/releasing devices for valvesSlide valveEngineeringPressure reduction

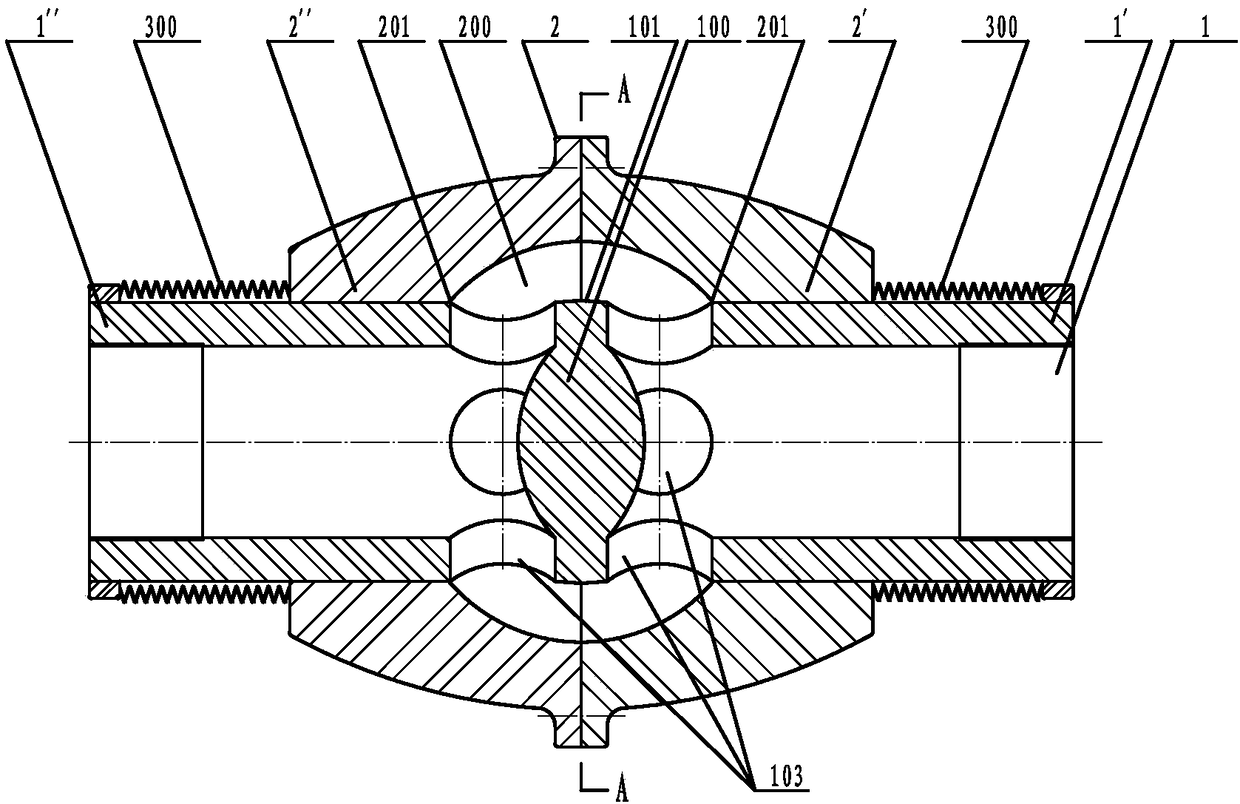

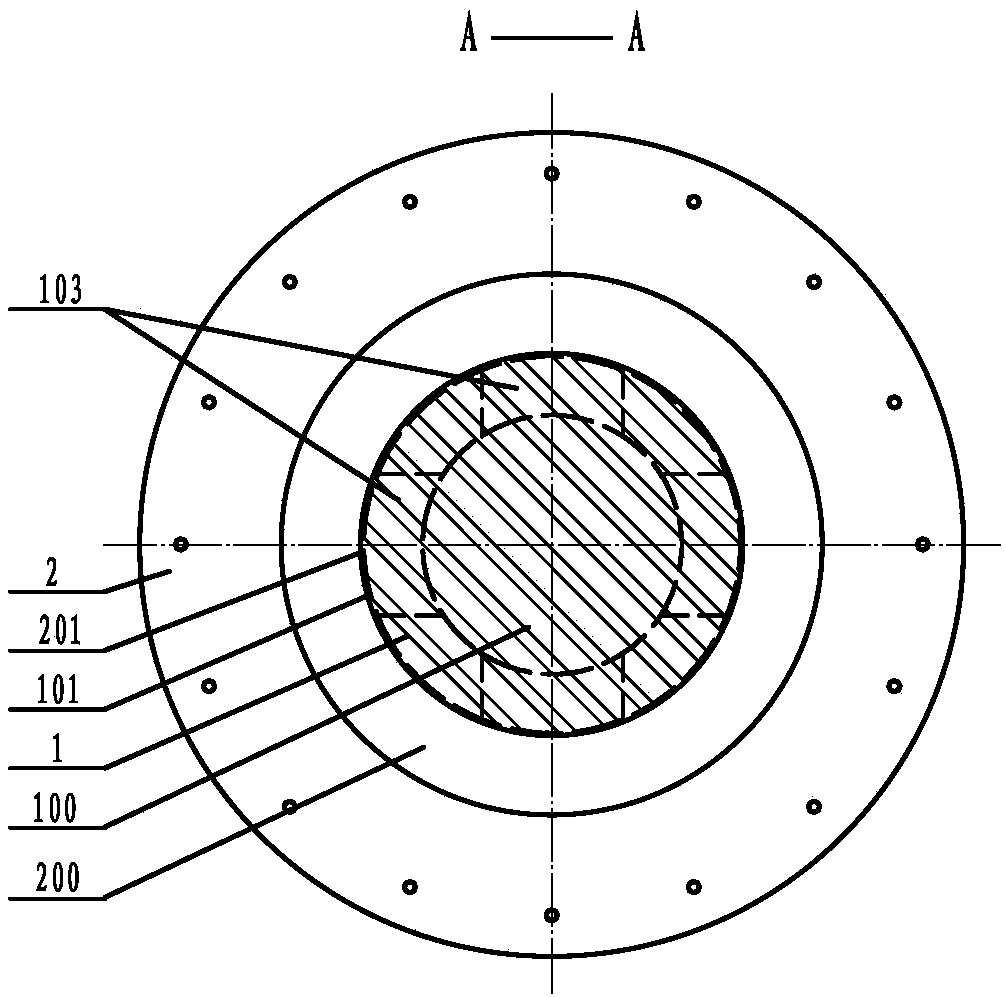

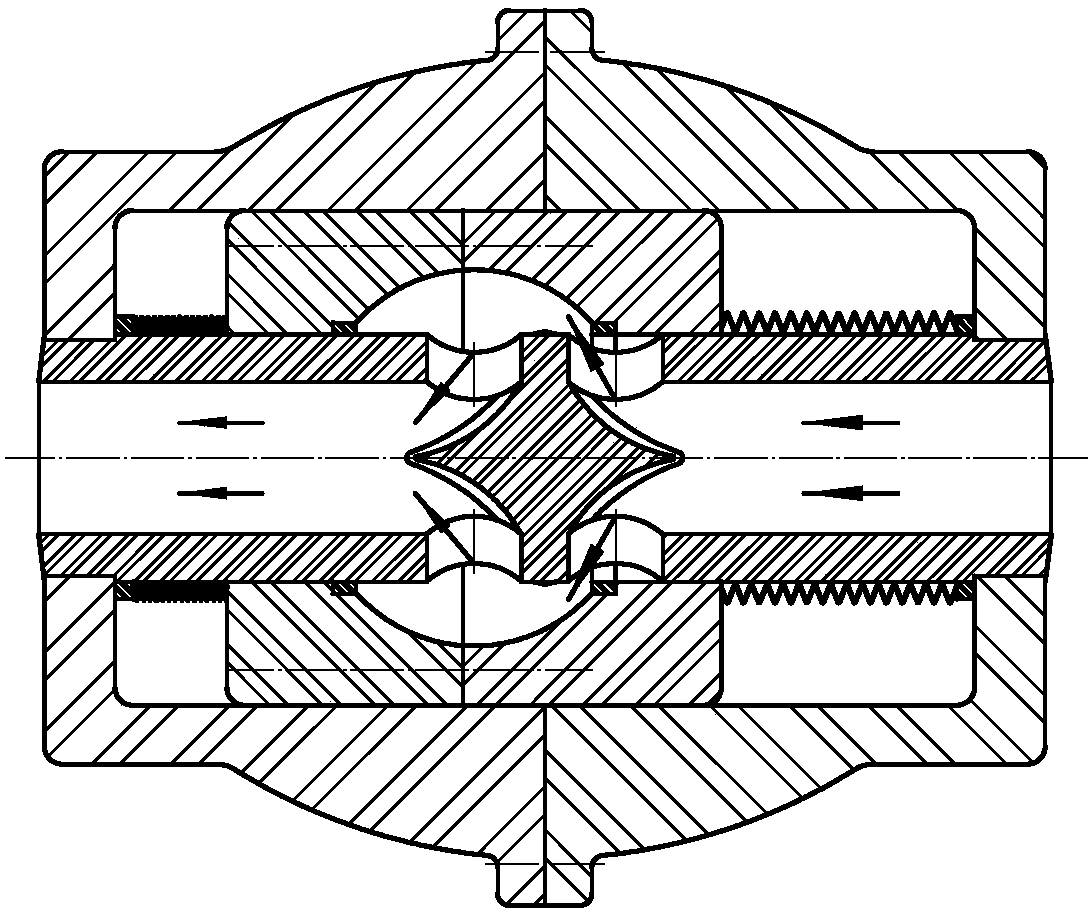

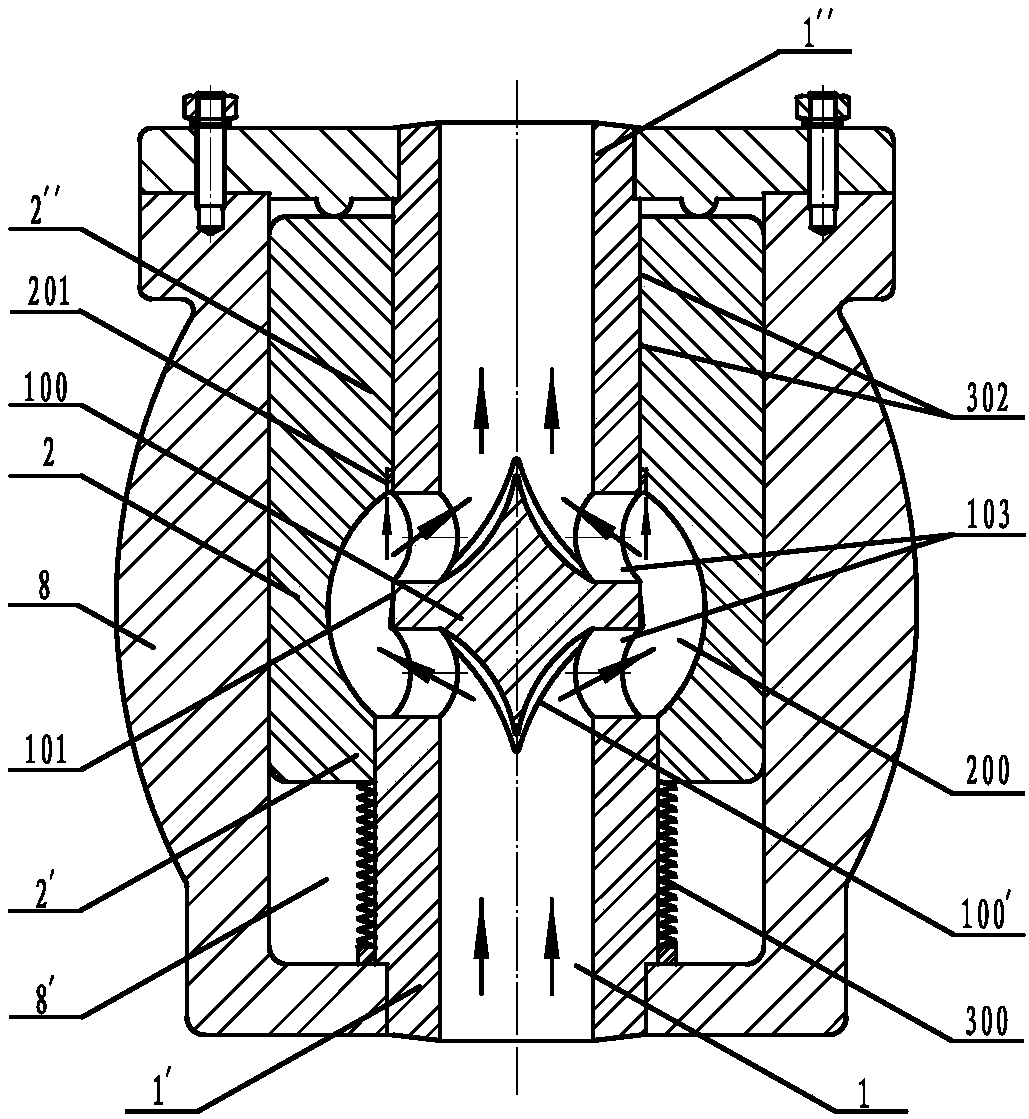

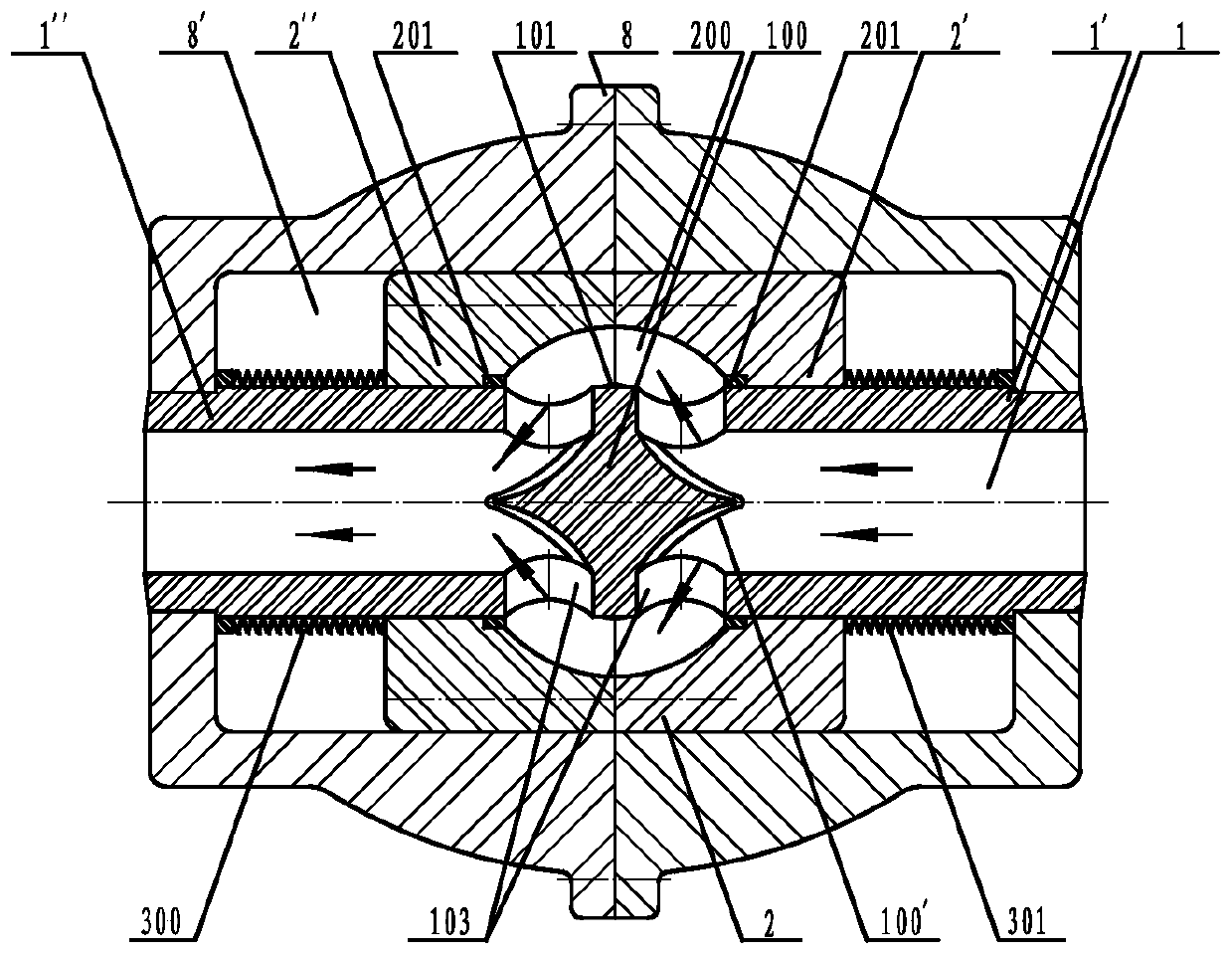

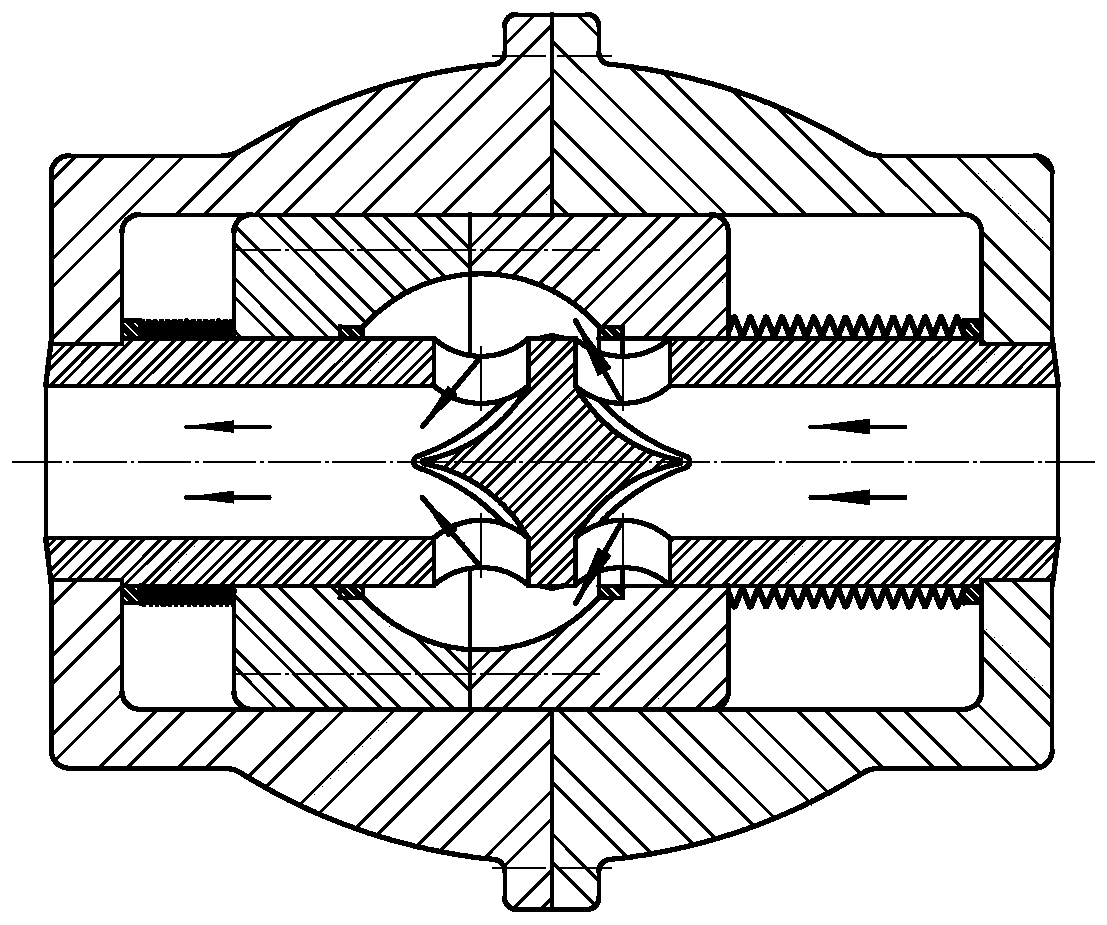

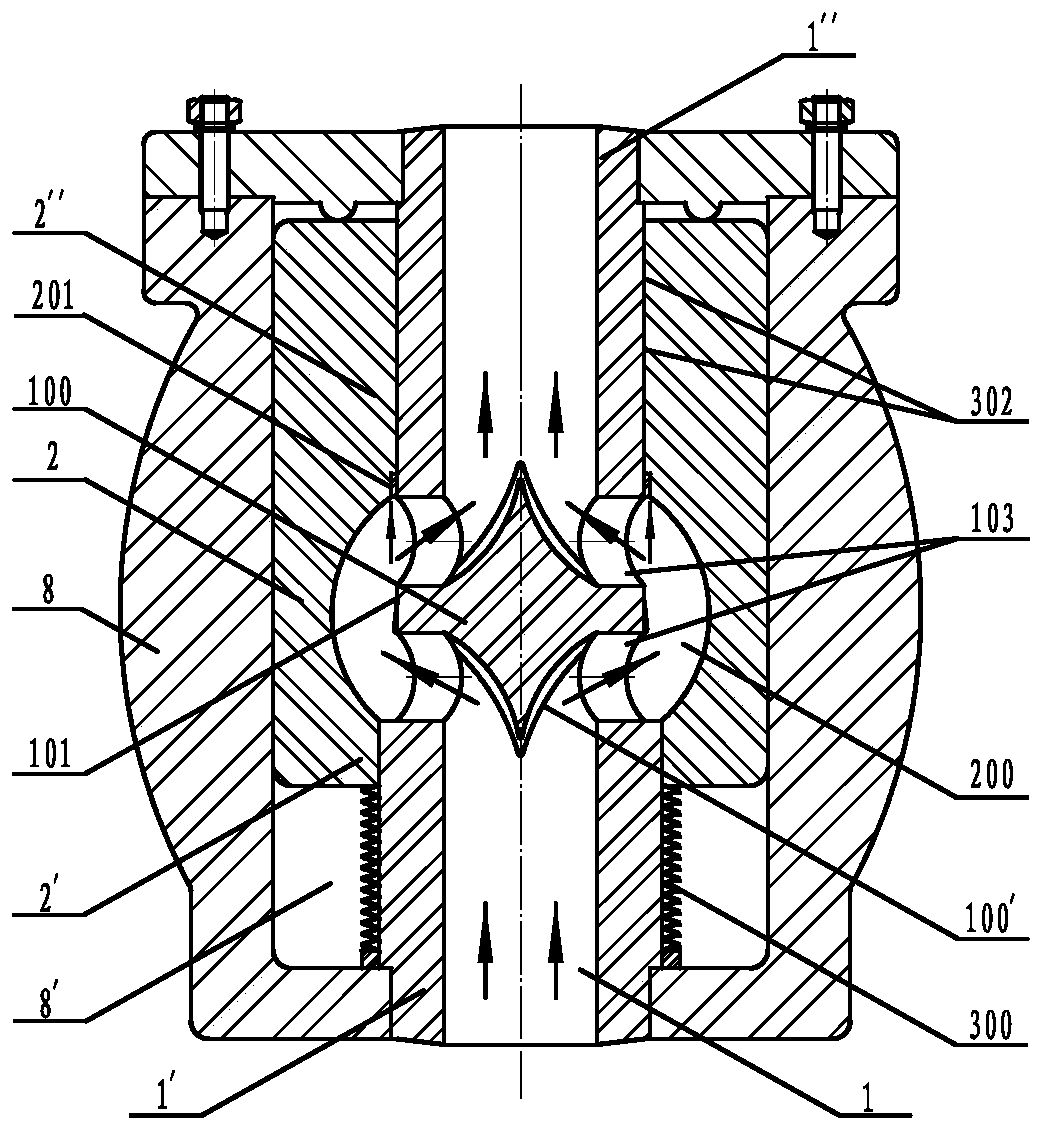

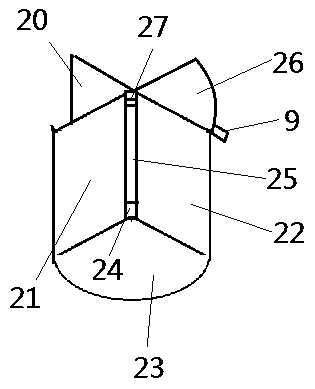

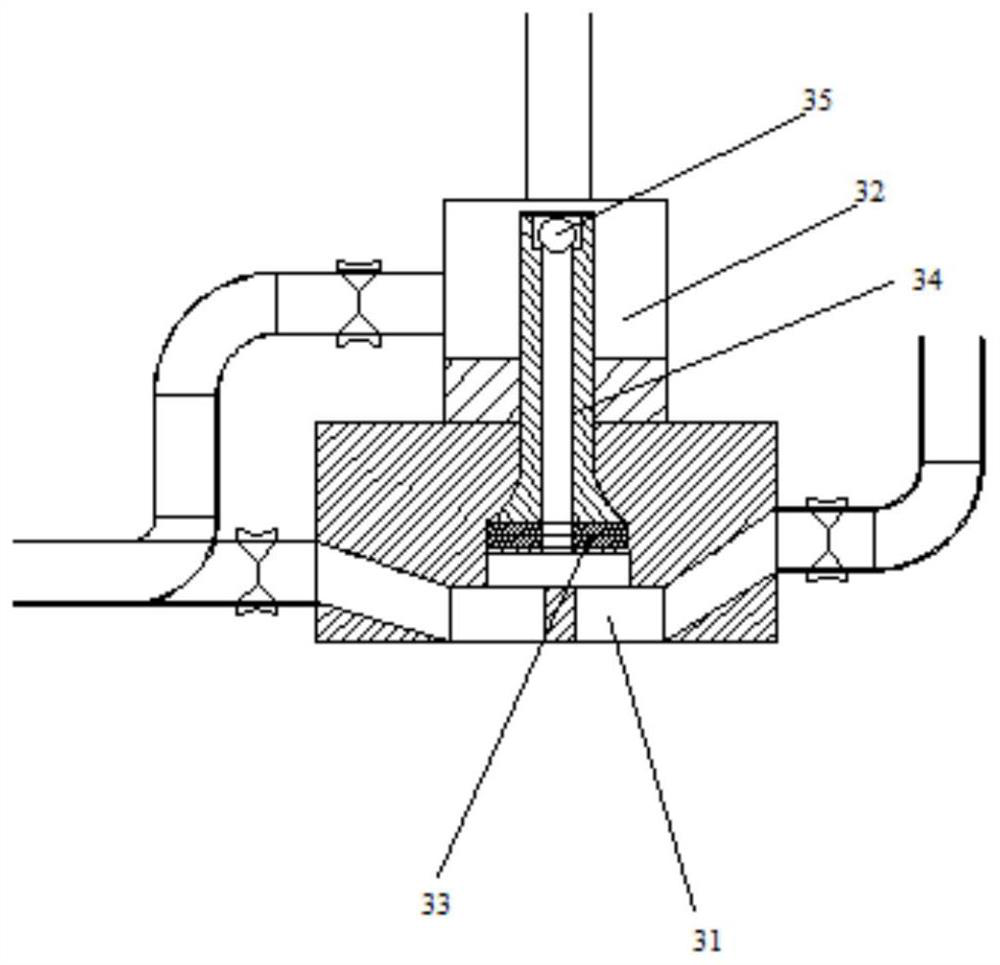

The invention provides a core pipe valve, and belongs to the field of valves. The core pipe valve is an original brand-new-structure valve, and refers to starting and stopping, pressure starting and stopping, adjustment, safety, decompression, returning stopping, pressure reduction, emergency cutting-off and the like. A valve element pipe is a fixing piece and coaxially penetrates through a sleeveI of a valve body, a valve body cavity and a sleeve II of the valve body; an axial partition is arranged in the middle of the valve element pipe, and two adjacent sides of the partition in the axialdirection are separately at least one radial circulating hole of a pipe section I and at least one radial circulating hole of a pipe section II; an annular valve element which surrounds the partition,an annular valve seat of at least one sleeve throat of the sleeve I and an annular valve seat of at least one sleeve throat of the sleeve II form a sealing pair; the difference between the outer diameters of the pipe section I and the pipe section II is greater than or equal to 0, the pipe section I is in shaft hole type fit with the sleeve I, the pipe section II is in shaft hole type fit with the sleeve II, and at least one combined portion is provided with a seal; and under the effect of two direction potential energy, the valve body axially moves in an axial direction relative to the valveelement pipe to implement starting and stopping and function transformation. The core pipe valve is simple in structure, convenient to manufacture, low in starting and stopping resistance and good insafety, reliability and sensitivity, and adapts to various working conditions, and the efficiency is improved.

Owner:卢星霖

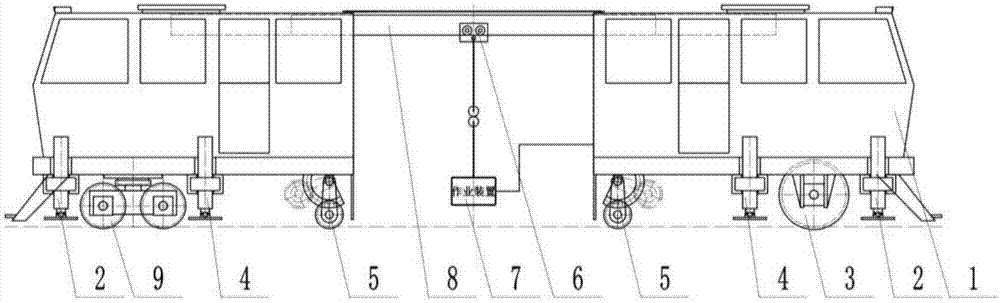

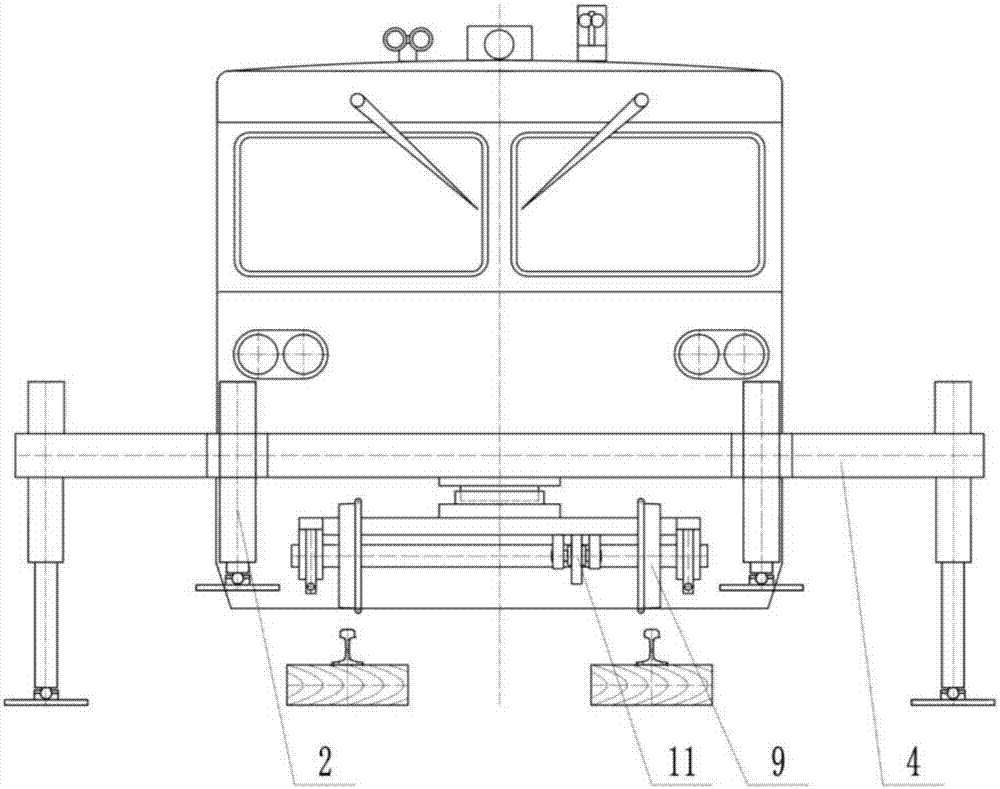

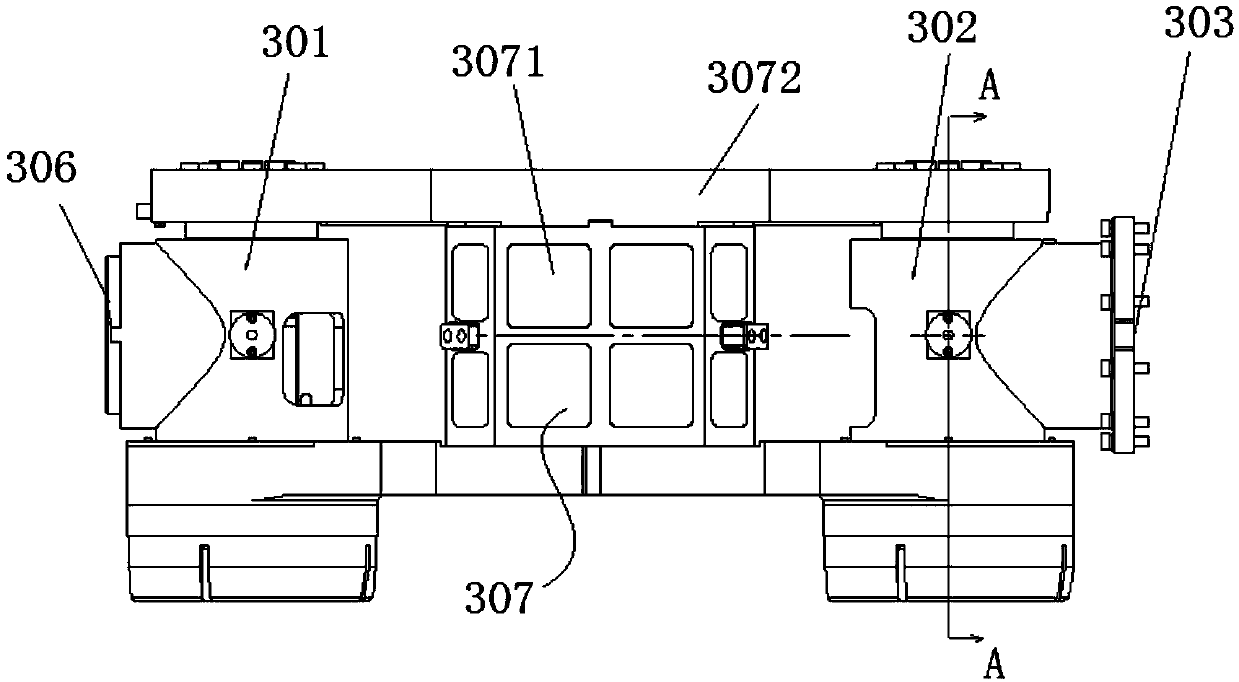

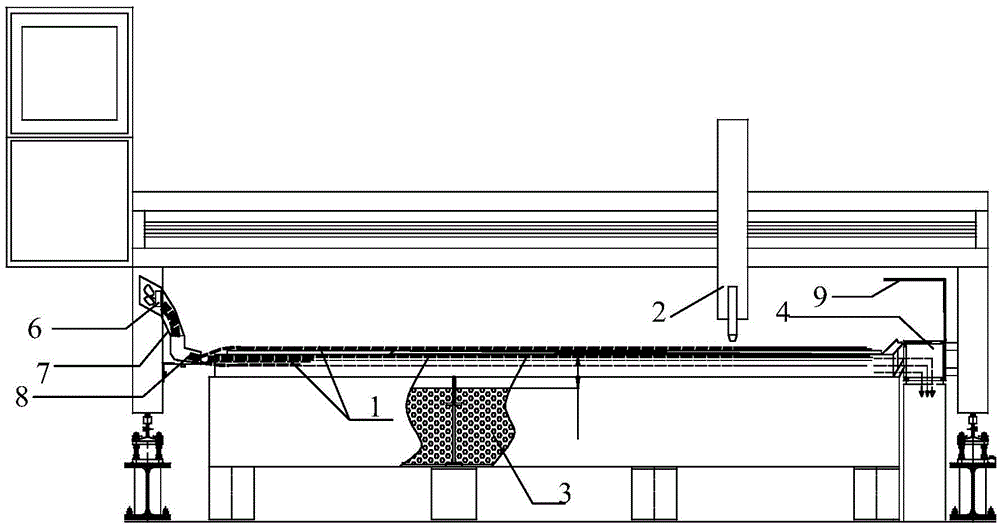

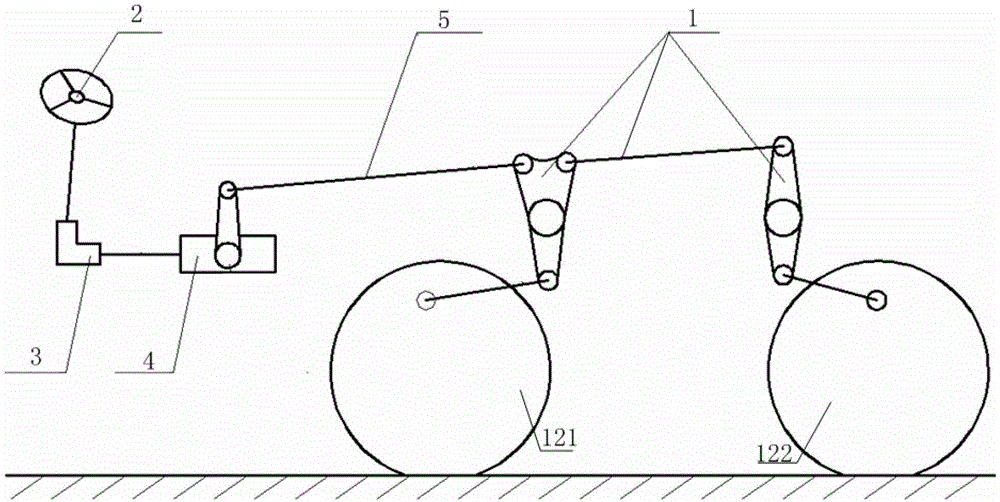

Telescopic-type two-way operation lateral evacuation multifunctional operating vehicle and application method

PendingCN107964840AEasy to operateEasy to driveRailway transportRailway track constructionUltimate tensile strengthAutomotive engineering

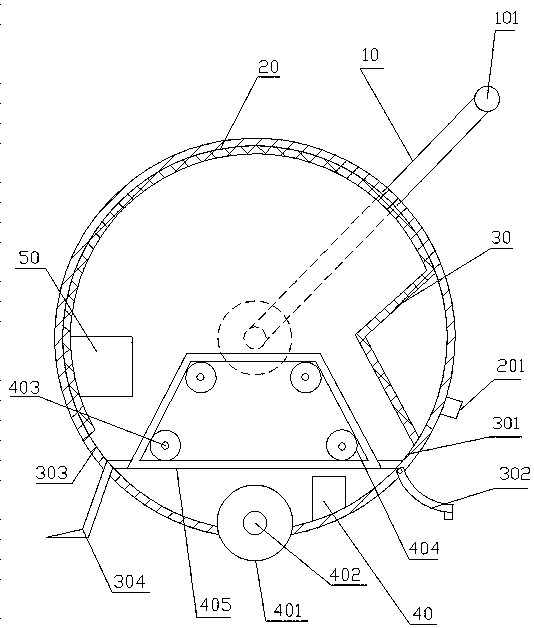

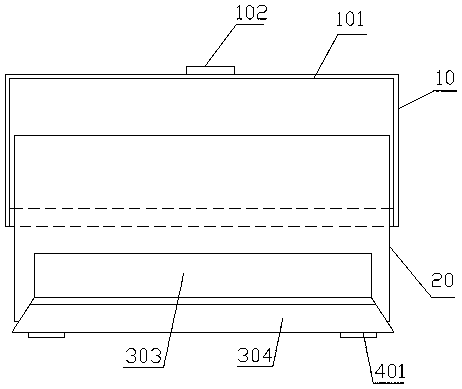

The invention relates to the technical field of engineering technology equipment and methods, in particular to a telescopic-type two-way operation lateral evacuation multifunctional operating vehicleand an application method. The telescopic-type two-way operation lateral evacuation multifunctional operating vehicle comprises a fixing lifting mechanism and a transverse moving lifting mechanism; and the operating vehicle is composed of a front vehicle body and a rear vehicle body, the front vehicle body is connected with the rear vehicle body through a telescopic mechanism used for realizing the contraction and the expansion between the front vehicle body and the rear vehicle body, the operating vehicle is provided with a suspension system used for hanging and moving a working device, and the bottom of the operating vehicle is provided with a rail clamping device. Compared with the prior art, the telescopic-type two-way operation lateral evacuation multifunctional operating vehicle andthe application method have the advantages that the operating vehicle adopts a telescopic structure, and the vehicle bodies can be longitudinally telescoped to facilitate operation, driving and transfer; the vehicle body can transversely avoid track lines, the operating vehicle is conveniently operated in a long and large area, work efficiency is higher, and the adaptation range is wider; vehiclelifting and steel rail lifting are properly combined to reduce the labor intensity and improve the construction efficiency; and various operating equipment can be installed to adapt to various operating conditions, and the universality is high.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

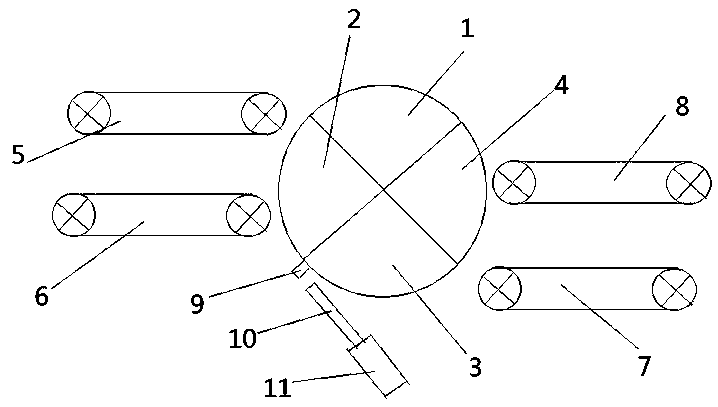

Active transmission device for hybrid electric vehicle

InactiveCN101890904AAdapt to various working conditionsSimple structureGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingEngineeringElectric vehicle

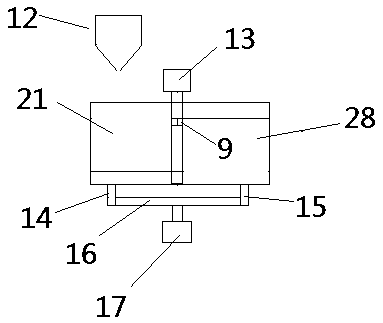

The invention relates to an active transmission device for a hybrid electric vehicle. The device comprises an axis fixed gear transmission, a transmission electronic control gear shift operating mechanism, a clutch and an electric operating mechanism thereof, an electronic control unit, a main driving motor and a synchronous mechanism, wherein the driving part of the clutch is connected with a vehicle engine flywheel, and the driven part of the clutch is connected with the front end of an input shaft of the axis fixed gear transmission; the main driving motor is connected with the synchronous mechanism; the synchronous mechanism and the tail end of the input shaft or an output shaft of the axis fixed gear transmission are separated from each other to cut off power or meshed with each other to synchronously rotate; and the electronic control unit controls the control unit of the main driving motor, the electronic control gear shift operating mechanism and the operating mechanism of the synchronous mechanism through electrical signals. The active transmission device for the hybrid electric vehicle solves the problem of power interruption in the transmission gear shift process; the synchronous mechanism has the advantages of compact structure, low cost, reliability and durability; the motor rotor structure reduces the rotational inertia of the motor, saves materials and improves the power density; and the device is convenient to assemble and disassemble.

Owner:TONGJI UNIV

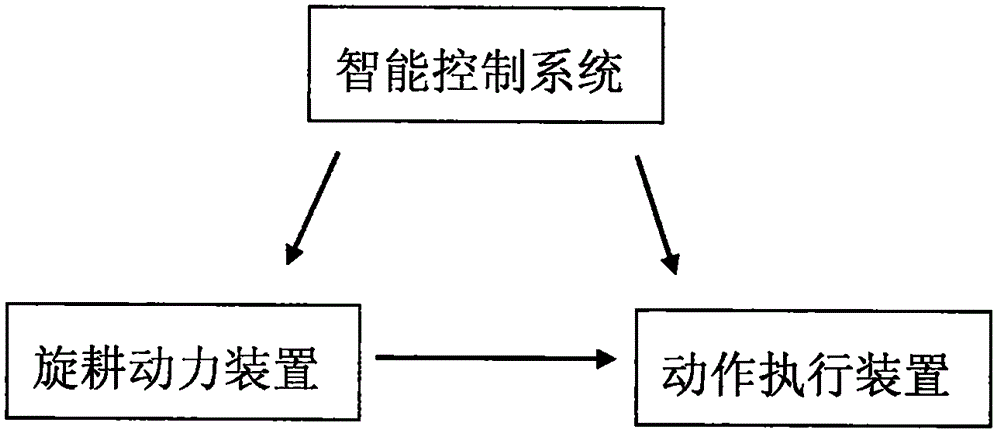

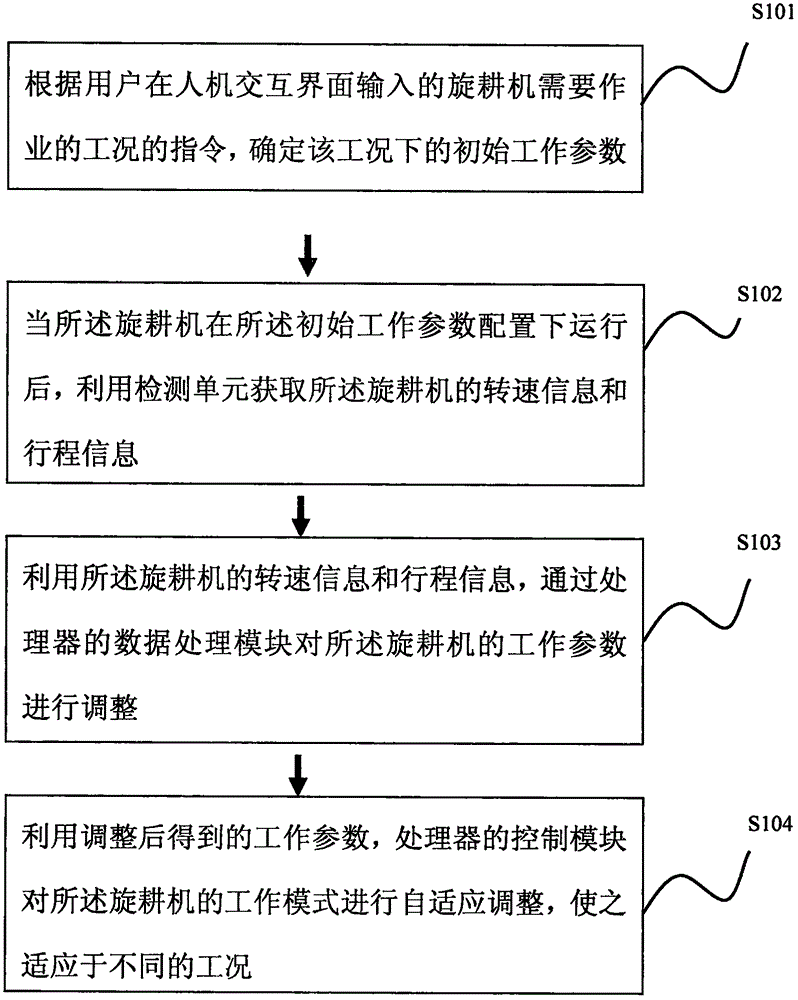

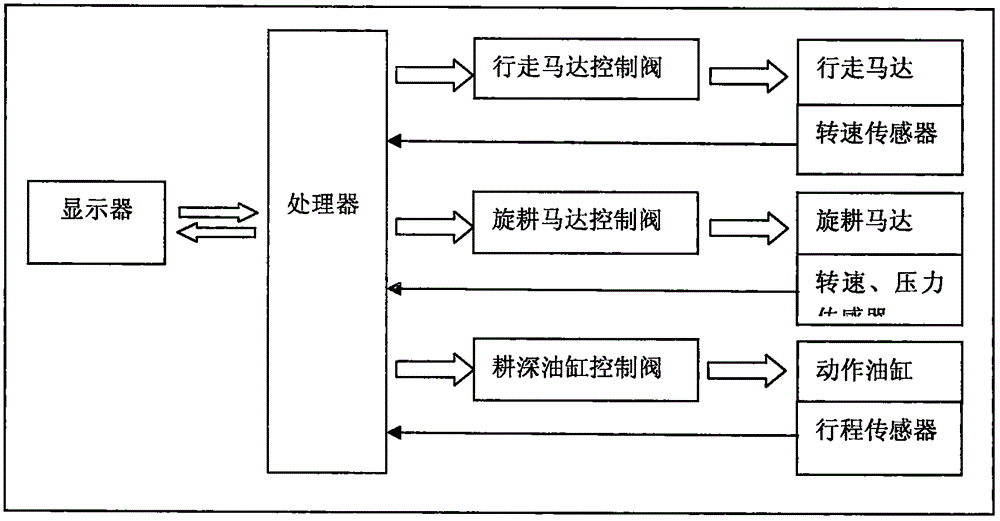

Intelligent rotary tiller and intelligent control method thereof

InactiveCN105850240AAdjust working mode in real timeIntelligent adjustment of working parametersTilling equipmentsProgramme control in sequence/logic controllersIntelligent control systemAgricultural engineering

The invention provides an intelligent rotary tiller and an intelligent control method thereof and relates to the field of agricultural machinery. The intelligent rotary tiller comprises a rotary tillage power device, an action executing device and an intelligent control system enabling rotary tillage equipment to automatically adapt to and automatically adjust related parameters in different working conditions. The intelligent control method includes: according to a working condition in which the rotary tiller needs to work, determining initial working parameters in the working condition, and sending the same to a processor; after the rotary tiller runs under configuration of initial working parameters, utilizing a detection unit and the processor to acquire rotating speed information and stroke information of the rotary tiller; utilizing the rotating speed information and the stroke information of the rotary tiller to adjust working parameters of the rotary tiller through the processor; utilizing the working parameters acquired after adjusting to adjust working modes of the rotary tiller to enable the rotary tiller to adapt to different working conditions. By using the intelligent control method, working parameters can be adjusted intelligently to adapt to various working conditions.

Owner:DANGYANG CITY TIANGONG IND

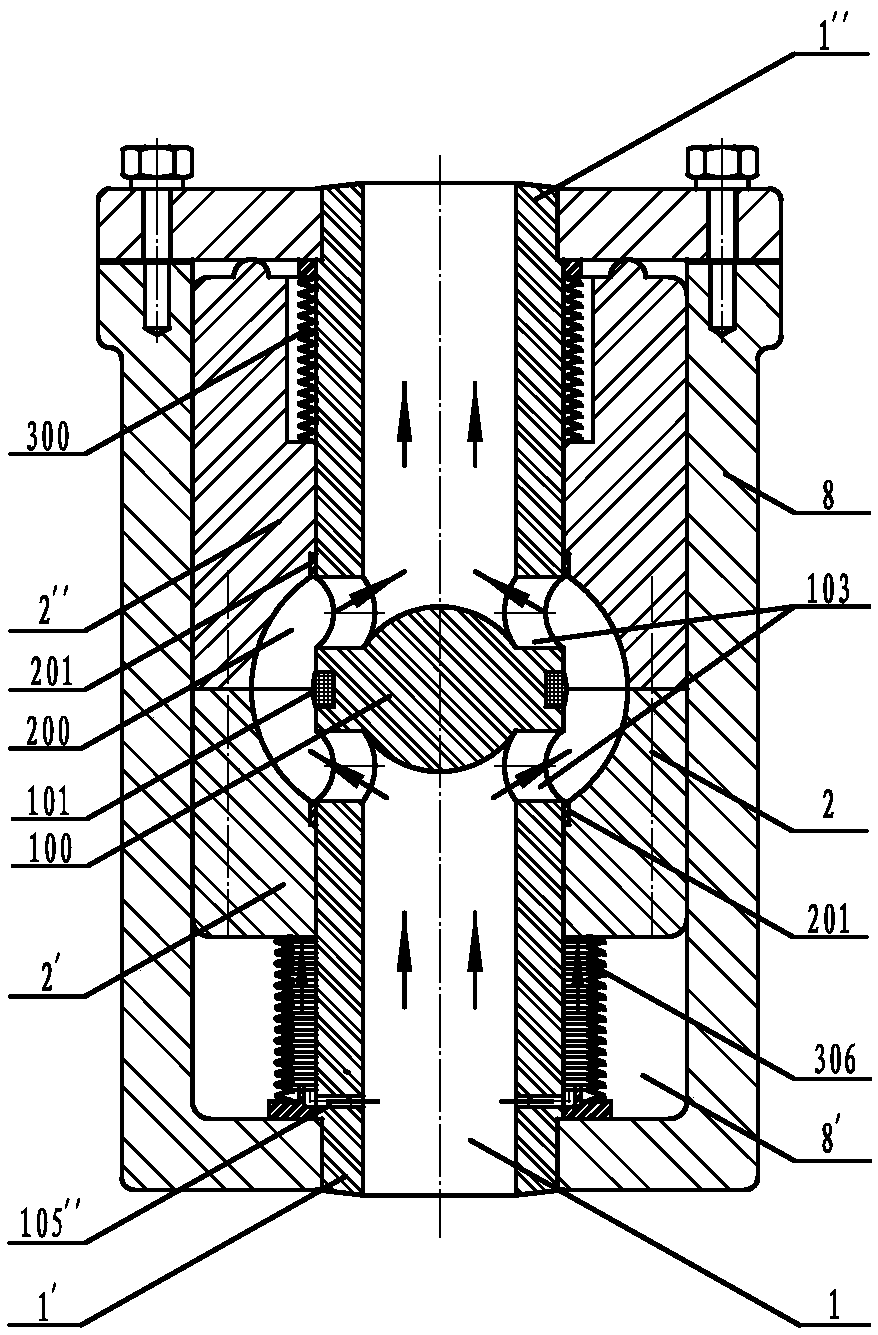

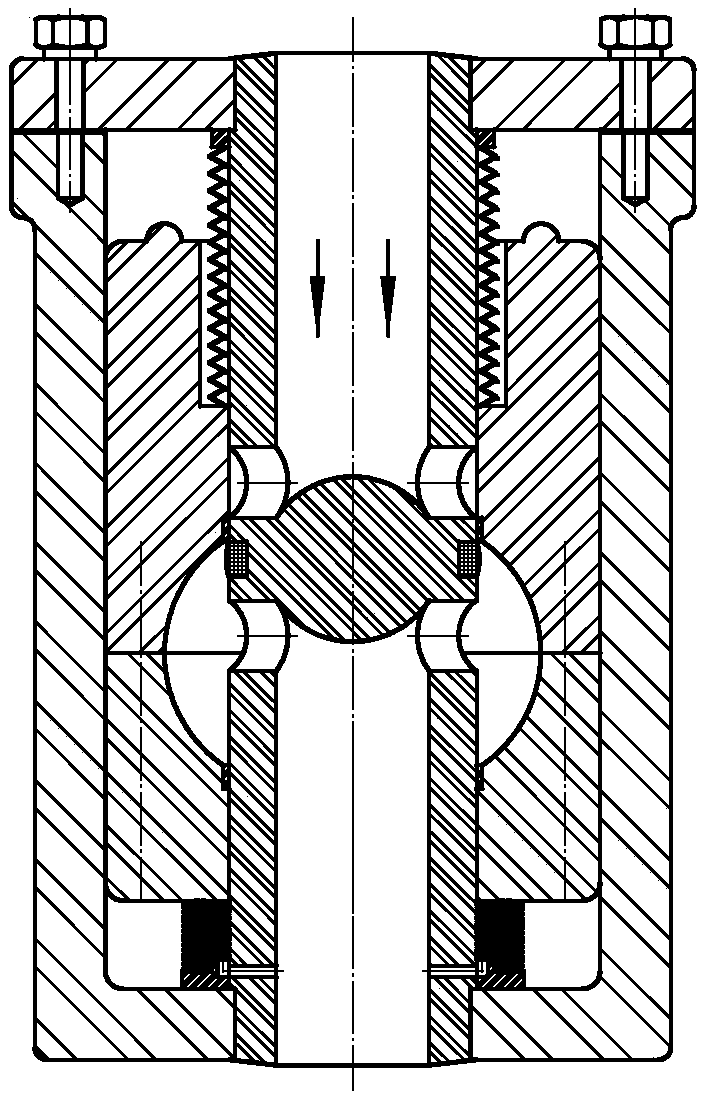

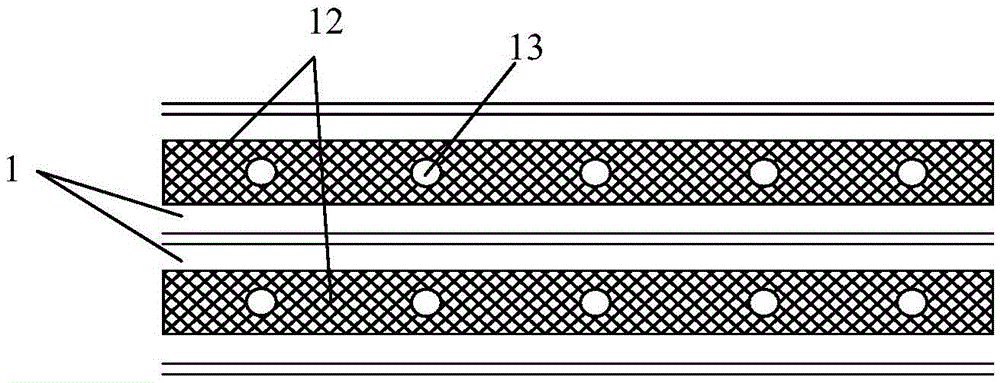

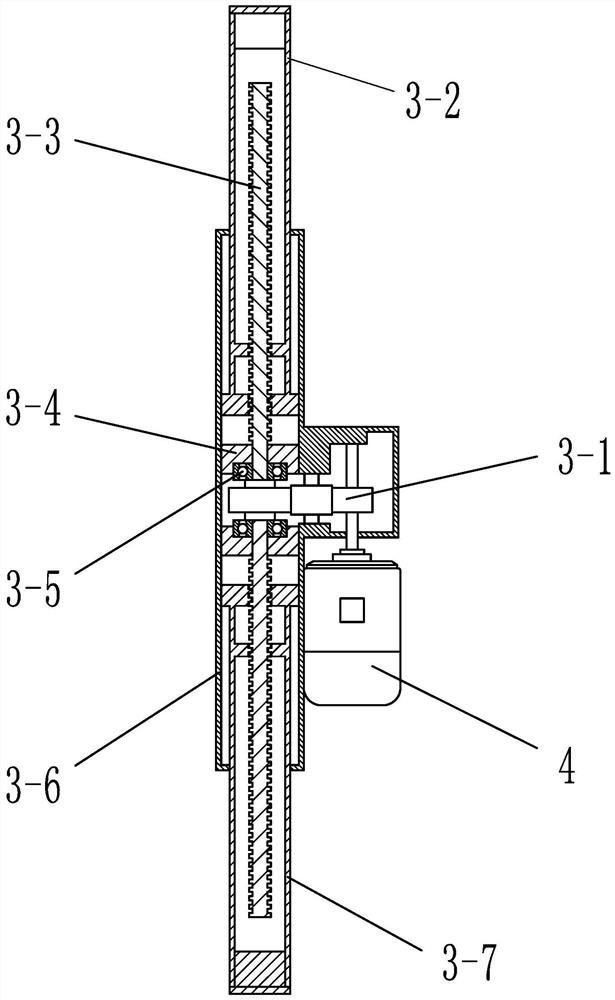

Double valve body core pipe valve

ActiveCN108426044ASimple structureEasy to manufactureOperating means/releasing devices for valvesCheck valvesReciprocating motionEngineering

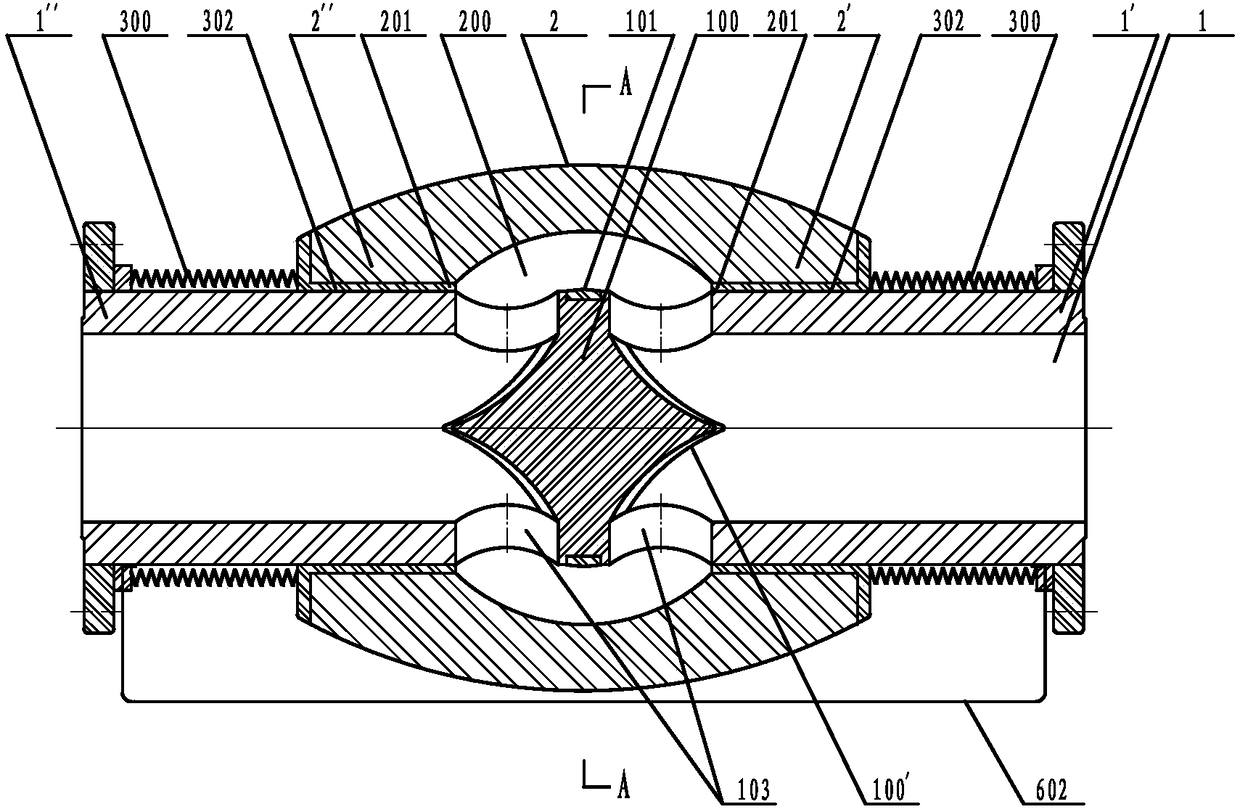

A double valve body core pipe valve is the main part of a double valve body core pipe valve plate in a core pipe valve mother series invented by the inventor originally. A valve core pipe wrapped in an outer valve body inner cavity is a fixed part which coaxially penetrates through a sleeve pipe I of a valve body, a valve body inner cavity and a sleeve pipe II of the valve body. An axial interlayer is arranged in the middle of the valve core pipe. The two adjacent axial edges of the interlayer are provided with at least one radial communicating hole of the input section and the output section.An annular valve core surrounding the interlayer and an annular valve seat of the larynx part of at least one of the sleeve pipe I and the sleeve pipe II form a sealing pair. The difference of the outer diameters of the input section and the output section is larger than or equal to 0. The input section and the sleeve pipe I as well as the output section and the sleeve pipe II are in shaft hole type fit, and at least one combined part is sealed. Under the action of bidirectional potential energy, the valve body does axial reciprocating motion in an outer valve body inner cavity, and opening,closing and function conversion are achieved. Opening and closing resistance is small, leakage is avoided, extending characteristics are wide, safety, reliability and flexibility are achieved, maintenance is reduced, efficiency is improved, and the double valve body core pipe valve adapts to various work conditions.

Owner:卢星霖

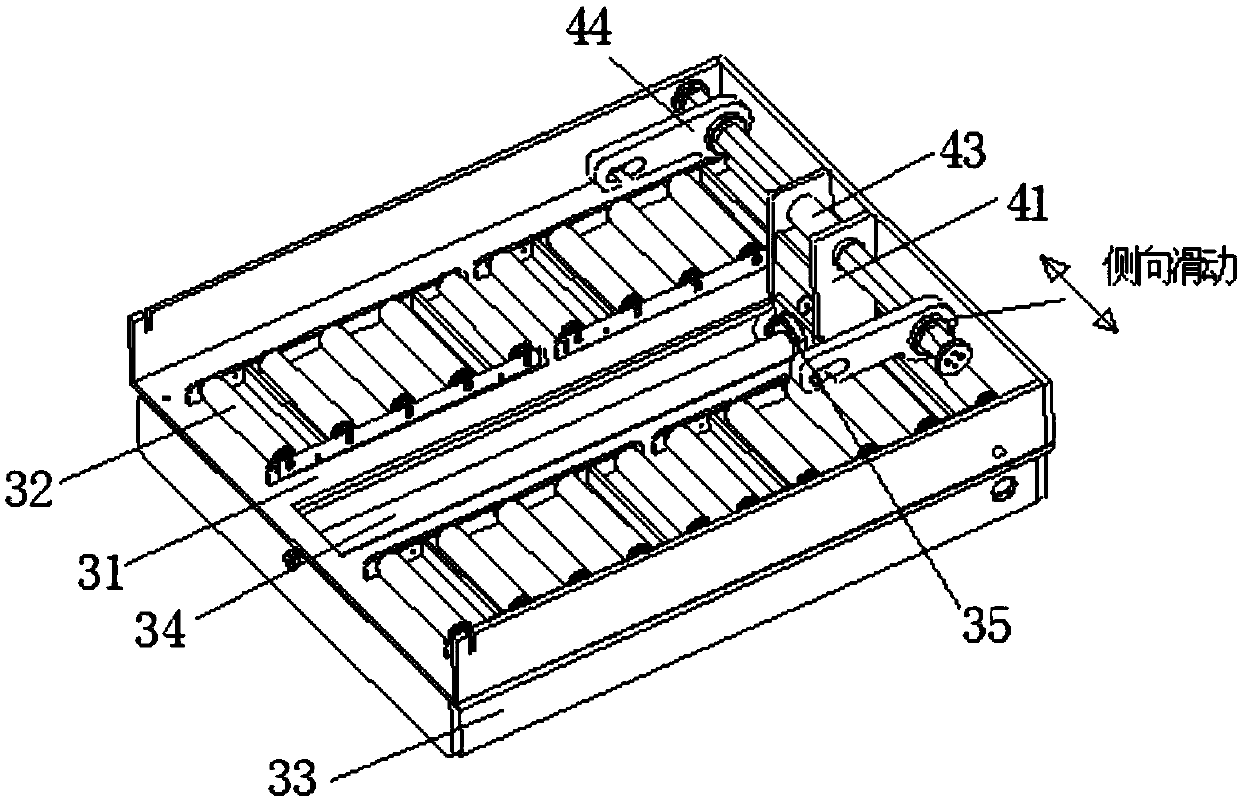

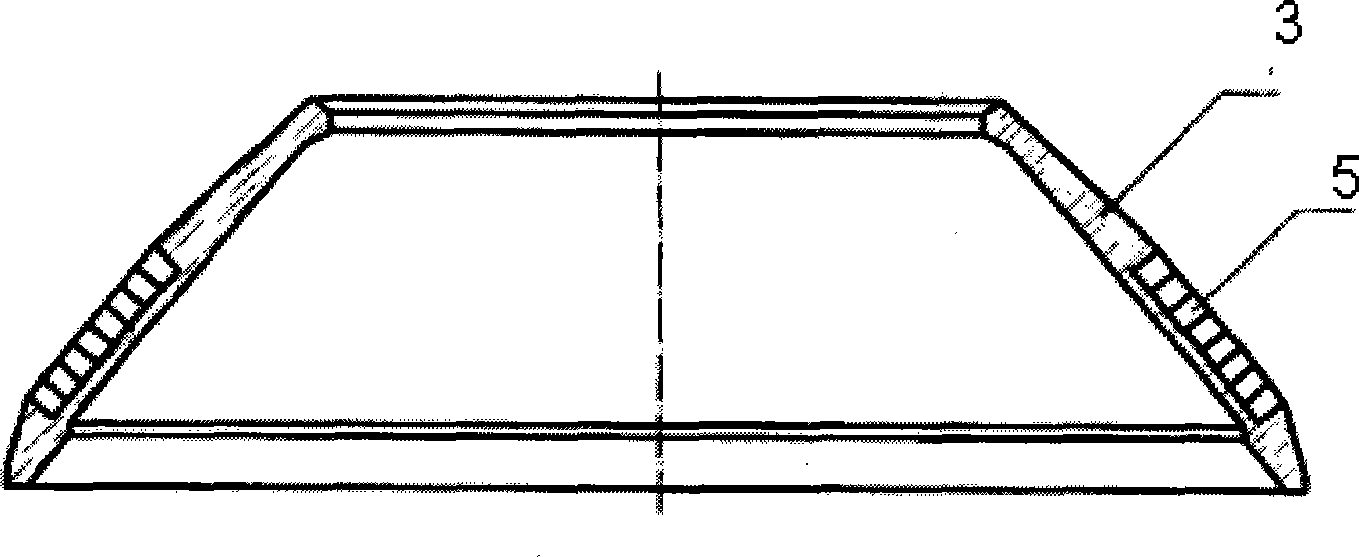

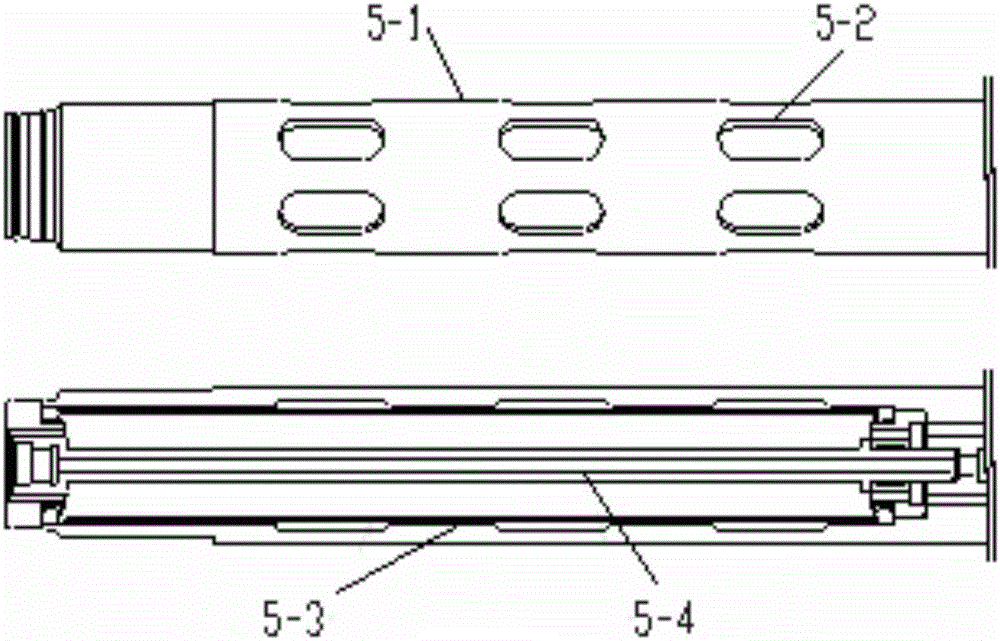

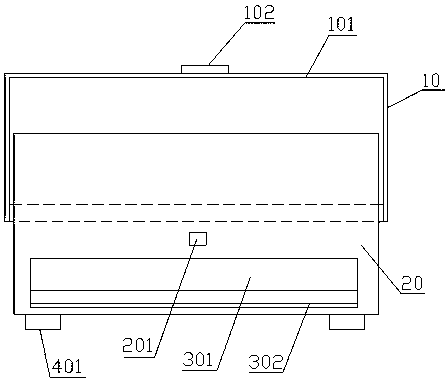

Push-and-pull device applicable to loading and unloading of molds in multiple specifications

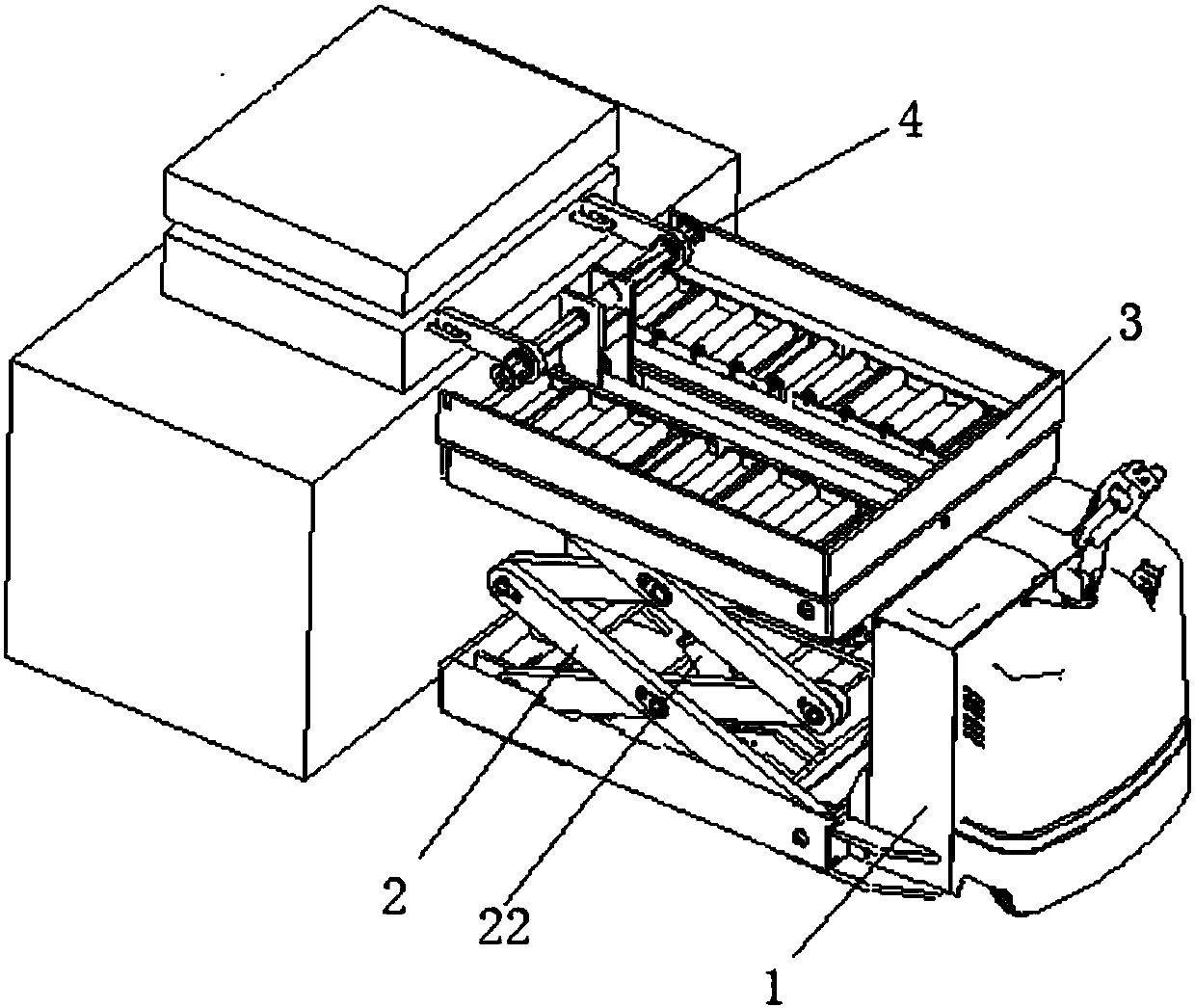

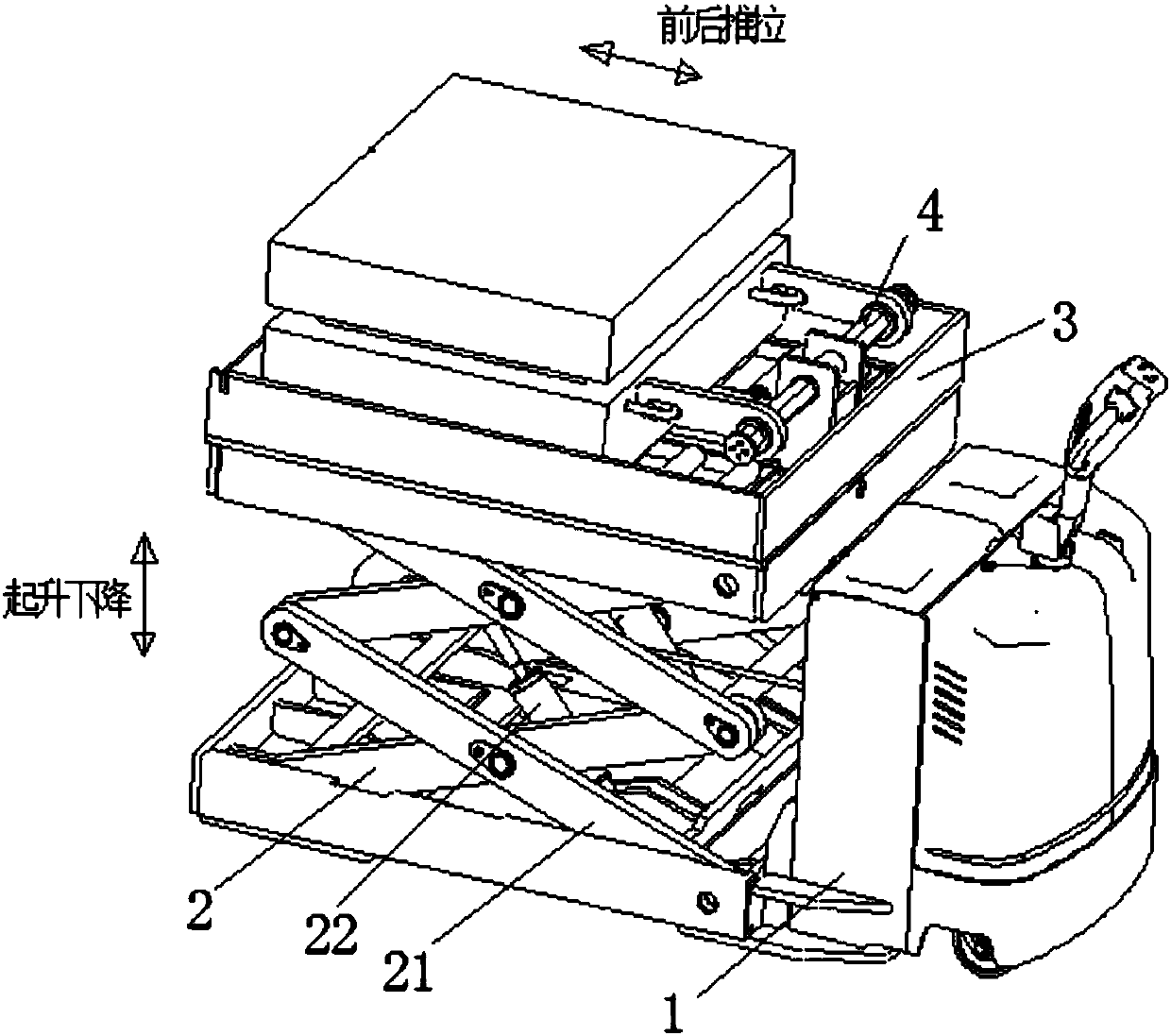

PendingCN107857206AEasy to installImprove performanceLifting framesConveyor partsPush and pullCompression molding

The invention discloses a push-and-pull device applicable to loading and unloading of molds in multiple specifications. The push-and-pull device comprises a liftable mold platform mounted on a forklift body; a push-and-pull mechanism is mounted on the mold platform and comprises a push-and-pull arm; push-and-pull rods for pushing and pulling the molds are mounted on the push-and-pull arm; the push-and-pull arm is mounted on a fixing seat capable of moving on the mold platform; and rollers or rolling wheels which are used for supporting the molds and facilitating movement of the molds are distributed on the mold platform. The push-and-pull device is compact in structure and stable in action, the push-and-pull rods of the push-and-pull mechanism can slide in the axis direction of the push-and-pull arm to adjust the distance between the push-and-pull rods, the push-and-pull device is applicable to quick transformation of an existing forklift so as to meet various working condition requirements and is also applicable to quick loading and unloading working conditions of the various molds, such as injection molds, compression molds, stamping molds and the like, in the multiple specifications, the working manner for loading and unloading of the molds through cooperation of the existing forklift and a travelling crane with auxiliary devices is replaced, the mold loading and unloading working efficiency is improved, and meanwhile, the injury risk of operators is reduced.

Owner:BANYITONG SCI & TECH DEVING

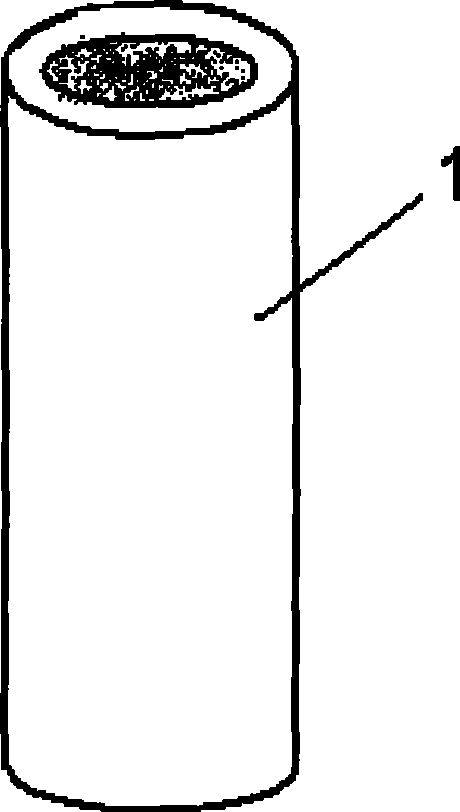

Method for preparing column shaped horniness phase composite wear-resistant jaw plate

InactiveCN101412101AImprove wear resistanceHigh tensile strengthGrain treatmentsCompound aWear resistant

The invention discloses a method for preparing a composite crushing plate with a columnar hard phase. A gear rack of the composite crushing plate with the columnar hard phase prepared by the method is formed by compounding a high hardness columnar hard phase and a high tenacity base metal. The method comprises the following steps: weaving alloy powder core materials into an alloy powder core material framework according to the shape of the gear rack on the crushing plate; fixing the framework on the crushing plate through binding or welding; through a casting method, performing in situ reaction on the alloy powder core materials to generate the columnar hard phase by using the high temperature of melted base molten metal; and performing the metallurgical combination of the hard phase and a base metal interface to form a high wear resistant high tenacity composite material on the gear rack of the crushing plate. The composite crushing plate prepared by the method has the advantages of high wear resistance, high tenacity, high tensile strength, high compression strength and the like. The method has the characteristics of small equipment input, low cost, simple operation and the like, and can be widely applied to various jaw type crushers.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

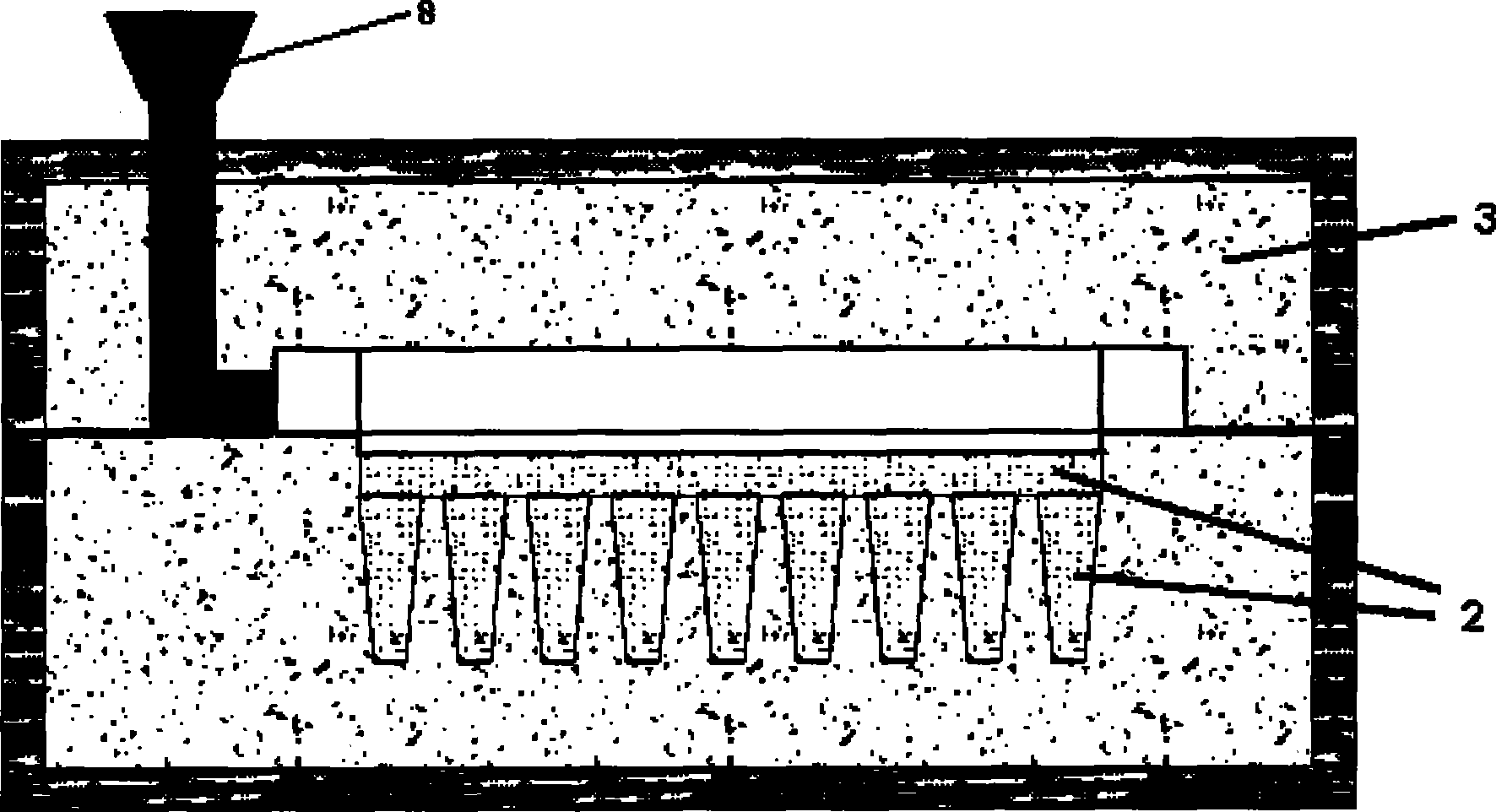

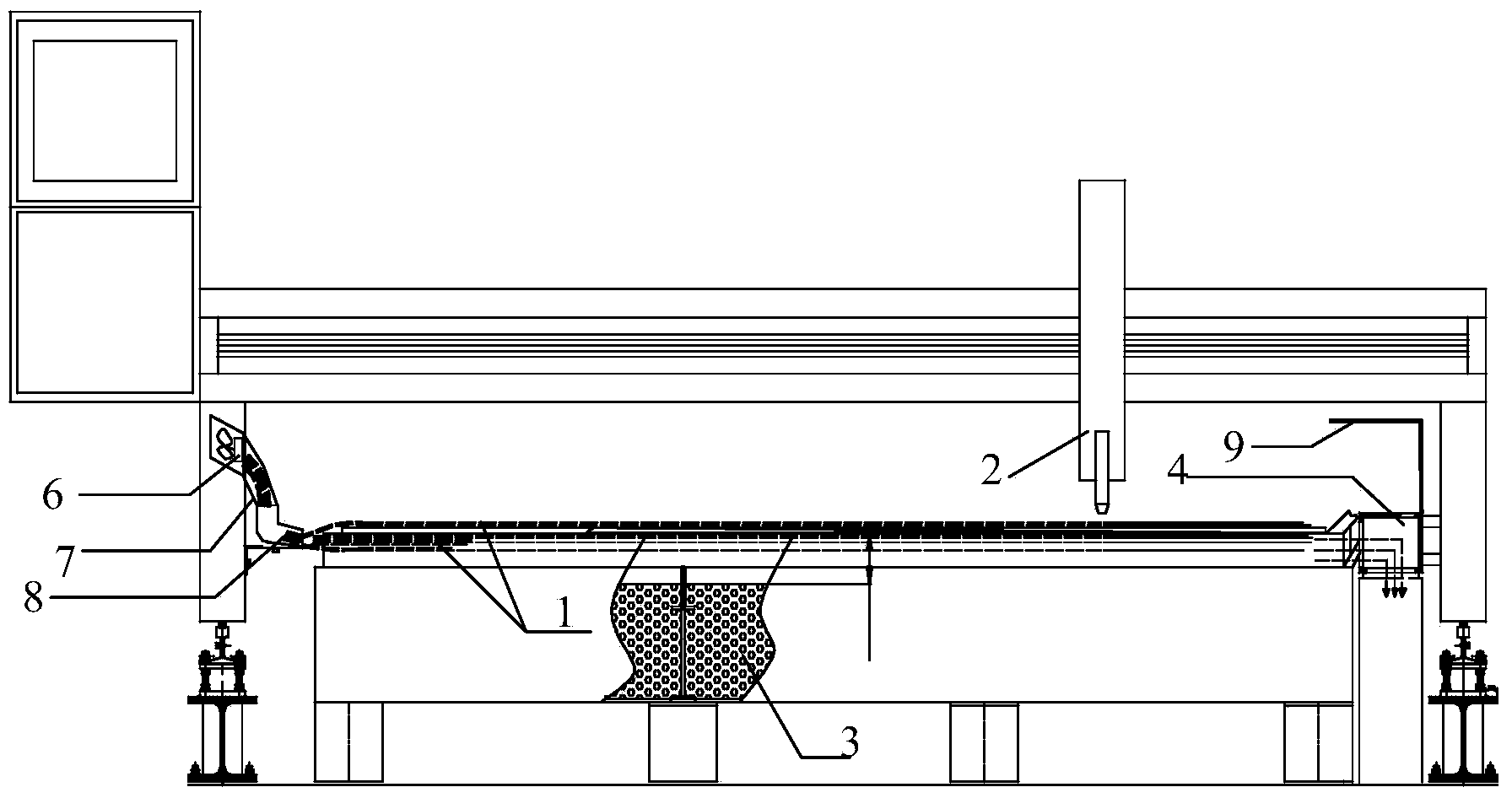

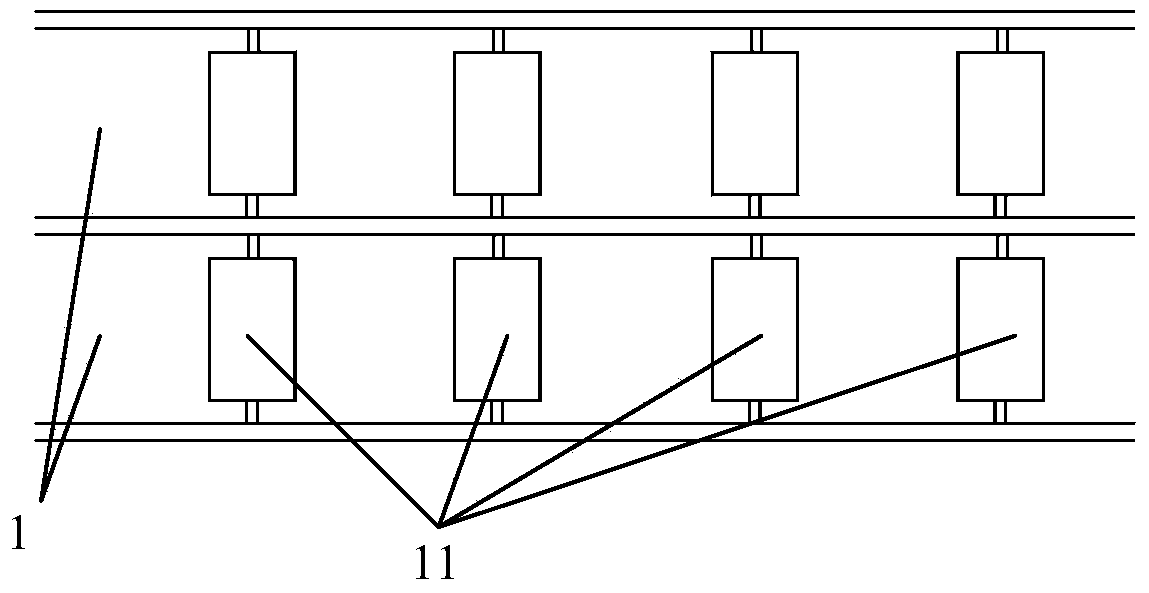

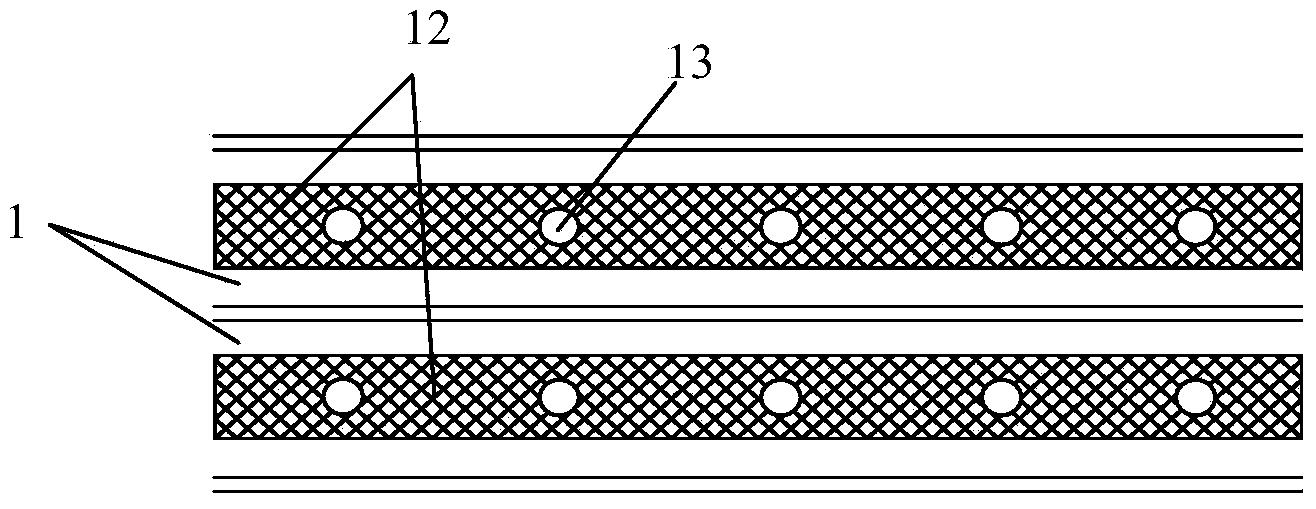

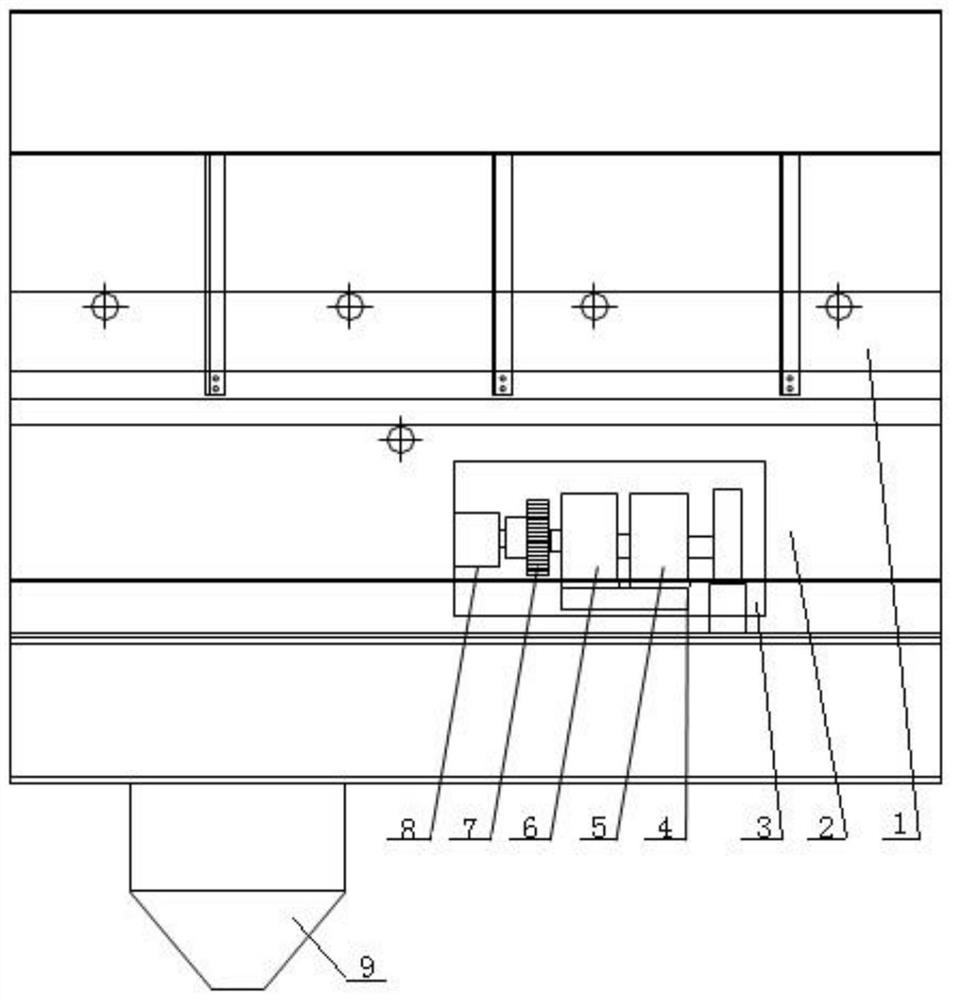

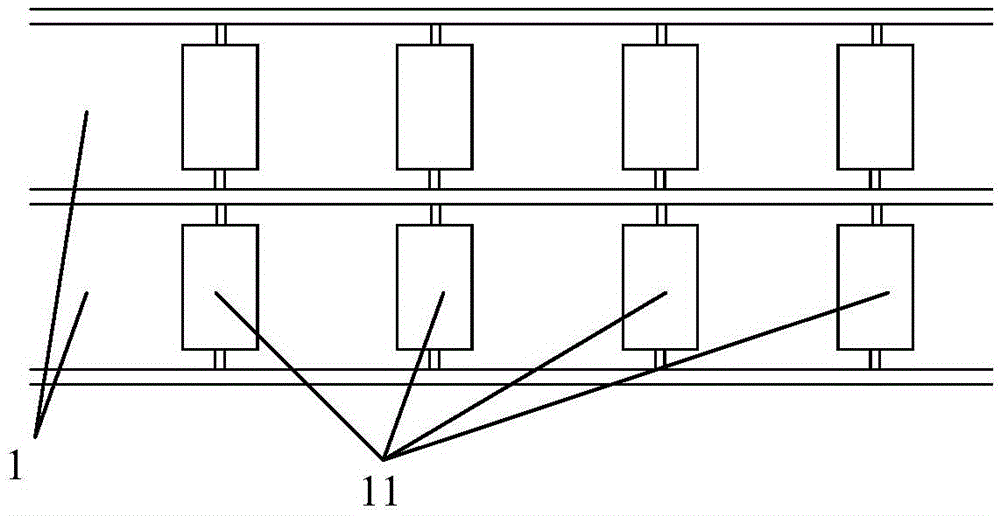

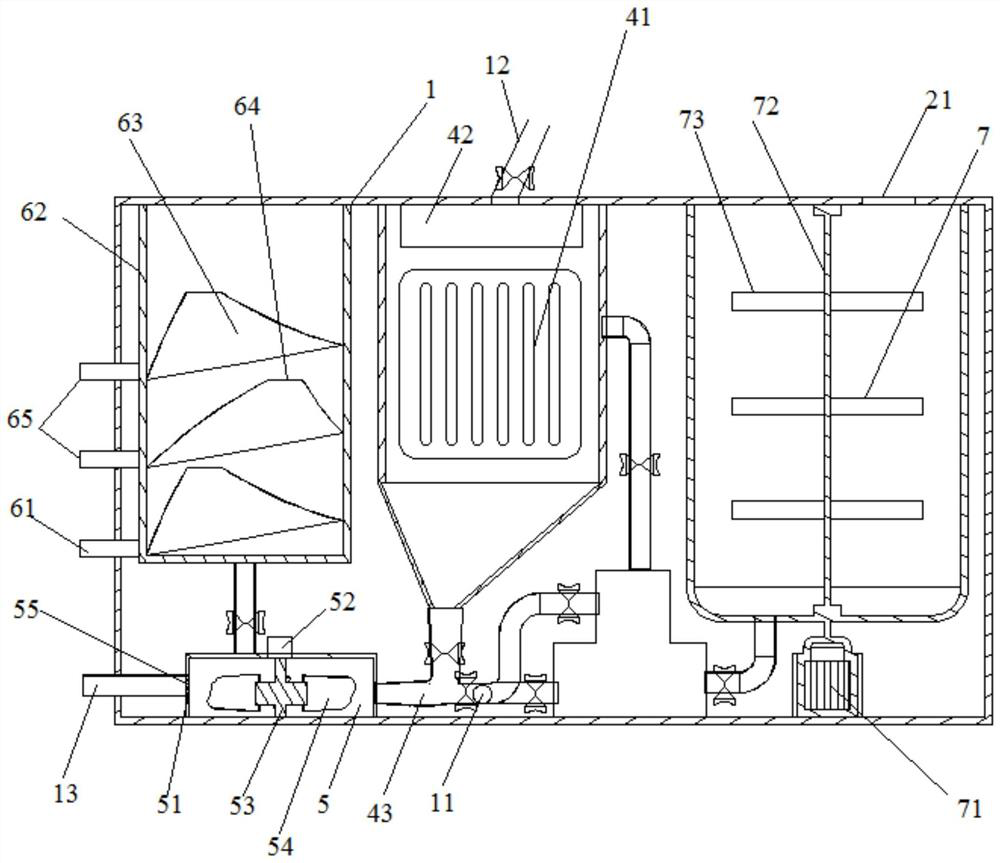

Dust removing system of plasma cutting machine

InactiveCN103831515AHigh strengthReduce intensityDirt cleaningPlasma welding apparatusEngineeringFlue

The invention discloses a dust removing system of a plasma cutting machine. The dust removing system comprises a plurality of air flues and a cutting device, wherein the two ends of each air flue are respectively provided with an outlet, the air flues are horizontally arranged, the cutting device is arranged over the air flues, the outlet at one end of each air flue is connected with an air suction device, and the other end of each air flue is provided with a flow guide pipeline; the sectional area of the opening at one end of each flow guide pipeline is greater than that of the opening at the other end of the corresponding flow guide pipeline, one end, provided with the large opening, of each flow guide pipeline is provided with an axial flow fan, and the other end of each flow guide pipeline is arranged at one end, far away from the corresponding air suction device, of the corresponding air flue; an included angle ranging from 0 degree to 45 degrees is formed between the end, with the small opening, of each flow guide pipeline and the horizontal plane. Due to the facts that one side of each air flue is provided with the corresponding flow guide pipeline having the included angle with the horizontal plane and the axial flow fans are arranged, dust removing efficiency is higher; dust collection pipelines or wing-shaped slices are arranged inside the air flues, and therefore dust removing ability of the system is further improved.

Owner:SHANGHAI SHIPYARD

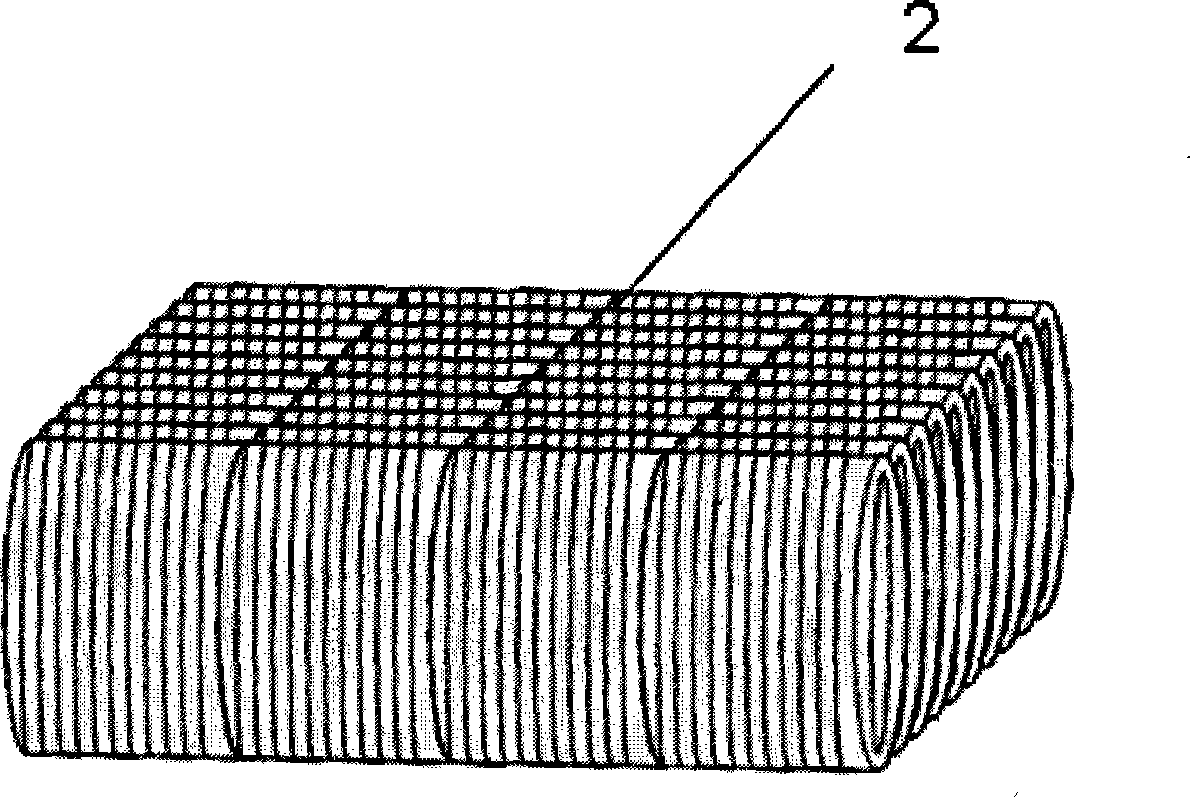

Method for preparing composite crushing wall and composite rolled mortar wall

InactiveCN101412100AShorten the crystallization processThe interface is firmly bondedGrain treatmentsIn situ reactionCast iron

The method discloses a method for preparing a composite breaking wall and a composite rolling wall, wherein the prepared composite breaking wall and the composite rolling wall have a composite wear resistant layer respectively. The method comprises the following steps: weaving alloy powder core wire materials into a three-dimensional framework structure; welding the three-dimensional wire material framework to a groove rolled in the outer wall of the breaking wall and a groove in the inner wall of the rolling wall respectively; through a casting method, pouring high temperature molten steel or molten cast iron into the three-dimensional wire material framework; and performing in situ reaction on alloy powder core wire / strip materials to generate a columnar hard alloy phase by using the high temperature of the molten metal, and performing the metallurgical combination of the hard alloy phase and a base metal phase interface to form a composite wear resistant layer with certain thickness in the groove in the outer wall of the breaking wall and the groove in the inner wall of the rolling wall respectively. Compared with other products of the same type, the composite breaking wall and the composite rolling wall have the characteristics of high wear resistance, high toughness, high tensile strength, high compression strength and the like, thus the use performance and the service life of the composite breaking wall and the composite rolling wall are improved. The method has the characteristics of small equipment input, low cost, strong process controllability, high rate of finished products and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

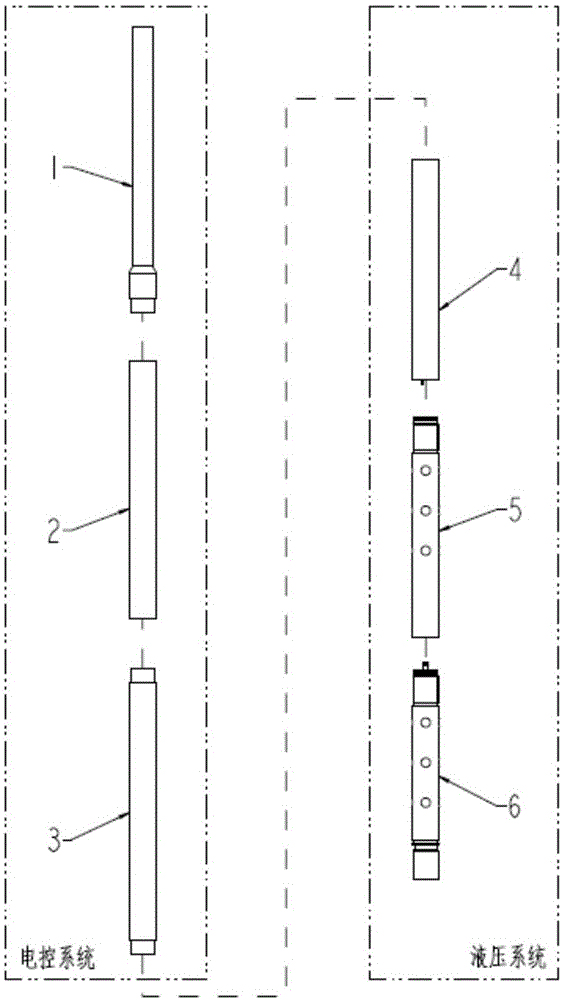

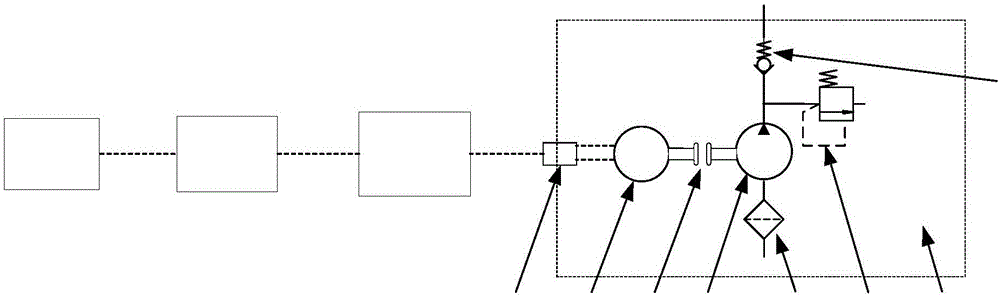

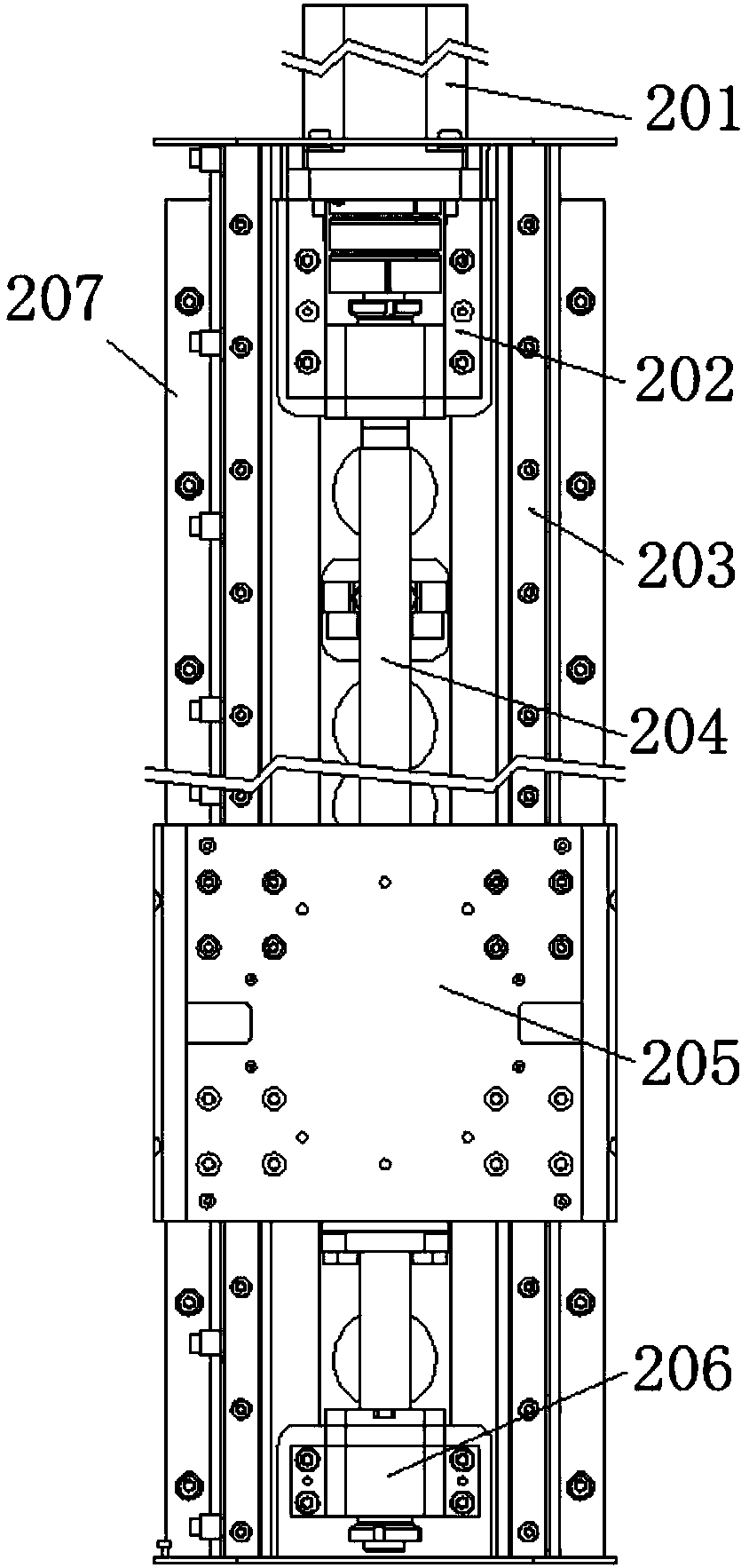

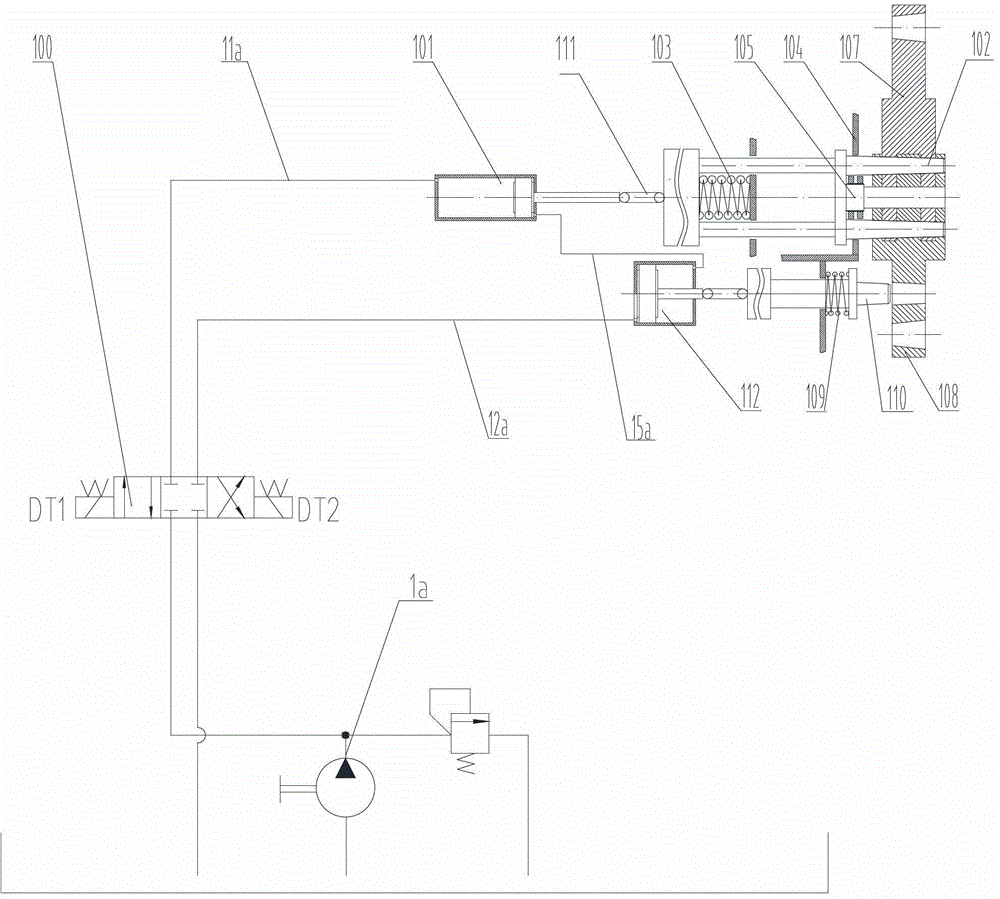

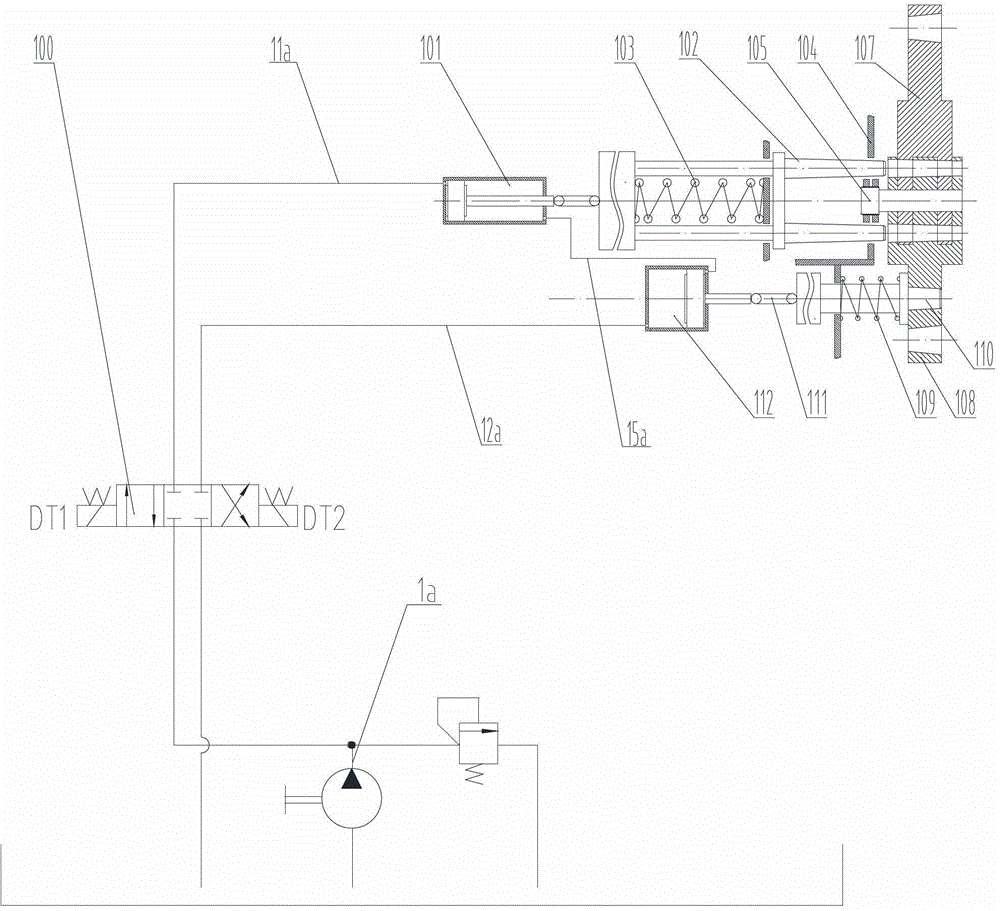

Electric hydraulic bridge plug setting system

InactiveCN106351608AStable outputAdapt to various working conditionsSealing/packingModel selectionCarrier signal

The invention relates to the field of oil field underground setting systems, in particular to an electric hydraulic bridge plug setting system. The electric hydraulic bridge plug setting system comprises an electronic control system and a hydraulic system, wherein one end of the electronic control system is connected with an external ground control system, the other end of the electronic control system is connected with the hydraulic system, one end of the hydraulic system is connected with the electronic control system, and the other end of the hydraulic system is connected with an external bridge plug. The electronic control system comprises a carrier wave communication module, a power source module and a motor driving module, the hydraulic system comprises a motor pump module, an oil tank module and a valve bank module, and the carrier wave communication module, the power source module, the motor driving module, the oil tank module and the valve bank module are connected in sequence. 48V constant value output is achieved under the broad input voltage of 150-300V; the effects of miniaturization of component and part model selection and good heat dissipation are solved, the mode of capsule oil storage is adopted, expansion caused by heat and contraction caused by cold of oil are achieved, pressure inside and outside an oil tank is balanced, the output oil space is effectively compensated.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

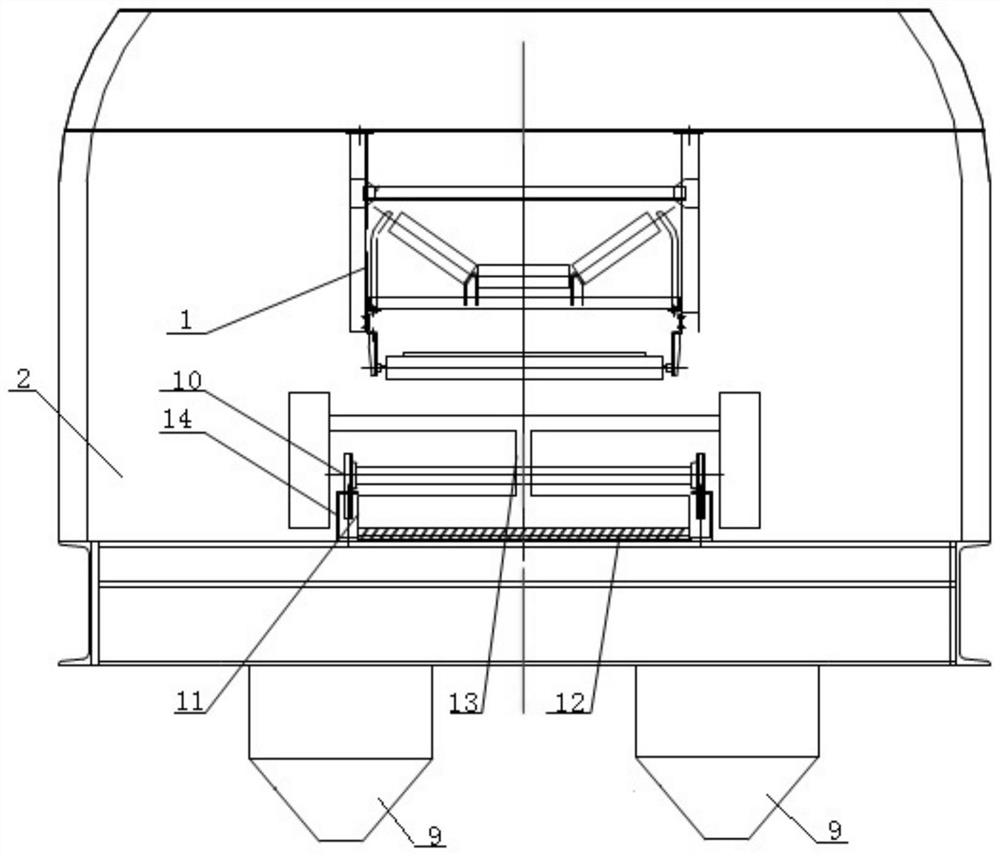

Dust removal device for closed corridor of suspension type belt conveyor

The invention relates to a dust removal device for a closed corridor of a suspension type belt conveyor. The dust removal device comprises a running rail, a running trolley, a dust hood, rolling brushes, a connection pipeline and a dust processing device; the running rail is arranged in the closed corridor, and the running trolley can move along the running rail; the bottom of the running trolleyis provided with the dust hood, the two sides of a dust suction inlet of the dust hood are provided with the rolling brushes correspondingly, and the rolling brushes make rolling contact with the ground of the closed corridor; the top of the suction hood is connected with the dust processing device arranged on the running trolley through the connection pipeline; and the dust processing device comprises a primary filter, a secondary filter, an induced draft fan and an air exhaust device in sequence. According to the dust removal device, the upper suspension type belt conveyor is adopted, the running trolley carries the dust processing device to continuously sweep the ground of the closed corridor along the working path of the belt conveyor, the problem that dust is accumulated on the groundof the closed corridor of the belt conveyor can be effectively solved, unsafe factors caused by manpower cleaning are eliminated, and the purposes of automatically and efficiently removing dust and improving the operation environment are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

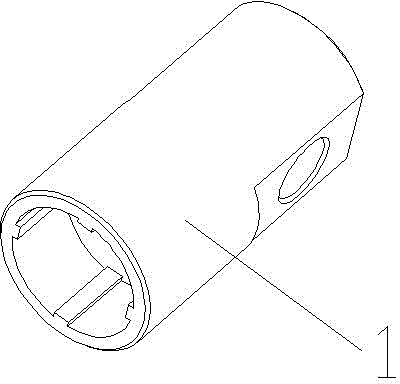

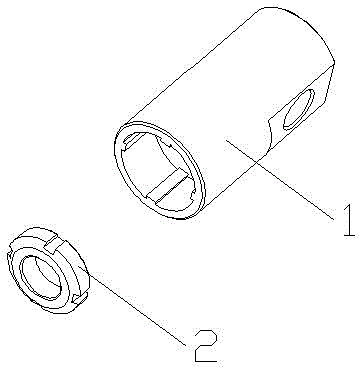

Wrench

InactiveCN104924246AAdapt to various working conditionsSpannersWrenchesCentre of rotationEngineering

The invention relates to a wrench. The wrench comprises a wrench body which is a hollow pipe; four stripe-shaped bosses, which are identical to four slots of a round nut in size, are uniformly and circularly formed on the inner wall of one end of the hollow pipe and around the rotating center of the hollow pipe; flat surfaces are formed on the external circumference of the other end of the hollow pipe and provided with perpendicular through holes. According to the wrench, the external circumference of one end of the wrench body is provided with the two flat surfaces in parallel and meanwhile the two parallel flat surfaces are provided with the perpendicular through holes, so that the wrench can achieve various application manners to adapt to various application conditions.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

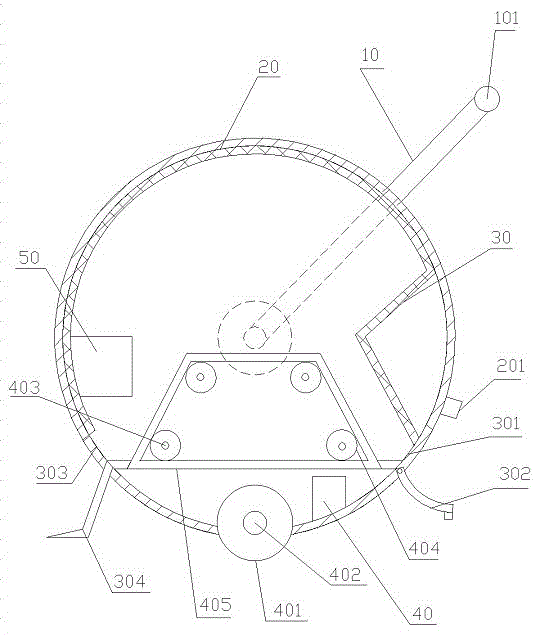

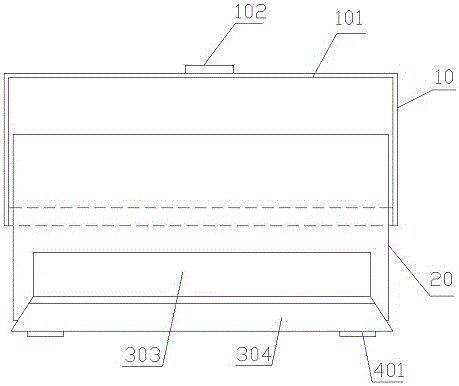

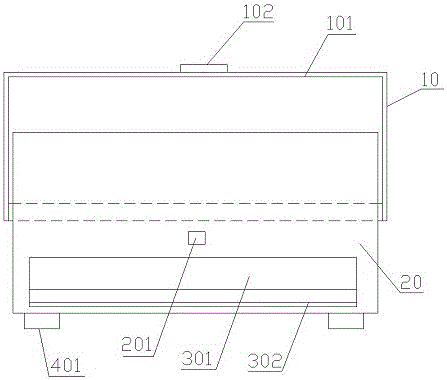

Fodder windrow turning and drying machine

The invention relates to the field of fodder processing, and particularly discloses a fodder windrow turning and drying machine. The fodder windrow turning and drying machine comprises a fixed frame, a turning barrel and a motor. A storage barrel is mounted in the turning barrel, and the storage barrel comprises a conveying device, a feeding port, a discharging port, a discharging plate and a shoveling plate. The feeding port is formed in one side of the storage barrel, and the discharging port is formed in the other side of the storage barrel. The conveying device is fixedly mounted in the storage barrel, one end of the conveying device is close to the feeding port, and the other end of the conveying device is close to the discharging port. One end of the discharging plate is connected with the discharging port, and the other end of the discharging plate is a free end inclined downwards. One end of the shoveling plate is connected with the feeding port, and the other end of the shoveling plate is a free end inclined downwards. The conveying device comprises a conveying belt, a transmission gear and a second transmission shaft, the conveying belt is engaged with the transmission gear, and the transmission gear is connected with the second transmission shaft. According to the scheme, fodder can be fast turned and dried, use is convenient, and labor is saved.

Owner:CHONGQING CHANGYUAN FEED CO LTD

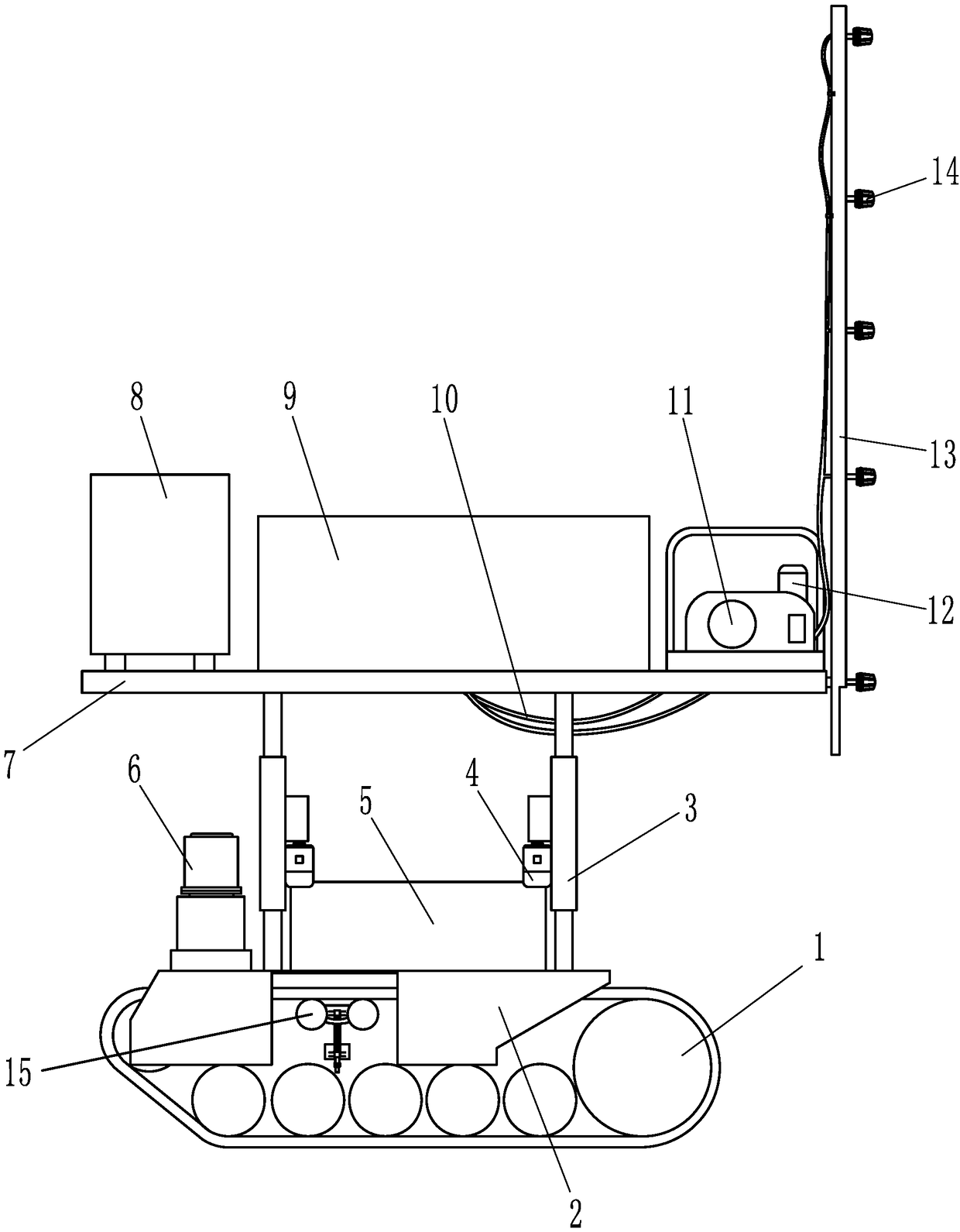

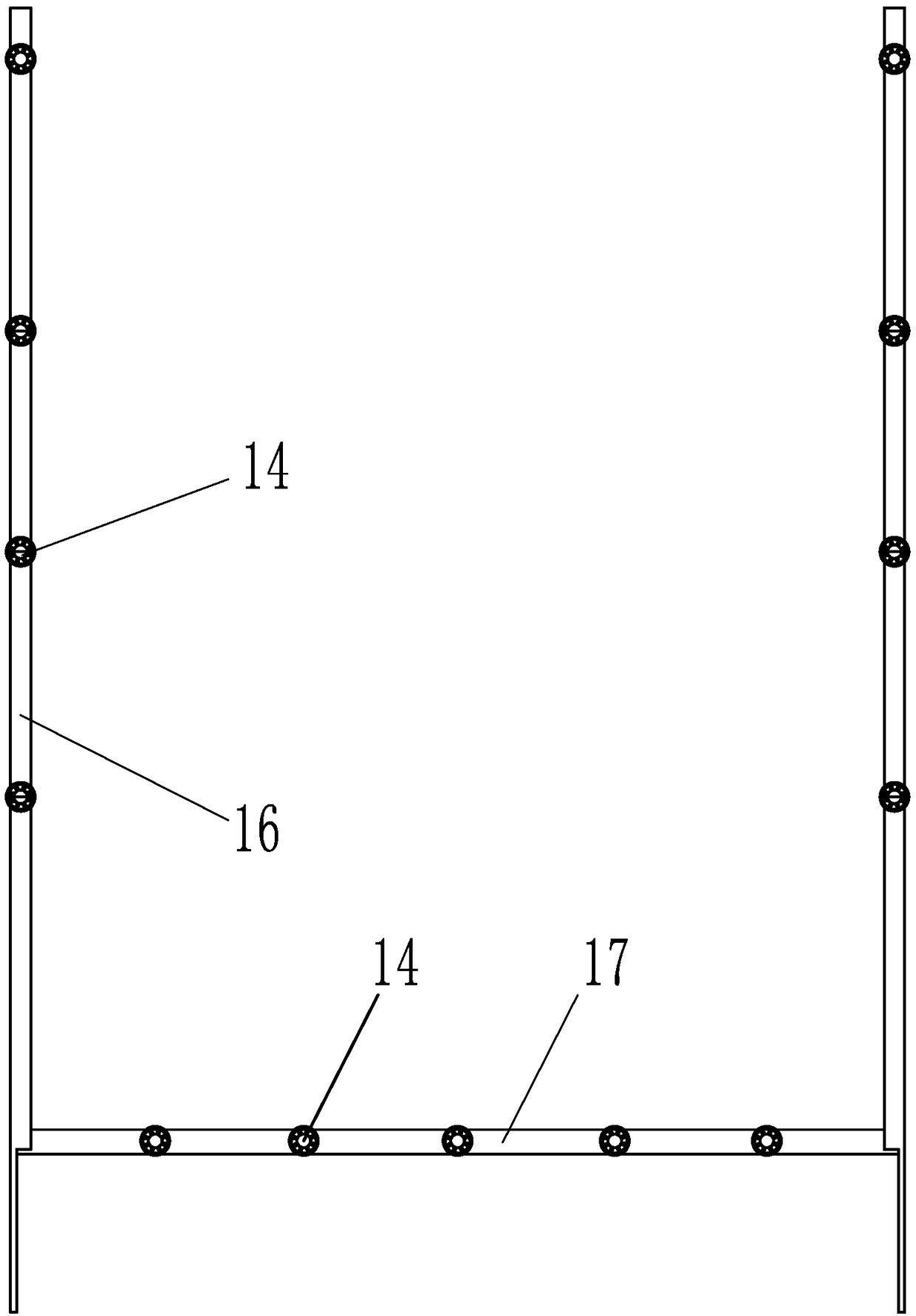

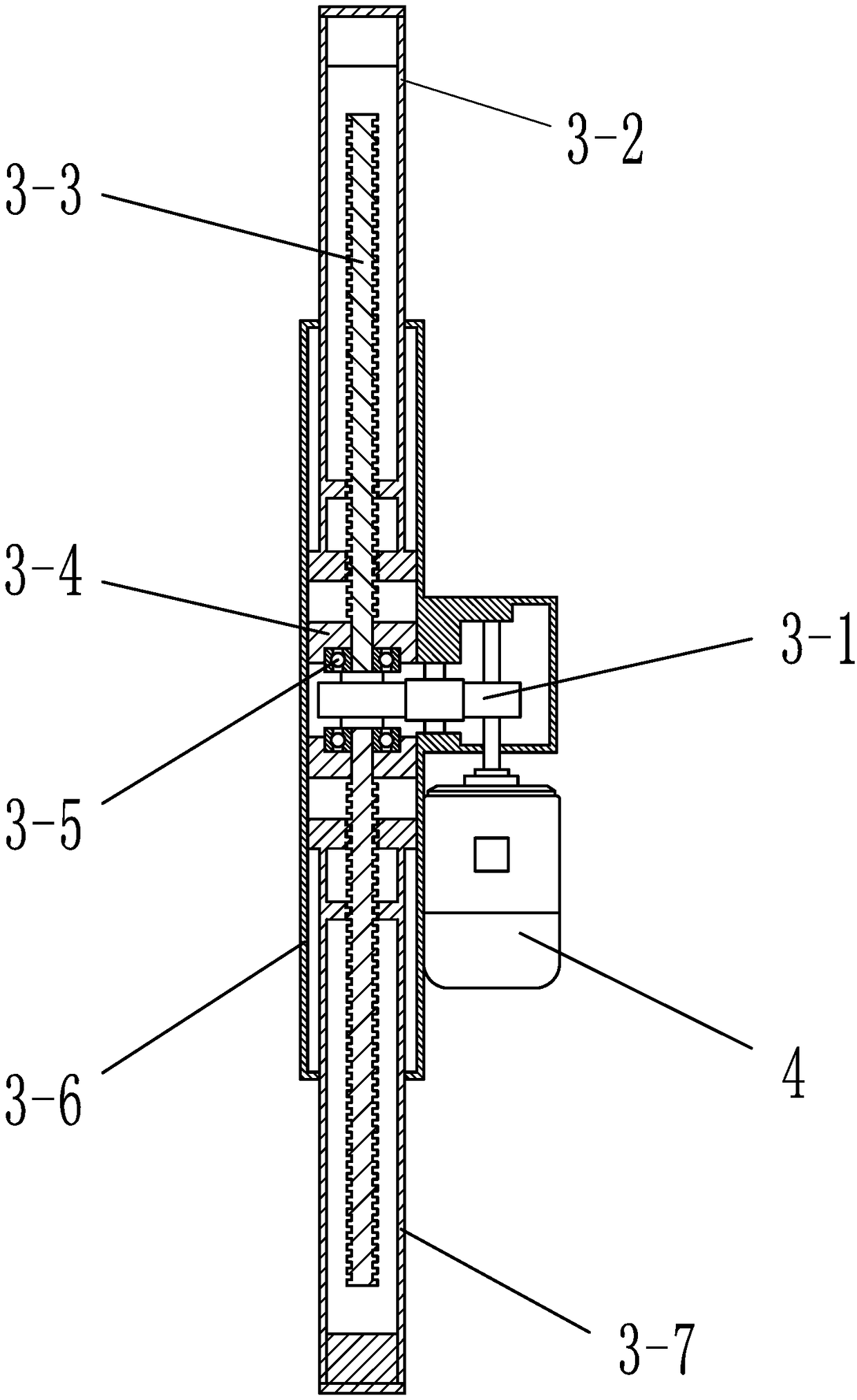

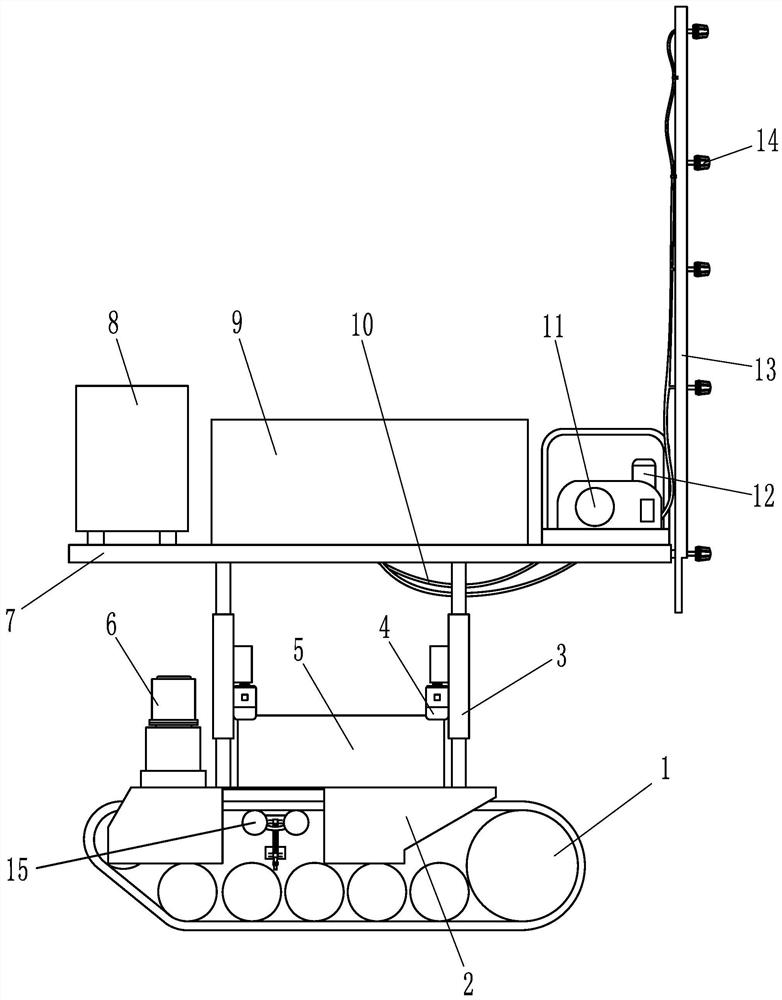

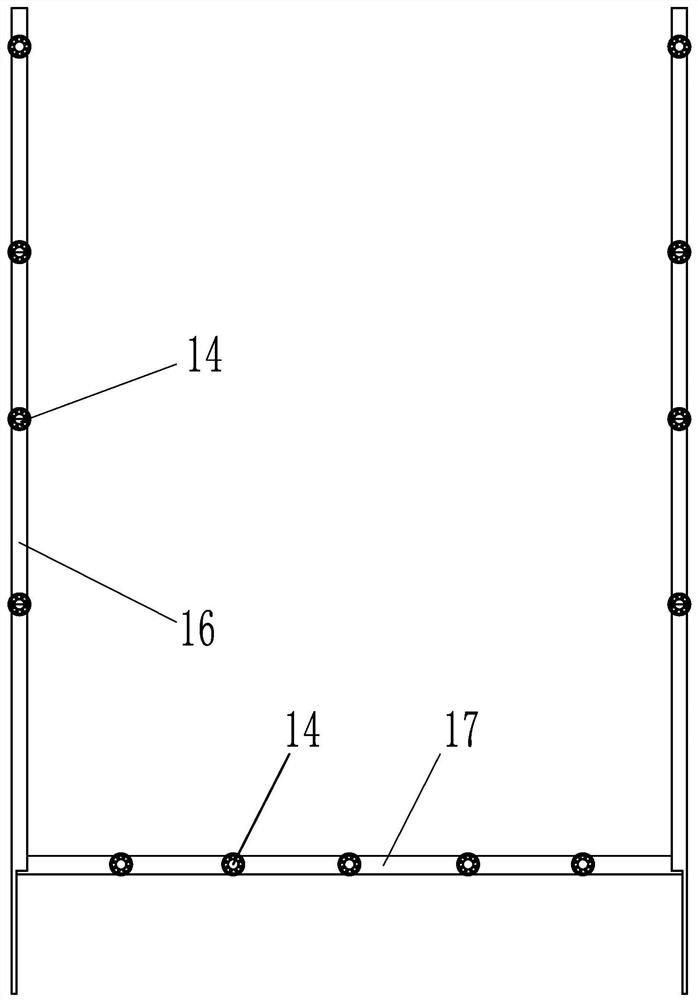

Self-propelled intelligent mist-spraying pesticide-applying trolley

ActiveCN108925538AAdapt to spraying height requirementsNovel structureInsect catchers and killersEngineeringFuture of robotics

The invention discloses a self-propelled intelligent mist-spraying pesticide-applying trolley, and belongs to the technical field of robots. The trolley is structurally constructed by connecting a walking mechanism, a supporting platform, an electric telescopic rod group, a driving device, a power box, a working platform, a control box, a pesticide box, a pipeline, a liquid pump, an air pump and adetachable spraying rod group. The structure is novel, and the movement of the pesticide-applying trolley, the lifting of the working platform and the spraying of a liquid pesticide are controlled through a wireless receiving module in the control box, and the working principle is clear. Compared with a device of conventional manual pesticide application operation, the trolley provided by the invention is high in automation degree, easy in operation and high in efficiency, and the trolley is suitable for working requirements of various working conditions and meets the requirements of sprayingheight of various crops, so that the poisoning phenomenon caused by direct contact of a human body with a pesticide is avoided.

Owner:YANGZHOU UNIV

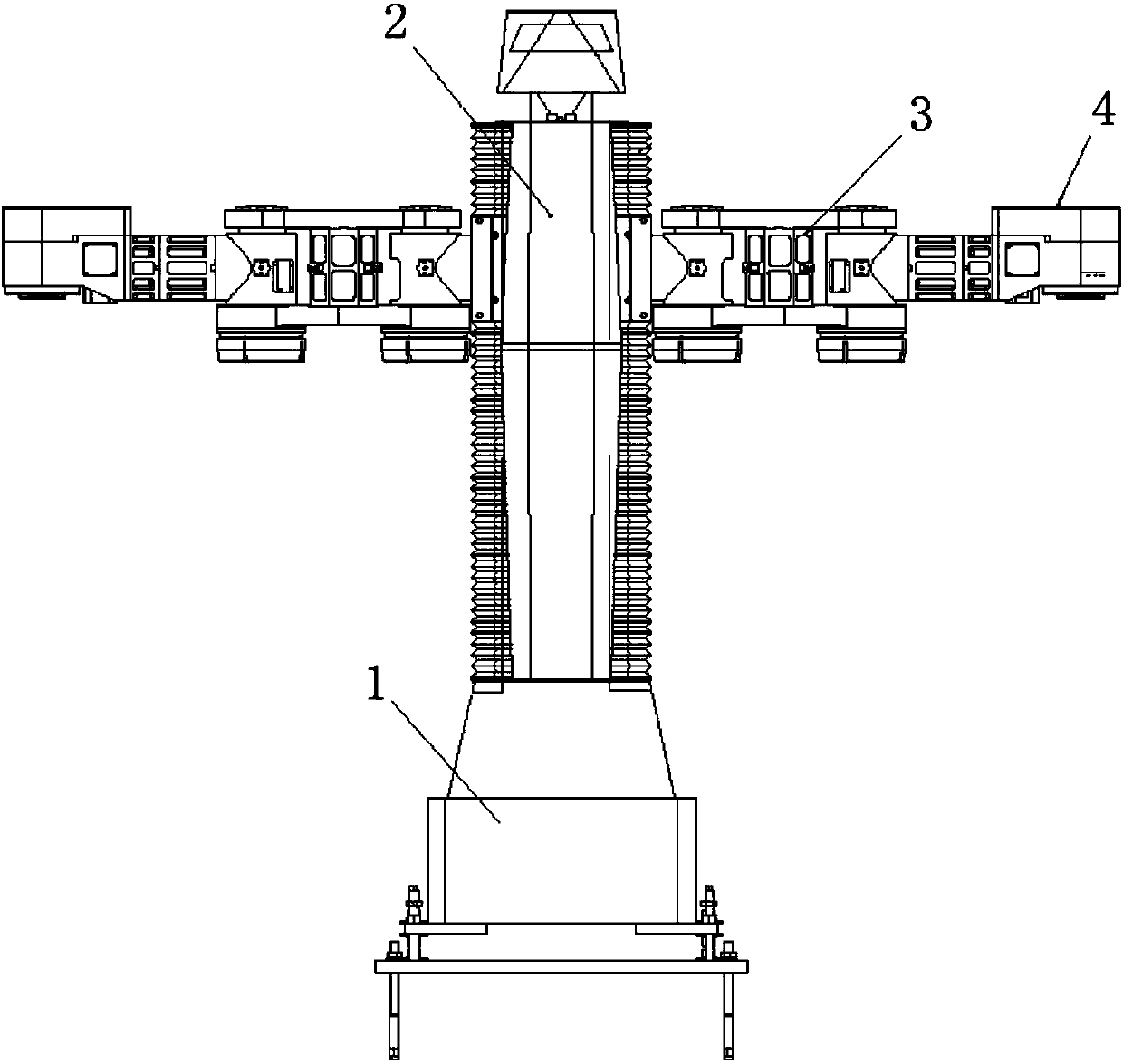

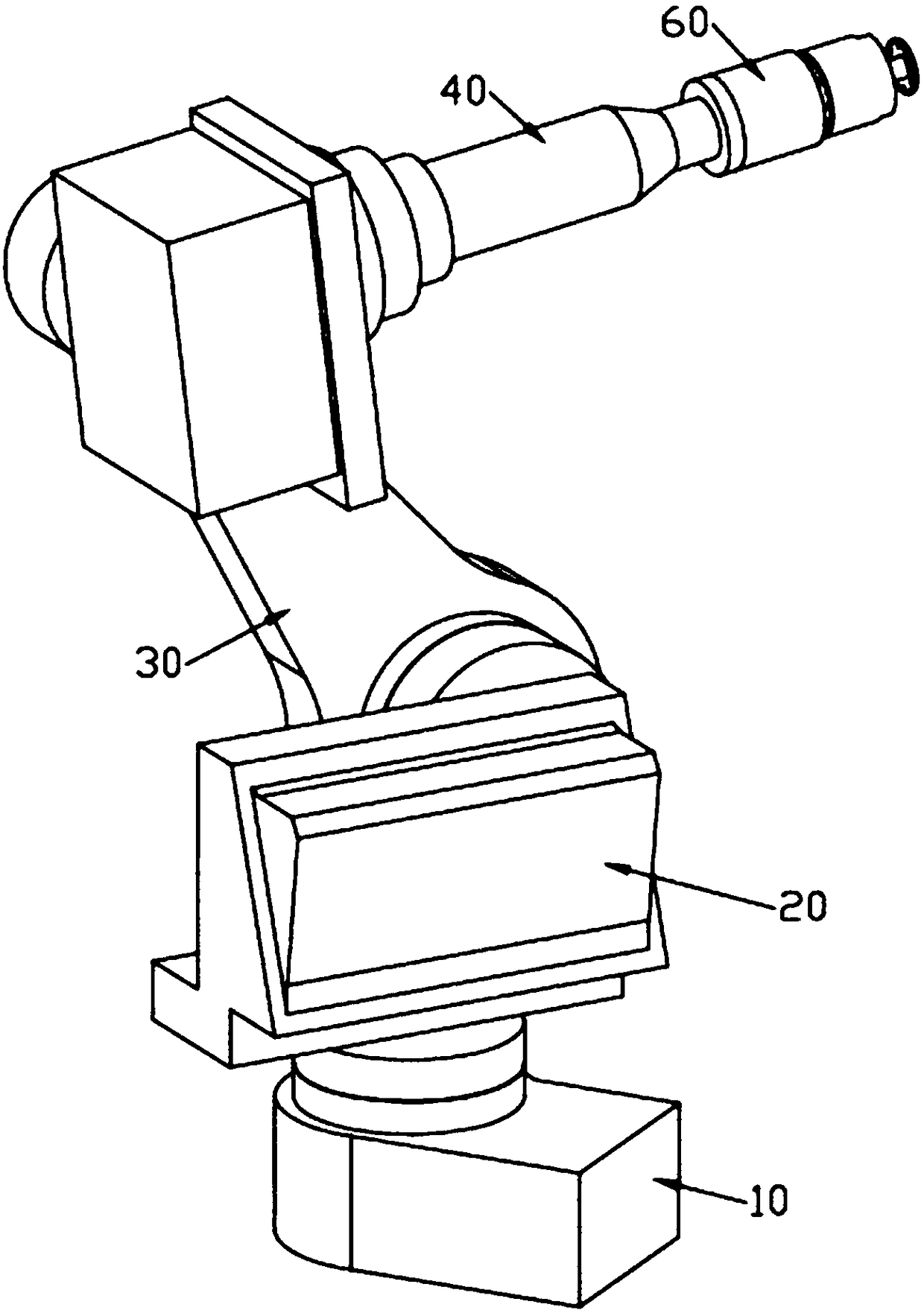

Coordination type double-arm industrial robot

ActiveCN109866203AIncrease working spaceIncrease load capacityProgramme-controlled manipulatorCoordination typeEngineering

The invention relates to the field of robots, in particular to a coordination type double-arm industrial robot. A rotating mechanism, a mechanical arm lifting mechanism and mechanical arms are included; the mechanical arm lifting mechanism is provided with a lifting base; the two mechanical arms are installed on the two sides of the lifting base correspondingly, and each comprise a first rotatingarm and a second rotating arm; the two ends of an arm body of each first rotating arm are provided with a first rotating joint and a second rotating joint correspondingly, and the arm body of each first rotating arm is driven by the corresponding first rotating joint to rotate; an arm body of each second rotating arm is driven by the corresponding second rotating joint to rotate; the arm body of each second rotating arm is provided with a rotating part driving mechanism and a rotating connecting part; the rotating mechanism is provided with a rotating waist portion and a rotating driving mechanism, and the rotating waist portion is driven by the rotating driving mechanism to rotate; and the lower end of an installing vertical base is fixedly connected with the rotating waist portion. The double arms of the coordination type double-arm industrial robot can act coordinately, the load capacity of the robot is improved, and the coordination type double-arm industrial robot can adapt to various work condition requirements.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

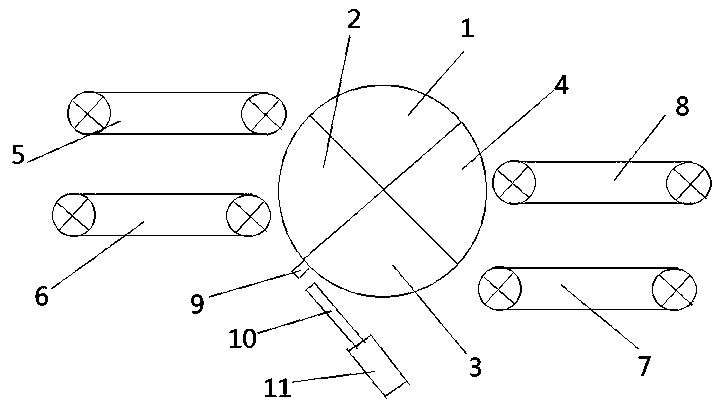

Working method for conveying sorting device

The invention provides a working method for conveying a sorting device. The sorting method comprises a first sorting region sorting method, a second sorting region sorting method, a third sorting region sorting method and a fourth sorting region sorting method. The second sorting region sorting method comprises a receiving method and an unloading method, wherein the receiving method comprises thestep that a material falls on a lower sorting plate I when the lower sorting plate I in a second sorting region rotates to a position below a discharging valve; and the unloading method comprises thefollowing steps that the lower sorting plate I is driven to rotate clockwise by an auxiliary motor when a third sorting region rotates to a position below the discharging valve, a connecting baffle isused for baffling the material on the lower sorting plate I to make the material fall on a fourth conveying belt, and the material is conveyed downstream; and afterwards the auxiliary motor is used for driving the lower sorting plate I to rotate anticlockwise so as to rotate and returns to the original position in a light loading manner in a direction opposite to the rotation direction of a sorting platform.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Doppler velometer

InactiveCN103675825AAccurate speed measurementAdapt to various working conditionsAcoustic wave reradiationTransceiverAnalyser

The invention provides a Doppler velometer. The Doppler velometer comprises a sound wave transceiver, a frequency analyzer and an arithmetic device. In each measuring process, the sound wave transceiver sends sound wave signals twice to a target to be measured, and the second-time sound wave signals are sent after the first-time sound wave signals are returned; the frequency analyzer analyzes the frequencies of the returned signals corresponding to the two-time sound wave signals; the arithmetic device calculates absolute velocity of the target to be measured according to the time interval for sending the sound wave signals twice, the round-trip time of the sound wave signals each time, and the frequencies of the returned signals corresponding to the sound wave signals at any one time. The Doppler velometer can measure the absolute velocity of the target to be measured in a moving state, so that the Doppler velometer is suitable for measurement in various conditions.

Owner:SUZHOU FENGZHIHUO DIGITAL TECH

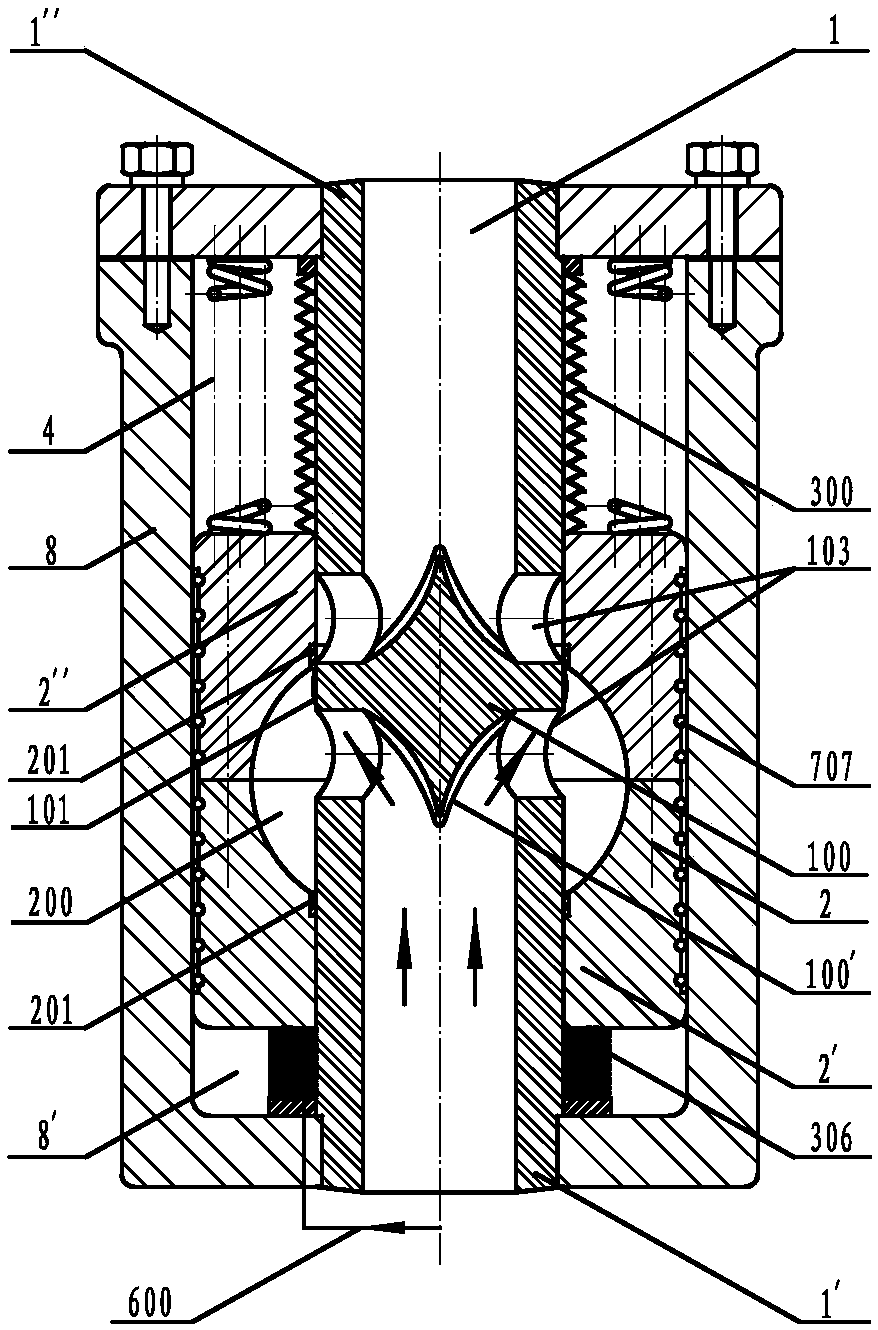

Drive core pipe valve of dual valve body bellows pressure cabin

The invention provides a drive core pipe valve of a dual valve body bellows pressure cabin, and relates to pressure opening and closure, pulse, non-return, safety, regulation, pressure reduction, emergency shutoff and the like; a valve core pipe wrapped in an inner cavity of an outer valve body serves as a fixing piece to coaxially penetrate a sleeve I of a valve body, an inner cavity of the valvebody and a sleeve II of the valve body; the middle part of the valve core pipe is provided with an axial interlayer, and the two adjacent axial sides of the interlayer are each provided with at leastone radial circulation hole of an input section and an output section; a sealing pair is formed by an annular valve element surrounding the interlayer, and an annular valve seat of at least one sleeve throat of the sleeve I and the sleeve II; the input section and the sleeve I as well as the output section and the sleeve II are cooperated in an axle hole mode, and the joint parts are provided with seals; and the joint part between the input section and the sleeve I is provided with the bellows pressure cabin, and the bellows pressure cabin and a front pressure cavity of the valve are throughby manes of a channel. Under the effect of potential energy in two directions, the valve body does axial reciprocating motion in the inner cavity of the outer valve body so that the effects of openingand closure and function switching are achieved. The drive core pipe valve is safe, reliable, leak-free and multipurpose.

Owner:卢星霖

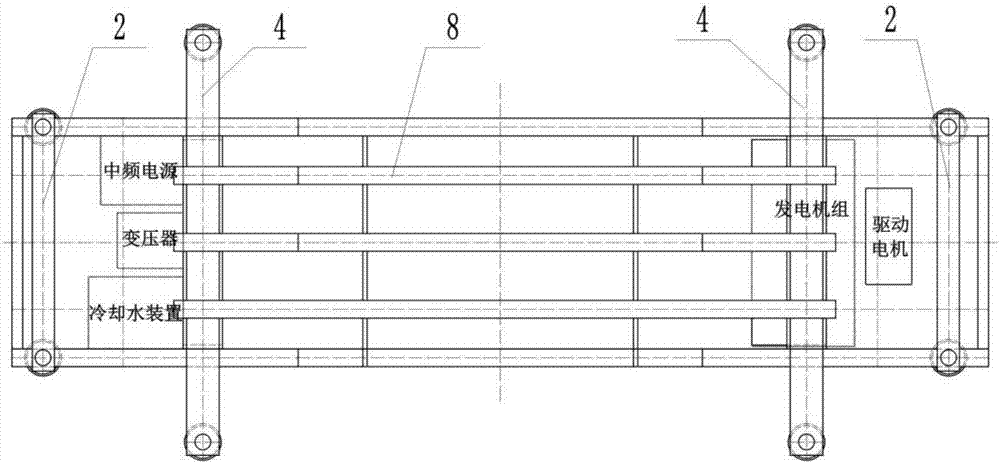

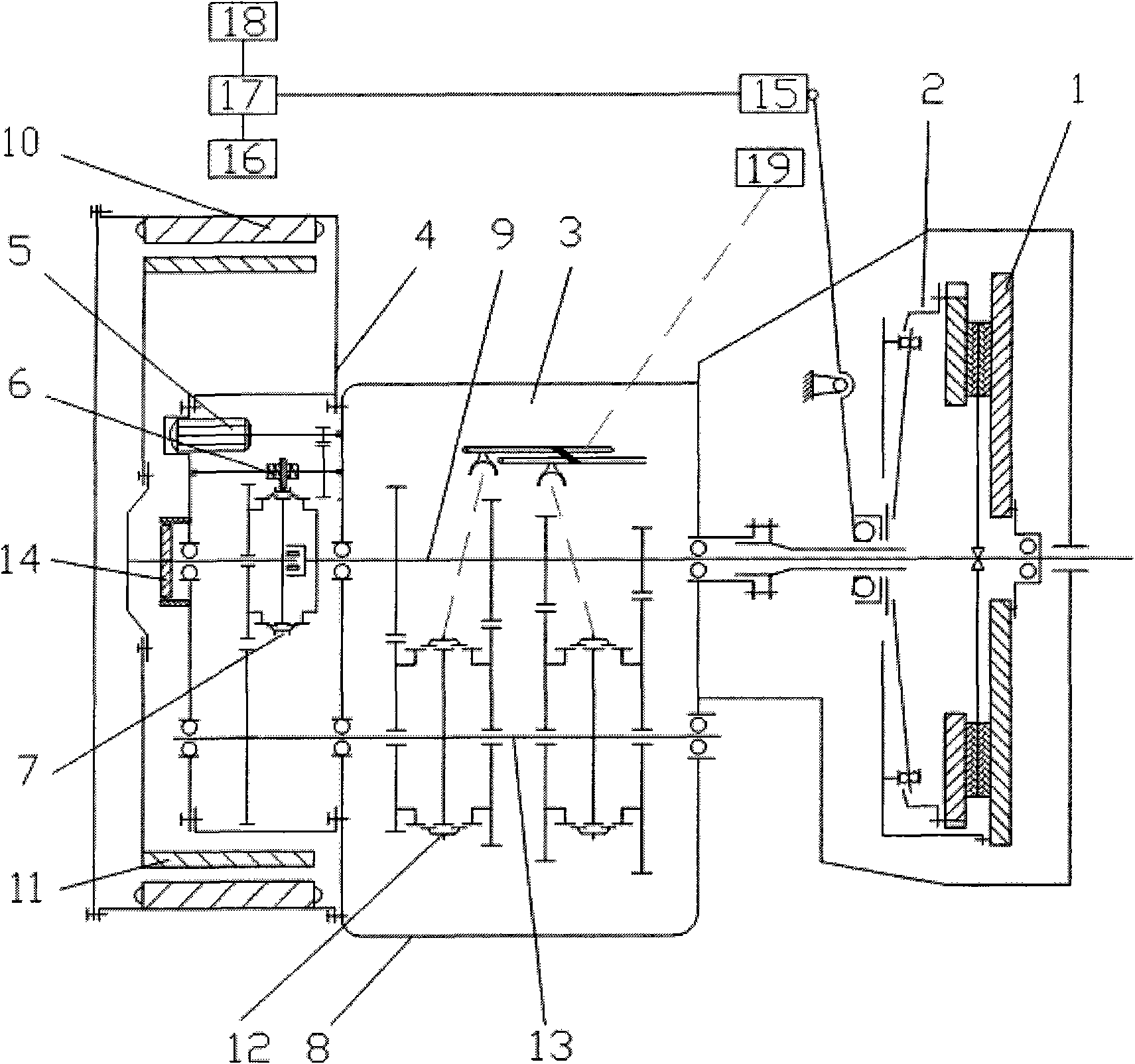

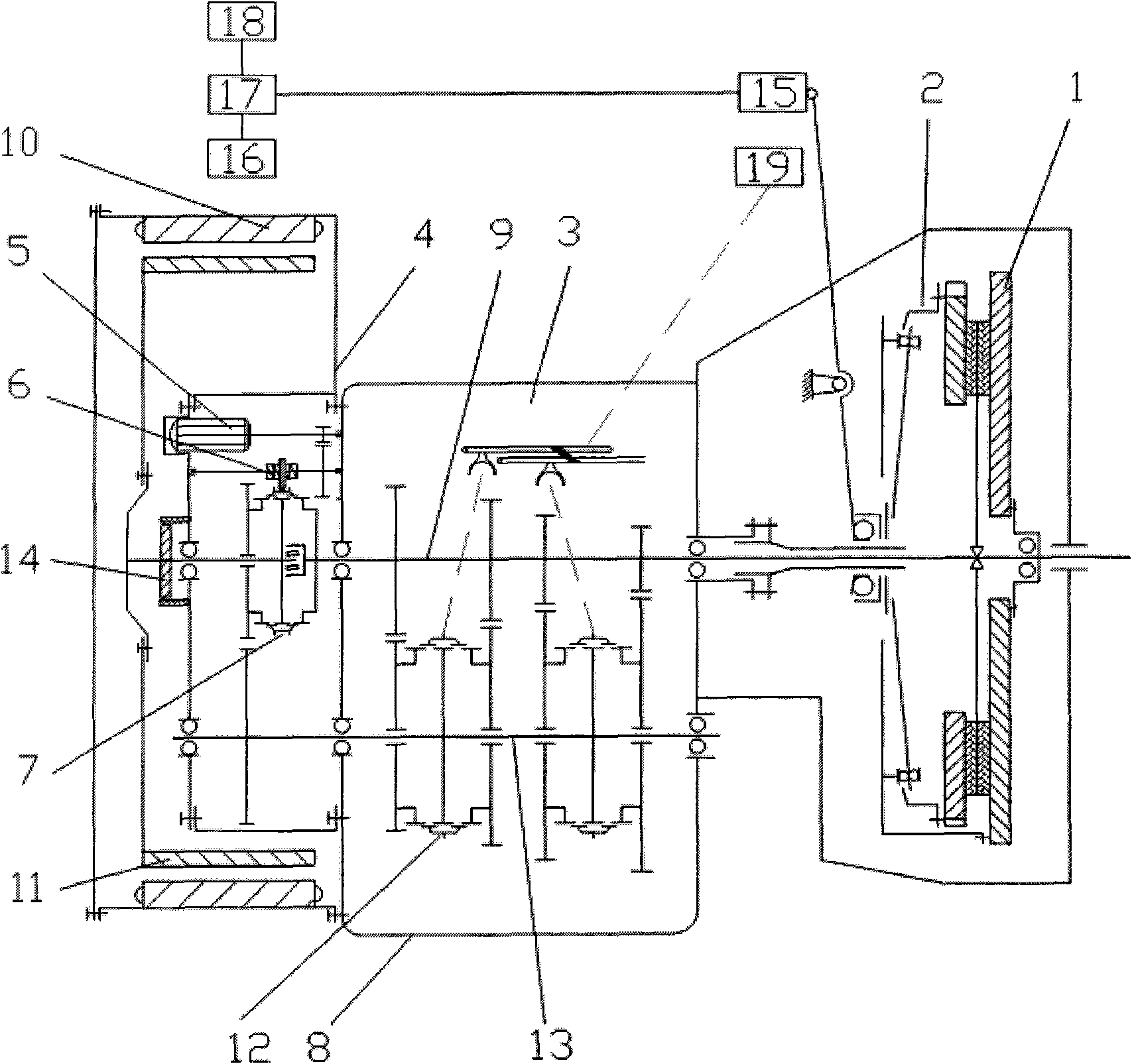

Main and auxiliary motor coupling and range-extending driving system

InactiveCN104417379AIncrease the number of revolutionsReduce lossElectric machinesPropulsion using engine-driven generatorsReduction driveEngineering

The invention discloses a main and auxiliary motor coupling and range-extending driving system, which adopts two motors, wherein one motor serves as a main driving motor, the other motor serves as a generator for a range extender and also is used for being coupled with the main driving motor to take part in the driving operation (hereafter called auxiliary motor), one end of the output shaft of the auxiliary motor is connected to an engine by a clutch while the other end of the output shaft of the auxiliary motor is placed opposite to the output shaft of the main driving motor, and coaxially inserted into the coupler of a reducer; when in driving, the engine is separated from the auxiliary motor by the clutch, and meanwhile combine with the coupler in the reducer, thus achieving the main and auxiliary motor coupling driving; when a vehicle has small requirement on the power, the auxiliary motor can be idle or compatible for generating electricity; the above components are integrated into a machine, a plurality of driving modes, including single motor independent driving when in small power, double motor coupling driving when in large power, engine and main and auxiliary motor combined driving when in extra large load and range-extending generation driving when a battery is lack of power can be obtained under the network control of the whole vehicle; the system includes the engine, the clutch, the auxiliary motor, the reducer, the main driving motor, a generation unit controller and a double-motor controller.

Owner:CHANGZHOU HAOKANG NEW ENERGY DEV

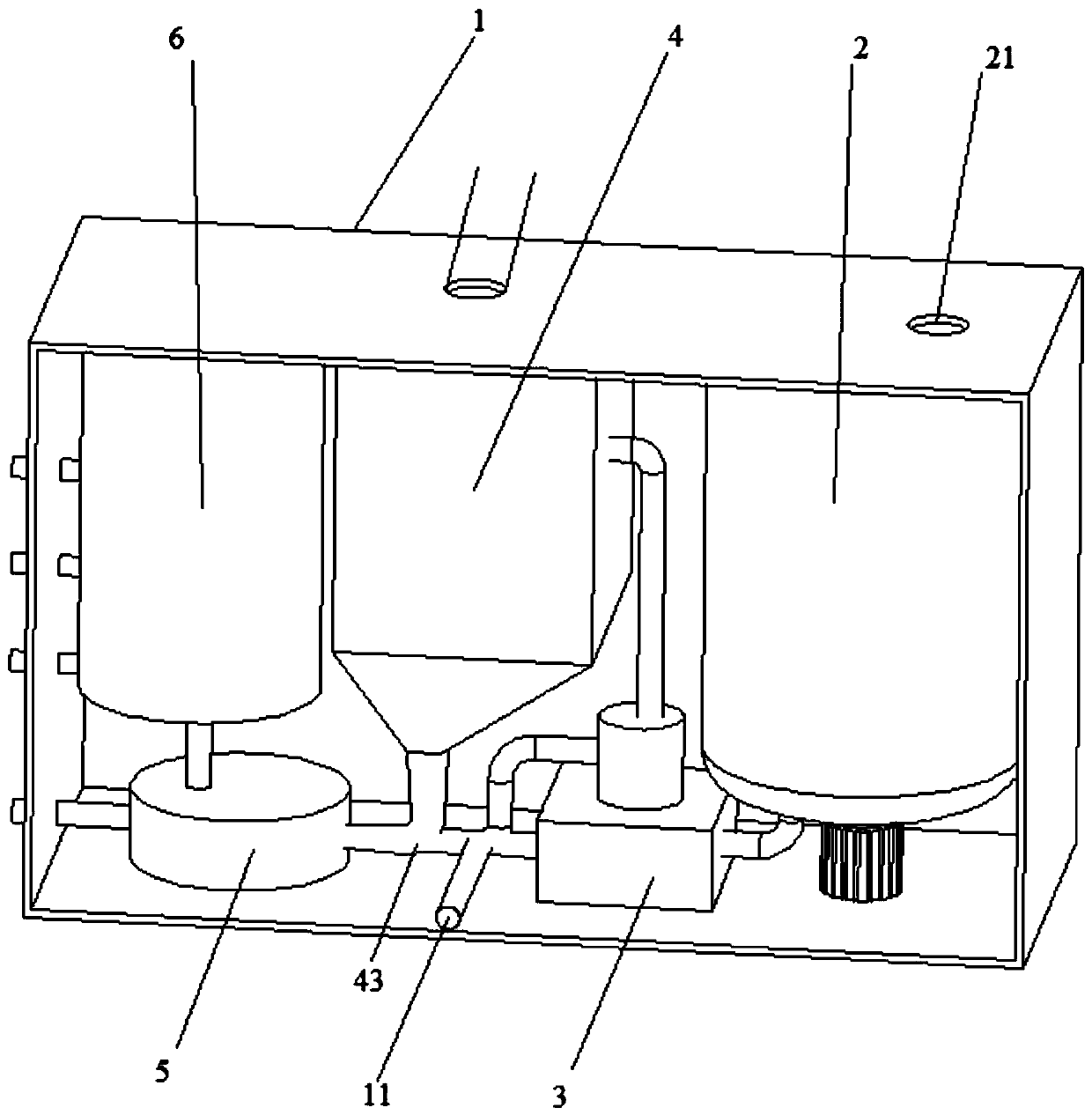

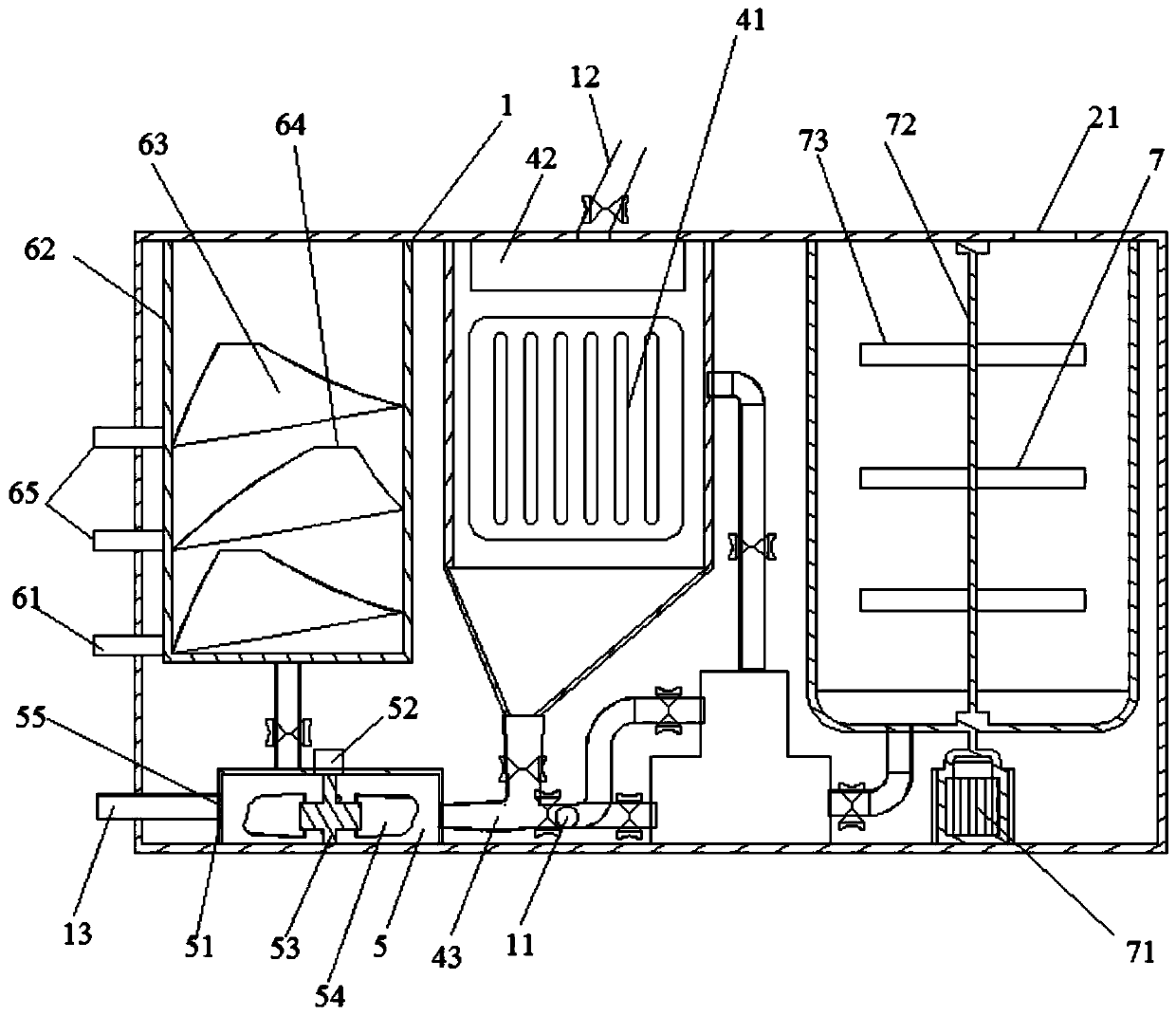

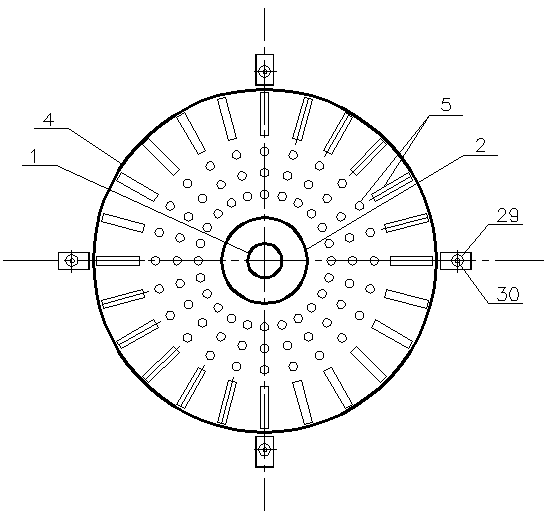

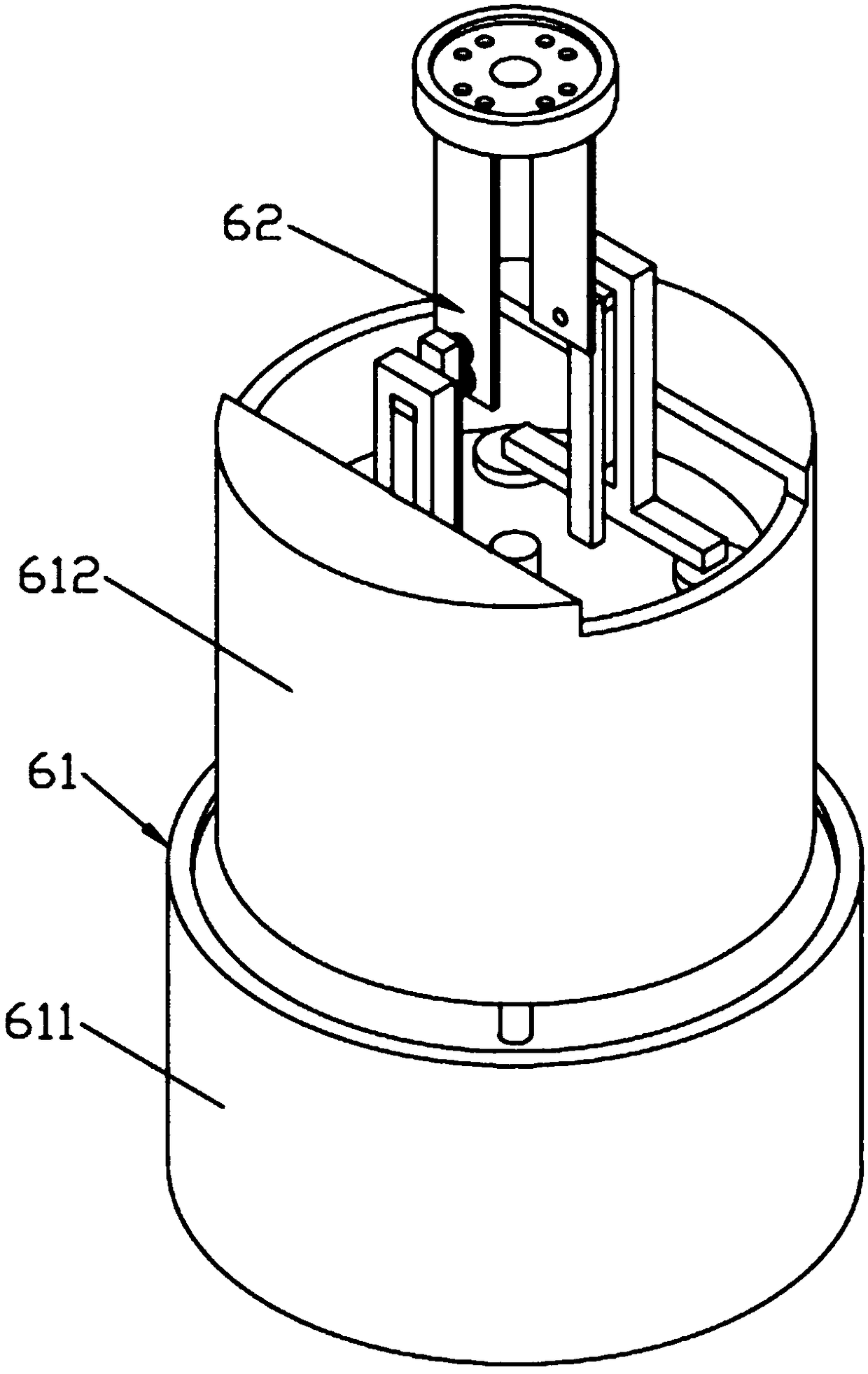

Polishing solution polishing particle circularly extracting device

ActiveCN110370171AAvoid Agglomeration and PrecipitationAffecting workGrinding/polishing apparatusUltrasonic atomizationGreen manufacturing

The invention discloses a polishing solution polishing particle circularly extracting device which comprises a box body as well as a polishing solution storage device, a polishing solution ultrasonicatomization device, a polishing solution drying device, a polishing particle and airflow mixing device, and a polishing particle separating device all arranged in the box body, wherein a polishing solution stirring device is arranged in the polishing solution storage device; and polishing waste solution is collected and stirred in the polishing solution storage device, is atomized in the polishingsolution ultrasonic atomization device, enters the polishing solution drying device to be dried, then enters the polishing particle and airflow mixing device, and finally enters the polishing particle separating device, so that separation of particles with different masses is realized according to different gravity ranges of different particles. The polishing solution polishing particle circularly extracting device can recycle the polishing solution after polishing treatment to greatly lower the economic cost of the polishing process and increase the green manufacturing degree of the polishing process.

Owner:NORTHEASTERN UNIV

Dust removal system for plasma cutting machine

InactiveCN103831515BAdapt to various working conditionsImprove dust removal efficiencyDirt cleaningPlasma welding apparatusEngineeringFlue

The invention discloses a dust removing system of a plasma cutting machine. The dust removing system comprises a plurality of air flues and a cutting device, wherein the two ends of each air flue are respectively provided with an outlet, the air flues are horizontally arranged, the cutting device is arranged over the air flues, the outlet at one end of each air flue is connected with an air suction device, and the other end of each air flue is provided with a flow guide pipeline; the sectional area of the opening at one end of each flow guide pipeline is greater than that of the opening at the other end of the corresponding flow guide pipeline, one end, provided with the large opening, of each flow guide pipeline is provided with an axial flow fan, and the other end of each flow guide pipeline is arranged at one end, far away from the corresponding air suction device, of the corresponding air flue; an included angle ranging from 0 degree to 45 degrees is formed between the end, with the small opening, of each flow guide pipeline and the horizontal plane. Due to the facts that one side of each air flue is provided with the corresponding flow guide pipeline having the included angle with the horizontal plane and the axial flow fans are arranged, dust removing efficiency is higher; dust collection pipelines or wing-shaped slices are arranged inside the air flues, and therefore dust removing ability of the system is further improved.

Owner:SHANGHAI SHIPYARD

Cranes and their steering systems and rocker arms

ActiveCN102874309BAchieve all-wheel steeringImproved ability to adjust postureSteering linkagesFluid steeringLocking mechanismEngineering

The invention discloses a crane as well as a steering system and a rocker arm thereof. The rocker arm comprises a fixed shaft, a front-axle rocker arm, a rear-axle rocker arm, a first locking mechanism and a second locking mechanism, wherein the front-axle rocker arm is hinged with the fixed shaft and provided with a first front-axle locking hole; the rear-axle rocker arm is hinged with the fixed shaft and provided with both a first rear-axle locking hole and a second rear-axle locking hole; the first locking mechanism is provided with a first locking part matched with both the first front-axle locking hole and the first rear-axle locking hole, as well as a first drive part for driving the first locking part to get in or out of the first front-axle locking hole and the first rear-axle locking hole; and the second locking mechanism is provided with a second locking part matched with the second rear-axle locking hole, as well as a second drive part for driving the second locking part to get in or out of the second rear-axle locking hole. The rocker arm has both a rocker arm linkage state and a rear-axle rocker arm locking state, so that the crane has both an all-wheel steering mode and a front-wheel rotating and rear-wheel locking mode correspondingly. The rocker arm has the advantages that the steering adjustment method is flexible and the rocker arm can adapt to various working conditions.

Owner:SANY HEAVY IND CO LTD (CN)

Dual body core tube valve

ActiveCN108426044BSimple structureEasy to manufactureOperating means/releasing devices for valvesCheck valvesReciprocating motionEngineering

A double valve body core pipe valve is the main part of a double valve body core pipe valve plate in a core pipe valve mother series invented by the inventor originally. A valve core pipe wrapped in an outer valve body inner cavity is a fixed part which coaxially penetrates through a sleeve pipe I of a valve body, a valve body inner cavity and a sleeve pipe II of the valve body. An axial interlayer is arranged in the middle of the valve core pipe. The two adjacent axial edges of the interlayer are provided with at least one radial communicating hole of the input section and the output section.An annular valve core surrounding the interlayer and an annular valve seat of the larynx part of at least one of the sleeve pipe I and the sleeve pipe II form a sealing pair. The difference of the outer diameters of the input section and the output section is larger than or equal to 0. The input section and the sleeve pipe I as well as the output section and the sleeve pipe II are in shaft hole type fit, and at least one combined part is sealed. Under the action of bidirectional potential energy, the valve body does axial reciprocating motion in an outer valve body inner cavity, and opening,closing and function conversion are achieved. Opening and closing resistance is small, leakage is avoided, extending characteristics are wide, safety, reliability and flexibility are achieved, maintenance is reduced, efficiency is improved, and the double valve body core pipe valve adapts to various work conditions.

Owner:卢星霖

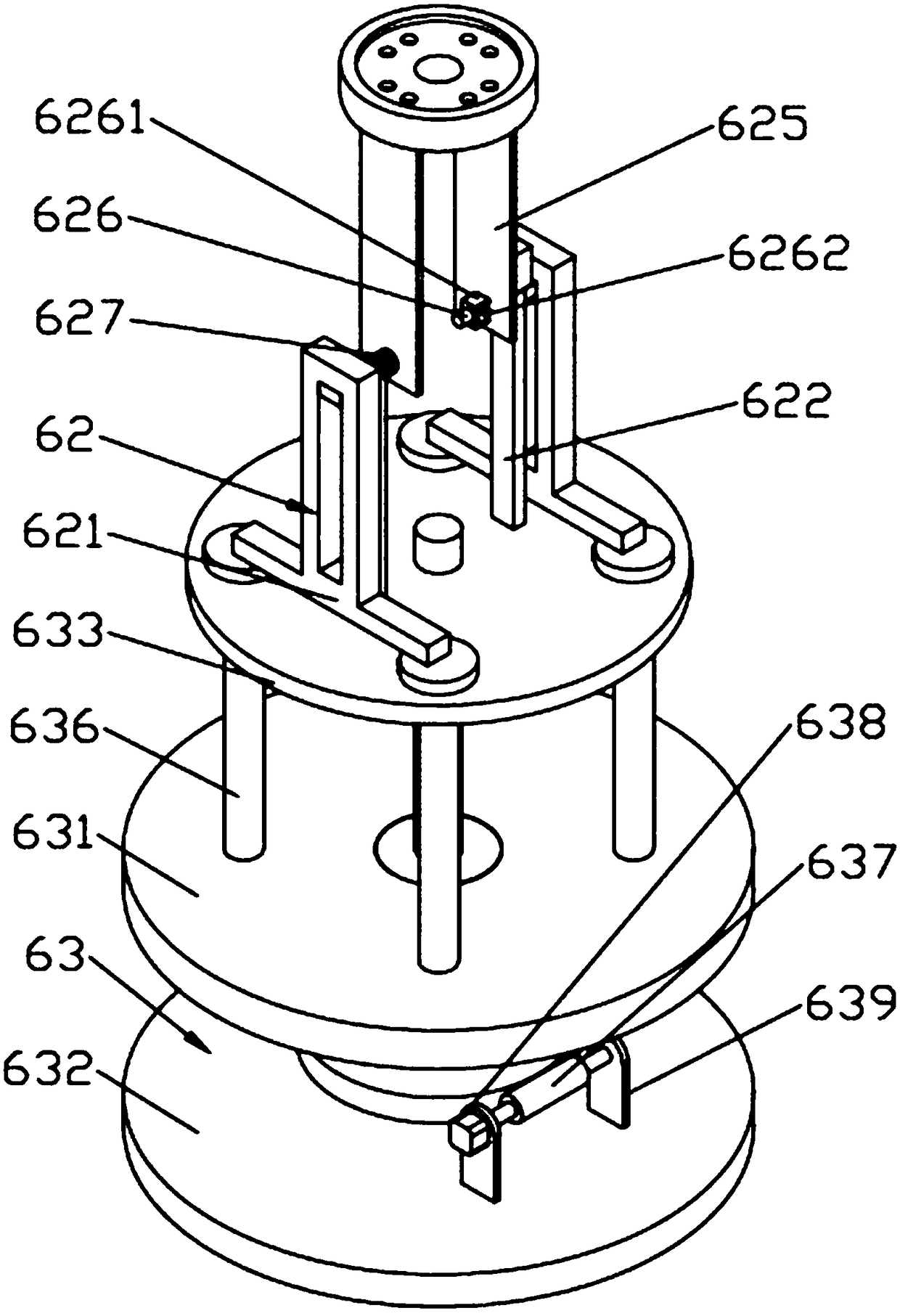

Conveying and sorting device

ActiveCN109647714AIncrease delivery speedImprove work efficiencyPlastic recyclingGradingElectric machineryEngineering

The invention discloses a conveying and sorting device. The conveying and sorting device comprises a first sorting area, a second sorting area, a third sorting area, a fourth sorting area, a first conveying belt, a second conveying belt, a third conveying belt, a fourth conveying belt, a supporting rod, a piston rod, an air cylinder, a discharging valve, a main motor, a first supporting column, asecond supporting column, a supporting connecting frame, an auxiliary motor, a ball head, a protective pad, a connecting baffle plate I, a connecting baffle plate II, a connecting baffle plate III, aconnecting baffle plate IV, a lower sorting plate I, a lower sorting plate II, an upper sorting plate, a lower connecting ring, a main shaft and an upper connecting ring; the sorting area, the secondsorting area, the third sorting area and the fourth sorting area form a sorting platform, materials in the discharging valve fall onto the sorting platform, and the sorting platform rotates continuously under the driving of the main motor, so that the materials can move; and the lower sorting plate I is arranged in the second sorting area, the upper sorting plate is arranged in the third sorting area, the lower sorting plate II is arranged in the fourth sorting area, no sorting plate is arranged in the first sorting area, and the discharging valve is positioned above the first sorting area inthe initial state.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Feed stacking machine

ActiveCN106743734BAdapt to various working conditionsFeeding-stuffLoading/unloadingFixed frameDrive shaft

The invention relates to the field of fodder processing, and particularly discloses a fodder windrow turning and drying machine. The fodder windrow turning and drying machine comprises a fixed frame, a turning barrel and a motor. A storage barrel is mounted in the turning barrel, and the storage barrel comprises a conveying device, a feeding port, a discharging port, a discharging plate and a shoveling plate. The feeding port is formed in one side of the storage barrel, and the discharging port is formed in the other side of the storage barrel. The conveying device is fixedly mounted in the storage barrel, one end of the conveying device is close to the feeding port, and the other end of the conveying device is close to the discharging port. One end of the discharging plate is connected with the discharging port, and the other end of the discharging plate is a free end inclined downwards. One end of the shoveling plate is connected with the feeding port, and the other end of the shoveling plate is a free end inclined downwards. The conveying device comprises a conveying belt, a transmission gear and a second transmission shaft, the conveying belt is engaged with the transmission gear, and the transmission gear is connected with the second transmission shaft. According to the scheme, fodder can be fast turned and dried, use is convenient, and labor is saved.

Owner:CHONGQING CHANGYUAN FEED CO LTD

A self-propelled intelligent spraying trolley

ActiveCN108925538BAdapt to spraying height requirementsNovel structureInsect catchers and killersControl engineeringAir pump

A self-propelled intelligent spraying pesticide trolley belongs to the field of robot technology, and is structurally composed of a walking mechanism, a supporting platform, an electric telescopic rod group, a driving device, a power supply box, a working platform, a control box, a medicine box, pipelines, and a liquid pump , the air pump and the detachable spray rod group are connected, and the structure is novel. The movement of the spraying car, the lifting of the working platform and the spraying of the liquid medicine are controlled through the wireless receiving module in the control box. The working principle is clear; it is different from the traditional manual application. Compared with the medicine operation, the present invention has high degree of automation, simple operation and higher efficiency, and is suitable for various working conditions and spraying height requirements of various crops, and avoids the poisoning phenomenon caused by the direct contact between the human body and the medicine.

Owner:YANGZHOU UNIV

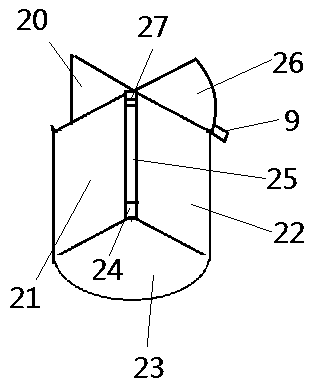

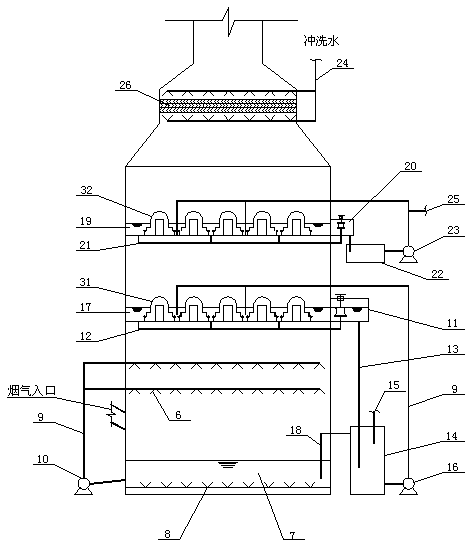

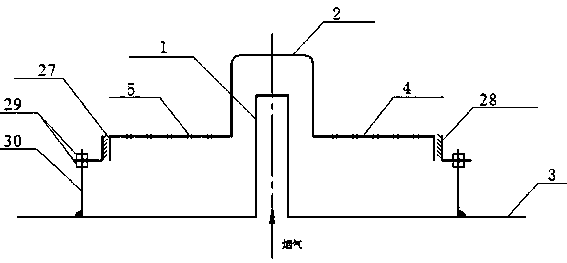

A desulfurization and dust removal method using ultra-low emission desulfurization and dust removal cyclone tray spray tower

ActiveCN106237824BImprove desulfurization efficiencyLow running costGas treatmentUsing liquid separation agentCycloneFlue gas

The invention relates to an ultra-low emission type desulfurization and dust removal rotational flow tray jet tower. The ultra-low emission type desulfurization and dust removal rotational flow tray jet tower comprises a desulfurization tower, wherein a sprinkling system is located on the lower portion of the desulfurization tower, a demister is located on the upper portion of the desulfurization tower, a size rotational flow tray mixer is arranged between the sprinkling system and the demister and located in a rotational flow tray mixer liquid storage tank, the size rotational flow tray mixer comprises a standpipe and a bubble cap, and the standpipe is covered with the bubble cap; multiple tray holes are formed in a tray of the size rotational flow tray mixer. The four desulfurization techniques including sprinkling, rotational flow, tray and bubbling are combined, the characteristics that the rotational flow tray can be used for uniform mixing and a bubbling technique absorbent is of a continuous phase and can achieve deep desulfurization are utilized, and deep desulfurization and deep dust removal are achieved. When the concentration of flue gas SO2 at an inlet of an absorption tower is below 10000 mg / Nm3, the requirement for ultra-low emission that the concentration of SO2 at an outlet is smaller than 35 mg / Nm3 can be met.

Owner:济南金孚瑞热能设备制造有限公司

A kind of polishing liquid polishing particle circulating extraction device

ActiveCN110370171BAvoid Agglomeration and PrecipitationAffecting workGrinding/polishing apparatusMetallurgyUltrasonic atomization

The invention discloses a polishing liquid polishing particle circulation extraction device, which comprises a box body, a polishing liquid liquid storage device arranged inside the box body, a polishing liquid ultrasonic atomization device, a polishing liquid drying device, and a polishing particle mixed with an air flow device and polishing particle separation device; the polishing liquid reservoir is provided with a polishing liquid stirring device. The polishing waste liquid is collected and stirred in the polishing liquid reservoir, atomized in the polishing liquid ultrasonic atomization device, and then enters the polishing liquid drying device. After drying, it enters the polishing particle and air flow mixing device, and then enters the polishing The particle separation device realizes the separation of particles of different qualities according to the different gravity ranges of different particle devices. The polishing liquid polishing particle recycling extraction device described in the present invention is a device capable of recycling the polishing liquid after polishing, which greatly reduces the economic cost in the polishing process and improves the green manufacturing degree of the polishing process.

Owner:NORTHEASTERN UNIV LIAONING

Universal robot with extension arm

ActiveCN108436895ALengthen or shorten the overall lengthAdapt to various working conditionsProgramme-controlled manipulatorArmsEngineeringForearm

The invention discloses a universal robot with an extension arm. The extension arm is arranged on a forearm of the robot, and the extension arm comprises a bracket body fixedly connected with the forearm, a first telescopic mechanism installed on the bracket body, a sliding mechanism fixed on the first telescopic mechanism, a swinging mechanism installed on the sliding mechanism and a resetting device installed on the swinging mechanism. The first telescopic mechanism can lengthen or shorten the extension arm, and increase or decrease the total length of the forearm and the extension arm so asto adapt to various working conditions; and the swing mechanism can swing to a certain extent relative to a swing drive mechanism, that is, the function of forearm bending is achieved to adapt to thevarious working conditions.

Owner:南通瑞强机械制造有限公司

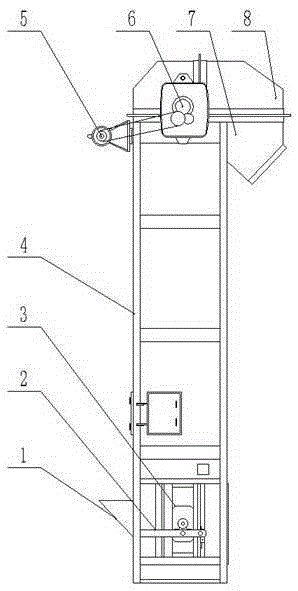

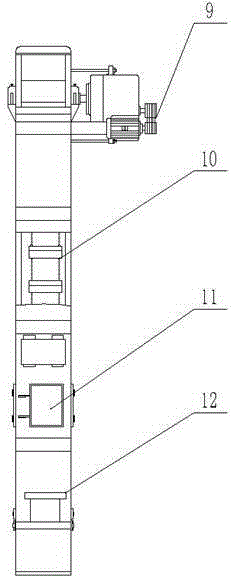

Vertical transporting bucket lifter

InactiveCN106586458AImprove lifting efficiencySimple structureConveyorsSupporting framesEngineeringPulley

The invention discloses a vertical transporting bucket lifter. The vertical transporting bucket lifter comprises a lifting motor, a material turner, a belt pulley and chain tracks. A lifter housing is mounted on one side of a charging barrel, a transparent observation hole cover is mounted on the upper portion of the charging barrel, a machine general switch is mounted on the side face of the lifter housing, a lifter upper cover is mounted on the upper portion of the lifter housing, a discharging barrel is mounted on one side of the lifter upper cover, a lifting table is mounted in the bottom of the lifter housing, the lifting motor is mounted on the upper portion of the lifting table, the chain tracks are mounted on two sides of the lifting motor, a variable frequency motor is mounted on the upper portion of the chain tracks, the belt pulley is mounted on one side of the variable frequency motor, and the material turner is mounted on one side of the belt pulley. The vertical transporting bucket lifter disclosed by the invention has the beneficial effects that the vertical transporting bucket lifter is high in material lifting efficiency, simple in structure and convenient to maintain; the transparent observation hole cover is loaded, so that the condition in the lifter is observed anytime conveniently and rapidly; the lifting height can be adjusted anytime, and the vertical transporting bucket lifter is suitable for various working conditions.

Owner:CHONGQING GOERING LOGISTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com