Push-and-pull device applicable to loading and unloading of molds in multiple specifications

A push-pull device, multi-specification technology, applied in the direction of lifting device, transportation and packaging, conveyor objects, etc., can solve the problems of low work efficiency and hidden safety hazards, and achieve the effect of reliable performance, stable action and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] See attached picture.

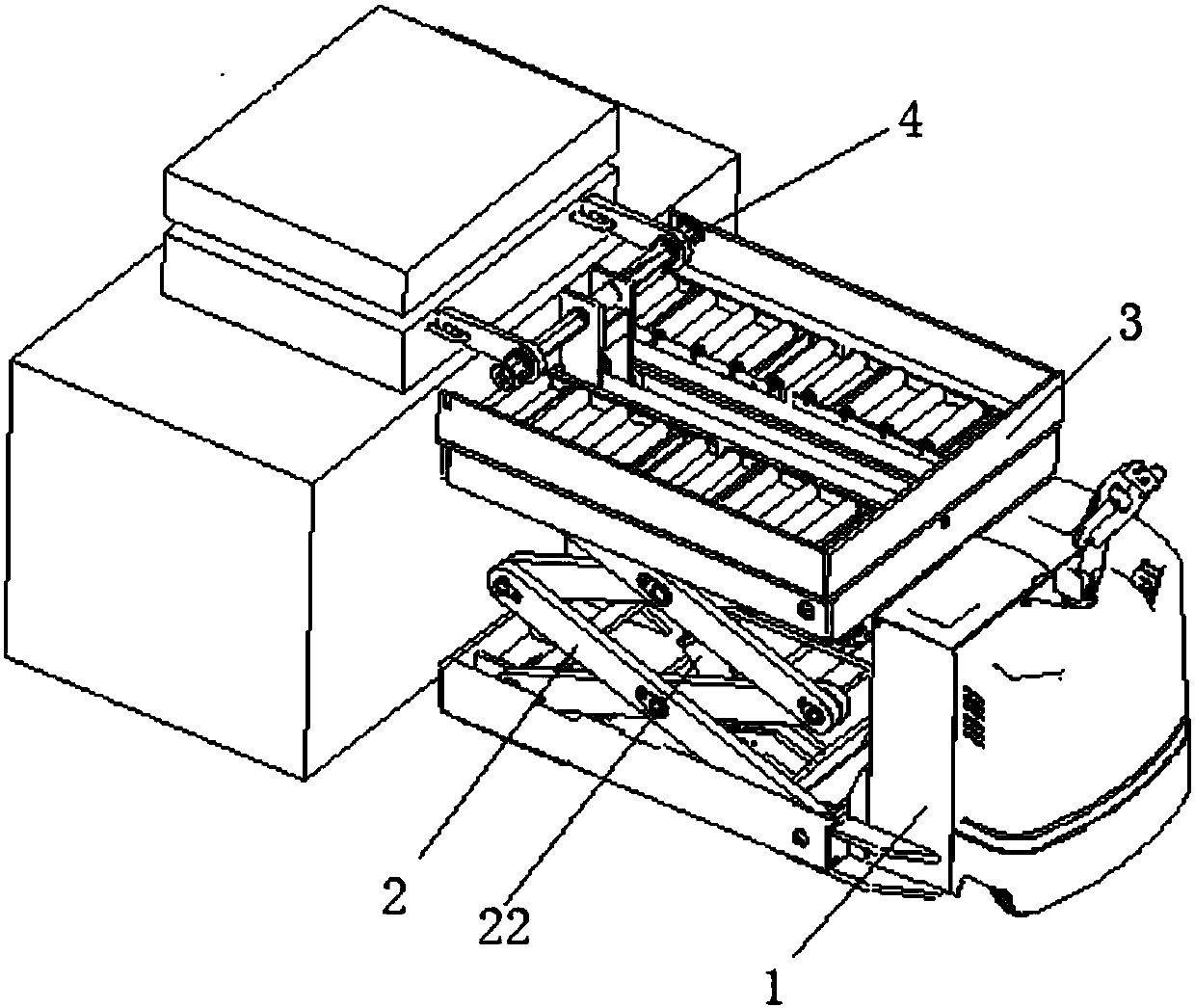

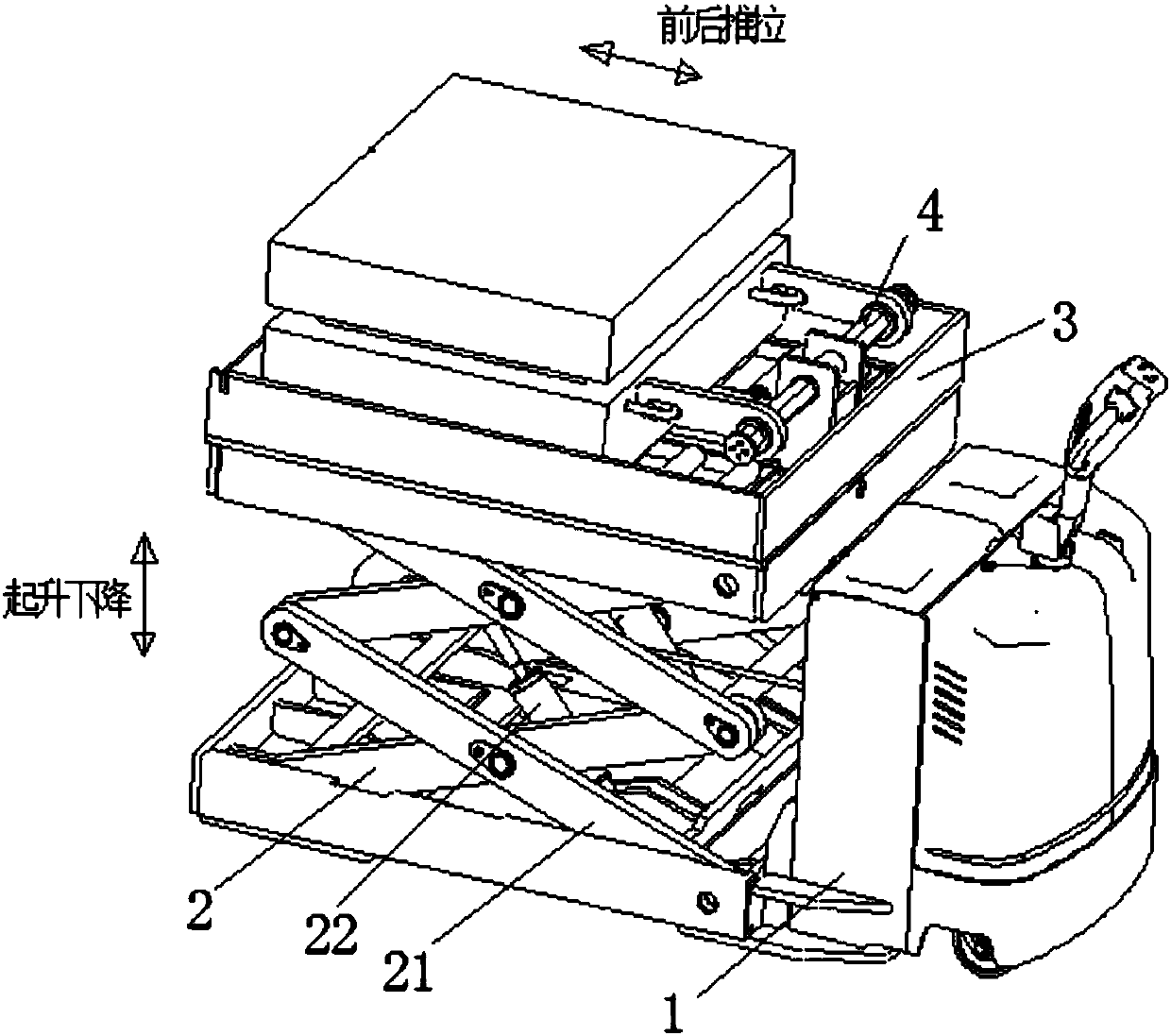

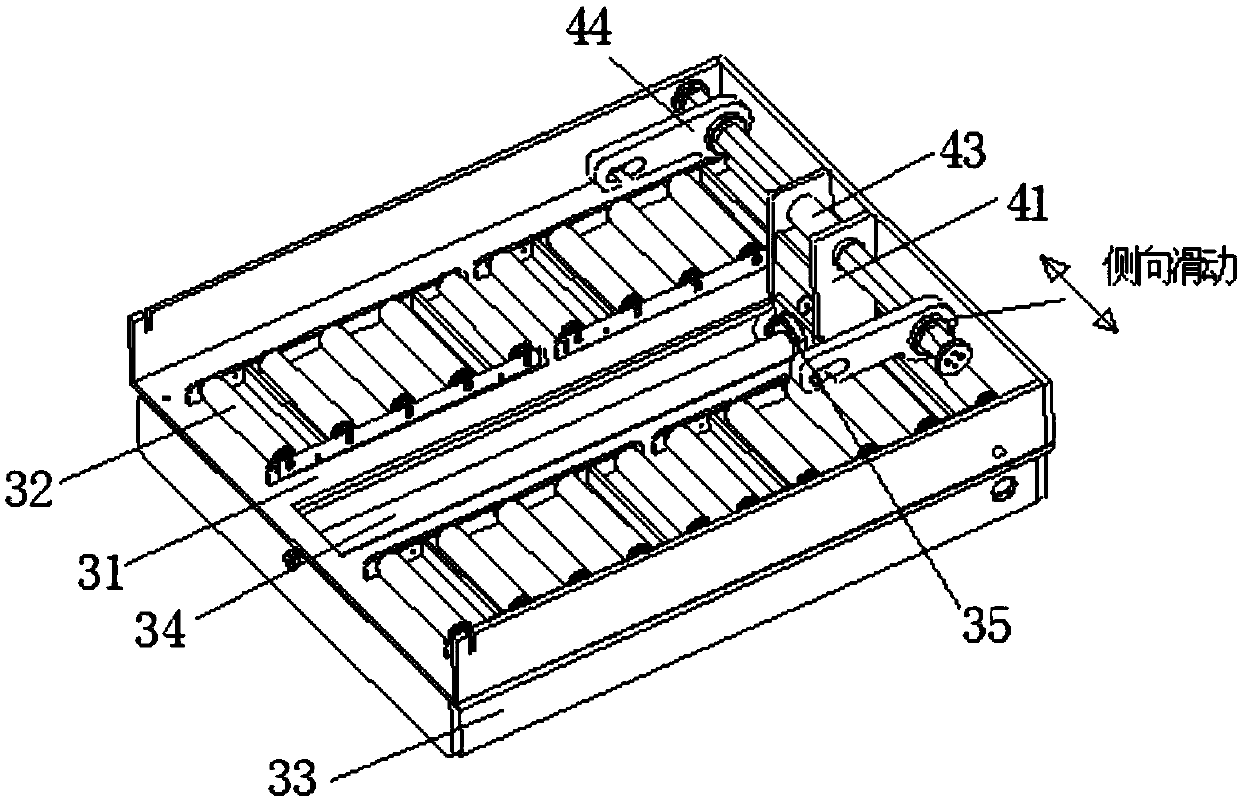

[0029] like figure 1 and figure 2 As shown: a push-pull device suitable for loading and unloading multi-standard molds, which is characterized in that it includes a liftable mold platform 3 installed on the forklift body 1, a push-pull mechanism 4 is installed on the mold platform 3, and the forklift body 1 It includes not only the lifting device 2, but also the drive system, steering system, electrical system and hydraulic system of the forklift. The forklift body 1 realizes the driving and steering functions of the mold truck, and provides hydraulic power for the lifting device 2 and the push-pull mechanism at the same time. .

[0030] The lifting device 2 is assembled into a scissor lifting structure through the connecting rod 21. One end of the telescopic oil cylinder 22 is fixed on the forklift body 1, and the other end of the telescopic oil cylinder 22 is fixed on the connecting rod 21. The lifting and lowering action of the lifting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com