Patents

Literature

41results about How to "Low layout space requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

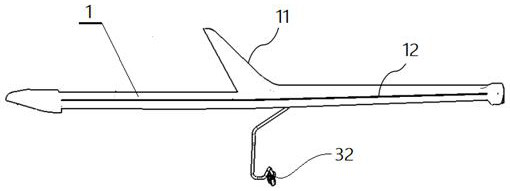

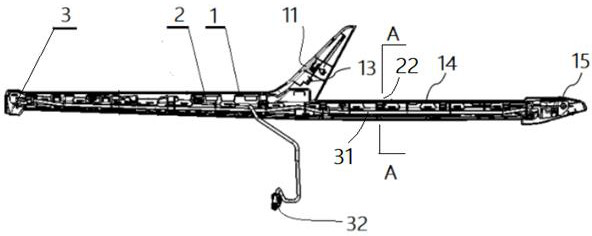

Stealth exhaust system

ActiveCN102926888AImprove adaptabilityImprove infrared stealth performancePower plant exhaust arrangementsJet propulsion plantsThroatRadar

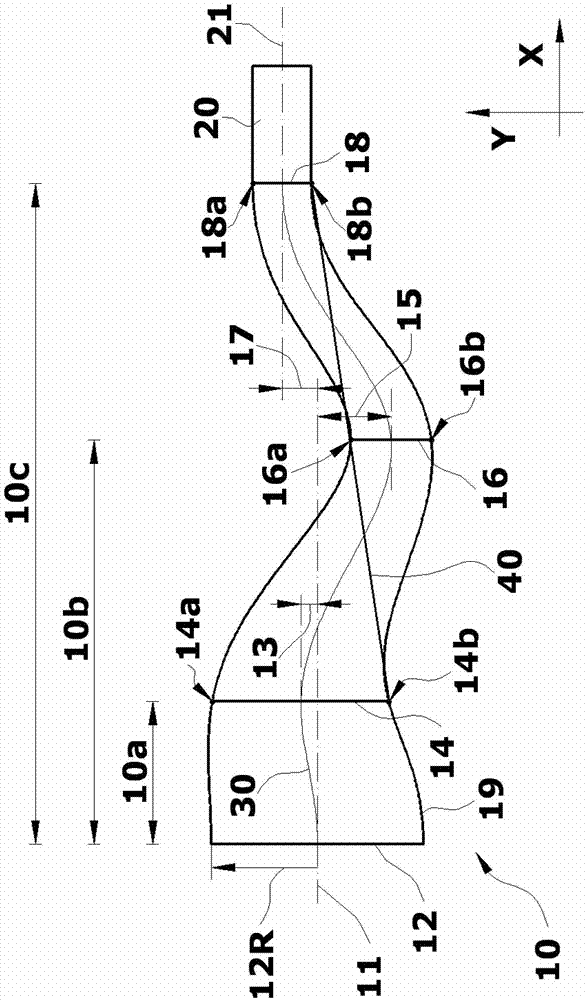

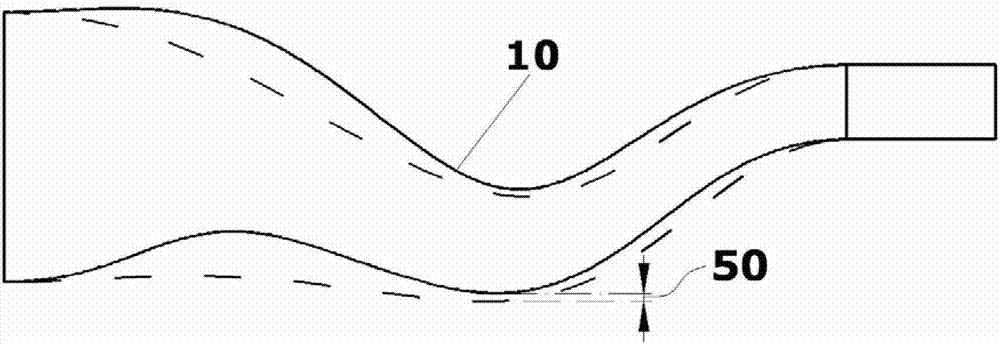

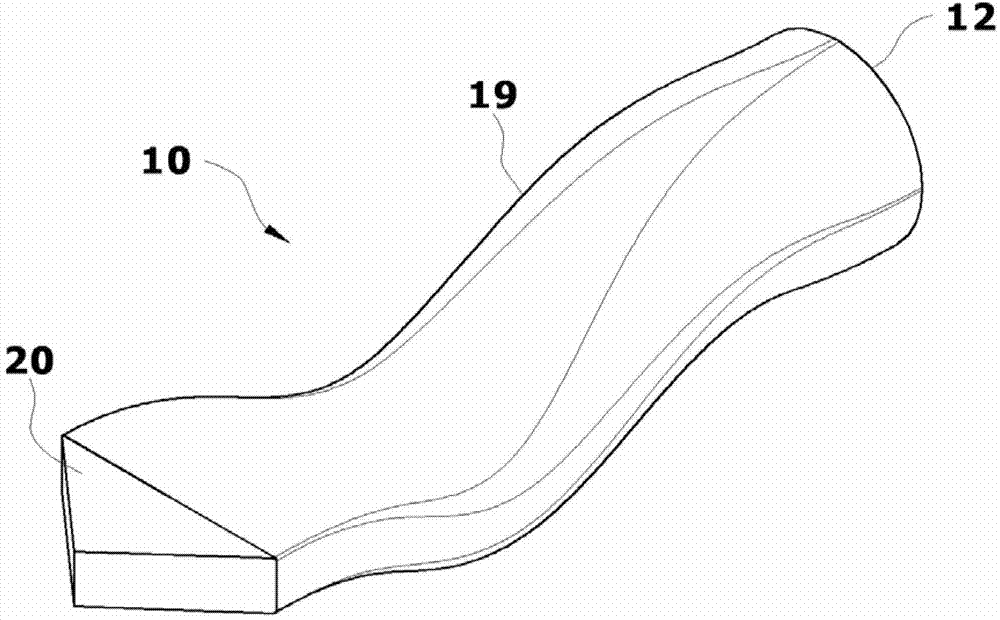

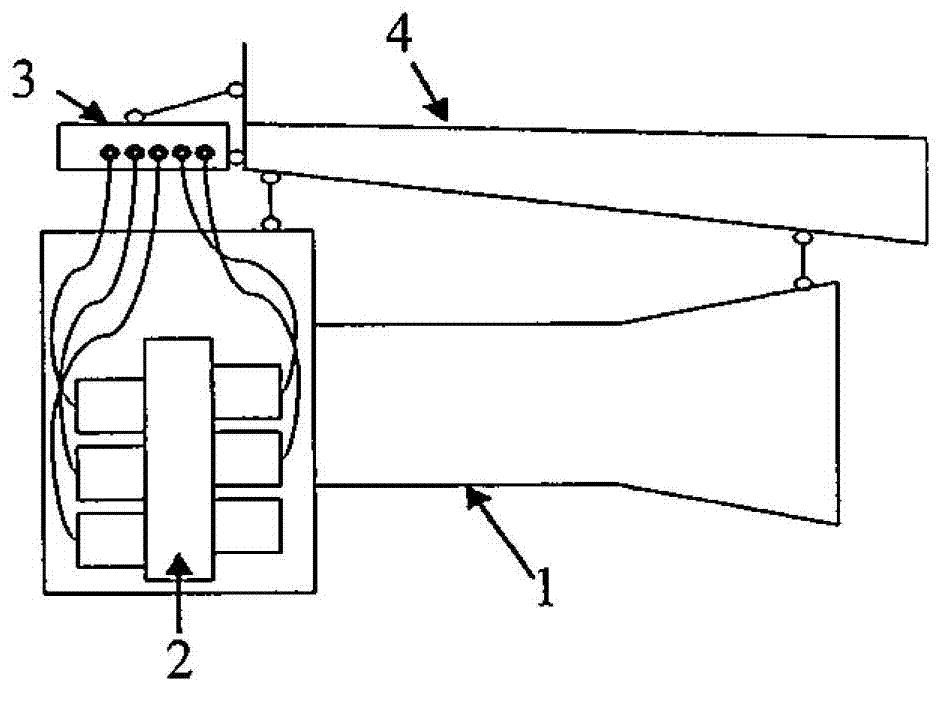

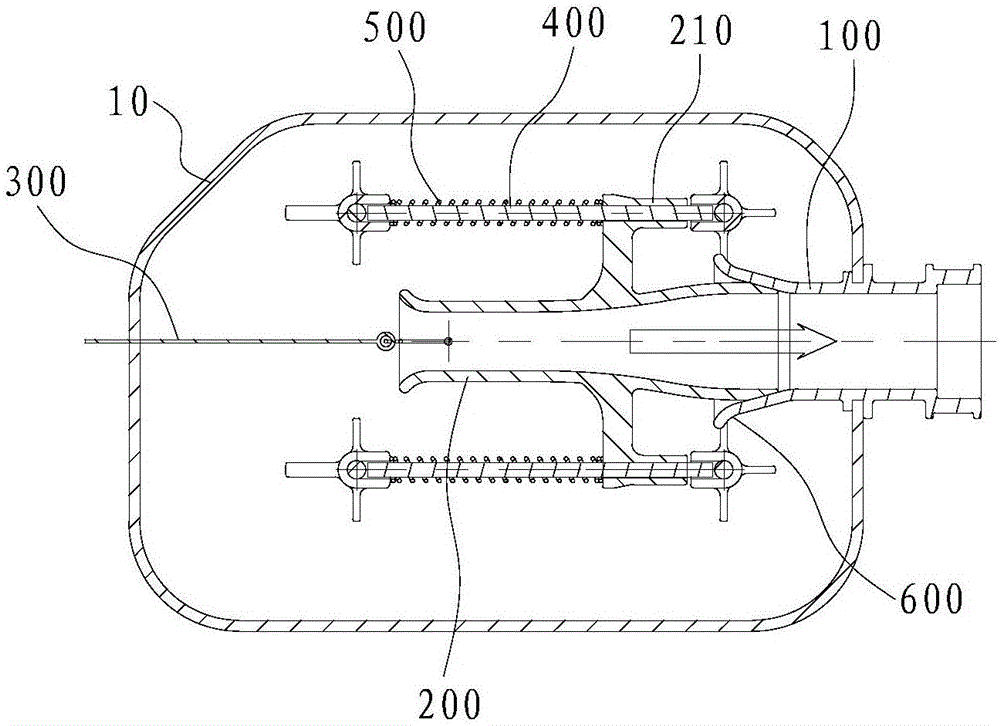

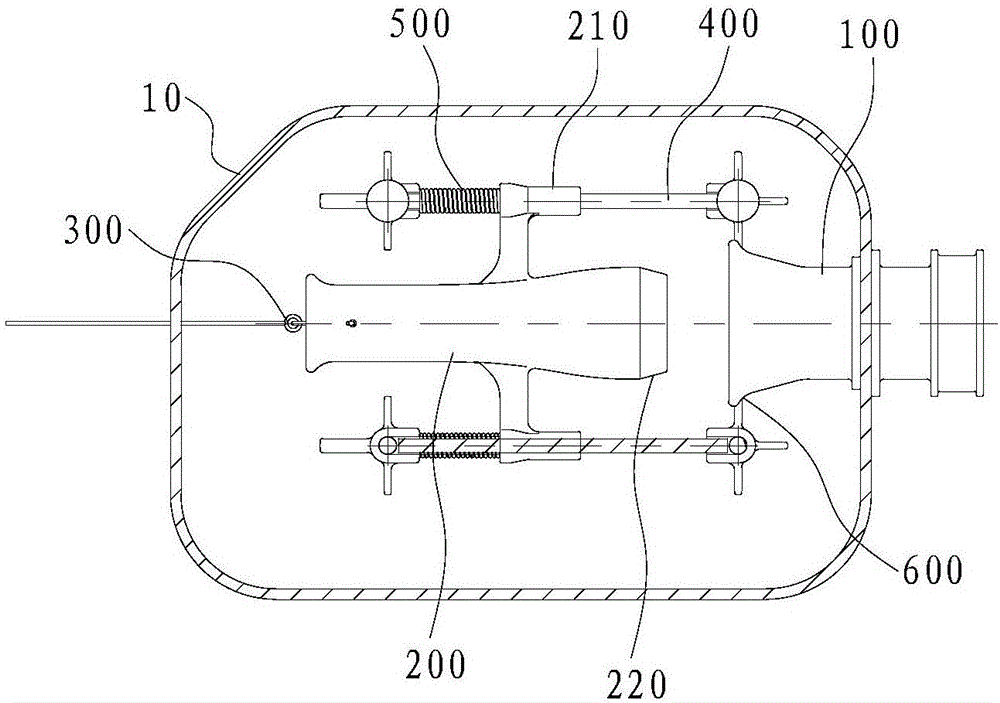

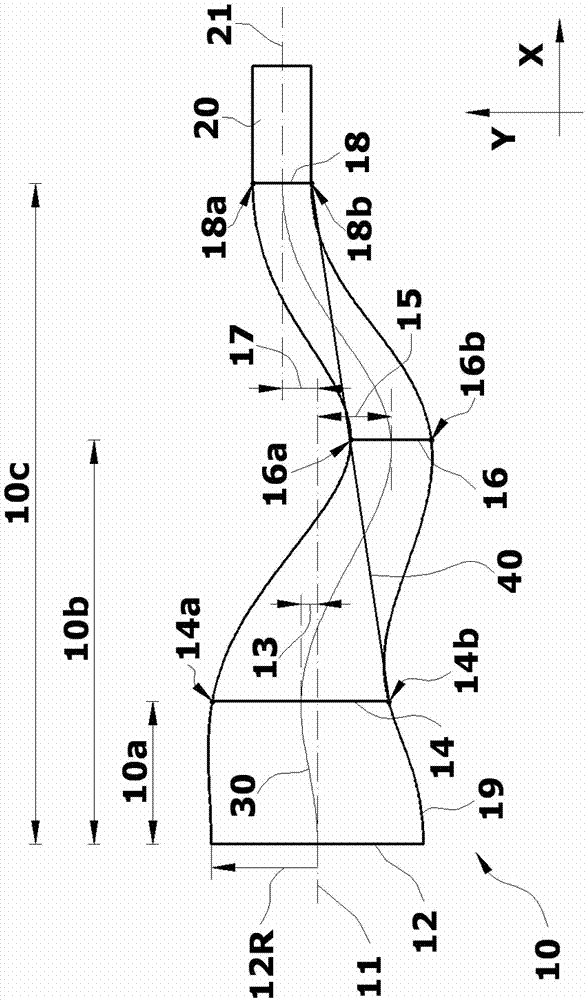

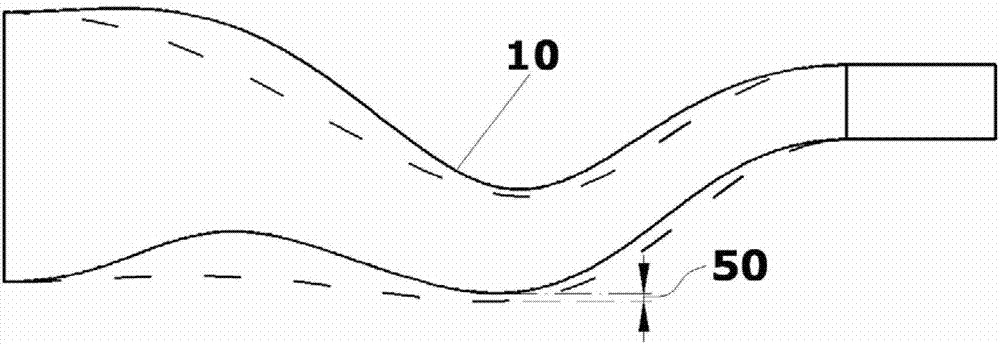

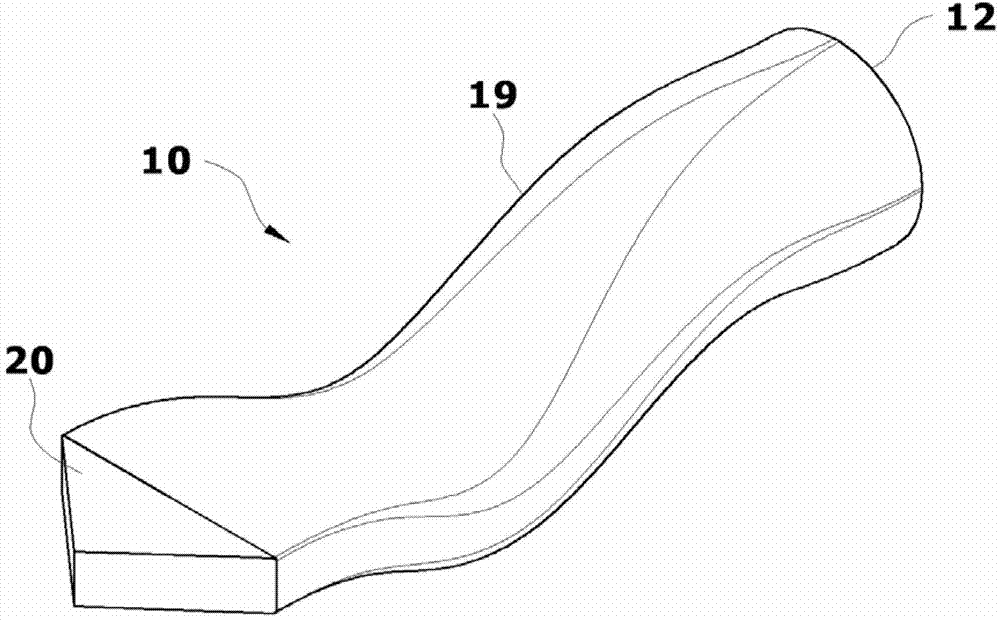

The invention relates to an exhaust system applied to an air vehicle, in particular to a stealth exhaust system. A cross-section shape of a throat of a spray pipe is designed to a non-round shape with an aspect ratio greater than 1, so that mixing of high-temperature exhaust airflow of an engine and ambient air is strengthened, the exhaust temperature is reduced, and an infrared stealth property of the exhaust system is improved. Central lines of the stealth exhaust system are three longitudinal S-bent curves, and the bent central lines can enable sidewalls of the spray pipe to shield high-temperature components of the engine, therefore, the infrared stealth property of the exhaust system can be improved; and simultaneously, the bent central lines can also cause radar waves going into the stealth exhaust system from the rear to difficultly generate backward waves, therefore, a radar stealth property of the exhaust system can be improved. Properties of the exhaust system are considered while the stealth properties are ensured, so that a requirement of the stealth exhaust system on the layout space is reduced, and adaptability of the stealth exhaust system is strengthened.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

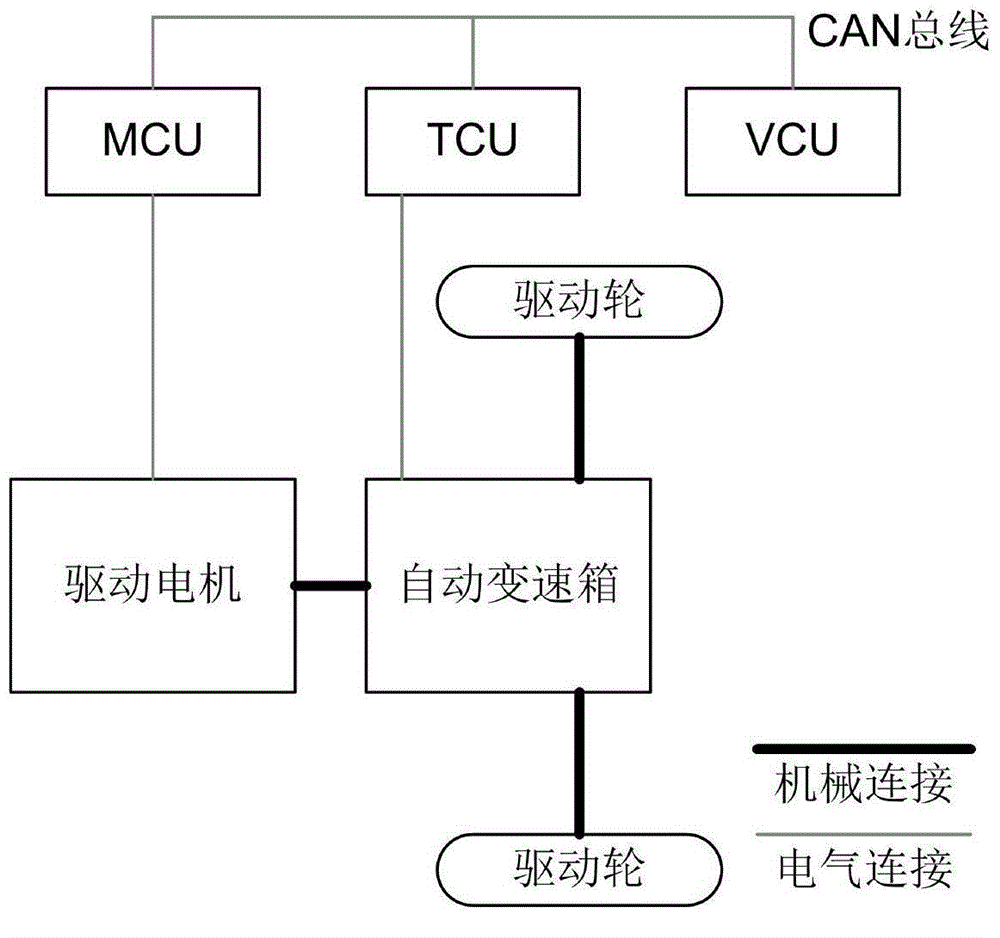

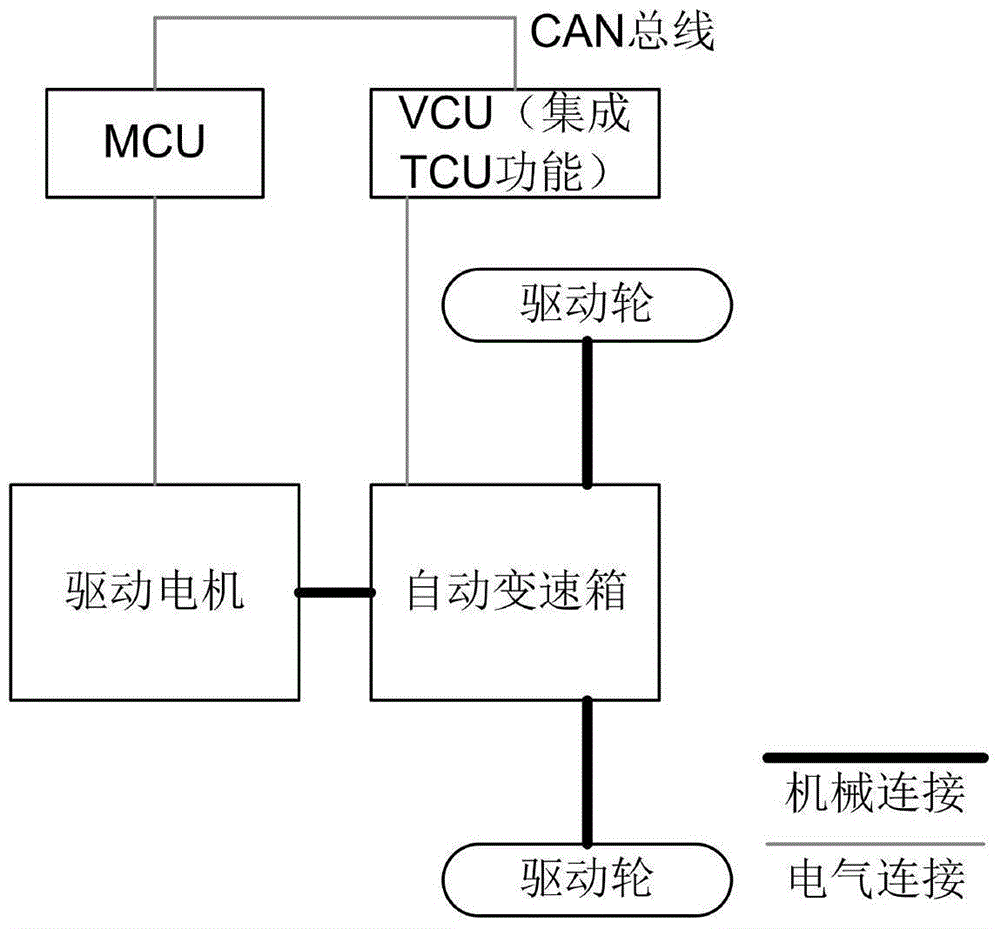

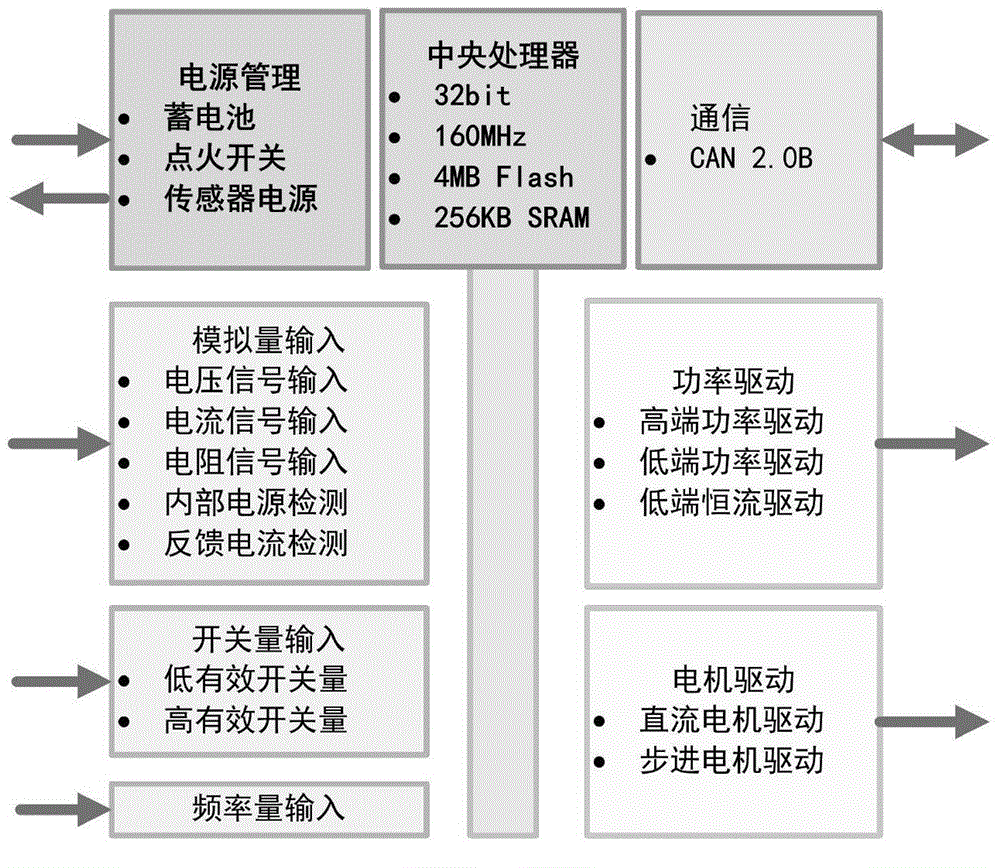

New-energy entire car controller integrated with transmission case control function

InactiveCN104802790ASmooth startReduce in quantitySpeed controllerElectric energy managementMotor driveNew energy

The invention provides a new-energy entire car controller integrated with a transmission case control function. The controller is integrated with the transmission case control function, i.e., an original entire car control function and a transmission case control function are integrated in the entire car controller, so that a special TCU (transmission control unit) is not needed any more; analog input, on-off input and frequency input are connected with respective sensors; a power-driven part and a motor-driven part are connected with respective actuators; the components are connected together with an internal bus on a controller circuit board by virtue of internal connecting wires so as to form a complete controller hardware circuit. New-energy entire car controller software integrated with the transmission case control function is realized by virtue of an entire car control algorithm and a transmission case control algorithm. The new-energy entire car controller can be used for shortening the development cycle, lowering the development cost, reducing automobile parts such as a controller, an auxiliary connector and wire harnesses and lowering the purchase costs of the parts.

Owner:BEIJING JIUZHOU HUAHAI TECH

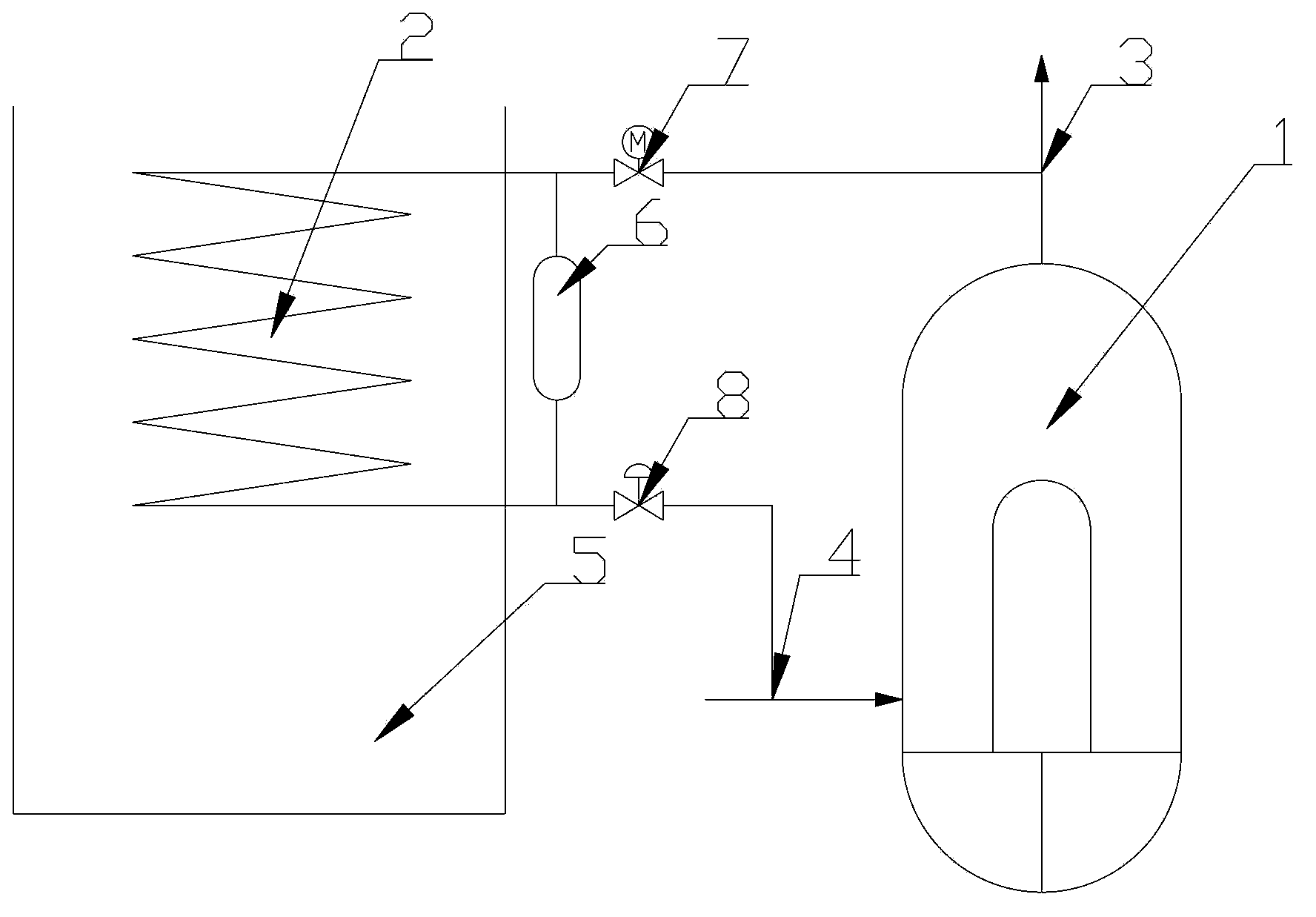

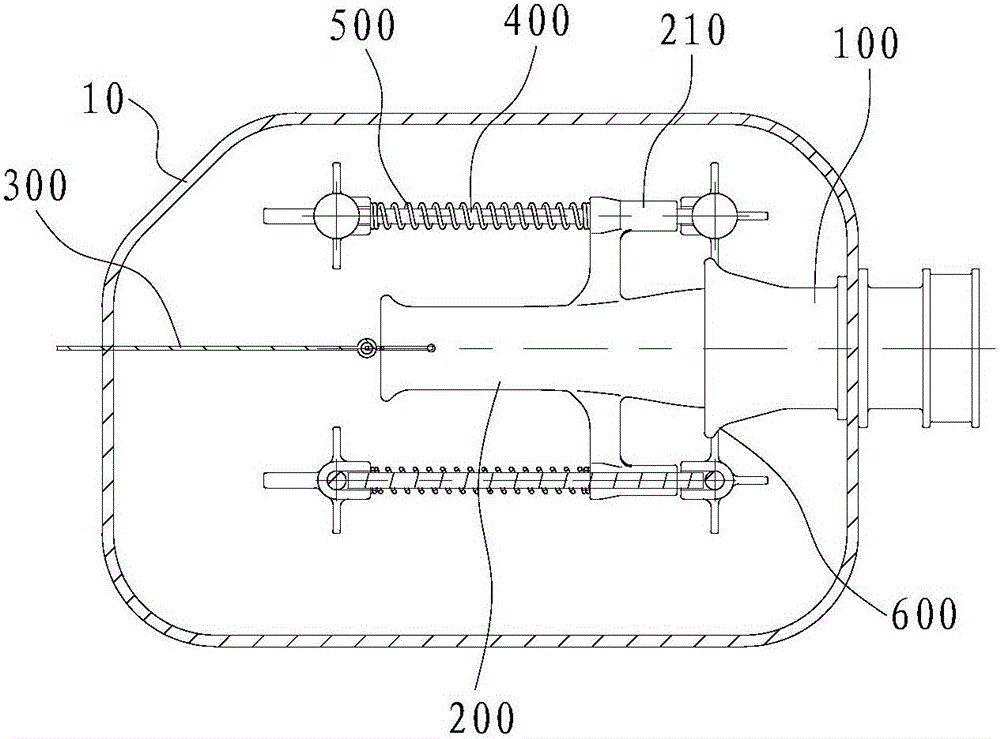

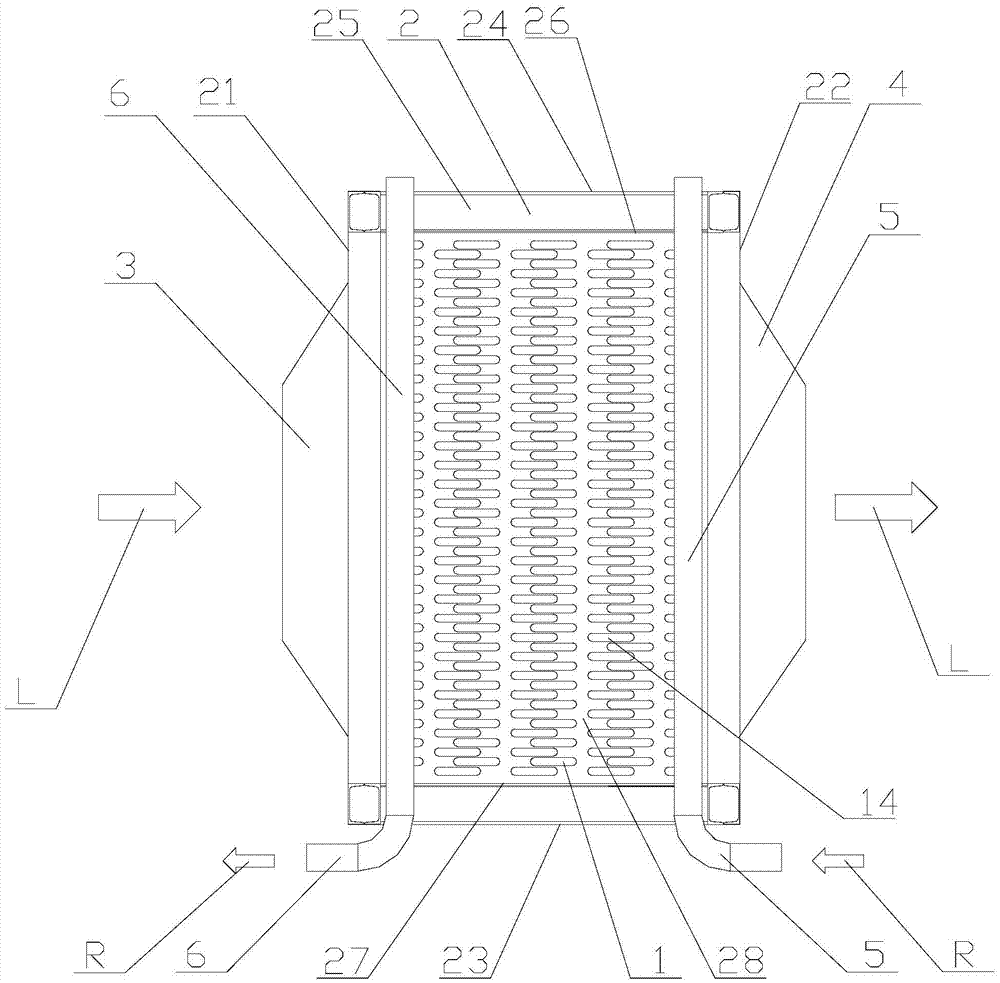

Passive waste heat discharging system on secondary side of steam generator

InactiveCN103778976AImprove heat transfer efficiencyEnsure safetyNuclear energy generationCooling arrangementSafe systemDecay heat

The invention belongs to a special safety system for a nuclear power plant, specifically relates to a passive waste heat discharging system on a secondary side of a steam generator. The passive waste heat discharging system comprises a direct current steam generator, wherein a passive discharged waste heat exchanger is arranged between a main steam pipeline and a main water feeding pipe of the direct current steam generator, and inlet and outlet pipelines of the passive discharged waste heat exchanger are respectively provided with an inlet isolating valve and an outlet isolating valve, and the outlet isolating valve is frequently closed. The passive waste heat discharging system provided by the invention is arranged on the main steam pipeline and the main water feeding pipeline at the side of the steam generator and fully utilizes the characteristic of high heat exchange efficiency between steam and water phases, and the decay heat of a reactor core is derived under a working condition of power cut of the whole plant; thus, the safety of a reactor is guaranteed, requirements on arrangement space are lowered, pipelines directly connected with a reactor coolant system are reduced, the cracking probability of the pipelines is reduced, and security is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

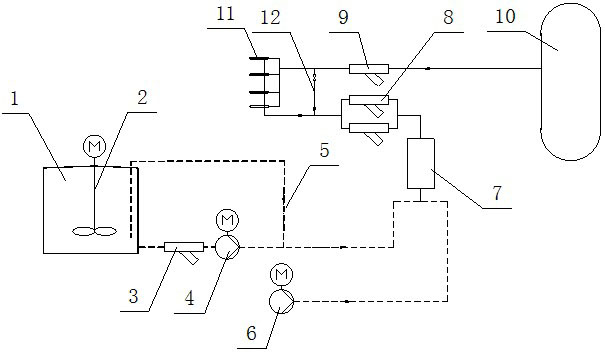

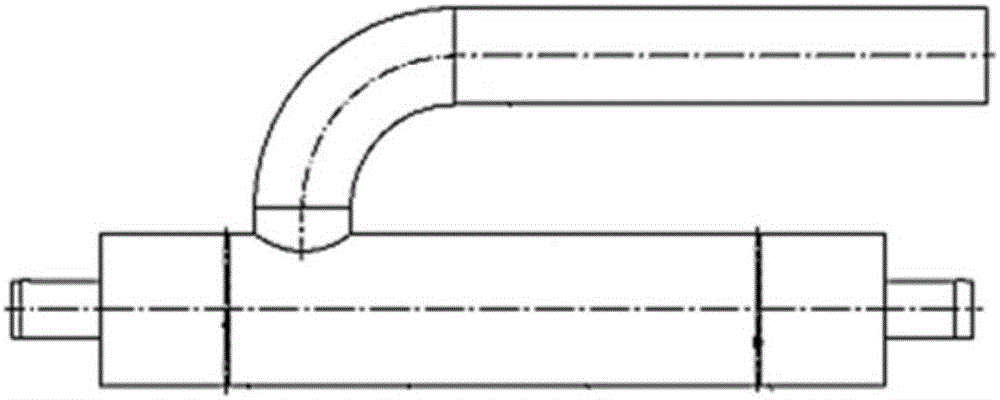

Ejection device for realizing SNCR (selective non-catalytic reduction) with CFB (circulating fluidized bed) furnace and using method

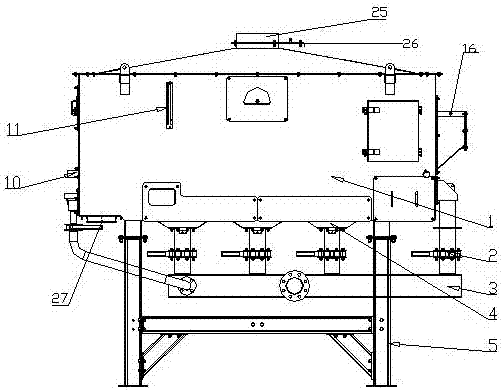

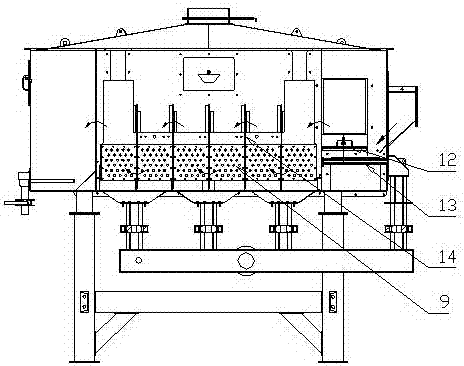

InactiveCN102580503AReduce resistanceGuaranteed uptimeDispersed particle separationFluidized bedFlue gas

The invention discloses an ejection device for realizing SNCR (selective non-catalytic reduction) with a CFB (circulating fluidized bed) furnace and a using method, and relates to a flue gas purifying and denitration device. The ejection device comprises an ejection gun, a urea solution pipeline and a compressed air pipeline, wherein the urea solution pipeline comprises a urea aqueous solution storage tank, a first filter group, a urea solution pump, a static mixer and a second filter group sequentially communicated through a pipeline; and the compressed air pipeline comprises a compressed air source, a compressed air buffer tank and a third filter group sequentially communicated through a pipeline. The denitration using method comprises the steps of placing the ejection gun at an inlet of a cyclone separator and inserting the ejection gun into a hearth for 0.05-0.5m for ejection, wherein the particle size of the liquid mist ejected by the ejection gun is distributed from 0-100 microns, and the average particle size is 30-50 microns. The ejection device disclosed by the invention has high denitration efficiency and reliable operation and is simple and easy to maintain. The denitration using method reduces the requirements of the technology on the placing space, simplifies the equipment and realizes low investment and maintenance cost.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

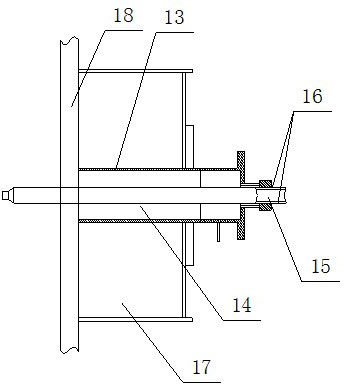

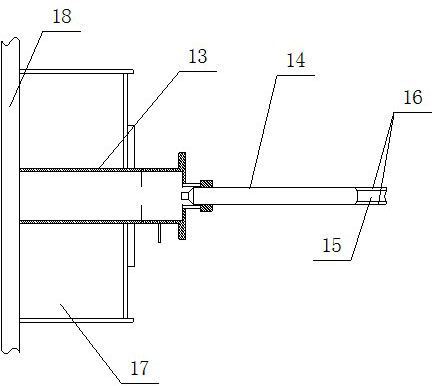

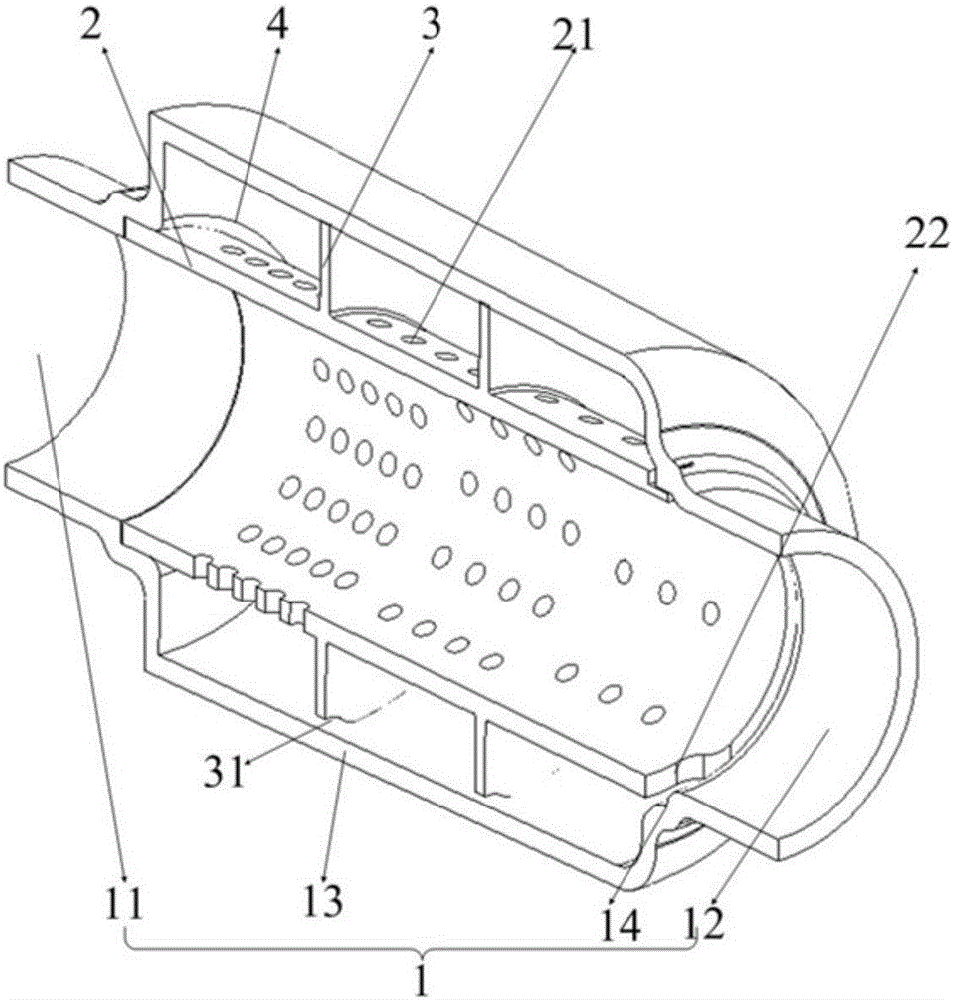

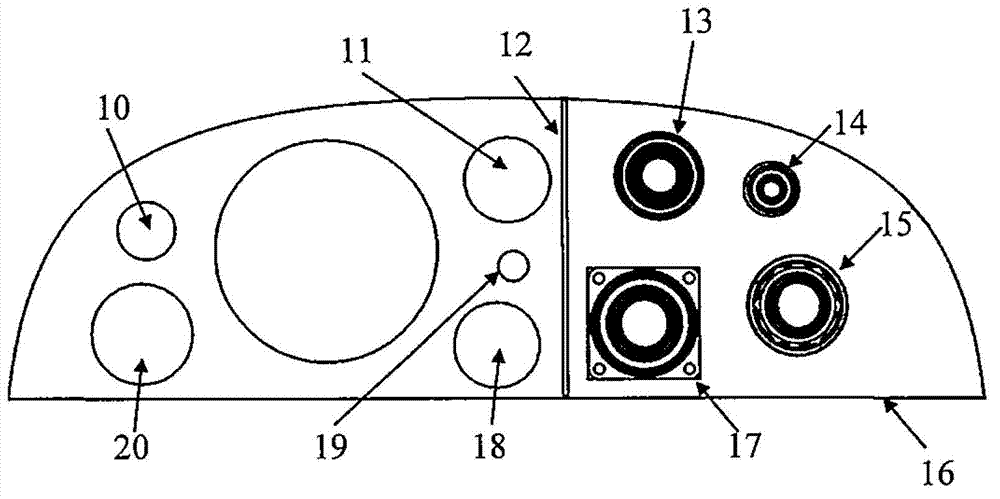

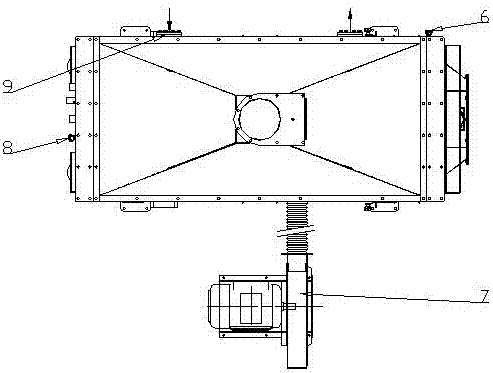

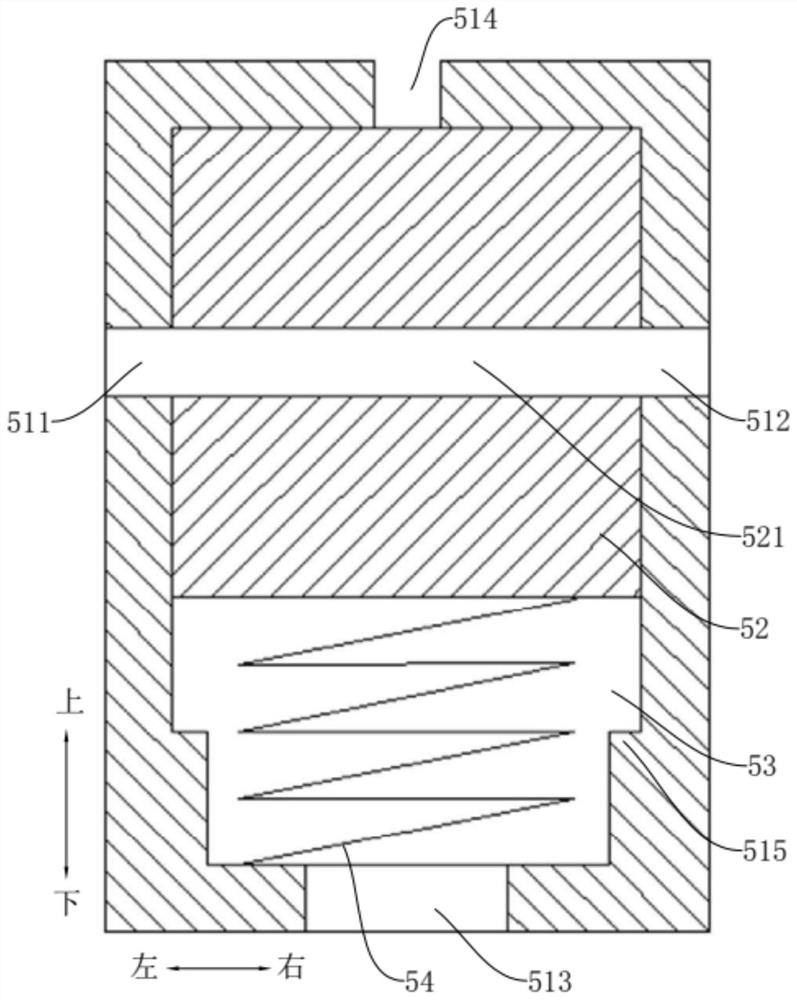

Noise abatement device of engine air inlet system

InactiveCN105822469AImprove the noise reduction effectLow layout space requirementMachines/enginesIntake silencers for fuelEngineeringCenter frequency

The invention relates to the technical field of noise abatement, and discloses a noise abatement device of an engine air inlet system. The noise abatement device comprises an outer shell and an inner pipe. The outer shell comprises an air inlet, an air outlet and a protruding part. The inner pipe is arranged in the outer shell in a sleeved manner and is fixedly connected with the inner wall of the outer shell at the positions of an inlet and an outlet of the inner pipe. After flowing into the outer shell from the air inlet, inflow air of an engine totally flows through the inner pipe and then flows out of the air outlet. The inner pipe and the protruding part are matched to form a cavity, and the cavity is divided by partition plates into at least two noise abatement chambers arranged in the inflow air flowing direction of the engine. The surface of the position, corresponding to each noise abatement chamber, of the inner pipe is provided with noise abatement holes communicating with the interior of the inner pipe and the noise abatement chamber. The noise abatement center frequencies of the noise abatement chambers are different. The noise abatement device of the engine air inlet system has a good noise abatement effect on inflow air noise with the wide frequency, connecting and arranging in the air inlet system are facilitated, and using is convenient.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

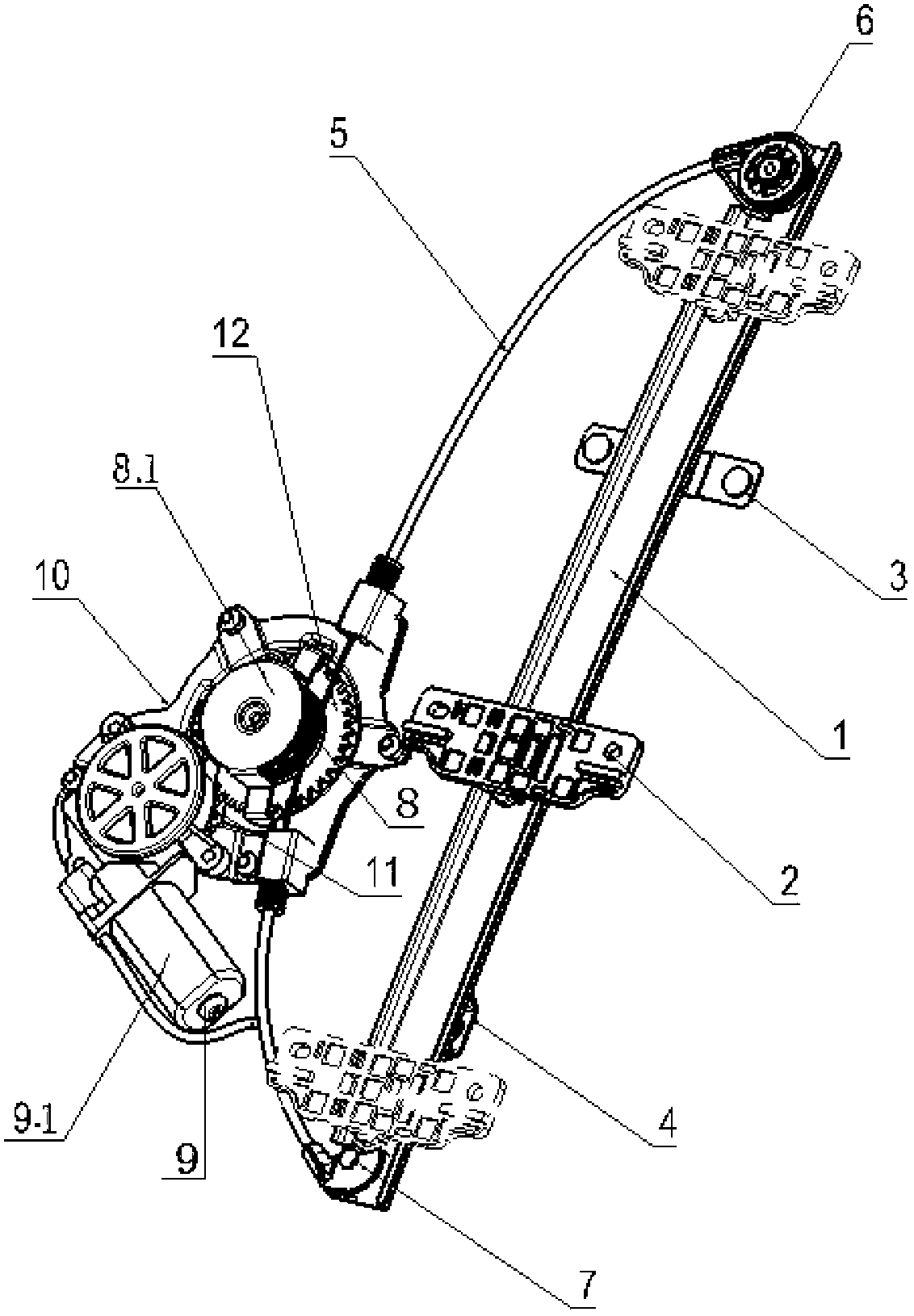

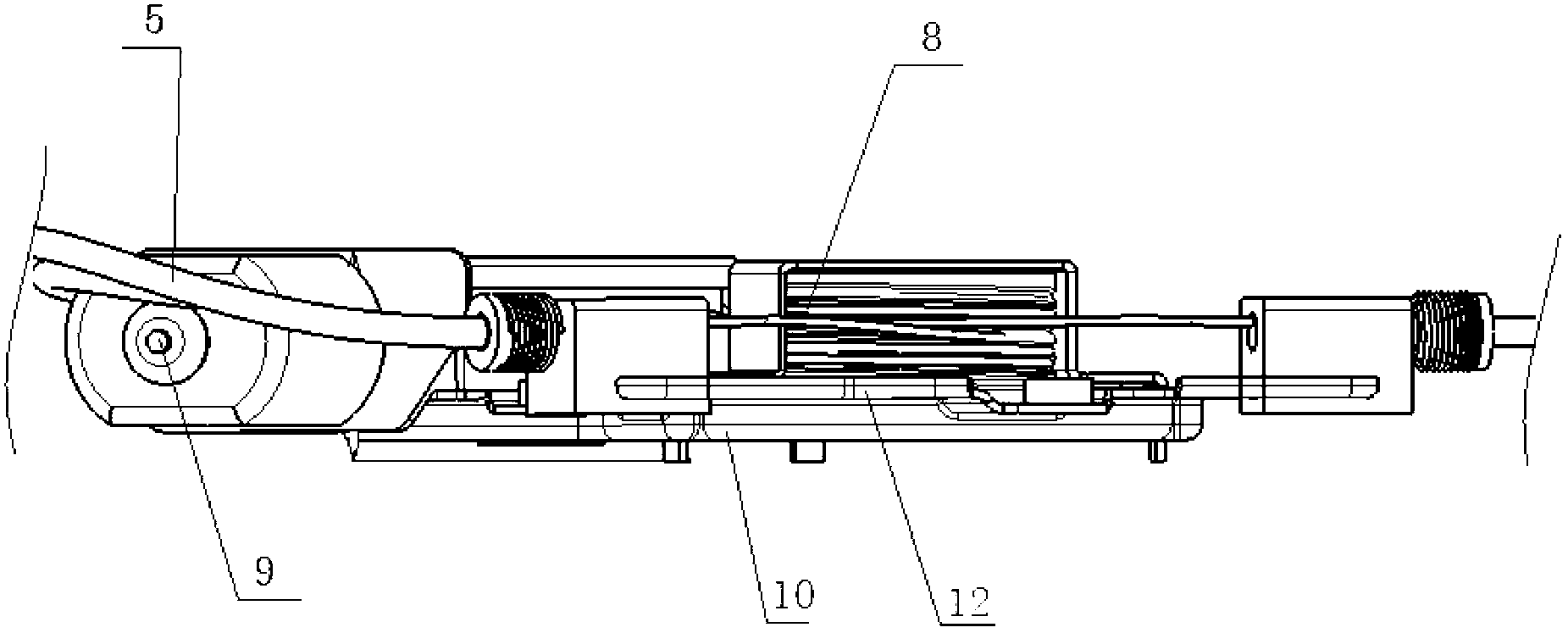

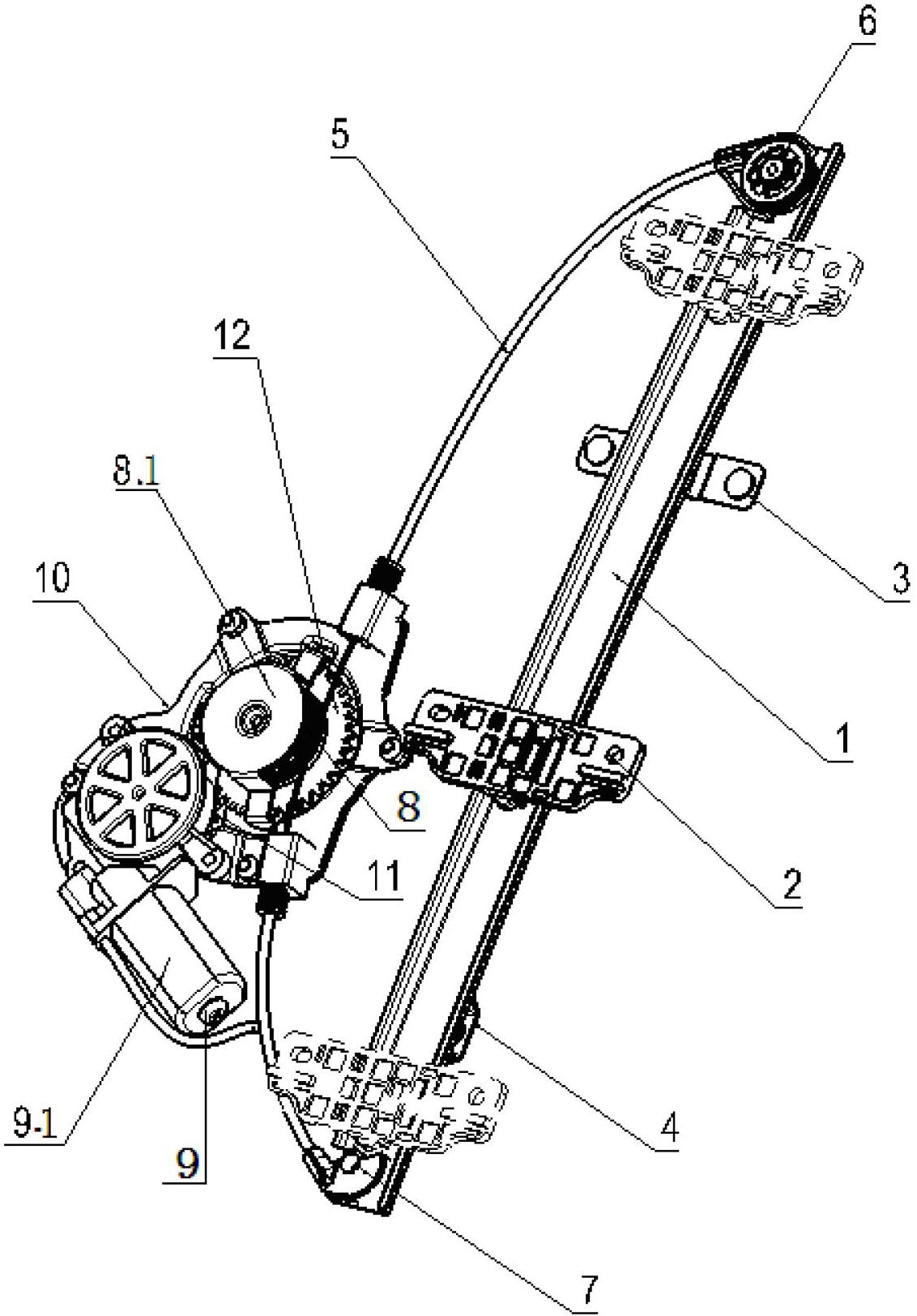

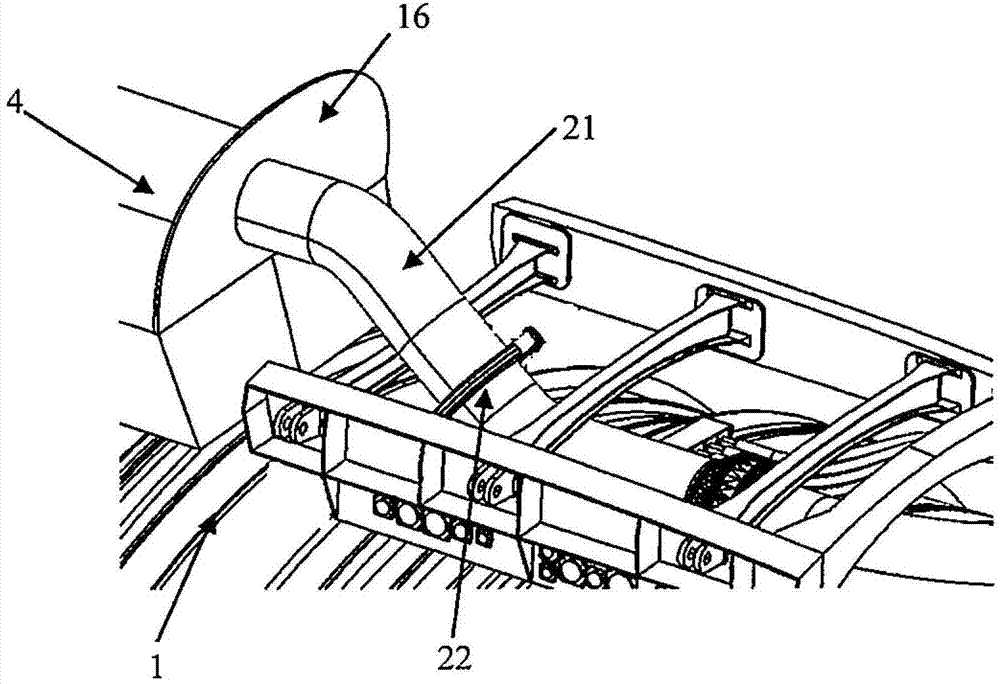

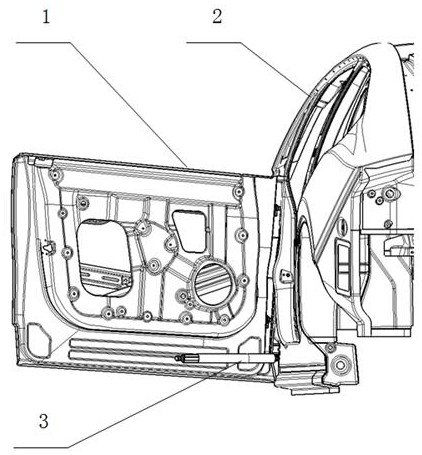

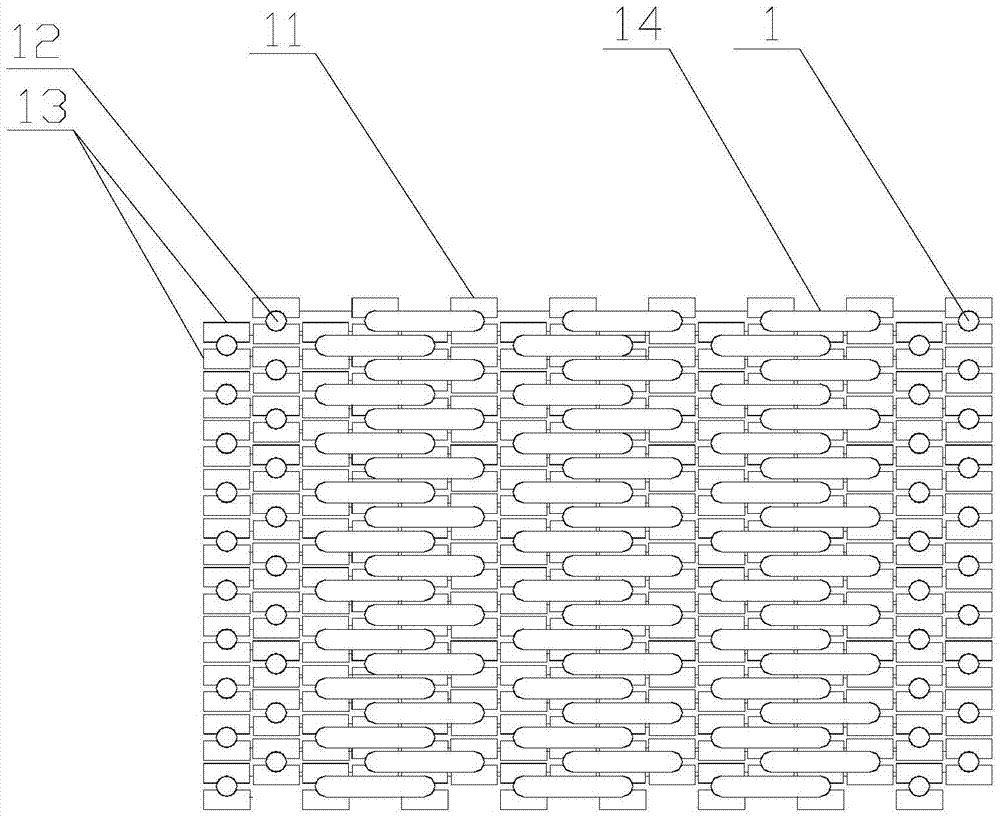

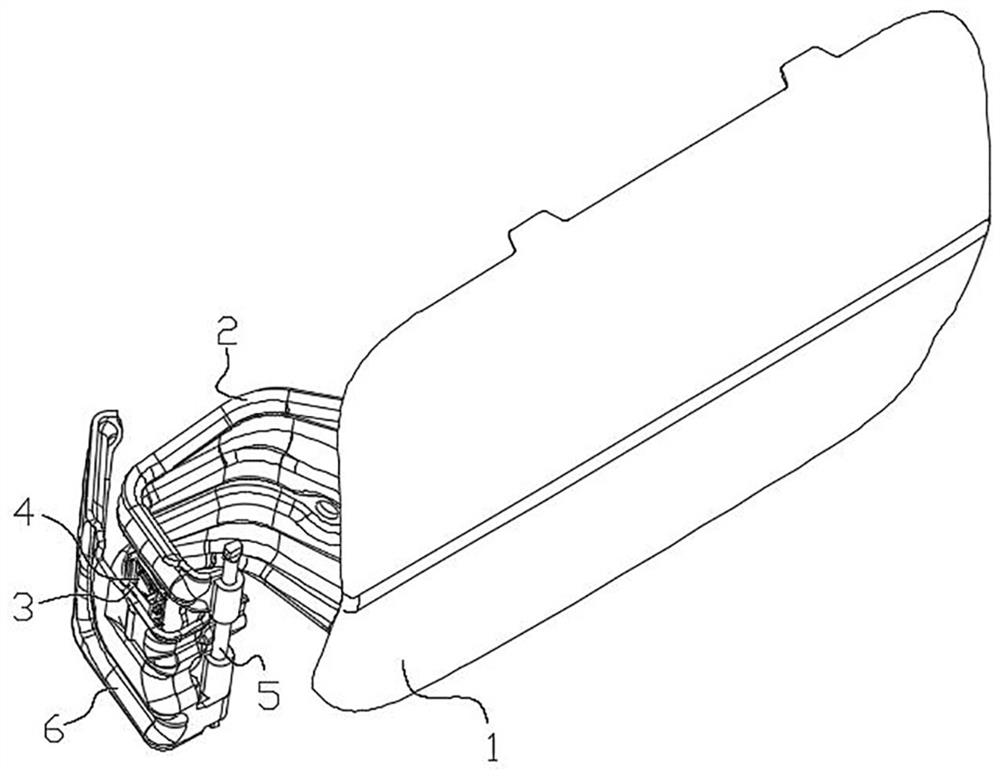

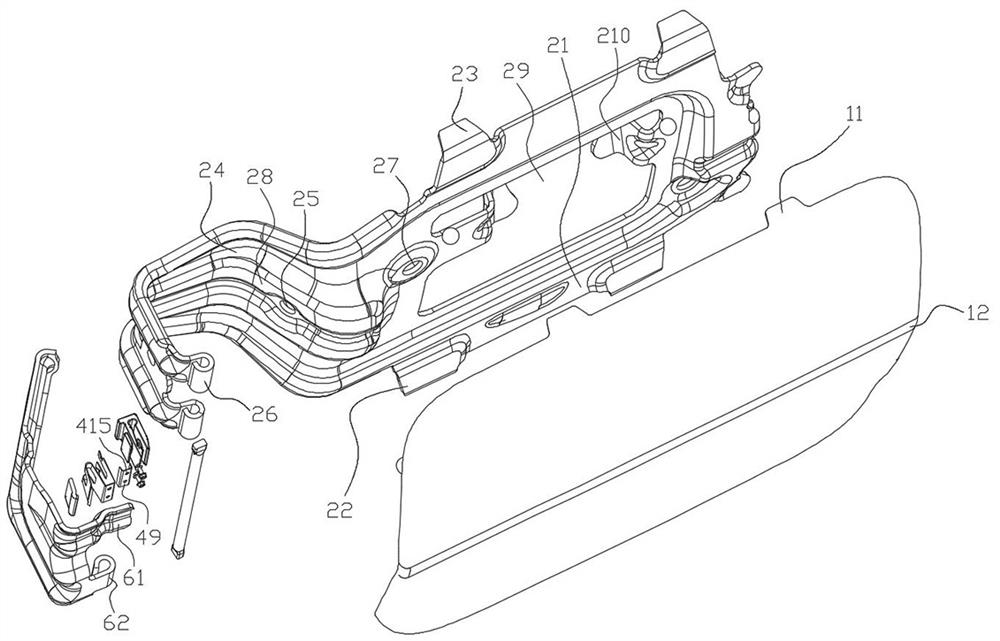

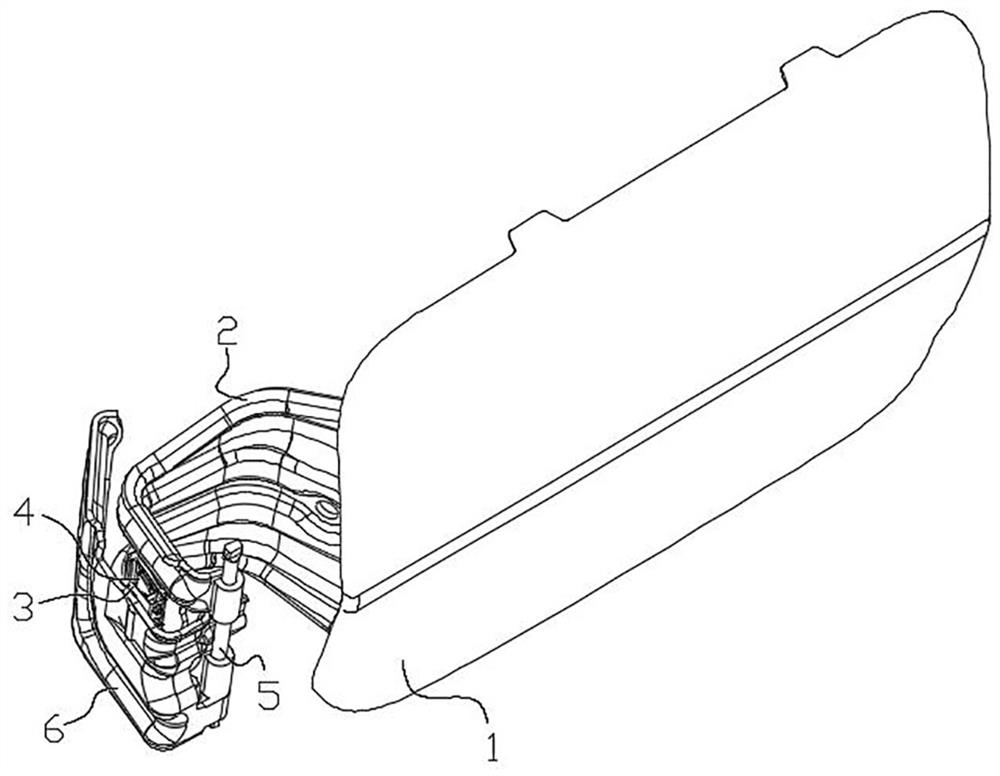

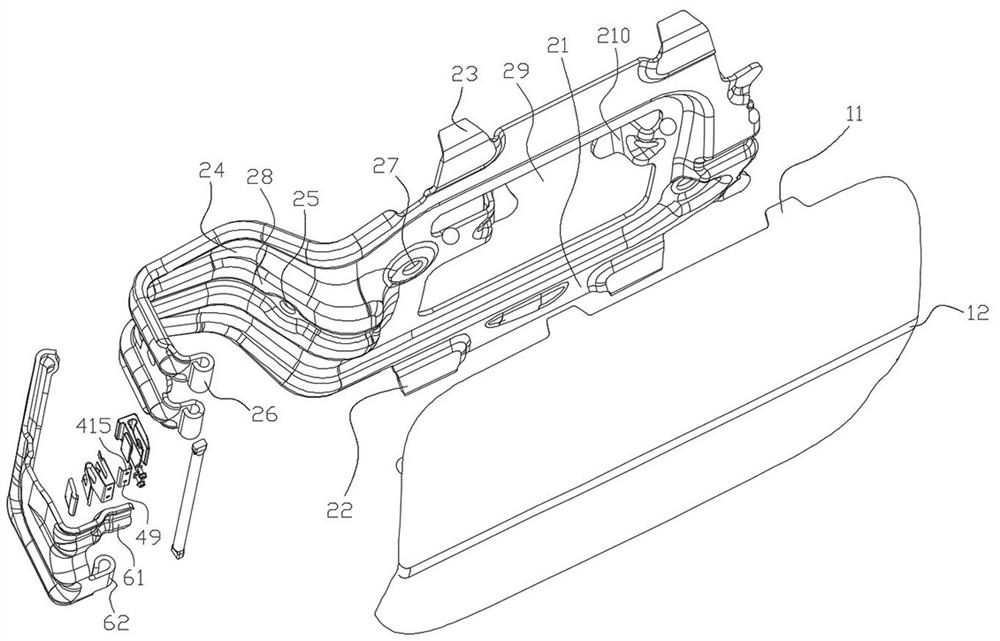

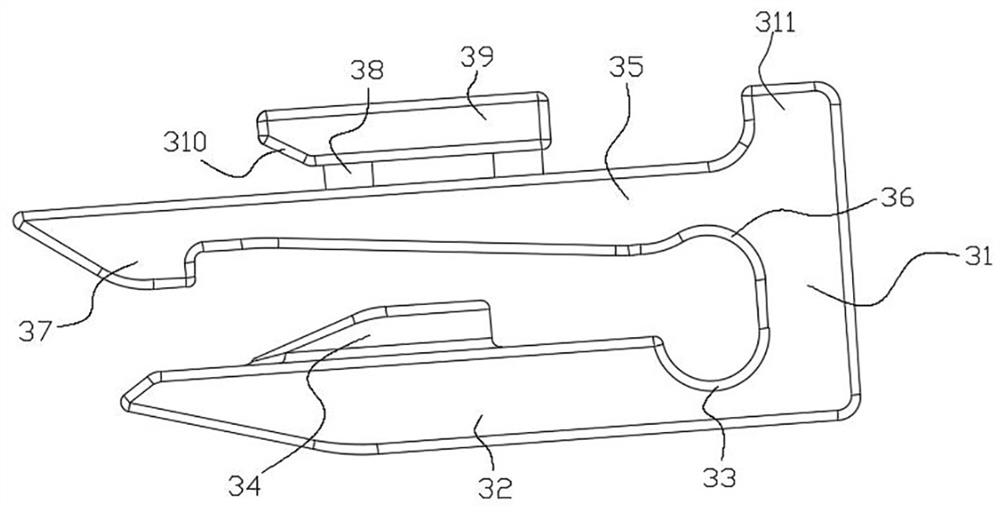

Rope-wheel type electric glass lifter

The invention belongs to the technical field of automobile glass lifters, and particularly relates to a rope-wheel type electric glass lifter. The rope-wheel type electric glass lifter comprises a guide rail, a sliding plate, an upper rope guide wheel, a lower rope guide wheel, a rope winding drum, a steel wire rope and a motor, wherein the sliding plate is sleeved on the guide rail; the upper rope guide wheel and the lower rope guide wheel are respectively positioned at the two ends of the guide rail; the steel wire rope is wound on the rope winding drum; and the two ends of the steel wire rope are respectively connected with the sliding plate after bypassing the upper rope guide wheel and the lower rope guide wheel. The rope-wheel type electric glass lifter also comprises a driving wheel and a driven wheel, wherein the driving wheel is connected with an output shaft of the motor; the driven wheel is meshed with the driving wheel; and the rope winding wheel is connected with an output shaft of the driven wheel. The rope-wheel type electric glass lifter has the advantages that the coaxial distribution mode of the motor and the rope winding drum in the rope-wheel type electric glass lifter is changed into a parallel distribution mode, the thickness of the motor and the rope winding drum is reduced by about 10mm, so that the requirement for the distribution space is low, and under the premise of keeping constant total width of an automobile body, the space in the automobile is greatly enlarged; and the structure is simple and the implementation is easy.

Owner:DFSK MOTOR LTD CHONGQING BRANCH CO

Aircraft engine system and design method for fan section mechanical interface thereof

InactiveCN103029840AOptimize layoutReduce weightPower plant arrangements/mountingFuel tank safety measuresElectric cablesDesign methods

The invention relates to an aircraft engine system and a design method for a fan section mechanical interface of the aircraft engine system, wherein the aircraft engine system comprises a vertical firewall, wherein a fan section of an engine and a hanger located in a non-fire area are separated by the vertical firewall; the vertical firewall is arranged on a bracket of the hanger; a distance from the vertical firewall to an external edge of the bracket of the hanger is less than 100mm; an outline of the vertical firewall is corresponding to the outline of the hanger; and interfaces of a hydraulic pipe, a fuel pipe and an extinguishing pipe of the aircraft engine system and through-wall sealing elements of a power supply cable and a signal cable are arranged on the vertical firewall. According to the invention, the vertical firewall is arranged at the front end of the hanger, so that the separation of the hanger from the fan section of the aircraft engine is directly realized, the firewall arrangement is greatly simplified and the weight is reduced.

Owner:COMAC +1

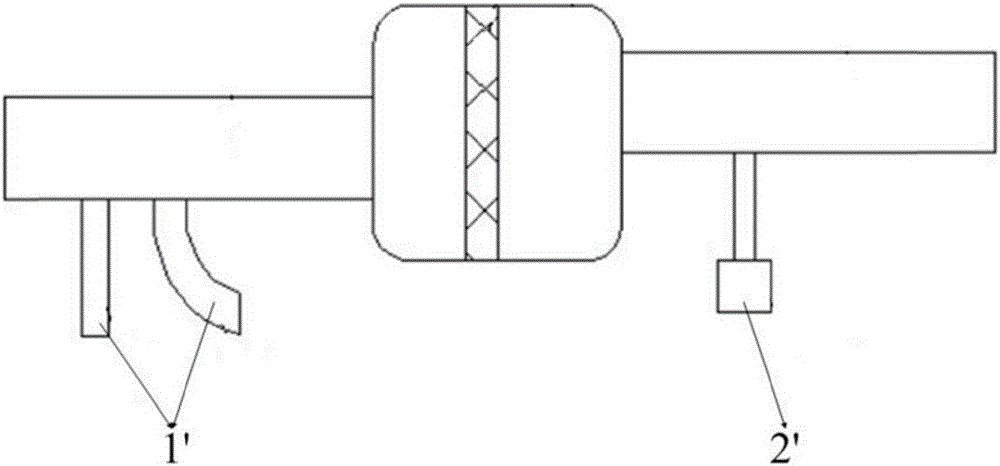

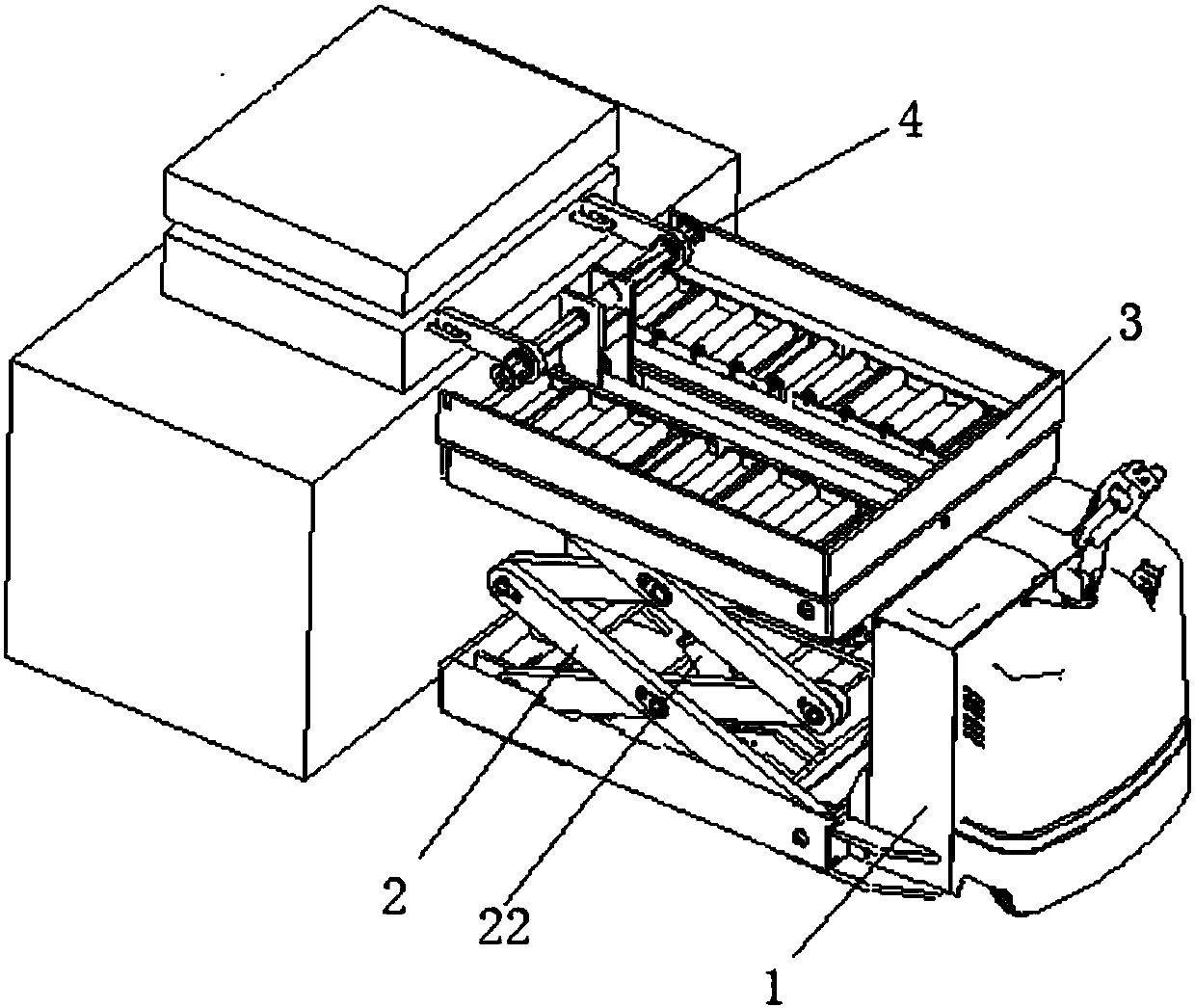

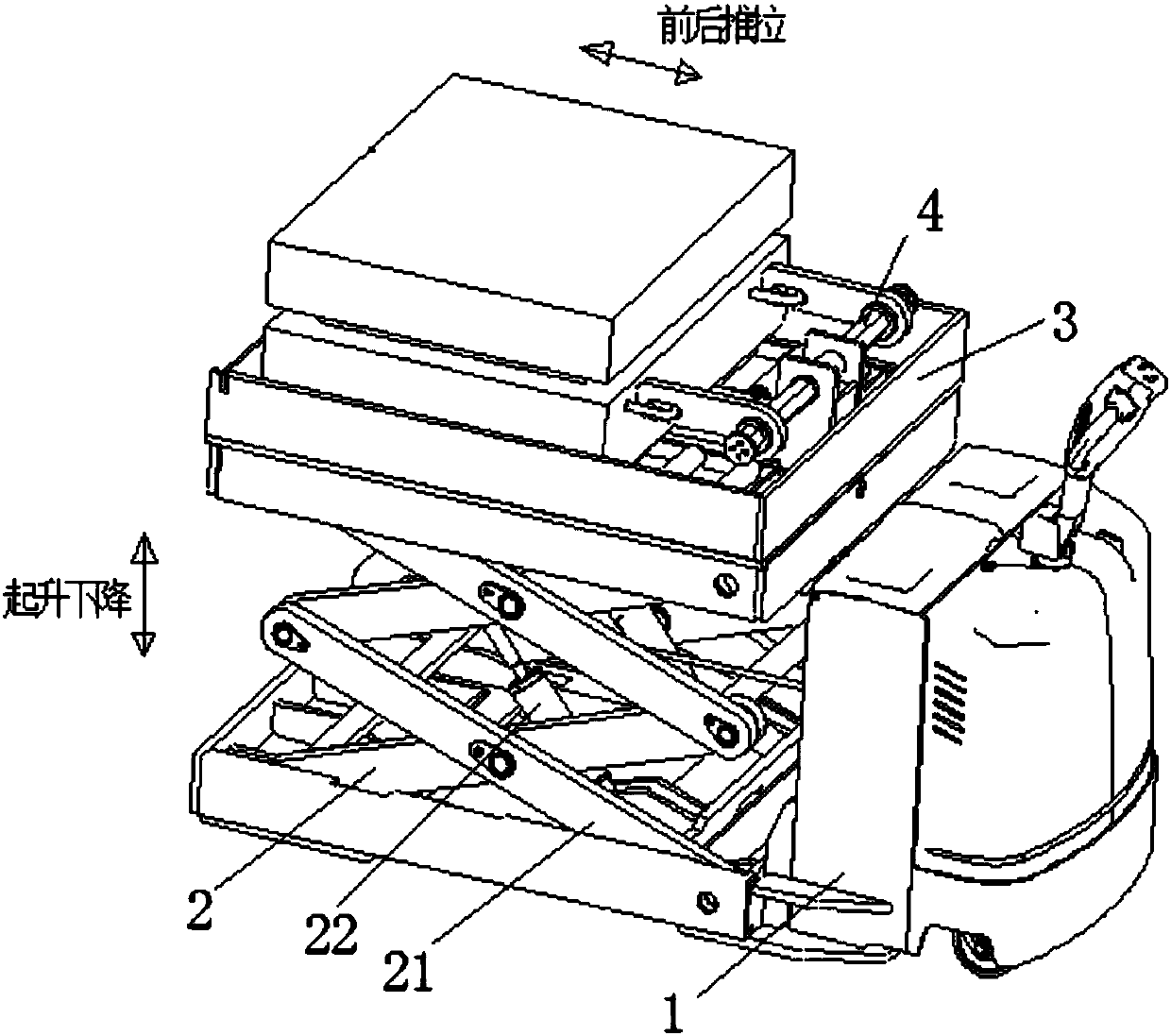

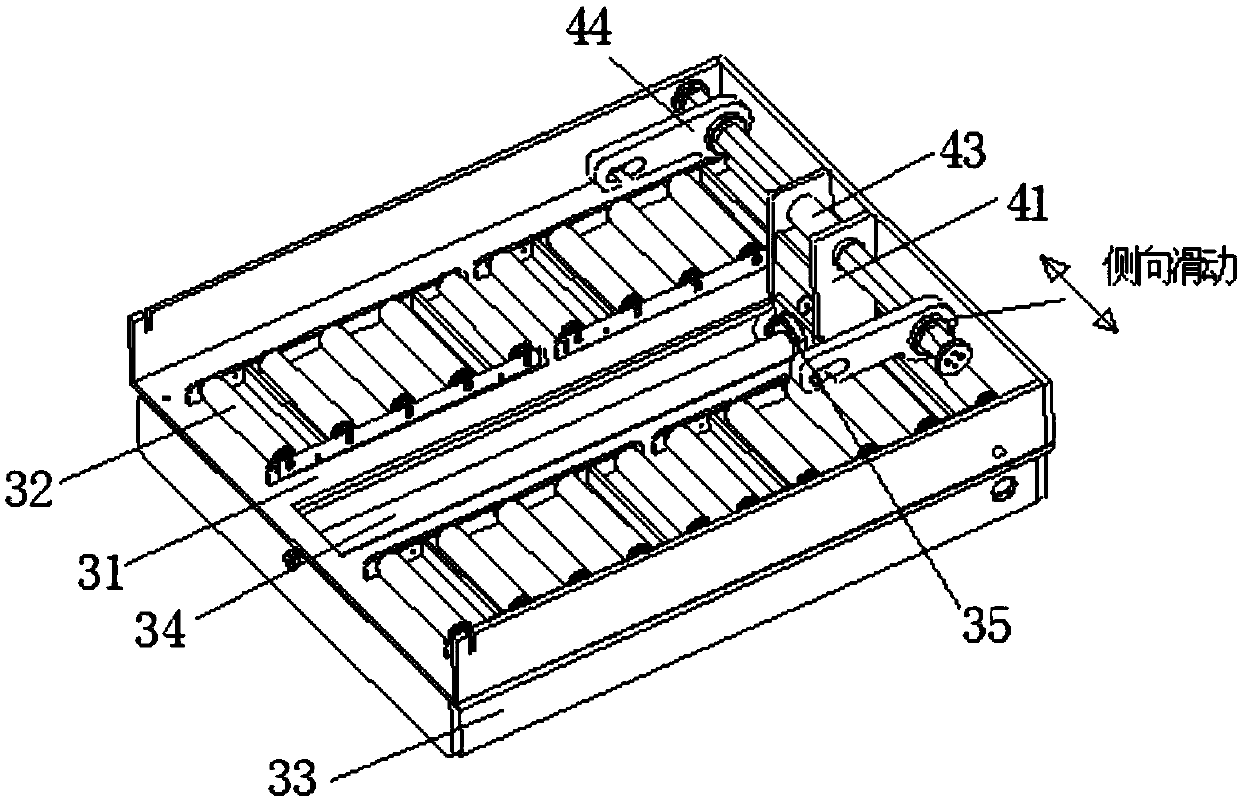

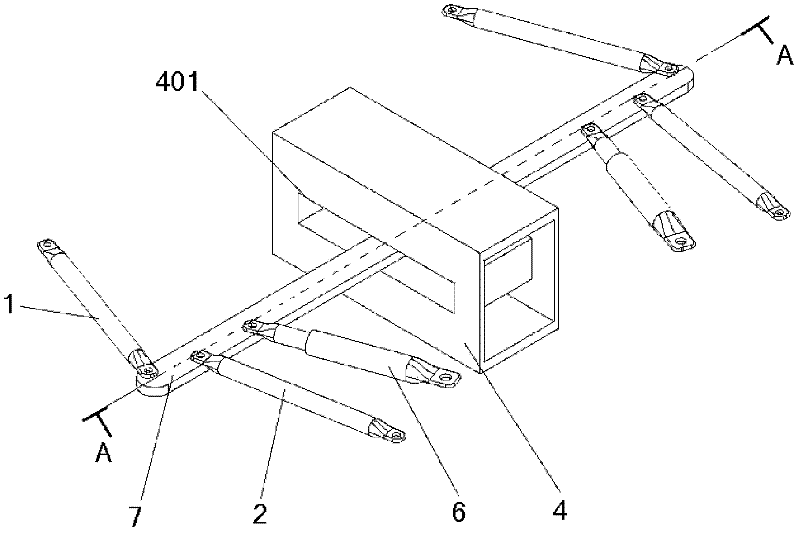

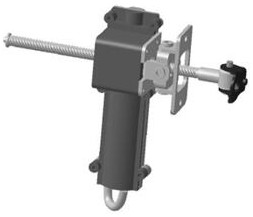

Push-and-pull device applicable to loading and unloading of molds in multiple specifications

PendingCN107857206AEasy to installImprove performanceLifting framesConveyor partsPush and pullCompression molding

The invention discloses a push-and-pull device applicable to loading and unloading of molds in multiple specifications. The push-and-pull device comprises a liftable mold platform mounted on a forklift body; a push-and-pull mechanism is mounted on the mold platform and comprises a push-and-pull arm; push-and-pull rods for pushing and pulling the molds are mounted on the push-and-pull arm; the push-and-pull arm is mounted on a fixing seat capable of moving on the mold platform; and rollers or rolling wheels which are used for supporting the molds and facilitating movement of the molds are distributed on the mold platform. The push-and-pull device is compact in structure and stable in action, the push-and-pull rods of the push-and-pull mechanism can slide in the axis direction of the push-and-pull arm to adjust the distance between the push-and-pull rods, the push-and-pull device is applicable to quick transformation of an existing forklift so as to meet various working condition requirements and is also applicable to quick loading and unloading working conditions of the various molds, such as injection molds, compression molds, stamping molds and the like, in the multiple specifications, the working manner for loading and unloading of the molds through cooperation of the existing forklift and a travelling crane with auxiliary devices is replaced, the mold loading and unloading working efficiency is improved, and meanwhile, the injury risk of operators is reduced.

Owner:BANYITONG SCI & TECH DEVING

Wheel rim driving system

ActiveCN103057398ALittle impact on performanceImprove space utilizationMotor depositionDrive shaftReducer

The invention discloses a wheel rim driving system which is arranged on the inner side of a vehicle wheel hub. The wheel rim driving system comprises a motor and a planetary reducer, wherein the motor and the planetary reducer are fixedly arranged on a suspension rack, an outer casing of the motor is integrally connected with an outer gear ring of the planetary reducer, an output shaft of the motor, an output shaft of the planetary reducer, and a driving shaft of the vehicle wheels are located on a same axis, and driving force of the motor firstly passes through the planetary reducer and then is transmitted to the vehicle wheels. The wheel rim driving system is simple in structure, light in weight, wide in application and the like.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Hydrogen control method and oxygen consumption device in low-power reactor containment

ActiveCN107767971AReduce oxygen concentrationEliminate Hydrogen RiskNuclear energy generationEmergency protection arrangementsEngineeringHydrogen combustion

The invention provides a hydrogen control method in a low-power reactor containment. An oxygen consumption device is arranged in a containment, and comprises an oxygen consumption container, an oxygenconsumption inlet, an oxygen consumption outlet, a top baffle and side baffles, wherein the oxygen consumption inlet and the oxygen consumption outlet are formed in the oxygen consumption container,and the top baffle and the side baffles are respectively arranged at the top and sides of the oxygen consumption container to protect and ensure the smooth flow of a gas. The hydrogen control method in the low-power reactor containment provided by the invention timely starts the oxygen consumption device in an accident to consume oxygen in the containment so that the oxygen concentration in the containment is lower than the limit for satisfying the hydrogen combustion to achieve non-combustion environmental conditions, thus eliminating the risk of hydrogen in the containment.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

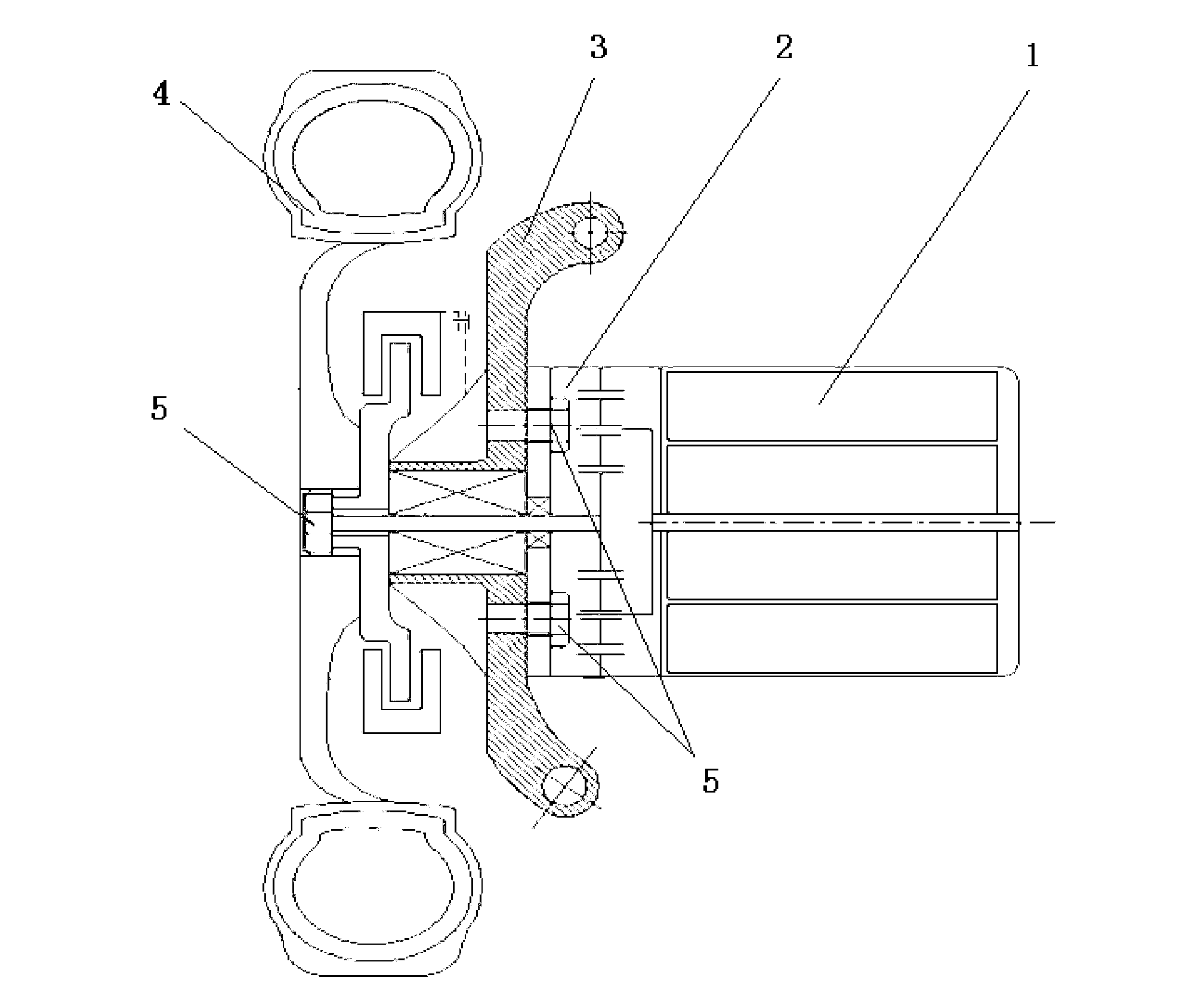

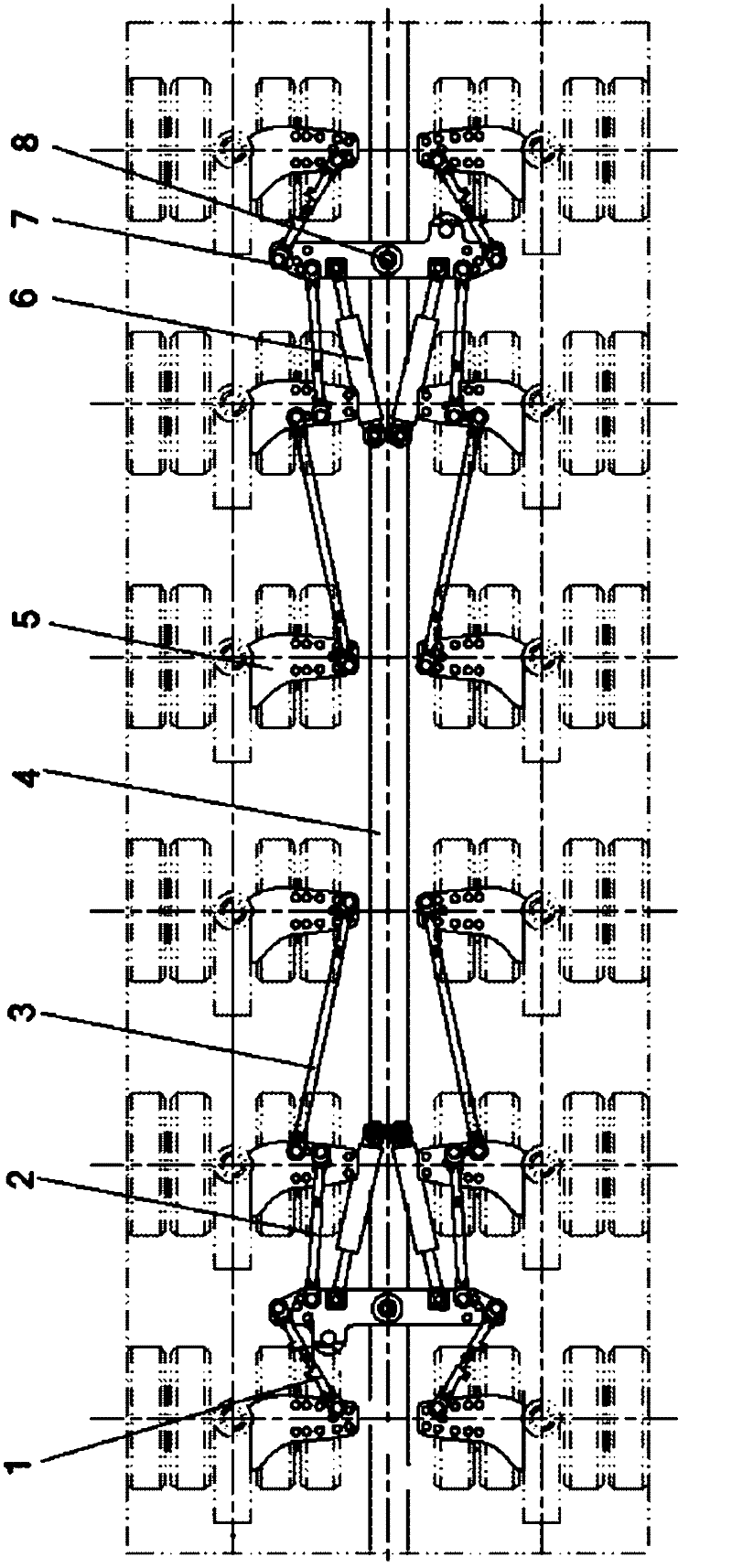

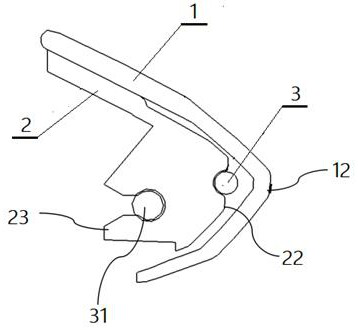

Segmental type sun gear steering plate of multi-axis hydraulic module combination trailer

The invention relates to a segmental type sun gear steering plate of a multi-axis hydraulic module combination trailer. The plate comprises a central gear (sun gear) and planet pieces at the left and right sides. The sun gear is a straight toothed cylindrical gear and installed on the transverse centre of a wing plate above or below a central longitudinal beam. The planet piece comprises side gears, a side plate, a connection shaft and a fixed base. The side gears are straight toothed cylindrical gears. The side gears are arranged at the left and right sides of the sun gear and meshed with the sun gear. The two side gears are completely same in shapes and parameters. The connection shaft is fixed on a web plate of the central longitudinal beam through the fixed base and can freely rotate in the axial hole of the fixed base. The connection shaft is simultaneously used as the gear shaft to be matched with the axial hole of the side gear. The connection shaft and the side gear can synchronously rotate without freedom degree. The connection shaft and the side plate are fixedly connected together without freedom degree. One end of the side plate and the connection shaft are connected into a whole. The other end of the side plate, like the original central steering plate, is connected to a steering hydraulic oil cylinder and a steering pull rod. The central longitudinal beam is prevented from being changed. The steering plate is flexible and variable in arrangement.

Owner:WUHAN UNIV OF TECH

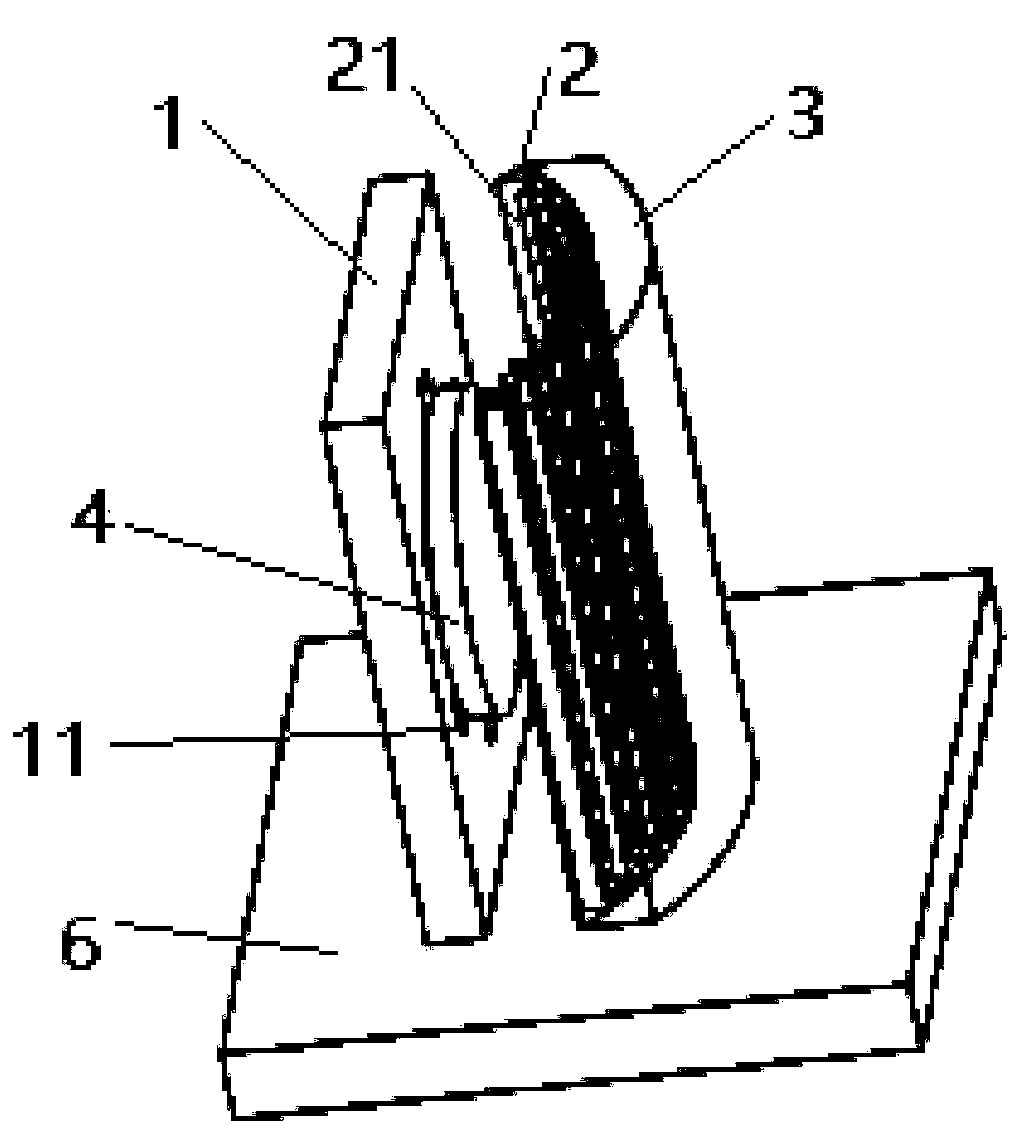

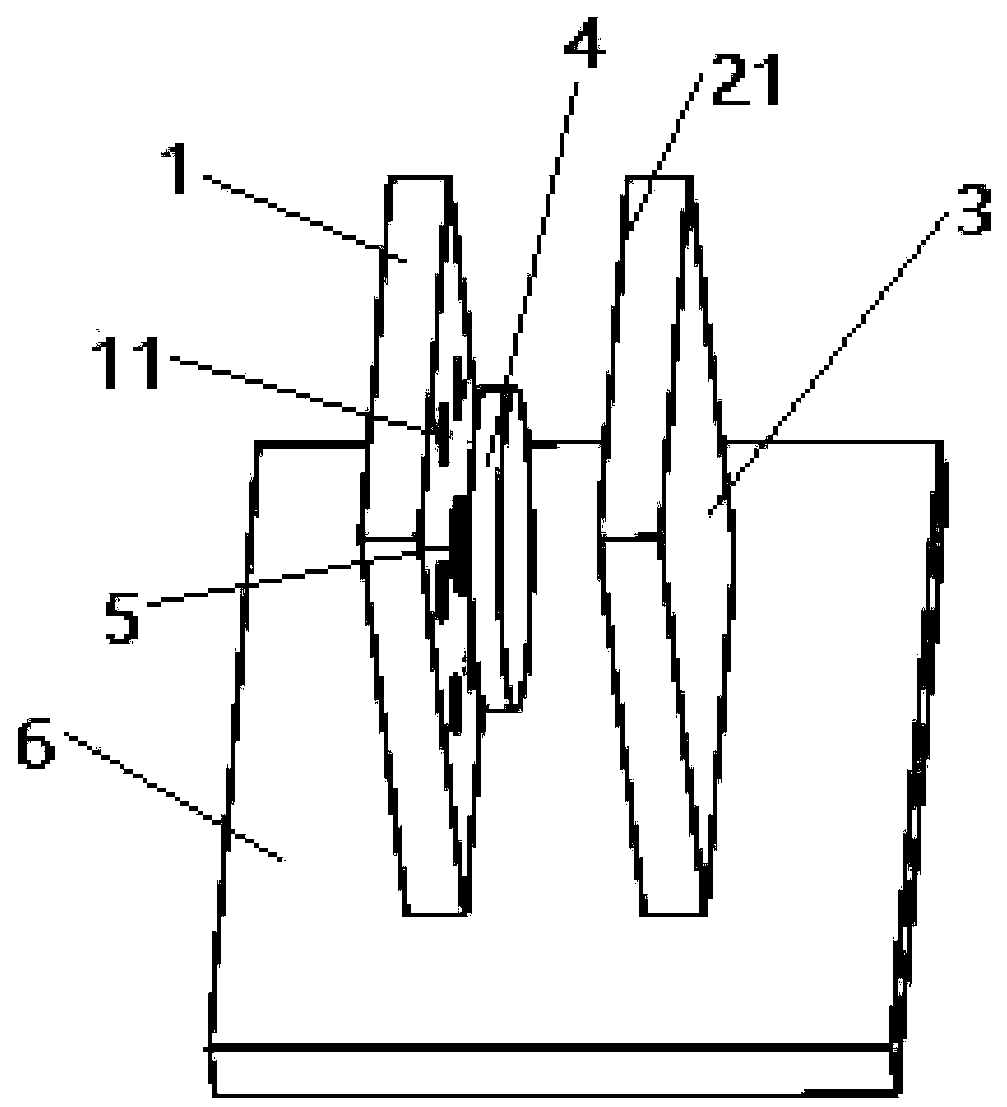

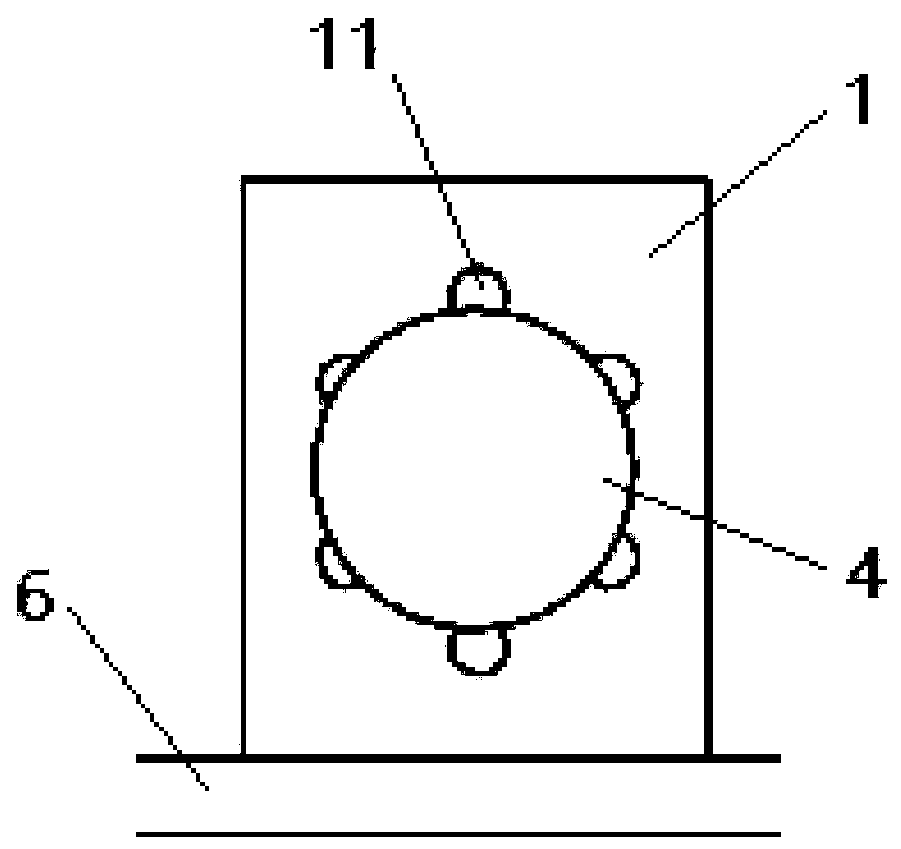

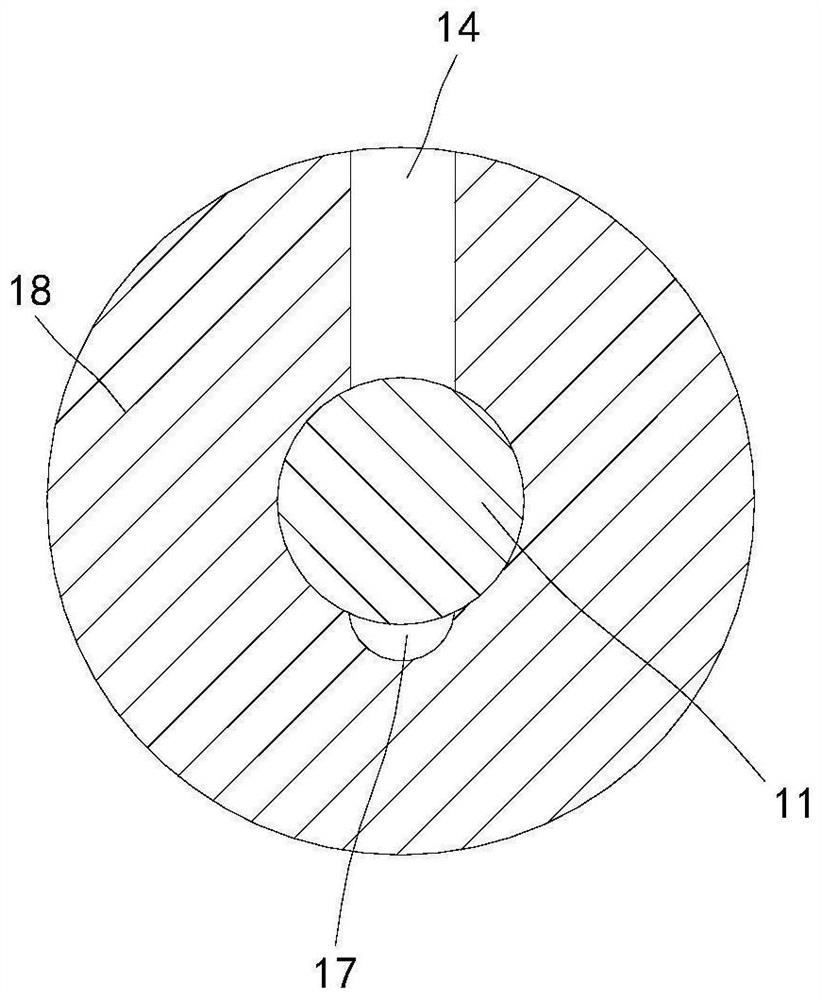

Oil-gas separating structure and engine

ActiveCN108729980ASeparation efficiency is stableLow costMachines/enginesCrankcase ventillationCrankcaseEngineering

The invention relates to an oil-gas separating structure, an engine cylinder cover and an engine. The oil-gas separating structure comprises a pore plate (1) and a flow blocking structure, wherein gasinlet pores (11) used for the entry of crankcase blow-by gas into the oil-gas separating structure are formed in the pore plate (1); the flow blocking structure is provided with an oil-gas separatingsurface (21); the oil-gas separating surface (21) comprises an impact zone of oil drops in the crankcase blow-by gas; and the flow blocking structure is configured to ensure that the area of the impact zone can be inversely proportionally changed along with the flow rate of the crankcase blow-by gas which enters the oil-gas separating structure. Through the above technical scheme, the oil-gas separating structure provided by the invention is simple, and the stable oil-gas separating efficiency can be achieved.

Owner:BEIQI FOTON MOTOR CO LTD

Engine air inlet system with continuously variable air inlet resistance, engine air inlet adjusting method and engine

InactiveCN106438133AIncrease intake resistanceWide range of changesEngine controllersMachines/enginesResistance forceAerospace engineering

The invention discloses an engine air inlet system with continuously variable air inlet resistance, an engine air inlet adjusting method and an engine. The system comprises a fixed air outlet pipe and a moving air outlet pipe capable of moving relative to the fixed air outlet pipe; the fixed air outlet pipe is fixed on an air inlet component of the engine; the moving air outlet pipe is mounted in the air inlet component; and an operating mechanism is arranged on the moving air outlet pipe and can control the moving air outlet pipe to move, so that the moving air outlet pipe makes contact with and is connected with the fixed air outlet pipe and is gradually separated from the fixed air outlet pipe. With the engine air inlet system with the continuously variable air inlet resistance, the engine air inlet adjusting method and the engine, smooth torque output is realized, the air inlet resistance has the relatively large change range and is fast in response relative to the displacement of the moving air outlet pipe, the action distance is short, and the requirement for arrangement space is not high.

Owner:JIANGMEN DACHANGJIANG GROUP CO LTD

Efficient sand temperature adjuster with grading function

ActiveCN107127293AEfficient and uniform cooling effectQuality improvementMould handling/dressing devicesFluidized bedEngineering

The invention discloses an efficient sand temperature adjuster with a grading function. The adjuster comprises a machine body and a cooling unit tube bundle, the feeding end of one side of the machine body is provided with a quantitative feeder, and a bundle spraying air tube is arranged in the machine body and close to the feeding end of the machine body; a feeding screening plate is arranged above the bundle spraying air tube, a fluidized bed is arranged below the cooling unit tube bundle, a main air tube is arranged at the bottom of the fluidized bed, and the fluidized bed is arranged to communicate with the main air tube; a branch air tube is vertically arranged at one end of the main air tube in a communicating mode and connected with the bundle spraying air tube; a row of material flow guiding plates are arranged on the fluidized bed at equal intervals; and a dust collector is further arranged above the machine body, and the discharging end of the machine body is further provided with an on-line sampling device. The sand temperature adjuster is compact in outline size, easy to arrange on a site, high in temperature reducing efficiency, convenient to adjust the sand flow temperature and little in overhauling and maintaining, dust removal equipment is integrated so that fine powder in molding sand can be removed, the quantitative feeding mode can further be ensured, and thus the molding sand treated on the fluidized bed is more uniform and orderly.

Owner:南通凯斯辛普森机械科技有限公司

Automatic opening and closing side opening door structure driven by electric supporting rod

PendingCN114278185AReduce manufacturing costSimple structurePower-operated mechanismDoorsSystem maintenanceEngineering

The invention discloses an automatic opening and closing side opening door structure driven by an electric supporting rod, which comprises an electric supporting rod system, the electric supporting rod system is respectively connected with a vehicle door inner plate, a doorsill inner plate, a doorsill outer plate and a doorsill reinforcer through spherical hinges, and a groove is arranged at the position of the electric supporting rod of the vehicle door inner plate. As long as positions and spaces for mounting actions of the electric supporting rod system are arranged on the vehicle inner plate, the doorsill inner plate, the doorsill reinforcing piece and the doorsill outer plate of the vehicle door system, the requirement for the arrangement space of the electric side opening door of the electric limiting stopper structure is reduced, and the electric limiting stopper structure has the advantages of being simple in structure, convenient to mount, good in system maintainability and the like. And the use cost is greatly reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

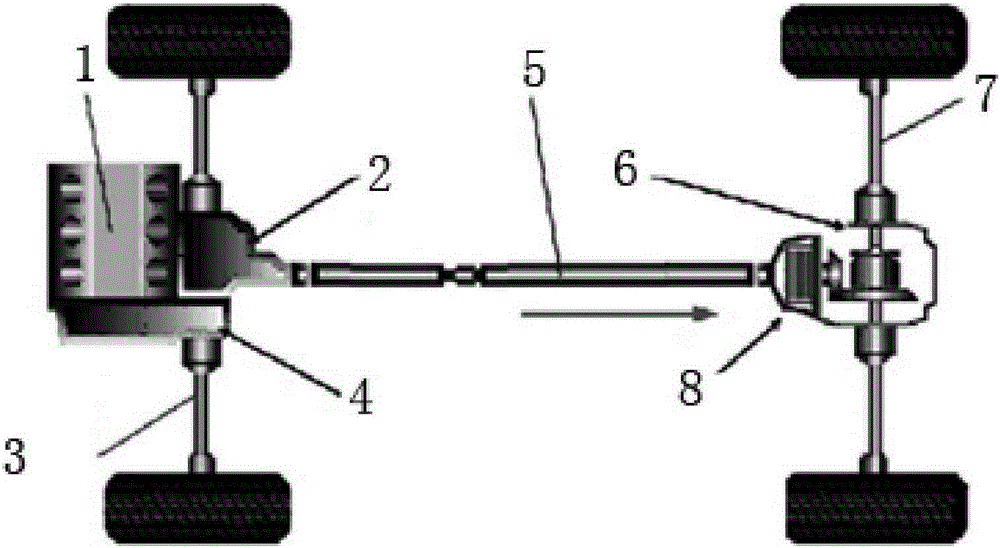

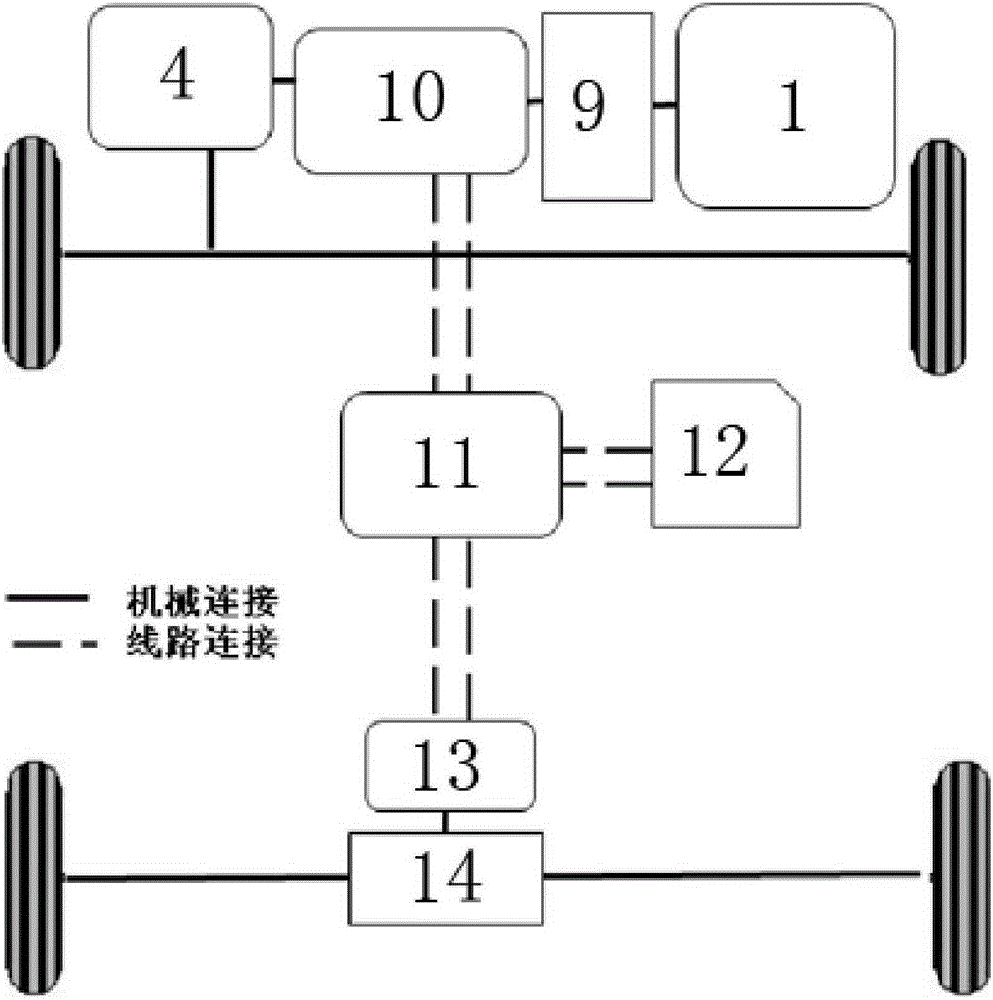

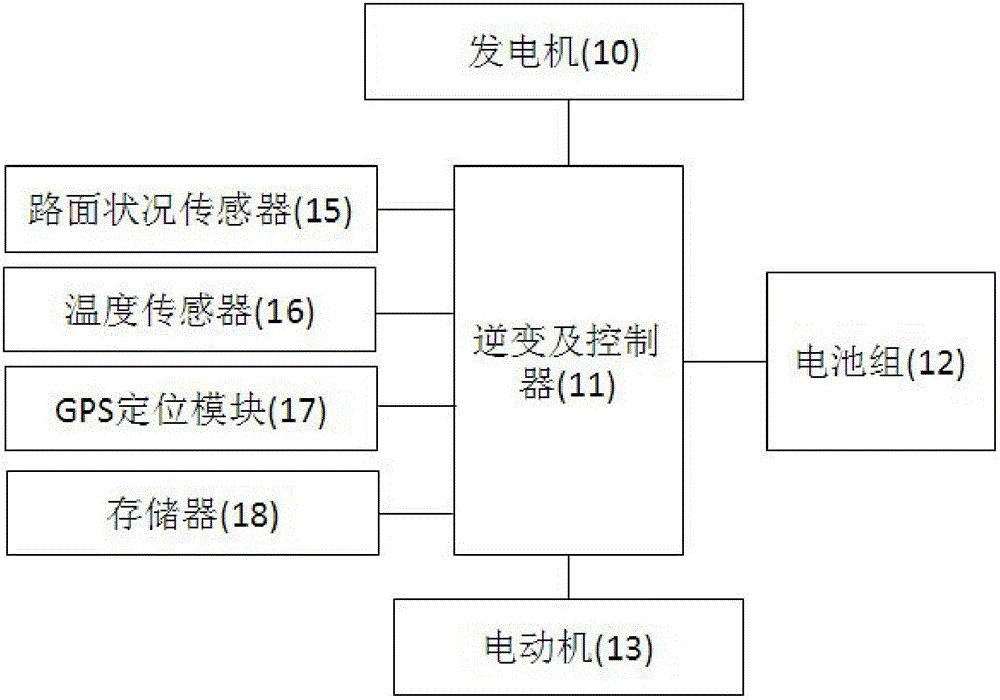

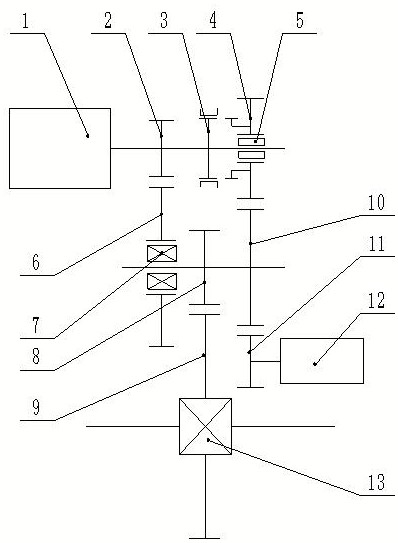

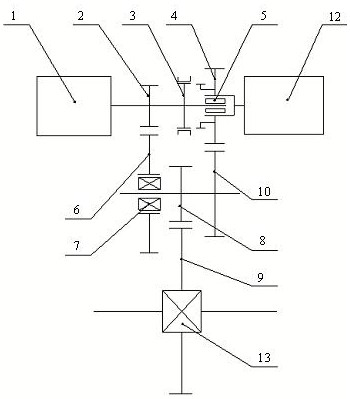

Driving system and method for hybrid electric four-wheel drive vehicle

ActiveCN103192691BAdd data itemsReduce lossHybrid vehiclesElectrodynamic brake systemsElectricityElectrical battery

The invention discloses a driving system and method for a hybrid power four-wheel drive automobile. The system comprises a battery module, an engine module, a generator and a gearbox, wherein the engine module is connected with the gearbox through the generator; the gearbox drives front wheels of the automobile through a transmission shaft and a drive axle; the driving system for the hybrid power four-wheel drive automobile further comprises an electric motor and a differential; the battery module is electrically connected with the generator and the electric motor respectively; the electric motor is connected with the differential; and the differential drives rear wheels of the automobile. The system collects and converts power of the automobile during breaking and downhill running into electric energy for storage, and the stored electric energy enables the electric motor to work to drive the rear wheels when four-wheel drive is needed, so that energy is saved, and the economical efficiency of the whole automobile is improved. The driving system and method are applicable to the hybrid power four-wheel drive automobile.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Atmosphere lamp device of automobile dashboard

PendingCN113415235ALow costAvoid the problem of uneven gap matchingLuminous strips generationDashboard lighting devicesDashboardLaser engraving

The invention relates to an automobile dashboard atmosphere lamp device. The automobile dashboard atmosphere lamp device comprises a right side decorating part arranged at the waist line position of an automobile dashboard, wherein a forked part is arranged in the middle of the right side decorating part, and the whole right side decorating part is in a Y shape and is of a long and narrow cavity structure. The lamp device is characterized in that a laser engraving part is arranged on a front face of the right decorative part, a welding rib and a Boss column are arranged on a rear face of the right decorative part, and a metal clamping seat is arranged on a rear face of the forked part; an atmosphere lamp mounting plate is arranged behind the right side decorating part and is connected to the right side decorating part through the welding ribs and the Boss columns; and an atmosphere lamp strip is arranged on the atmosphere lamp mounting plate and corresponds to the laser engraving part on the right side decorating part. According to the atmosphere lamp device, a problem of uneven fit clearance with the decorating part can be solved, the arrangement space of the atmosphere lamp assembly is reduced, and meanwhile, the cost is greatly reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

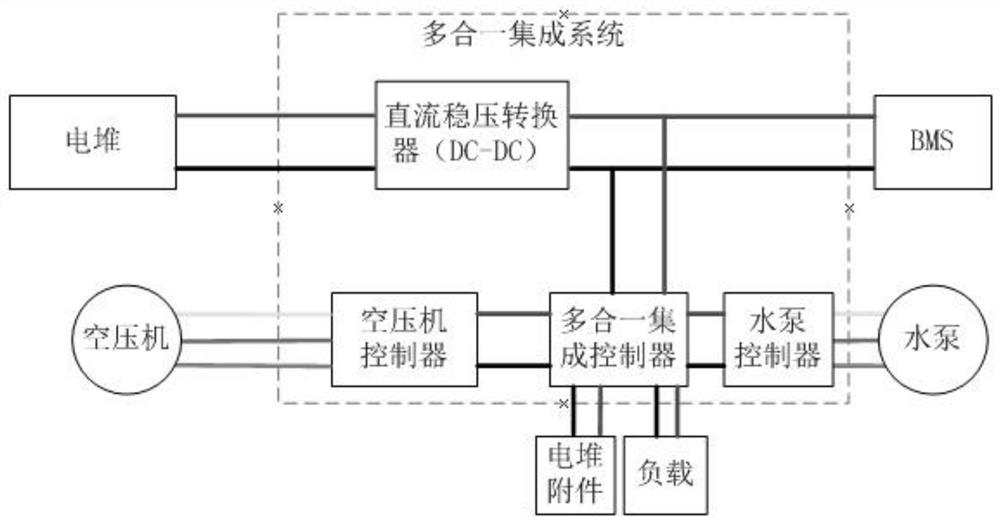

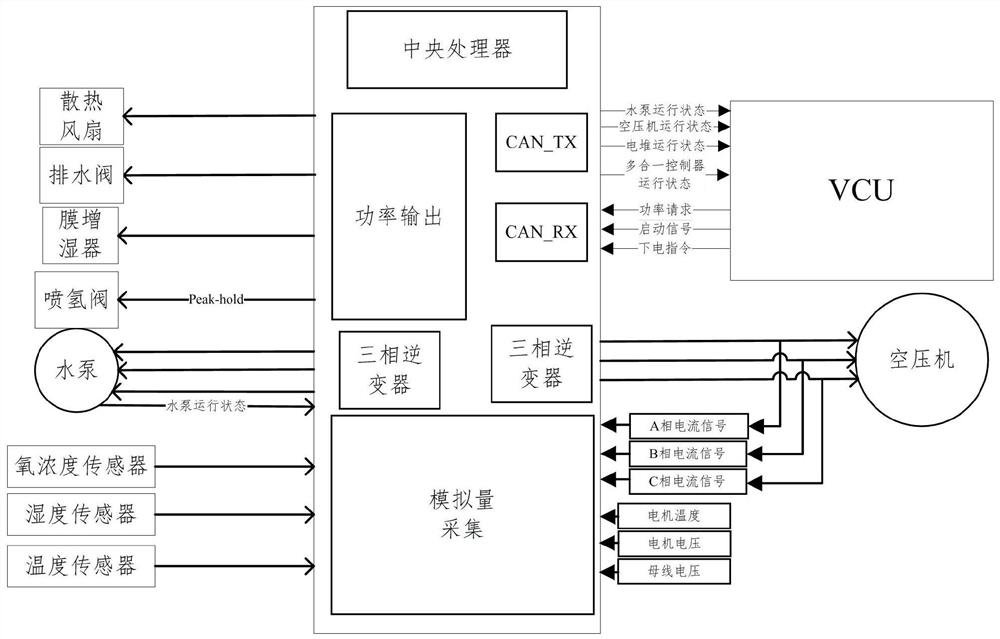

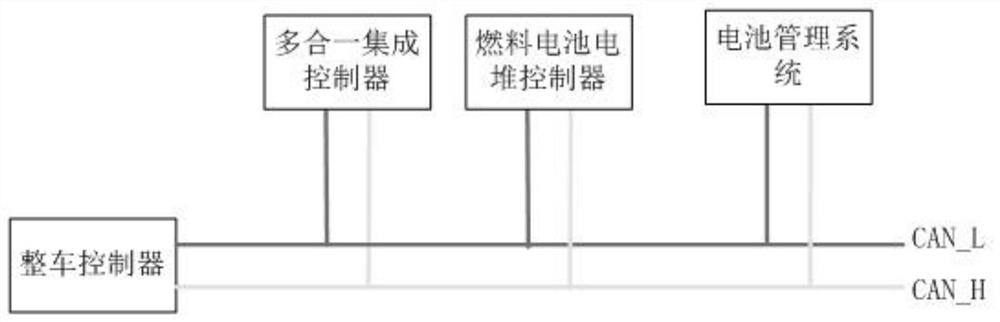

All-in-one integrated control system for fuel cell vehicle control

PendingCN111845459AMeet different power demandsIncrease output powerBattery/fuel cell control arrangementComplex mathematical operationsConvertersFuel cells

The invention provides an all-in-one integrated control system for fuel cell vehicle control. The system comprises a direct-current voltage stabilization converter, an all-in-one integrated controller, an air compressor controller and a water pump controller. The voltage input end of the direct-current voltage stabilization converter is connected with the high-voltage end of an electric pile of the fuel cell vehicle; the voltage output end of the direct-current voltage stabilization converter is connected with the voltage input ends of the all-in-one integrated controller, the air compressor controller and the water pump controller. An air compressor control signal output end of the all-in-one integrated controller is connected with a control signal input end of the air compressor controller; and a water pump control signal output end of the all-in-one integrated controller is connected with a control signal input end of the water pump controller.

Owner:BEIJING JIUZHOU HUAHAI TECH

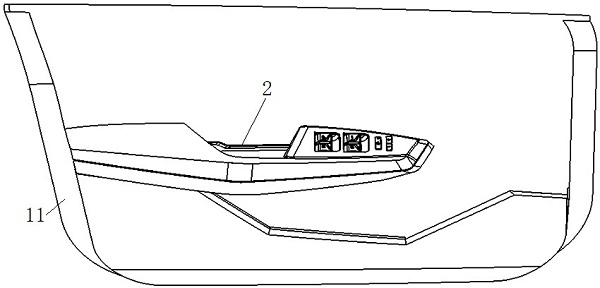

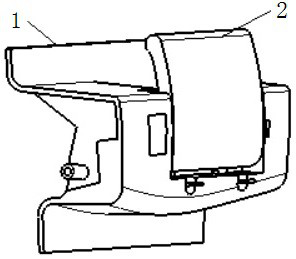

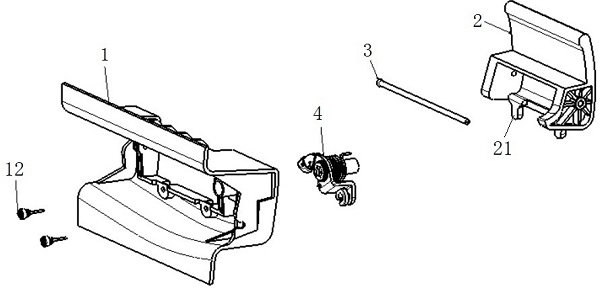

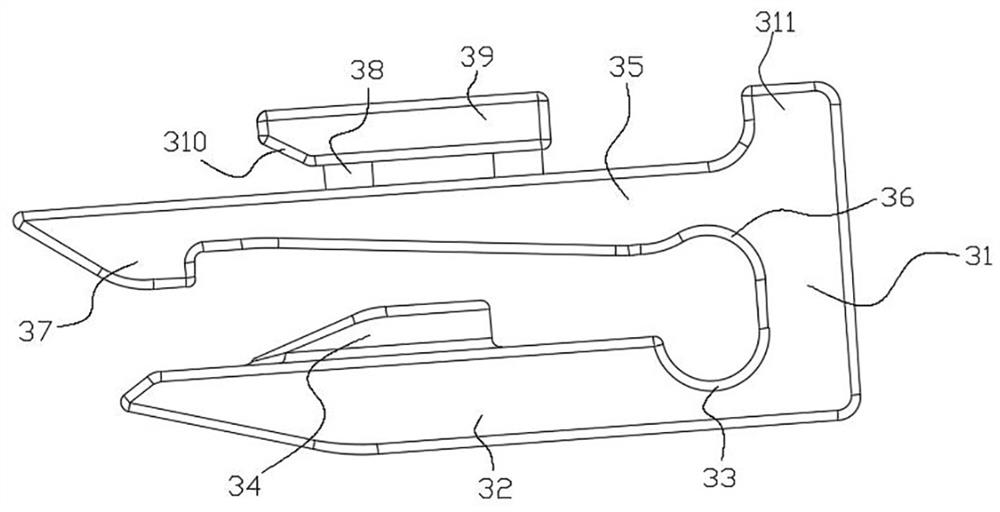

Vehicle door inward opening handle assembly and vehicle

The invention discloses a vehicle door inward opening handle assembly and a vehicle. The vehicle door inward opening handle assembly comprises a mounting base and a handle body, a first rotating shaft hinged to the handle body is arranged on the mounting base, a vehicle door lock body opening assembly is arranged on the mounting base, the vehicle door lock body opening assembly comprises a second rotating shaft fixed to the mounting base and a rotating piece fixed to the second rotating shaft, and the length direction of the second rotating shaft is perpendicular to the length direction of the first rotating shaft. A through hole allowing the second rotating shaft to penetrate through is formed in the middle of the rotating piece, the first end of the rotating piece is fixed to a vehicle door lock body pull wire, the second end of the rotating piece is correspondingly matched with a stirring protrusion at the lower end of the handle body, when the handle body rotates around the first rotating shaft, the stirring protrusion at the lower end of the handle body makes contact with the second end of the steering piece and drives the rotating piece to rotate around the second rotating shaft, and the vehicle door lock body pull wire is driven to move to unlock a vehicle door. The vehicle door lock body pull wire can be unlocked at a small opening angle, and then the constraint of a handle body opening envelope on the shape is released.

Owner:重庆长安新能源汽车科技有限公司

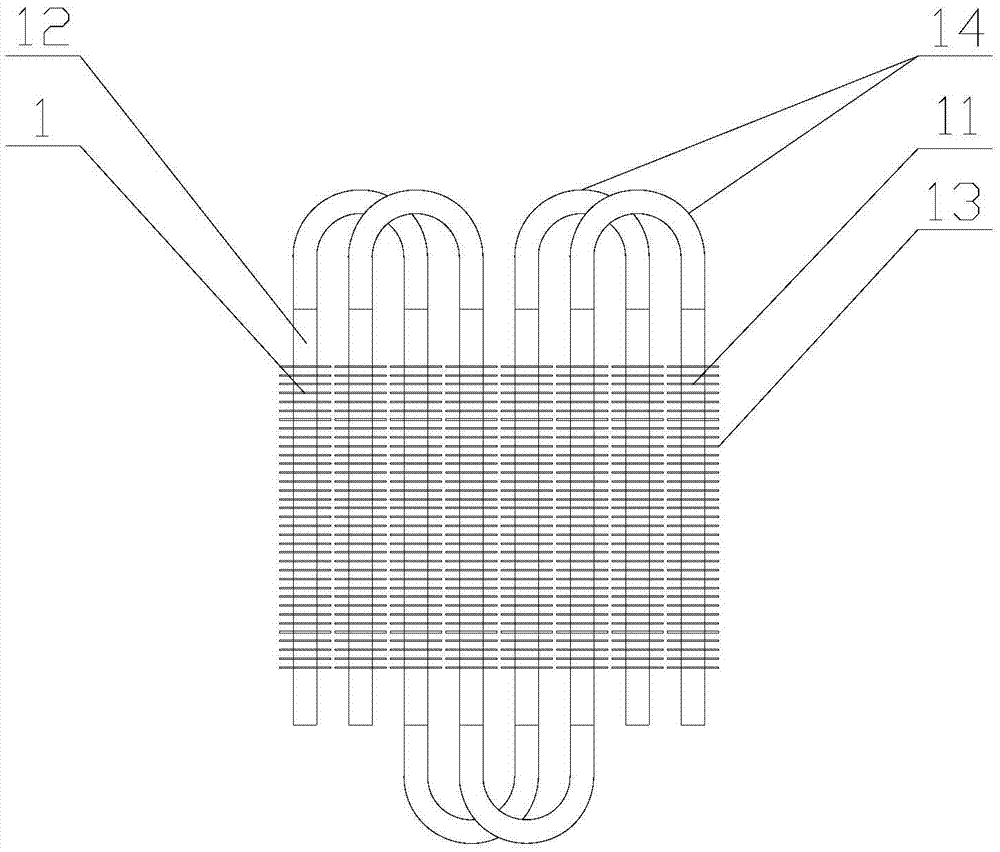

Serpentine tube row, heat-exchanging device and layout method of serpentine tube row

InactiveCN106996704AImprove adaptabilityIncrease the heating areaHeat exchanger casingsStationary tubular conduit assembliesWorking environmentReducer

The invention discloses a serpentine tube row, a heat-exchanging device and a layout method of the serpentine tube row. The serpentine tube row is used for generating heat exchange with a fluid medium of the outside and comprises serpentine tubes, a framework fixedly connected with the serpentine tubes, an inlet tube reducer and an outlet tube reducer. The multiple serpentine tubes are arranged in a staggered mode in parallel, and every two adjacent base tubes located on the same serpentine tube are arranged in sequence. The framework comprises a left surface frame connected with the inlet tube reducer and a right surface frame connected with the outlet tube reducer. The fluid medium enters the framework through the inlet tube reducer and makes contact with the serpentine tube row, and then the fluid medium flows out through the outlet tube reducer. Every two adjacent base tubes located on the same serpentine tube are arranged in sequence. The multiple serpentine tubes are sequentially arranged in a staggered mode. The serpentine tube row, the heat-exchanging device and the layout method of the serpentine tube row have the advantages and beneficial effects that adaptability to the working environment is high, the heating area and the overall heat transfer coefficient of the heat-exchanging device are increased, the heat exchange efficiency is improved, the requirement for arrangement space is lowered, and cost of investment is reduced; and no adhesion or crossing exists between fins, and dust accumulation cannot happen easily.

Owner:SHANGHAI YINGUO THERMAL ENERGY EQUIP

Transmission system for electric vehicle

ActiveCN112360935AAvoid normal workExpand the range of working conditionsToothed gearingsGearing detailsReduction driveElectric machinery

The invention relates to a transmission system of an electric vehicle. The transmission system comprises a first motor and a second motor, and comprises a two-gear speed reducer. According to the electric vehicle, a working condition range of the electric vehicle is expanded by arranging the second motor with low power.

Owner:科大国创极星(芜湖)科技有限公司

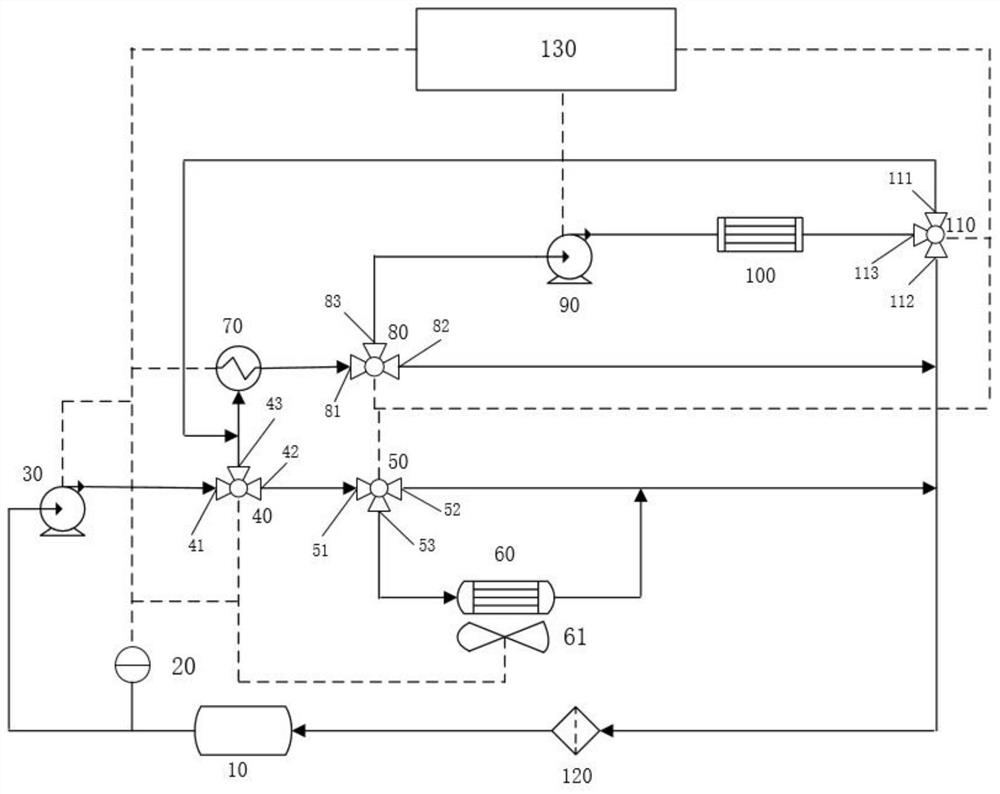

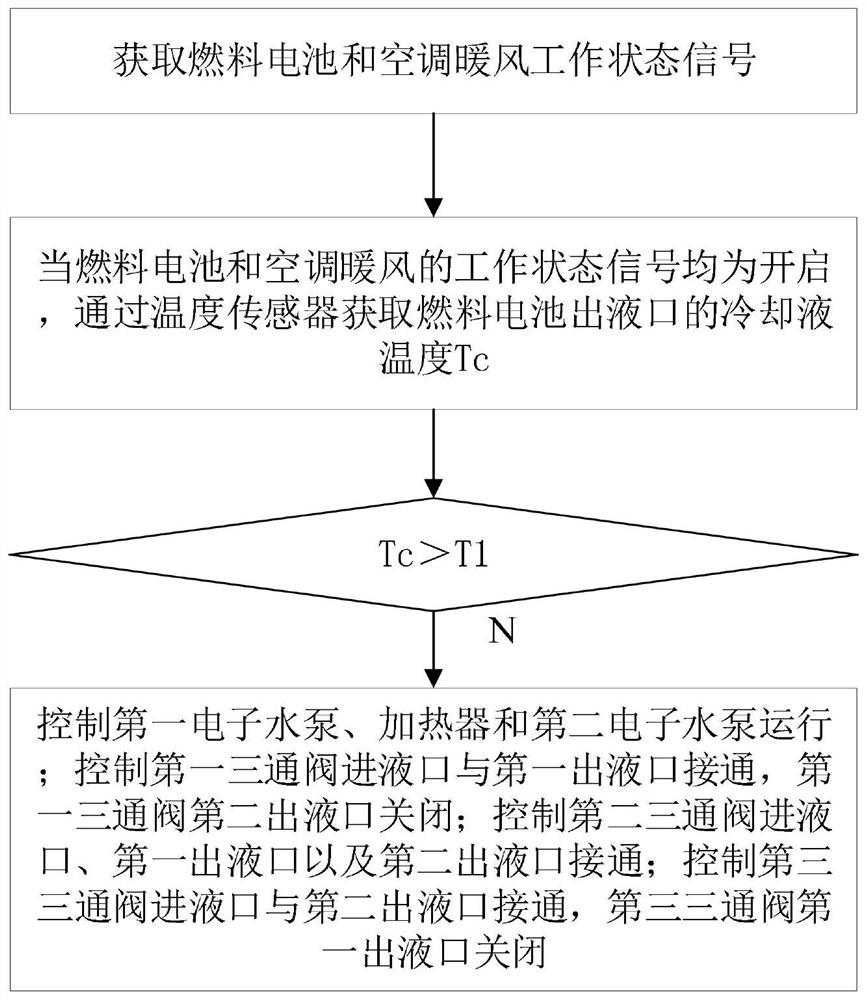

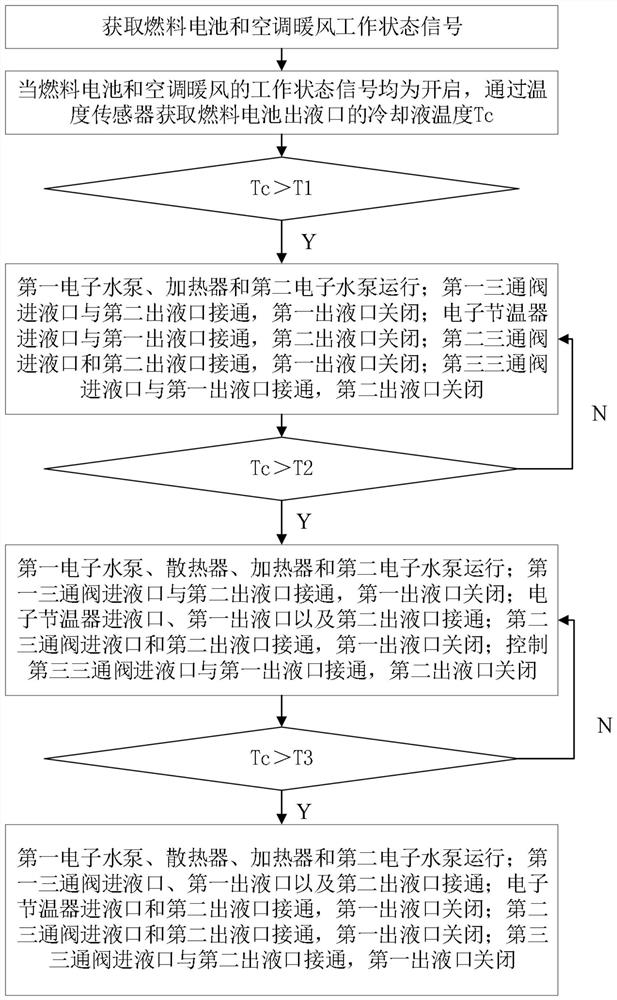

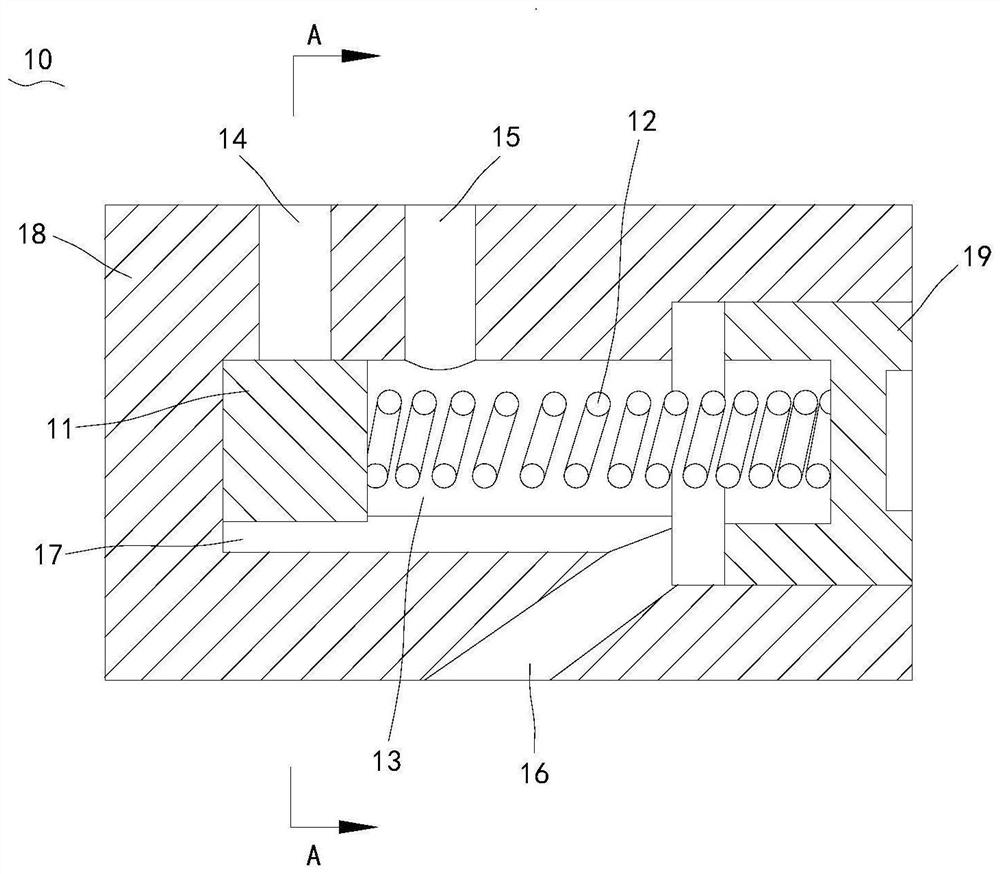

A fuel cell vehicle thermal management system, method, storage medium and vehicle

ActiveCN111634212BStart fastImprove adaptabilityAir-treating devicesVehicle heating/cooling devicesFuel cellsThermal management system

The invention discloses a fuel cell vehicle thermal management system, method, storage medium and vehicle. The system comprises: a liquid inlet of a first electronic water pump is connected to a liquid outlet of a fuel cell, and the liquid outlet is connected to a first three-way valve for liquid inlet. The first liquid outlet of the first three-way valve is connected to the liquid inlet of the heater, the liquid outlet of the heater is connected to the liquid inlet of the second three-way valve, and the first liquid outlet of the second three-way valve is connected to the fuel cell. The liquid port is connected, the second liquid outlet is connected with the liquid inlet port of the second electronic water pump, the liquid outlet port of the second electronic water pump is connected with the liquid inlet port of the air conditioner heater heat exchanger, and the liquid outlet port of the air conditioner heater heat exchanger is connected with the fuel cell The liquid inlet is connected; the first electronic water pump, the first three-way valve, the heater, the second three-way valve, and the second electronic water pump are all connected to the controller with electric signals. In the present invention, the controller controls the action of each three-way valve, electronic thermostat, heater, water pump, and fan to realize different circulation loops of the cooling liquid after collecting and analyzing the data collected by the sensor.

Owner:DONGFENG MOTOR CORP HUBEI

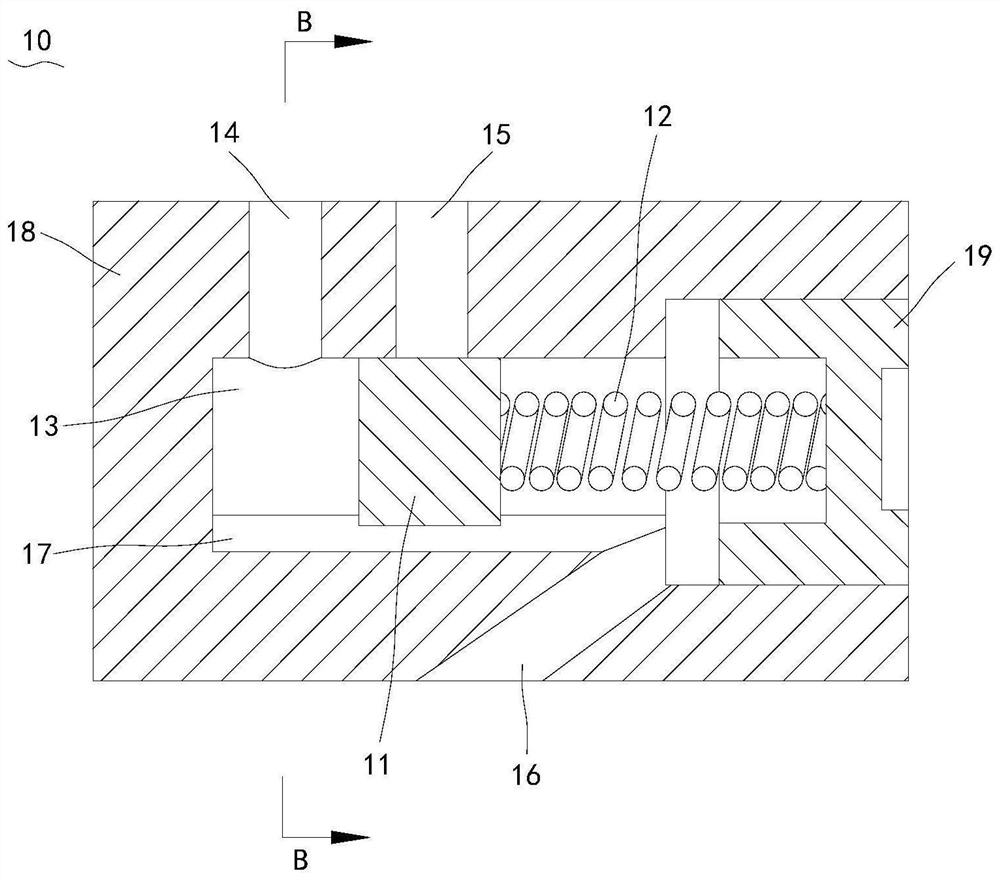

A control valve, a control oil circuit and a variable compression ratio engine

ActiveCN113530693BRelieve pressureHighly integratedEngine controllersMachines/enginesControl valvesVariable compression ratio

The invention relates to the technical field of engines, and discloses a control valve, a control oil circuit and a variable compression ratio engine including the control valve. The control valve includes a valve body, a valve core and an elastic member. The piece is connected to the first end of the valve chamber. The valve body is provided with a first inlet, a second inlet and a return port respectively connected with the valve chamber. The return groove communicates with the return port, and the control valve is applied to variable compression Compared with the control oil circuit of the engine, the return channel can be switched in a single control valve to realize the automatic oil filling and oil drain function of the two hydraulic chambers of the connecting rod control oil circuit, without the need to arrange too many oil circuits and reduce the layout space. It is required that the length of the connecting rod is switched by controlling the oil passage to realize the change of the engine compression ratio, so that the overall structure of the engine is compacted.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Engine crankcase ventilation system

PendingCN114076013ALow costImprove diagnostic accuracyMachines/enginesCrankcase ventillationControl theoryMechanical engineering

The invention discloses an engine crankcase ventilation system which comprises a crankcase, an intake manifold, a high-pressure load air outlet pipeline, a low-pressure load air outlet pipeline, a supercharger and a fault detection valve. The fault detection valve is connected with the high-pressure load air outlet pipeline and the low-pressure load air outlet pipeline. The fault detection valve has an initial state and a fault report state, the fault detection valve is configured to be switched from the initial state to the fault report state when the high-pressure load air outlet pipeline leaks or is disconnected, and the fault detection valve is configured to enable the low-pressure load pipeline to communicate with the external atmosphere in the fault report state. According to the ventilation system of the engine crankcase, the high-pressure load air outlet channel and the low-pressure load air outlet channel are associated through the fault detection valve, and the overall structure is simple, so that the diagnosis precision is improved, the diagnosis range is expanded, the reliability is improved, the structure is simple, the arrangement space requirement is reduced, and the cost is low.

Owner:深圳臻宇新能源动力科技有限公司

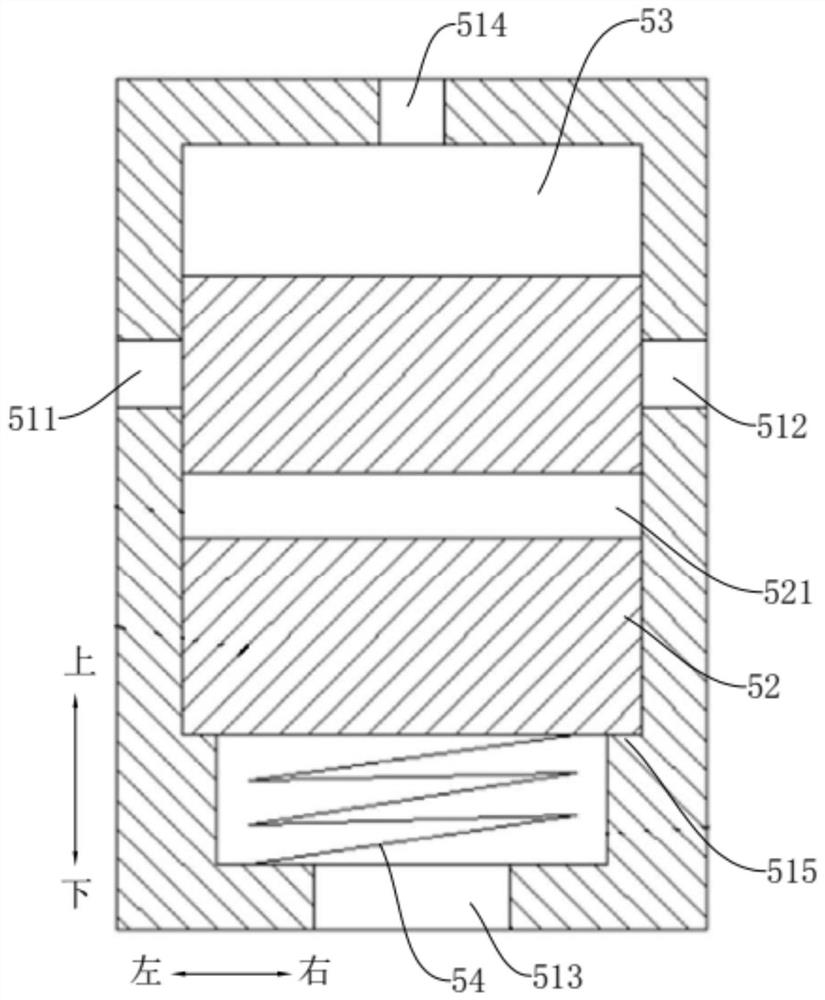

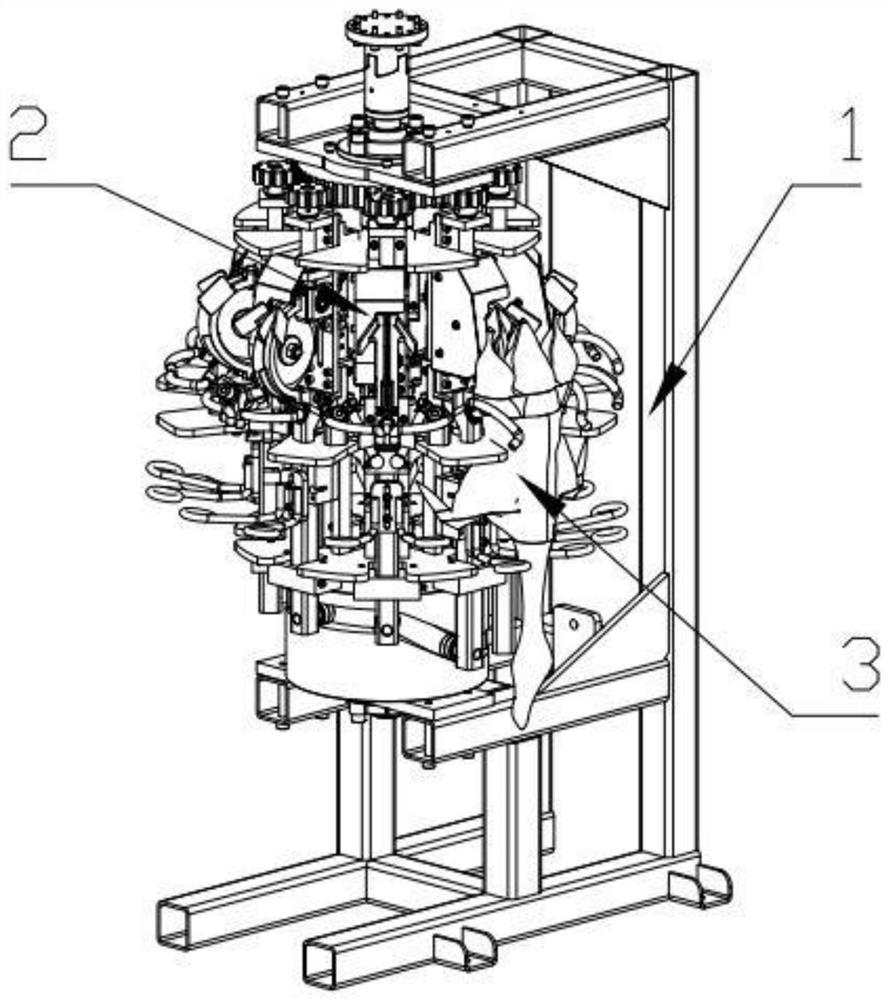

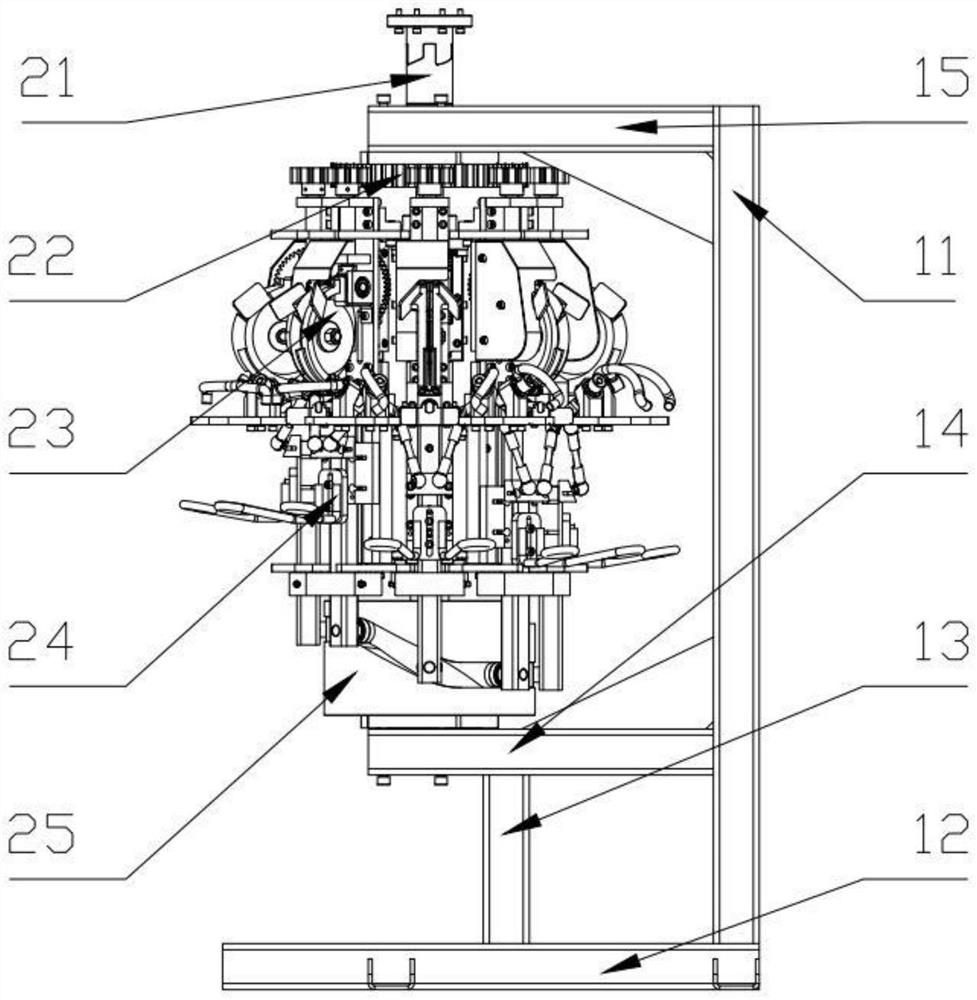

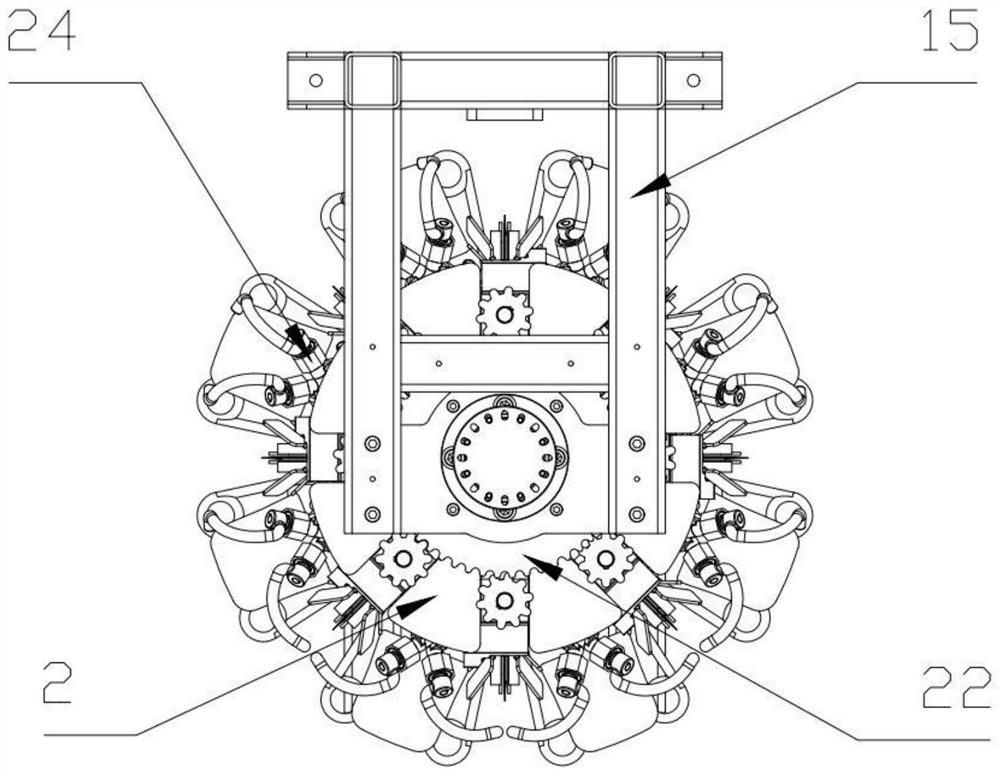

Automatic poultry carcass opening machine with high applicability

ActiveCN114073268AGuaranteed opening efficiencyLow layout space requirementPoultry processingStructural engineeringMechanical engineering

The invention provides an automatic poultry carcass opening machine with high applicability. The automatic poultry carcass opening machine comprises a rack and a carcass opening system, wherein the carcass opening system comprises a rotating shaft vertically arranged in the middle, a circular fluted disc is arranged on the upper portion of the rotating shaft, a positioning mounting disc is arranged in the middle of the rotating shaft, a plurality of cutting knife assemblies and enclasping lifting assemblies are evenly distributed in the circumferential direction of the positioning mounting disc, the lower portions of the cutting knife assemblies are connected with the positioning mounting disc, the upper portions of the cutting knife assemblies are connected with the circular fluted disc in a meshed mode through a gear, the enclasping lifting assemblies are connected to the lower portion of the positioning mounting disc, each enclasping lifting assembly comprises a moving block, a guide part is arranged on the lower portion of the rotating shaft, an undulating rail groove is formed in the guide part, the bottom of the moving block is slidably connected into the undulating rail groove, and the cutting knife assembly comprises a vertically-arranged carcass opening knife. According to the invention, the poultry carcass opening work is completed by matching the carcass opening knife with the effect of the enclasping lifting assembly so as to ensure the carcass opening efficiency; and the carcass opening machine can be suitable for carcass opening work of most poultry through the arrangement of the enclasping lifting module, so that the practicability and the applicability are extremely high.

Owner:南京深农智能装备有限公司

Adjustable oil filler cover plate with opening elastic piece mechanism

ActiveCN112977051AMeet the functional needs of daily useEasy bending initial positionFuel supplyEngineeringMechanical engineering

Owner:JIANGXI CHANGHE AUTO

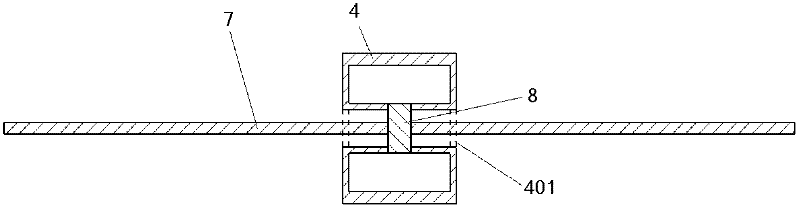

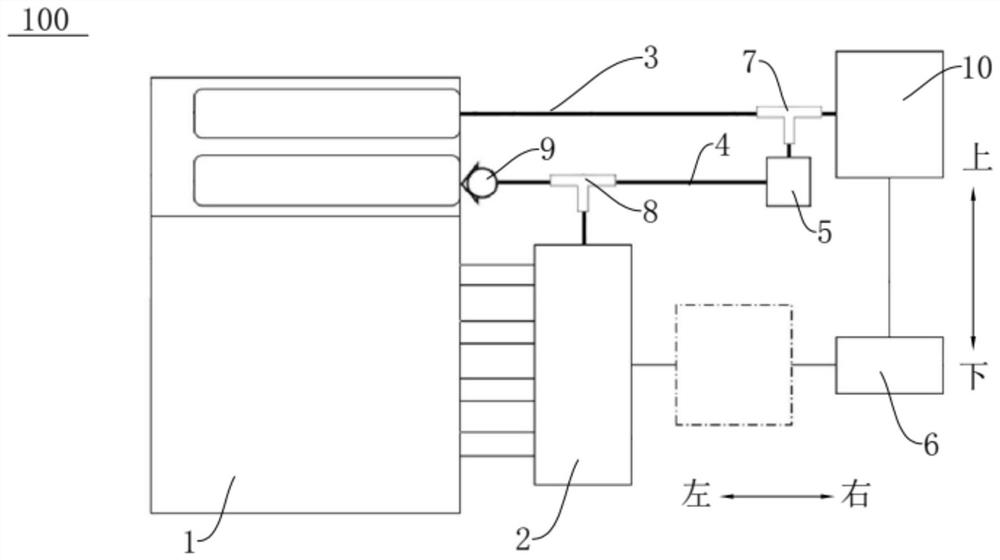

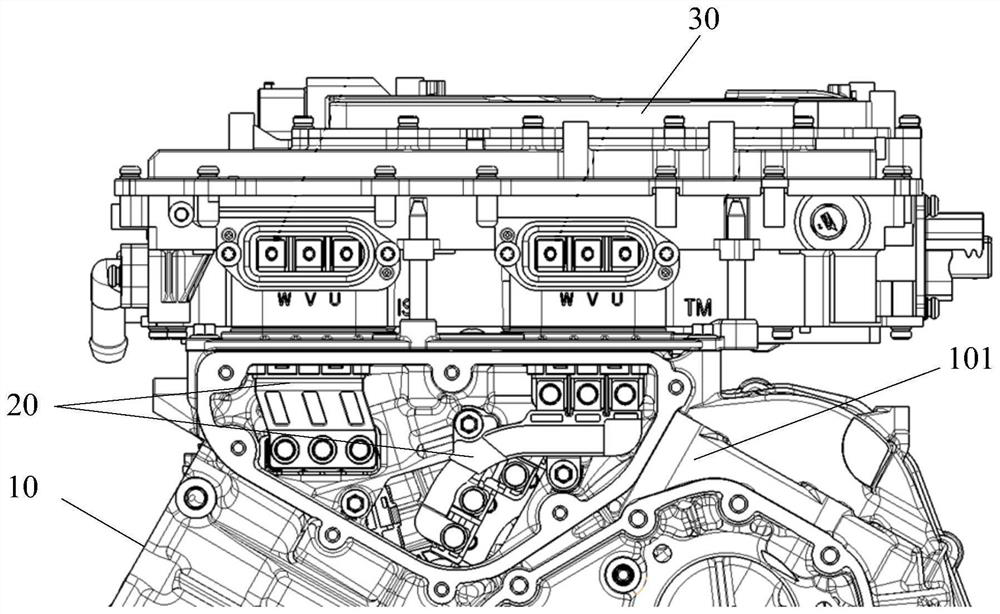

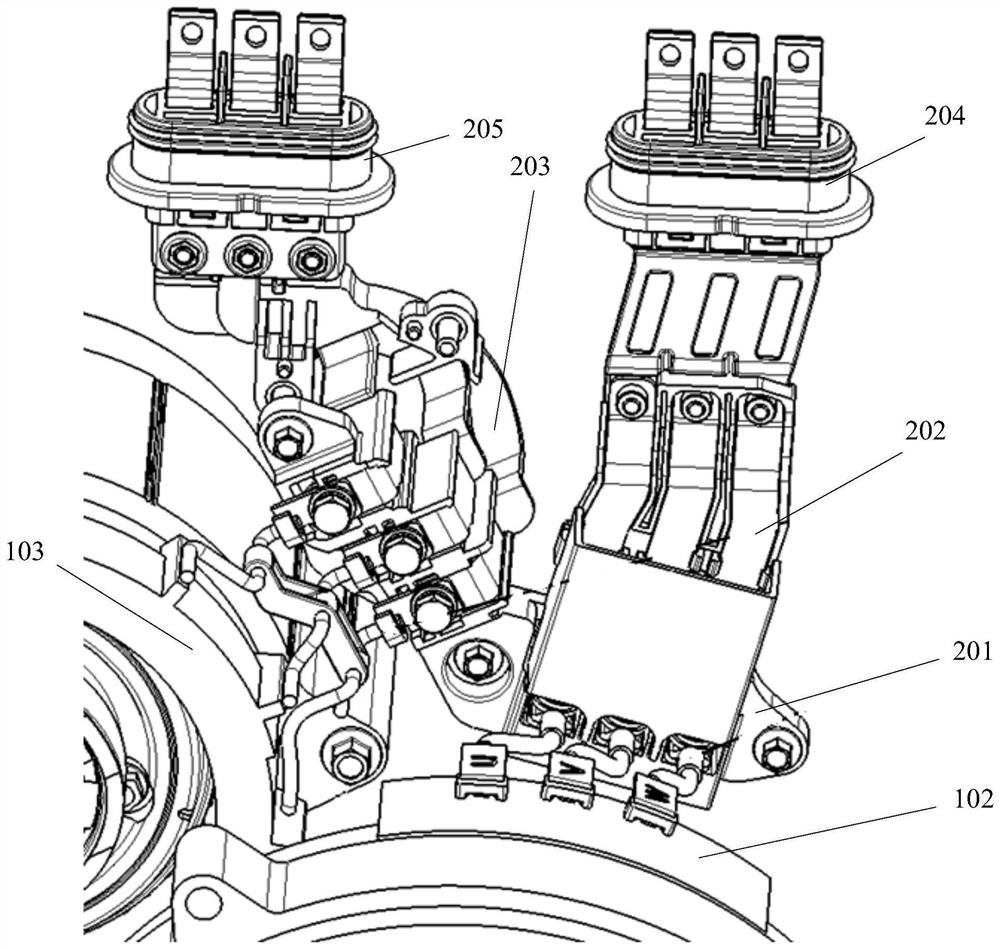

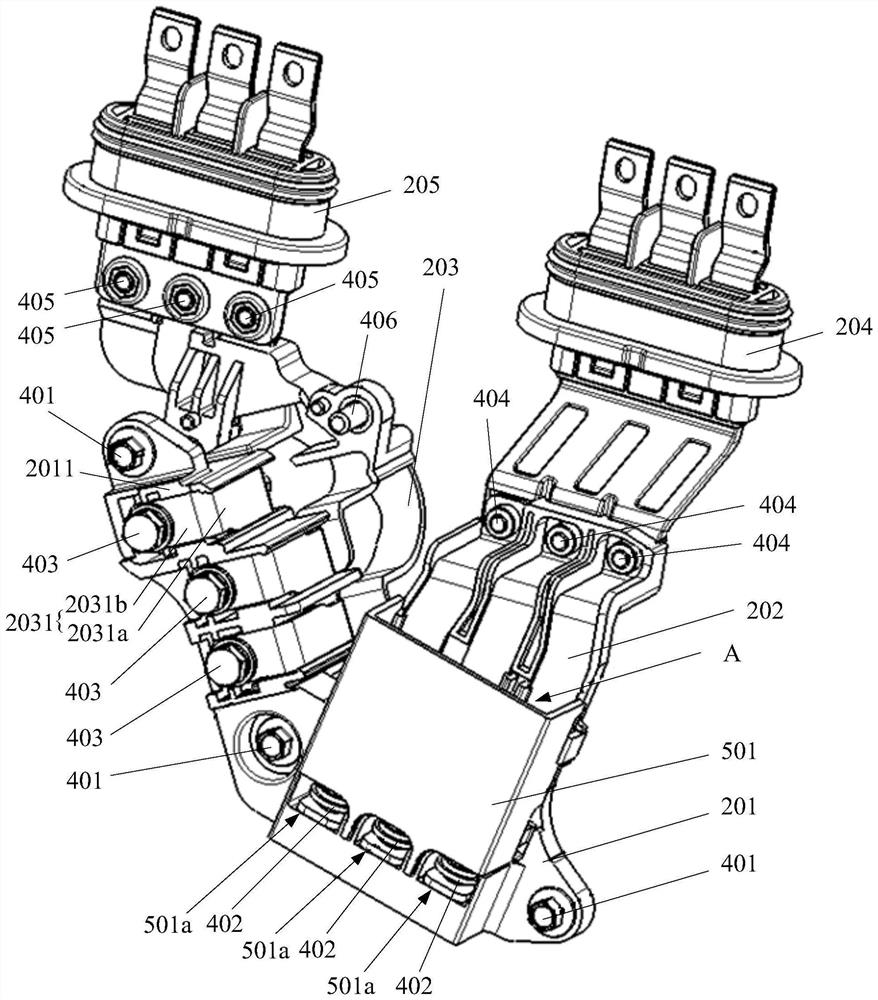

Motor systems for electric vehicles and electric vehicles

ActiveCN112248782BLow layout space requirementAvoid the problem of high layout space requirementsGearboxesElectric propulsion mountingBusbarElectric machinery

The present disclosure provides a motor system of an electric vehicle and an electric vehicle, belonging to the technical field of electric vehicles. The motor system includes a power assembly, a connection assembly and a motor controller; the connection assembly includes a terminal block, a first three-phase copper busbar, a second three-phase copper busbar, a first three-phase connector, and a second three-phase connector; the terminal block It is connected with the inner wall of the casing of the transmission; one end of the first three-phase copper bar is fixed on the wiring seat, and the other end is connected with the first three-phase connector; one end of the second three-phase copper bar is fixed on the wiring seat, and the other end is connected to the wiring seat. The second three-phase connector is connected; the motor controller is located outside the casing of the transmission and is connected with the first three-phase connector and the second three-phase connector. Copper bars and connectors have low cost, simple structure and small volume, and are easy to fix. They require less space for the layout of the front cabin of the vehicle, avoiding the high cost and occupying a large space caused by the use of three-phase high-voltage wiring harnesses to connect the motor controller and the motor. The problem of high requirements on the layout space of the front cabin of the whole vehicle.

Owner:CHERY AUTOMOBILE CO LTD

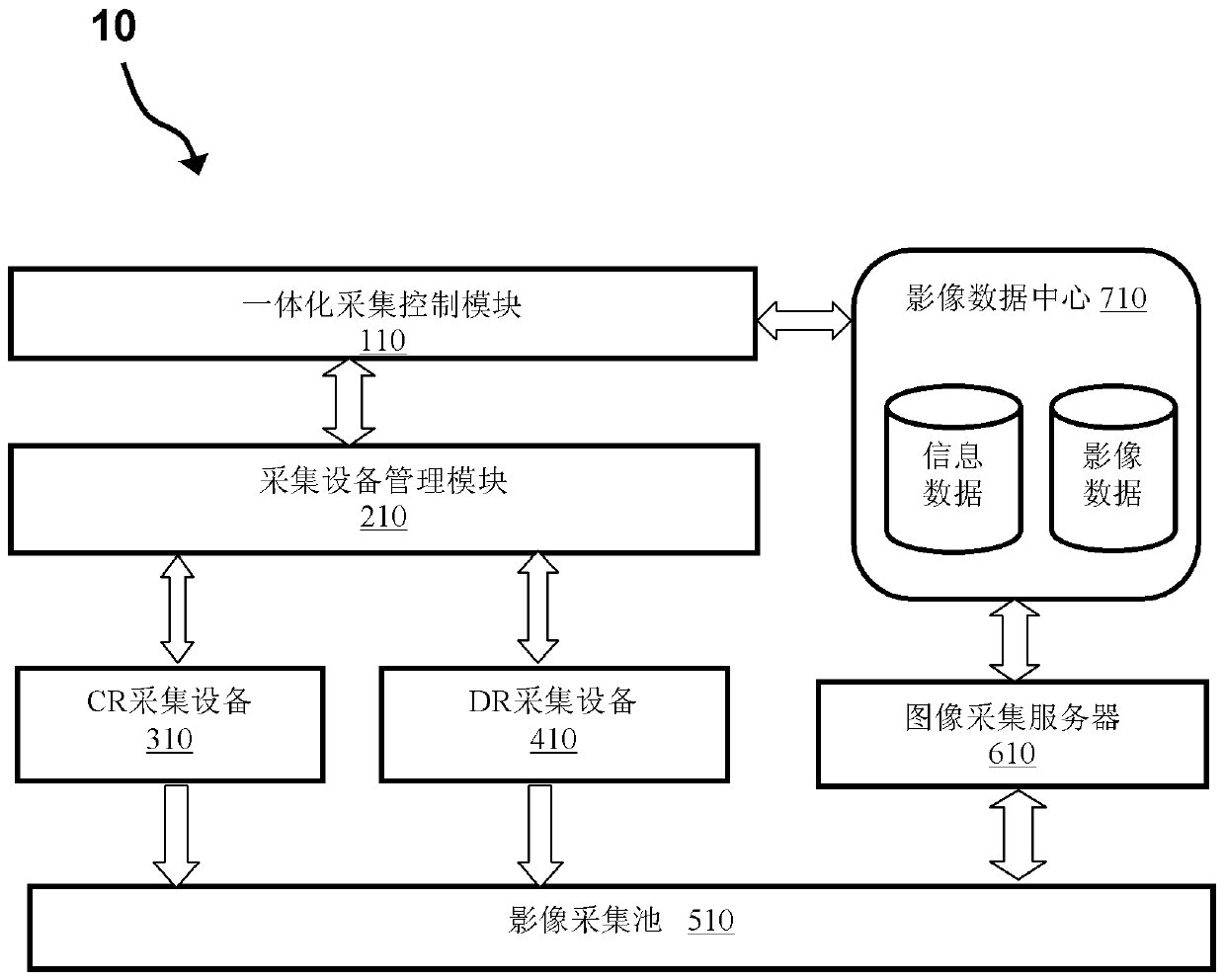

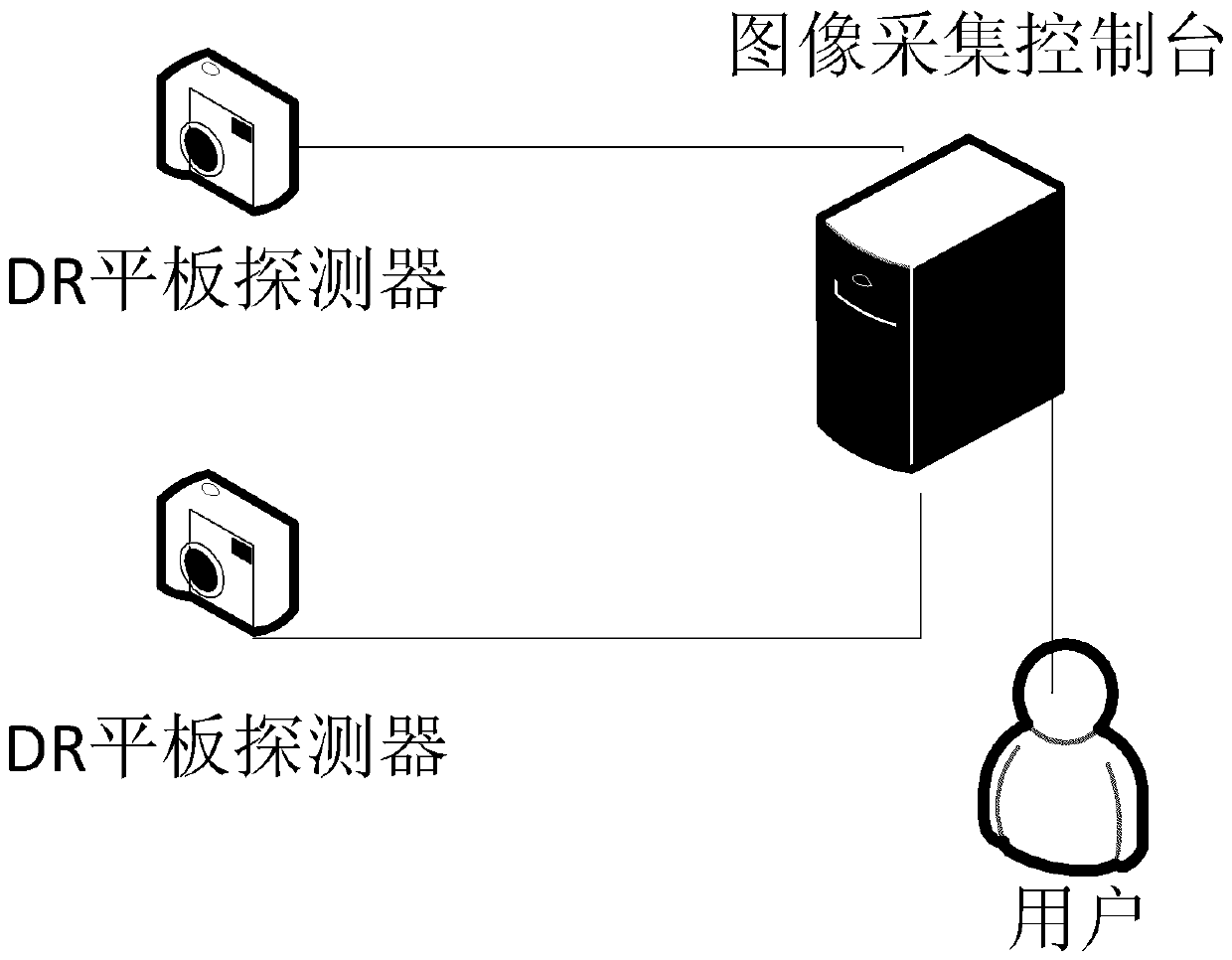

cr/dr image acquisition system, imaging control method and cr/dr system

ActiveCN104921739BEasy to operateEasy to learnRadiation diagnosticsDigital imagingAcquisition apparatus

The present invention provides a CR / DR image acquisition system, an imaging control method and a CR / DR system. The present invention relates to the technical field of digital imaging in medicine. The CR / DR imaging acquisition system includes an acquisition device management module, an image acquisition pool, an image acquisition service module, and an integral acquisition control module, wherein the integral acquisition control module is configured to operationally allow the CR / DR image acquisition system to work simultaneously in DR mode and CR mode, and the integral acquisition control module is at least in communication connection to the acquisition device management module and an image data center. The CR / DR image acquisition system and the CR / DR system of the invention have the advantages of simple handling, low cost and high efficiency, and can improve user experience.

Owner:RAYCO SHANGHAI MEDICAL PROD

A stealth exhaust system

ActiveCN102926888BImprove adaptabilityImprove infrared stealth performancePower plant exhaust arrangementsJet propulsion plantsRadarAmbient air

The invention relates to an exhaust system applied to an air vehicle, in particular to a stealth exhaust system. A cross-section shape of a throat of a spray pipe is designed to a non-round shape with an aspect ratio greater than 1, so that mixing of high-temperature exhaust airflow of an engine and ambient air is strengthened, the exhaust temperature is reduced, and an infrared stealth property of the exhaust system is improved. Central lines of the stealth exhaust system are three longitudinal S-bent curves, and the bent central lines can enable sidewalls of the spray pipe to shield high-temperature components of the engine, therefore, the infrared stealth property of the exhaust system can be improved; and simultaneously, the bent central lines can also cause radar waves going into the stealth exhaust system from the rear to difficultly generate backward waves, therefore, a radar stealth property of the exhaust system can be improved. Properties of the exhaust system are considered while the stealth properties are ensured, so that a requirement of the stealth exhaust system on the layout space is reduced, and adaptability of the stealth exhaust system is strengthened.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

An adjustable fuel filler cover with an opening spring mechanism

ActiveCN112977051BMeet the functional needs of daily useEasy bending initial positionFuel supplyEngineeringStructural engineering

Owner:JIANGXI CHANGHE AUTO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com