Serpentine tube row, heat-exchanging device and layout method of serpentine tube row

A heat exchange device, serpentine tube technology, applied in heat exchange equipment, fixed tubular conduit components, heat exchanger types, etc., can solve the problems of small layout space requirements, poor heat transfer effect, designer obstacles, etc. The effect of reducing investment cost, saving layout space and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

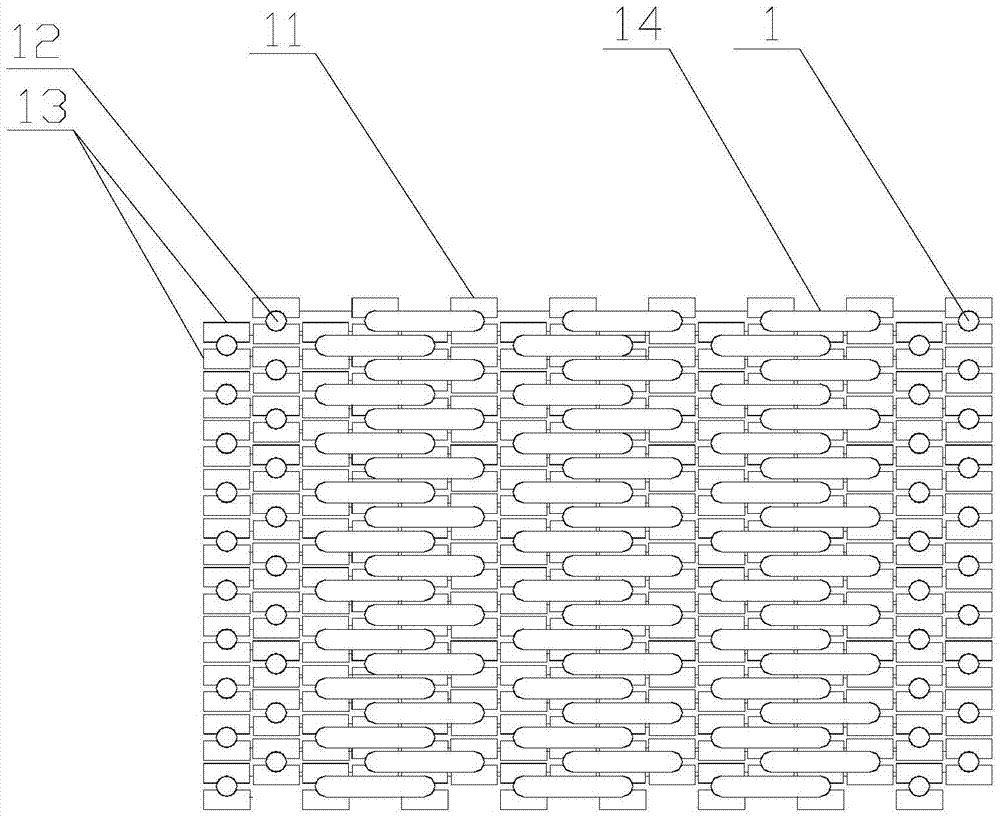

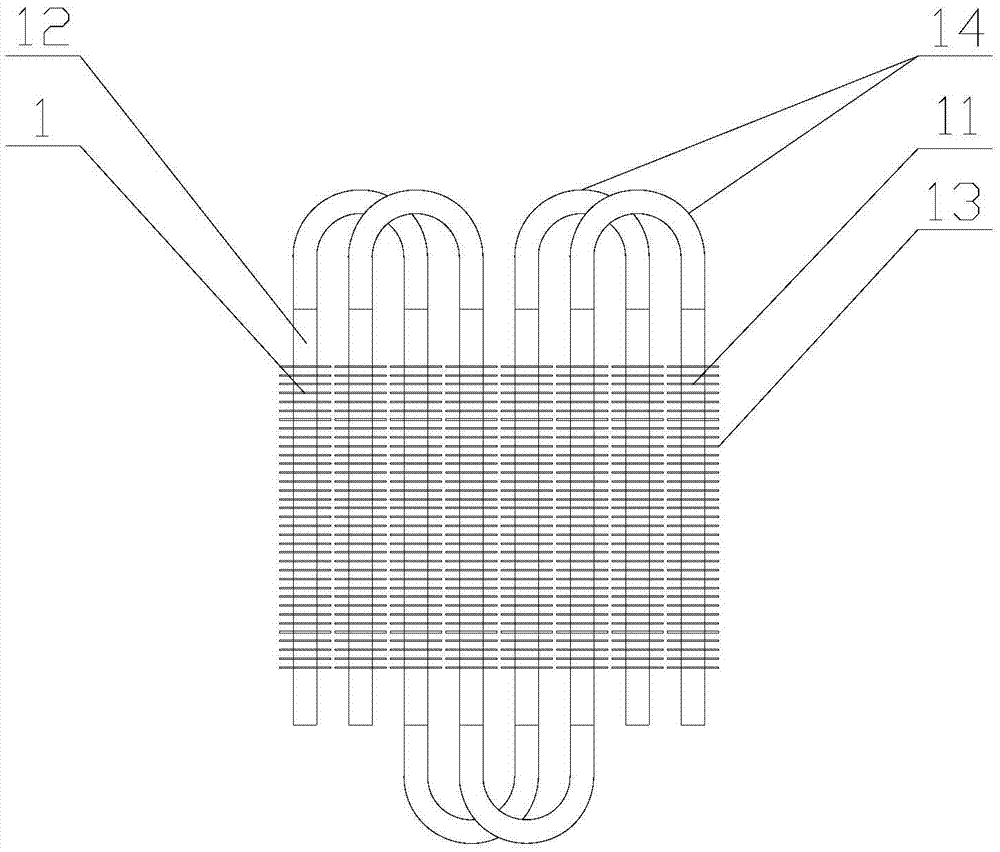

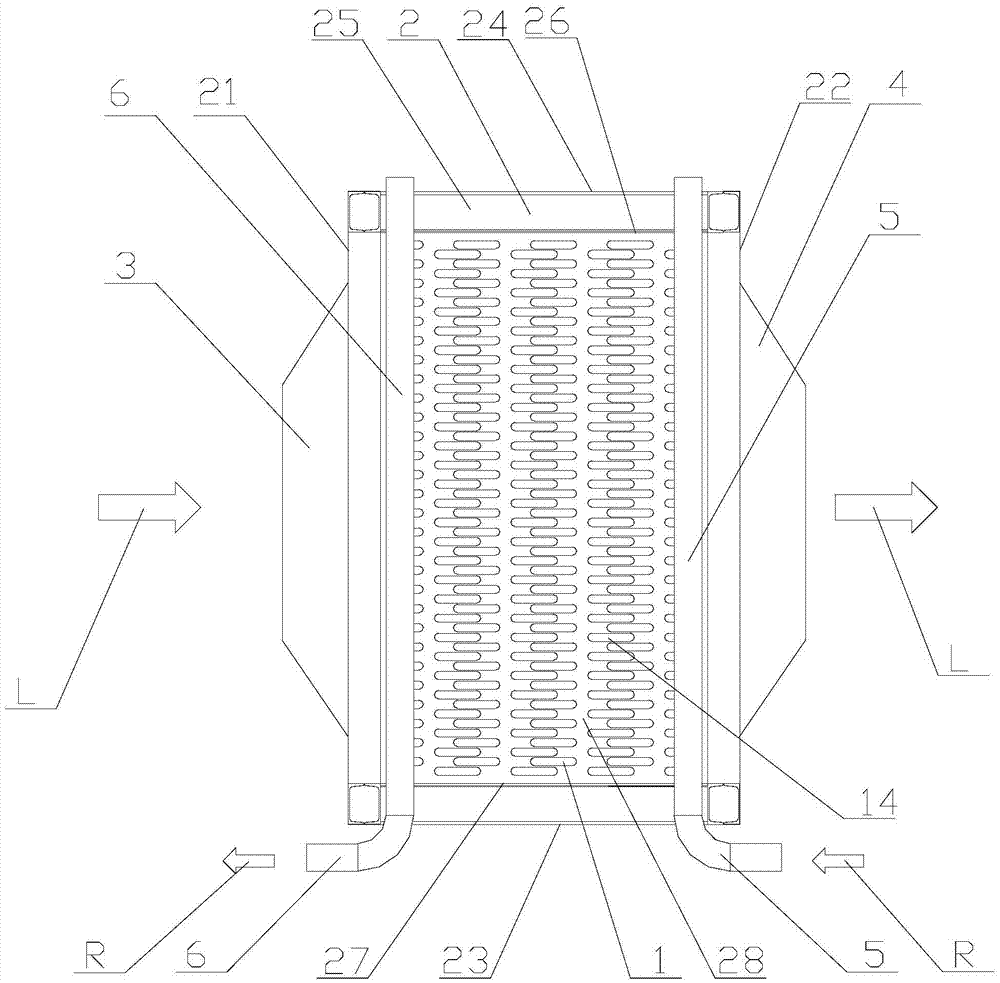

[0040] The present invention is a serpentine pipe row, such as figure 1 and figure 2 As shown, for heat exchange with the external fluid medium, the serpentine tube row includes several serpentine tubes 1; the serpentine tube 1 is composed of several finned tubes 11 connected end to end by several connecting elbows 14, and the fin The tube 11 includes a base tube 12 and fins 13; several serpentine tubes 1 are arranged parallel to each other along the radial direction of the base tube 12, and two adjacent base tubes 12 on the same serpentine tube 1 are arranged in a row .

[0041] Preferably, the fins 13 located in the same serpentine tube 1 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com