Ejection device for realizing SNCR (selective non-catalytic reduction) with CFB (circulating fluidized bed) furnace and using method

A spray device and spray gun technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of complex equipment, high investment and maintenance costs, low operation reliability, etc., and achieve good operation stability and smoke. Low air resistance and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

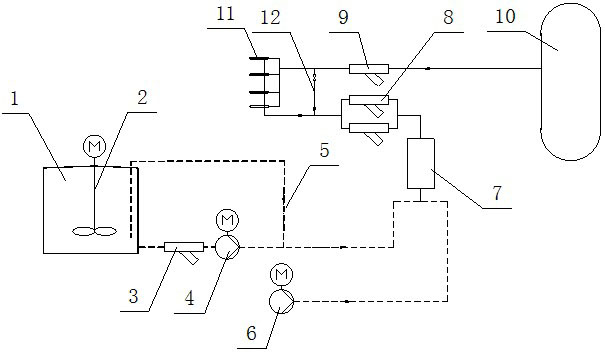

[0035] Such as figure 1 , 2 , shown in 3, a kind of injection device that is used for selective non-catalytic reduction denitrification, denitration agent selects urea for use, comprises the spray gun 11 that is provided with compressed air channel and urea solution channel, and the compressed air pipeline that communicates with spray gun 11 respectively and The urea solution pipeline, the urea solution pipeline includes the urea aqueous solution storage tank 1 (stores 40-50% mass concentration of urea aqueous solution, which is equipped with a stirrer 2), the first filter group 3 , urea solution pump 4, static mixer 7, second filter group 8, between urea solution pump 4 and static mixer 7, also be provided with a return pipeline 5 leading to urea aqueous solution storage tank 1, the inlet of static mixer 7 The end is also communicated with the dilution water pipeline provided with the dilution water pump 6. The compressed air pipeline includes a compressed air source, a com...

Embodiment 2

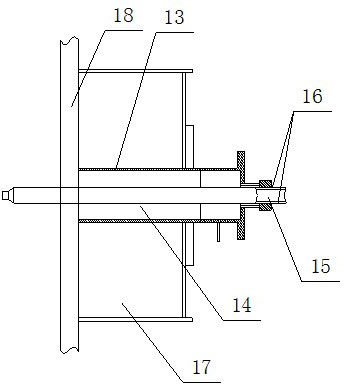

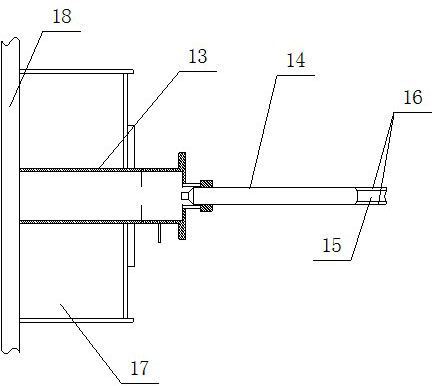

[0037] Such as Figure 4 , 5 As shown, a method for using the above spray device for denitrification, the spray gun is arranged at the entrance of the cyclone separator, the spray gun is inserted into the furnace 0.1m to spray, the particle size distribution of the liquid mist sprayed by the spray gun is 0-100 μm, and the average particle size is 50 μm , the concentration of denitration agent is controlled at 20%, the denitrification efficiency is 60%, and the NOx emission is 65mg / Nm 3 (6%O 2 ).

Embodiment 3

[0039] Such as Figure 4 , 5 As shown, a method for using the above-mentioned spray device for denitrification, the spray gun is arranged at the entrance of the cyclone separator, the spray gun is inserted into the furnace for 0.2m spraying, the particle size distribution of the liquid mist sprayed by the spray gun is 0-100 μm, and the average particle size is 45 μm , the concentration of denitration agent is controlled at 15%, the denitrification efficiency is 70%, and the NOx emission is 45mg / Nm 3 (6%O 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com