Aircraft engine system and design method for fan section mechanical interface thereof

A technology of aircraft engine and design method, which is applied to the arrangement/installation of power units, aircraft parts, and power units on aircraft, which can solve problems such as increased hanging weight, heavy firewall structure weight, and high space requirements, and achieve simplified layout , the effect of reducing weight and reducing structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

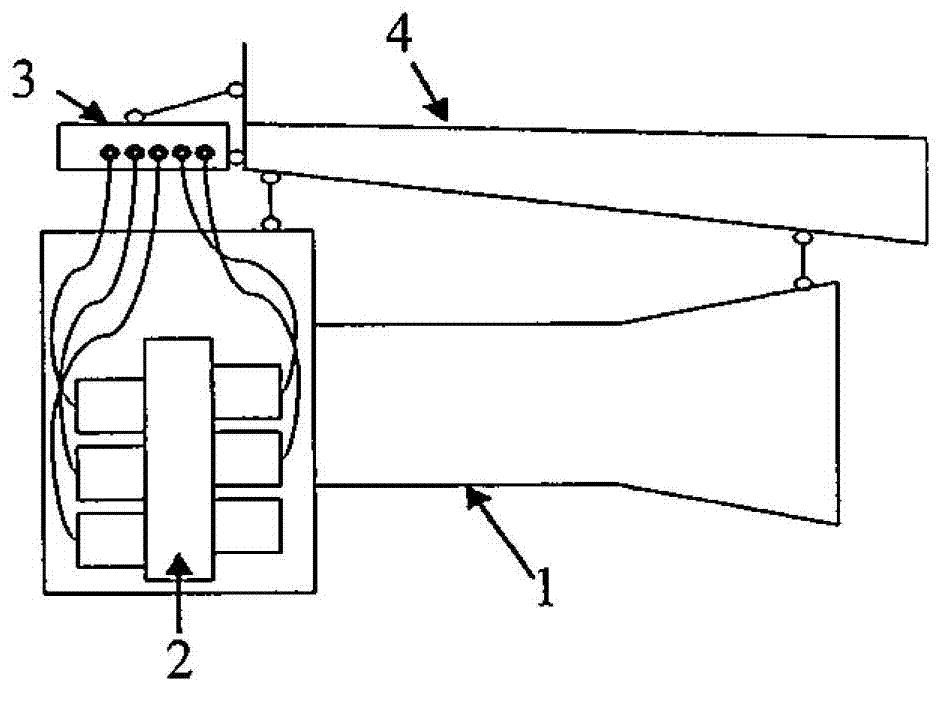

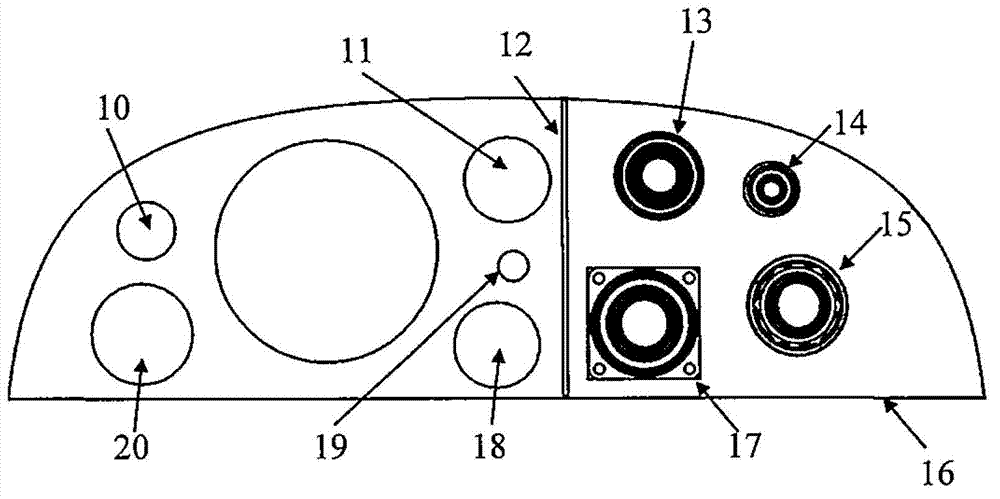

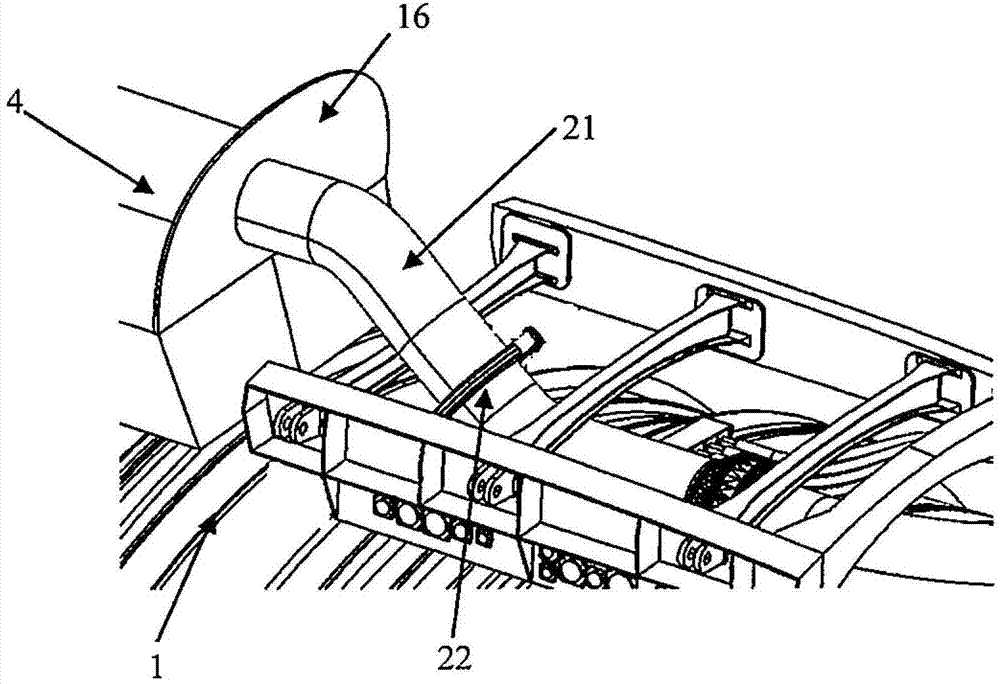

[0029] The aircraft engine system according to the present invention includes a hanger 4 and an engine 1, the hanger 4 has a bracket, and the engine 1 has a fan area as a fire area and a non-fire area. The aircraft engine system also includes a vertical firewall 16, which isolates the fan area of the engine from the hanger located in the non-fire area. The distance is less than 100mm, and the outer contour of the firewall corresponds to the outer contour of the suspension. Among them, the interfaces of hydraulic pipes, fuel pipes and fire extinguishing pipes of the aircraft engine system and the wall-penetrating seals of power supply cables and signal harnesses are arranged on the vertical firewall 16 .

[0030] The design method of mechanical interface according to the present invention comprises the following steps:

[0031] (1). Determine the position of the vertical firewall 16 on the bracket of the suspension 4, so that the distance from the vertical firewall 16 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com