An adjustable fuel filler cover with an opening spring mechanism

An adjustable fuel filler cap, which is applied to the layout combined with the fuel supply of internal combustion engines, power plants, vehicle components, etc., can solve problems such as inconsistent opening angles of fuel filler caps, and achieve low layout space requirements, firm fixation, and space-saving Occupy small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

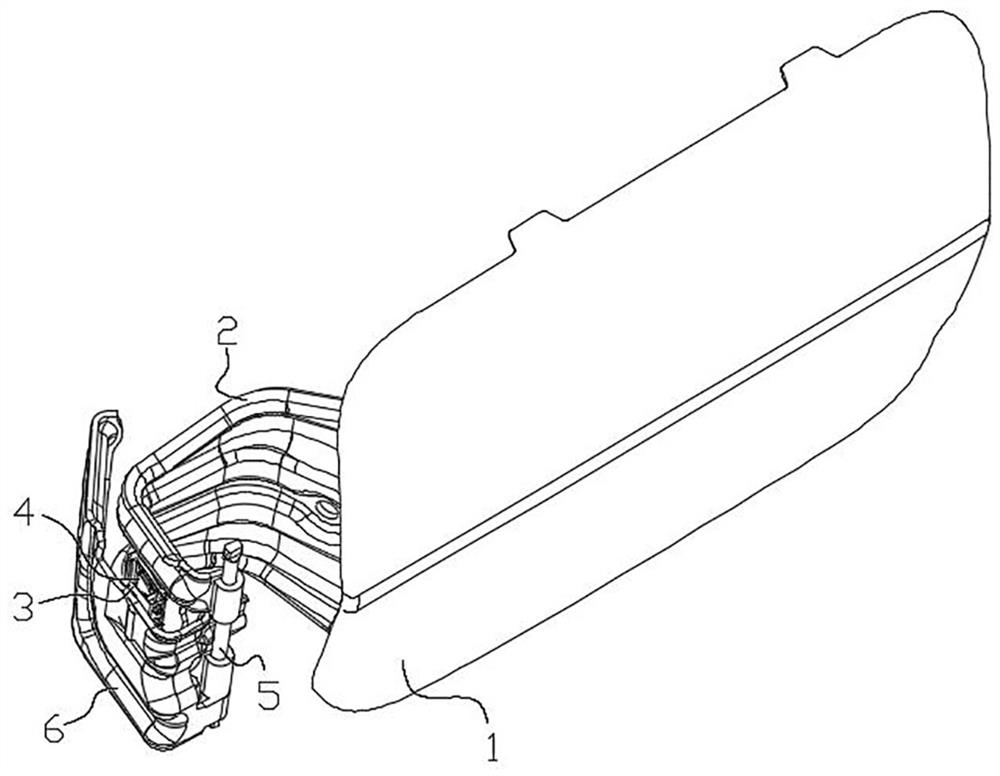

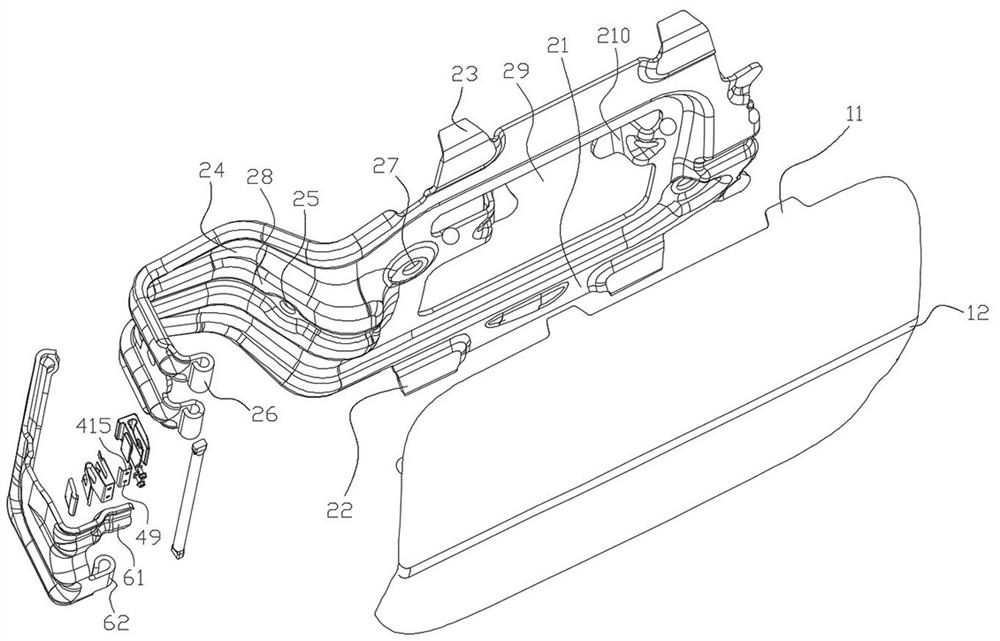

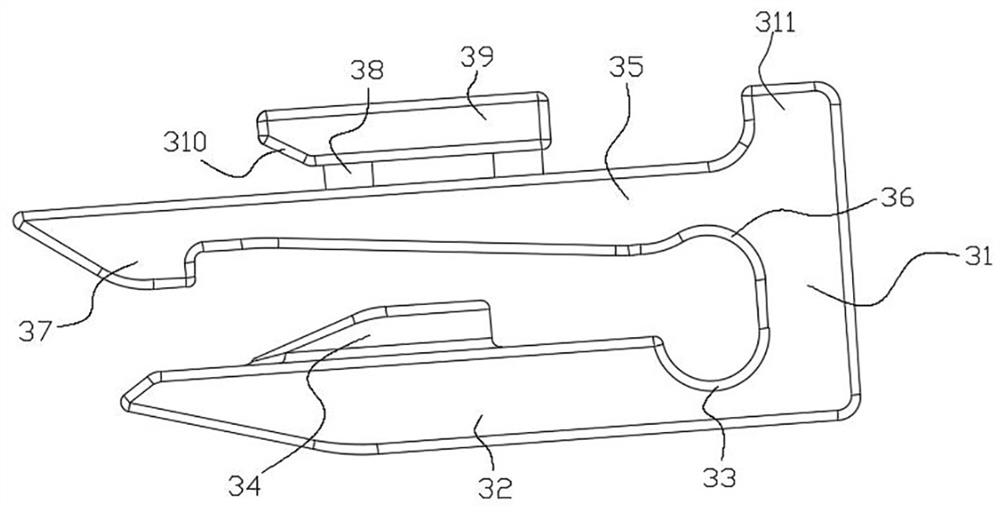

[0020] Such as Figure 1-6 An adjustable fuel filler cover with an opening spring mechanism is shown, which includes a cover outer plate 1 and a cover inner plate 2, and is characterized in that an opening spring plastic seat 3 is fixedly connected to the cover inner plate 2 , the opening spring plastic seat 3 is clamped with a cover plate opening shrapnel 4, such as Figure 5 As shown, the two second clamping plates 46 on the cover opening elastic piece 4 are attached to the end of the upper surface of the second mounting plate 35 away from the first connecting portion 31, so that the two second clamping plates 46 are respectively located on both sides of the connecting column 38 and Advance to the third limit protrusion 311 side, when the clip feet 47 on the two second clips 46 contact with the first clip 39, the clip feet 47 are deformed under the guidanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com