Efficient sand temperature adjuster with grading function

A regulator and high-efficiency technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the problems of large size, low heat exchange efficiency, short operating life, etc., to achieve equipment Low layout space requirements, simplified treatment process, efficient and uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

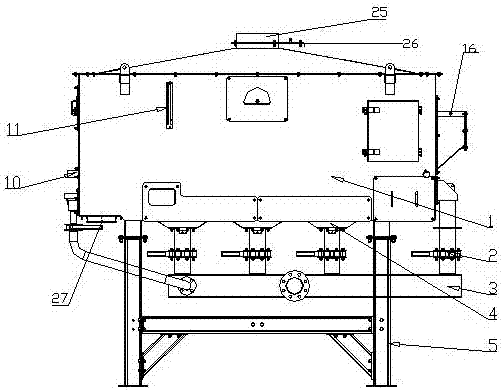

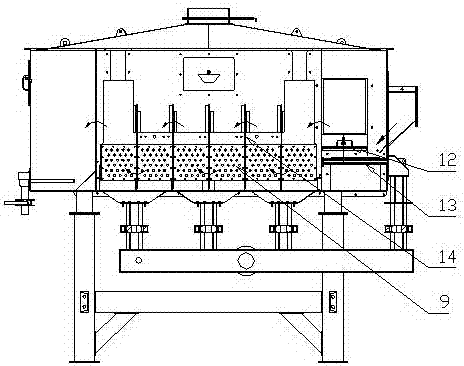

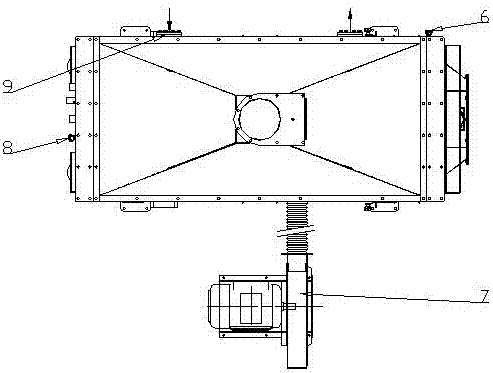

[0030] Refer to attached Figure 1-6 The shown high-efficiency sand temperature regulator with grading function includes a body 1 and a cooling unit tube bundle 9 installed inside the body 1. The cooling unit tube bundle 9 is provided with a cooling water inlet and a cooling water outlet. Described body 1 is installed on the support tripod 5,

[0031] The feed end on one side of the body 1 is provided with a quantitative feeder, and the inside of the body 1 is provided with a spray air pipe 13, and the spray air pipe 13 is close to the feed end of the body 1, and the spray air pipe 13 13 is provided with a feed sieve plate 12, a transition feed portion is formed between the feed sieve plate 12 and the spray gas pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com