Patents

Literature

32results about How to "Increase cost rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pleurotus eryngii culture material and preparation method thereof

InactiveCN104108975AReduce drynessSave the link of adding waterFertilizer mixturesAlkali soilBiological property

The invention relates to a method for utilizing fresh triarrherca sacchariflora and hybridized pennisetum alopecuroides for greenhouse cultivation of pleurotus eryngii, and the method belongs to a cultivation method for edible fungi in fungus production. The pleurotus eryngii culture material employs two kinds of fungus grass such as triarrherca sacchariflora and hybridized pennisetum alopecuroides, and auxiliary materials such as wheat bran, cob, lime and brown sugar, and five formulas are employed for greenhouse cultivation of pleurotus eryngii by using fresh fungus grass. Based on the biological characteristics of pleurotus eryngii, according to the principle of fully utilizing local resource, high-quality triarrherca sacchariflora and hybridized pennisetum alopecuroides grown in Tianjin area are selected as raw materials, and a scientific cultivation technology is utilized for cultivation of pleurotus eryngii. By taking fresh triarrherca sacchariflora and hybridized pennisetum alopecuroides as the main raw materials for greenhouse cultivation of pleurotus eryngii, the technical scheme has the advantages of large output, good quality, low cost, sufficient utilization of local saline-alkali soil, simple production technology and sustainable development.

Owner:杨士春

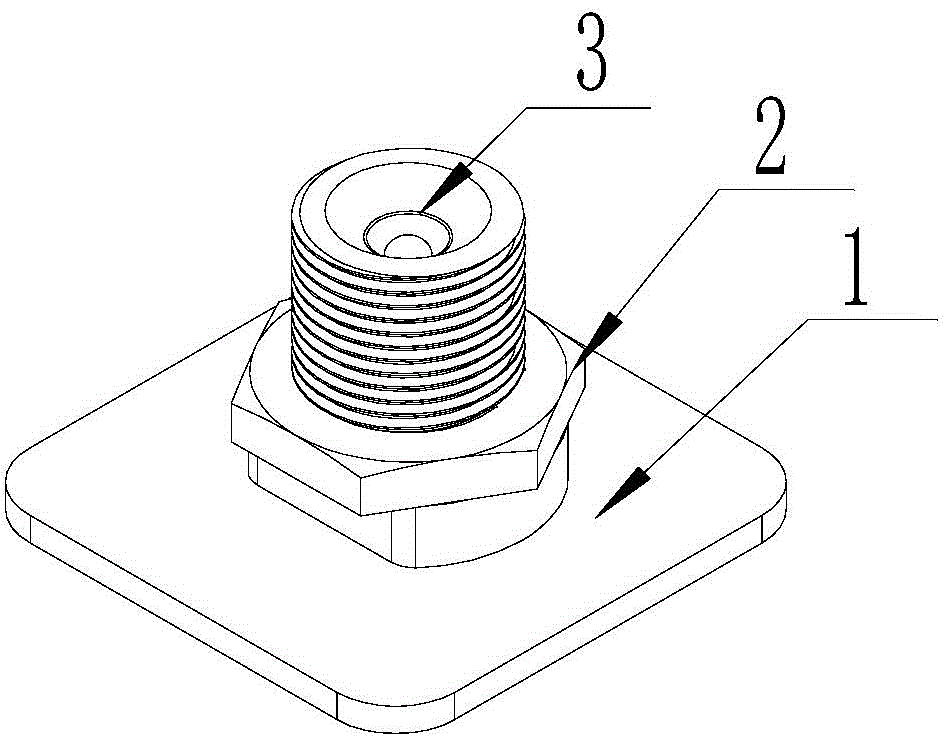

Liquid injection explosion-proof pole structure of cylindrical power battery

InactiveCN104466077ASimple structureImprove overcurrent capabilityCell sealing materialsPower batteryEngineering

The invention provides a liquid injection explosion-proof pole structure of a cylindrical power battery. The liquid injection explosion-proof pole structure comprises a pole, a pole nut and a safety valve plate, wherein the pole comprises a connection plate and a pole body, the connection plate is provided with the pole body, the pole body is provided with a pole thread, the pole thread on the pole body is matched with the pole nut, a battery cover plate is arranged between the connection plate and the pole nut, the pole nut is cooperated with the pole thread to fix the pole and the battery cover plate under the effect of given pre-tightening force, a liquid injection through hole and a welding step are formed in the pole body, the welding step is arranged on the upper end of the injection liquid through hole, the welding step is connected with the safety valve plate into a whole in a welding manner, the connection plate is connected with a tab inside a battery, and the pole nut is connected with an external conducting wire. The liquid injection hole is integrated with an explosion-proof valve, so that a liquid injection function and an explosion-proof function can be realized by virtue of the form of the pole, the battery structure is simplified, the difficulty that the pole space of the power battery is small can be solved, the over-current capacity of the battery is improved, and the liquid injection efficiency is also improved.

Owner:TIANJIN SHENLU ENERGY

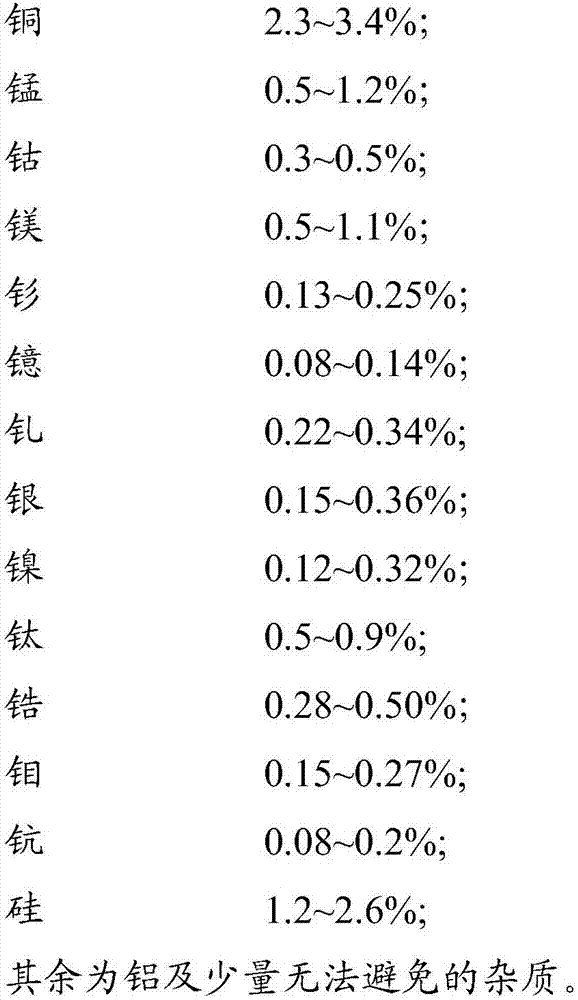

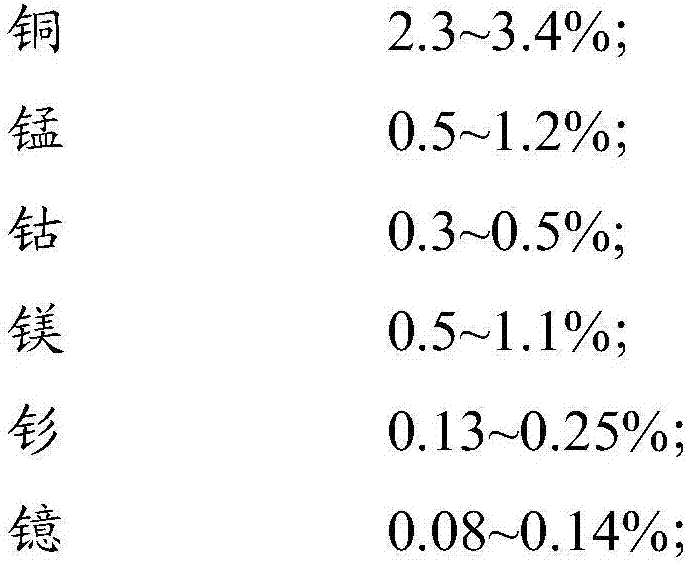

Antibacterial aluminum alloy material and preparation method thereof

The invention provides an antibacterial aluminum alloy material and a preparation method thereof. The antibacterial aluminum alloy material consists of the following components in percentage by weight: 2.3-3.4% of copper, 0.5-1.2% of manganese, 0.3-0.5% of cobalt, 0.5-1.1% of magnesium, 0.13-0.25% of samarium, 0.08-0.14% of ytterbium, 0.22-0.34% of gadolinium, 0.15-0.36% of silver, 0.12-0.32% of nickel, 0.5-0.9% of titanium, 0.28-0.50% of zirconium, 0.15-0.27% of molybdenum, 0.08-0.2% of scandium, 1.2-2.6% of silicon, and the balance aluminum and a few inevitable impurities. According to the antibacterial aluminum alloy material provided by the invention, samarium, ytterbium, gadolinium and silver are added into the aluminum alloy material, so that the antibacterial property of the aluminum alloy material is improved, and bacteria breeding is restrained; zirconium and molybdenum are added into the aluminum alloy material, so that strength and plasticity of the aluminum alloy material are improved; cobalt and scandium are added into the aluminum alloy material, so that casting cracks are effectively overcome, quality of aluminum alloy is improved, and the cost rate of the aluminum alloy product is increased. According to the experimental results, the antibacterial ratio of the aluminum alloy product is 99.999% or higher, hardness is 88 HAR or higher, strength is 552 MPa or higher, the elongation is 8.1% or higher, and a flow inspection qualification rate is 99% or higher.

Owner:合肥饰界金属制品有限公司

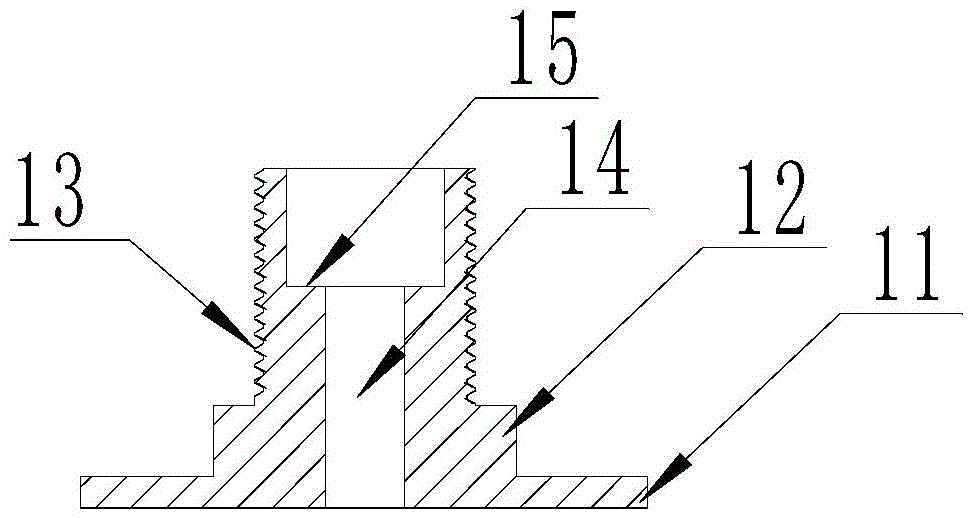

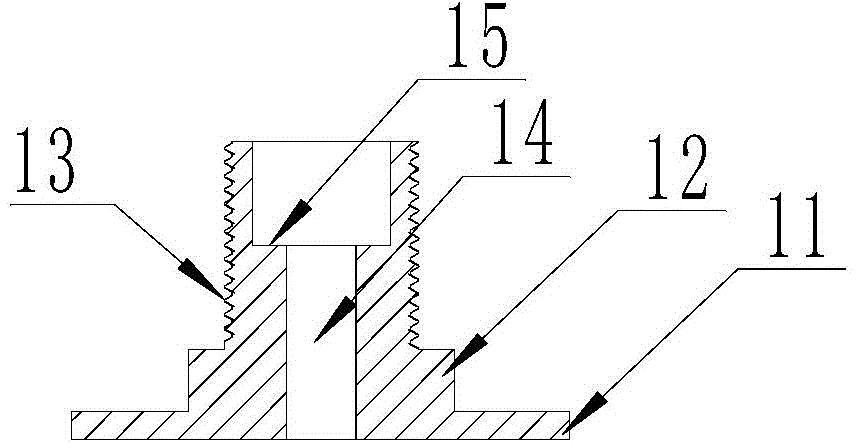

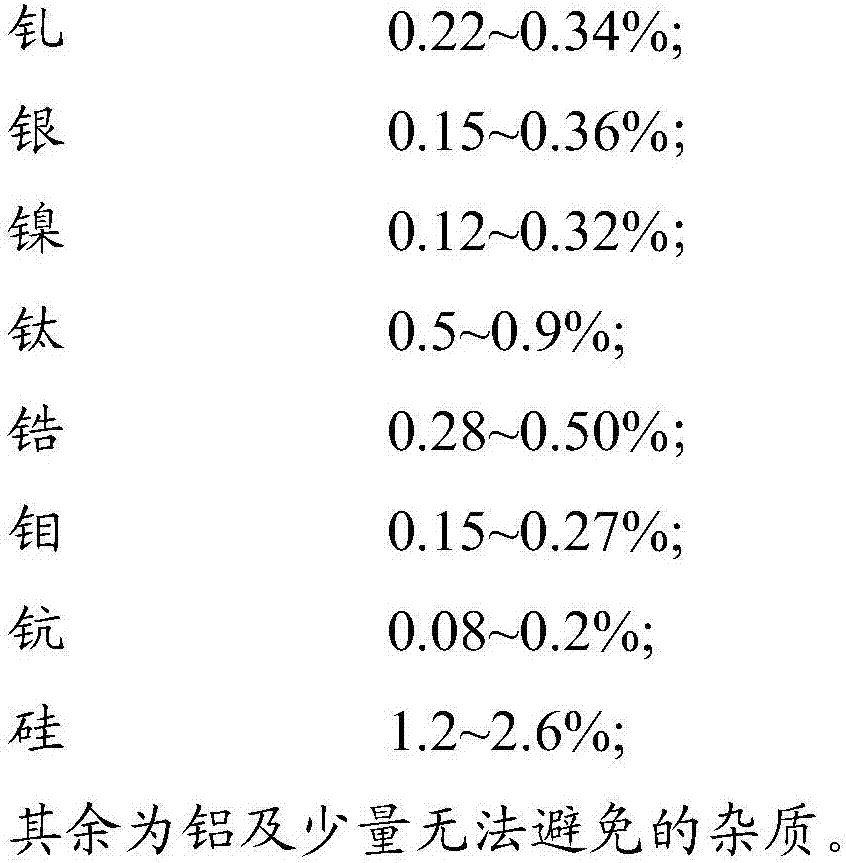

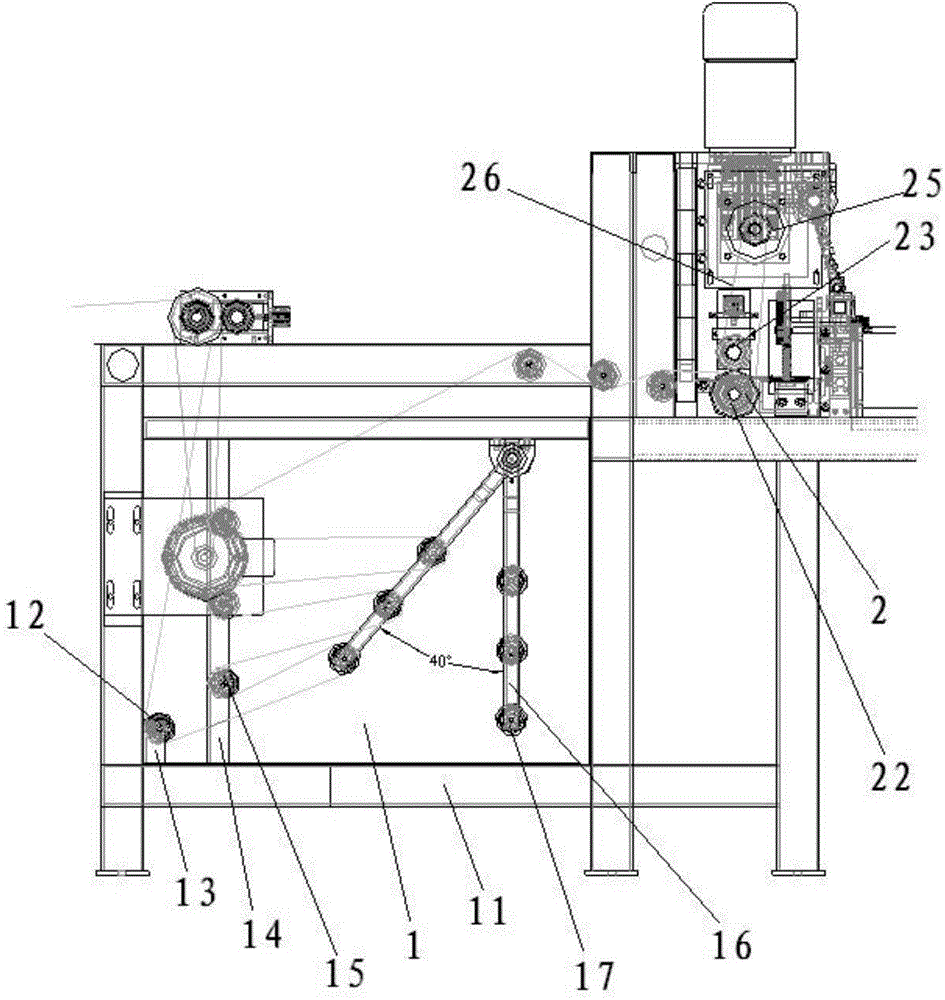

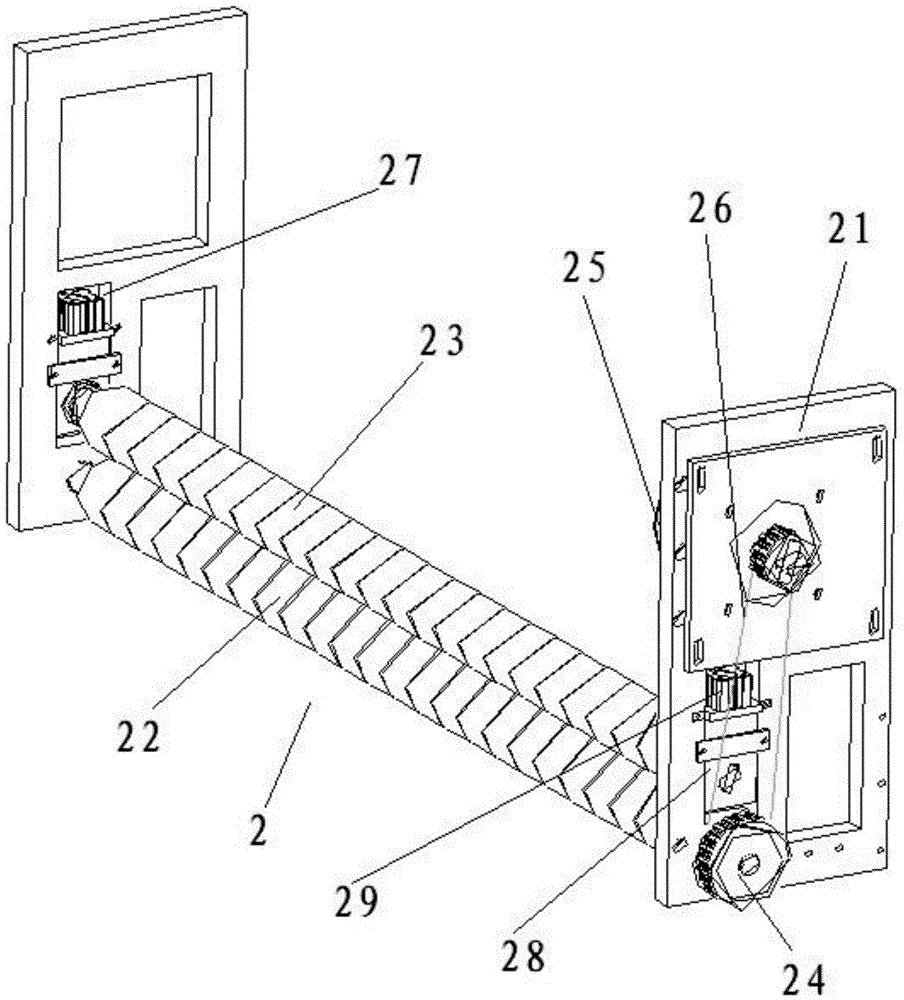

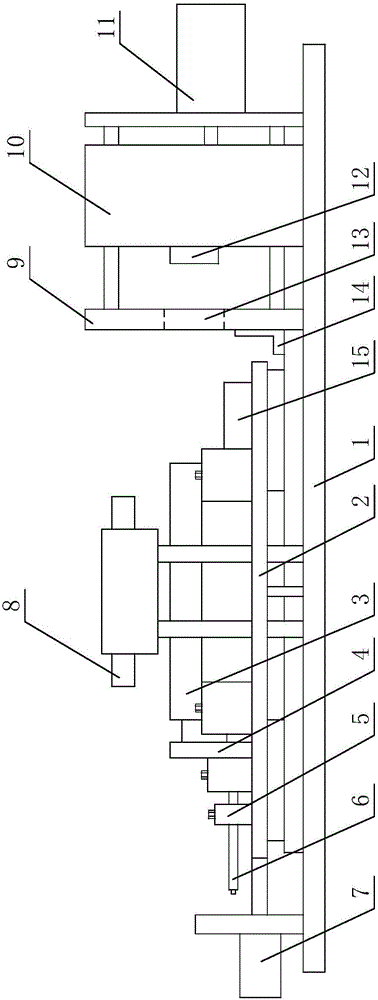

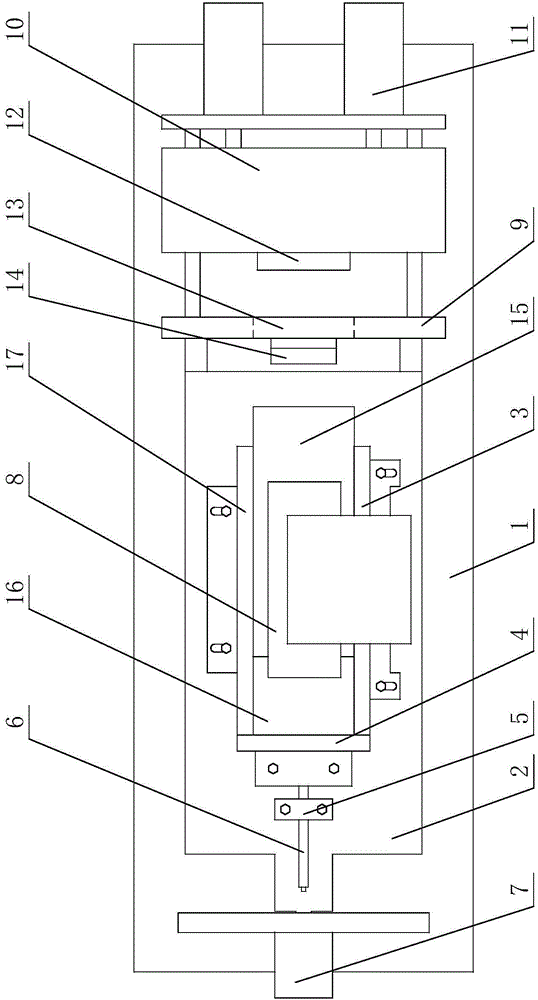

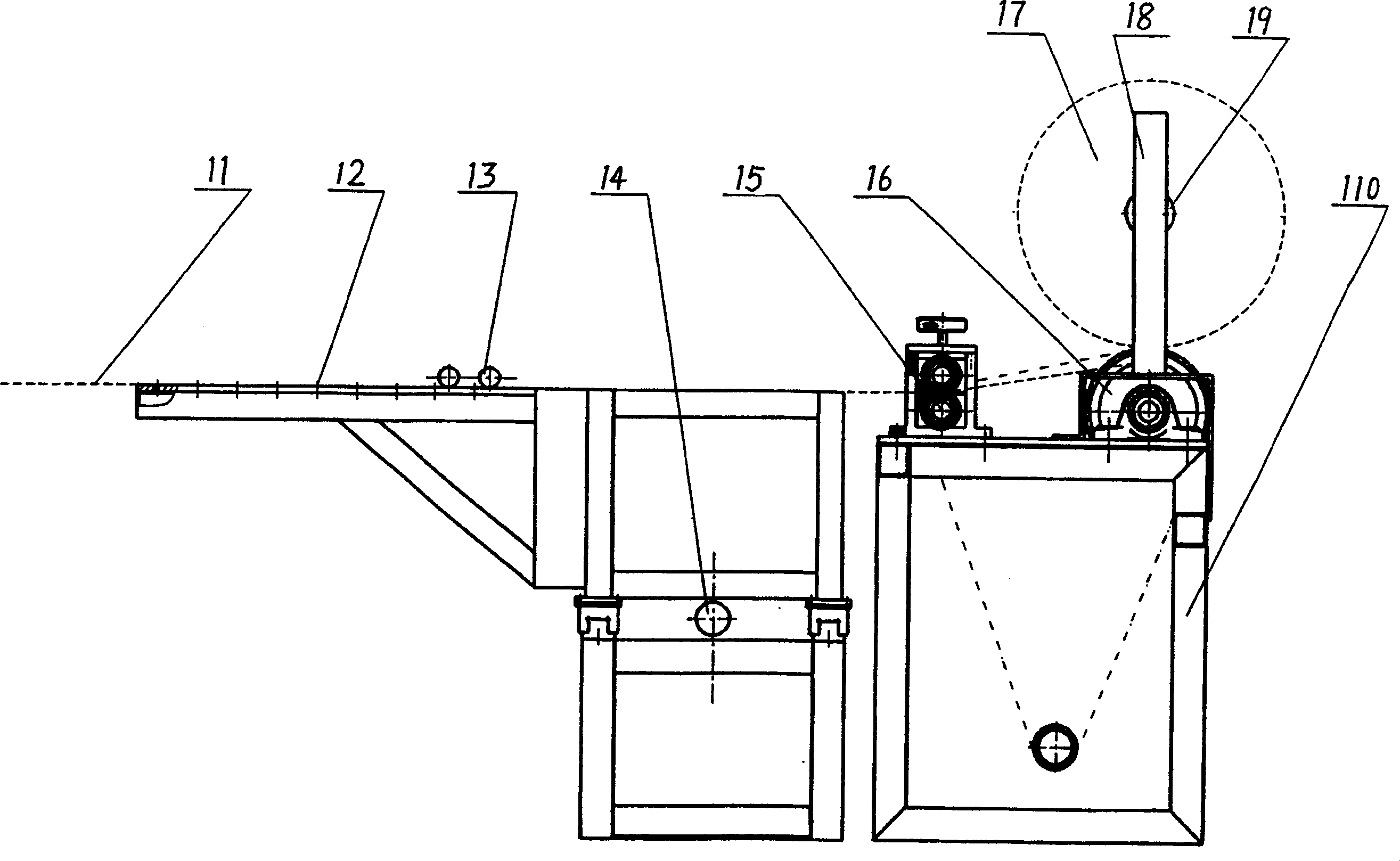

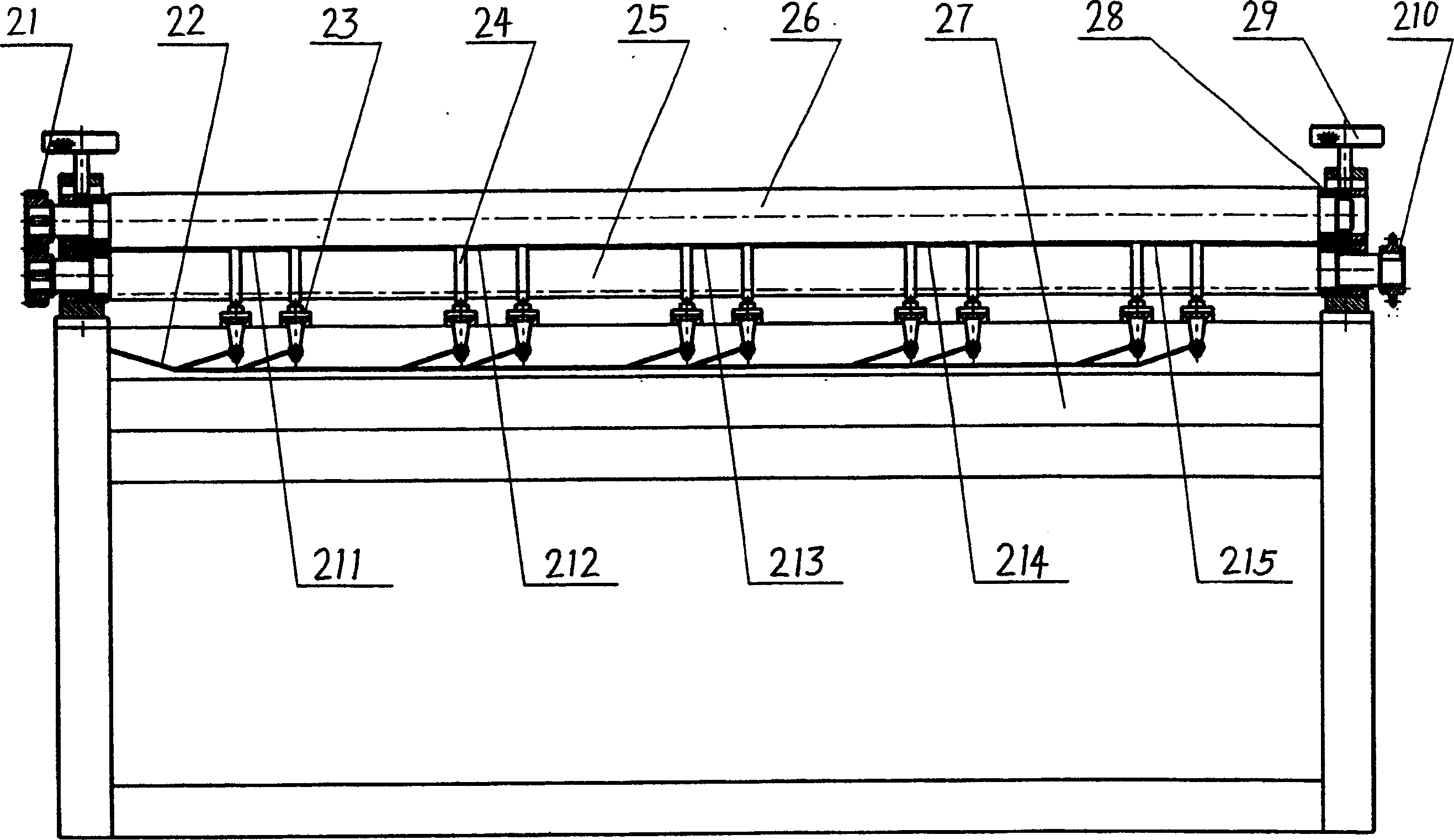

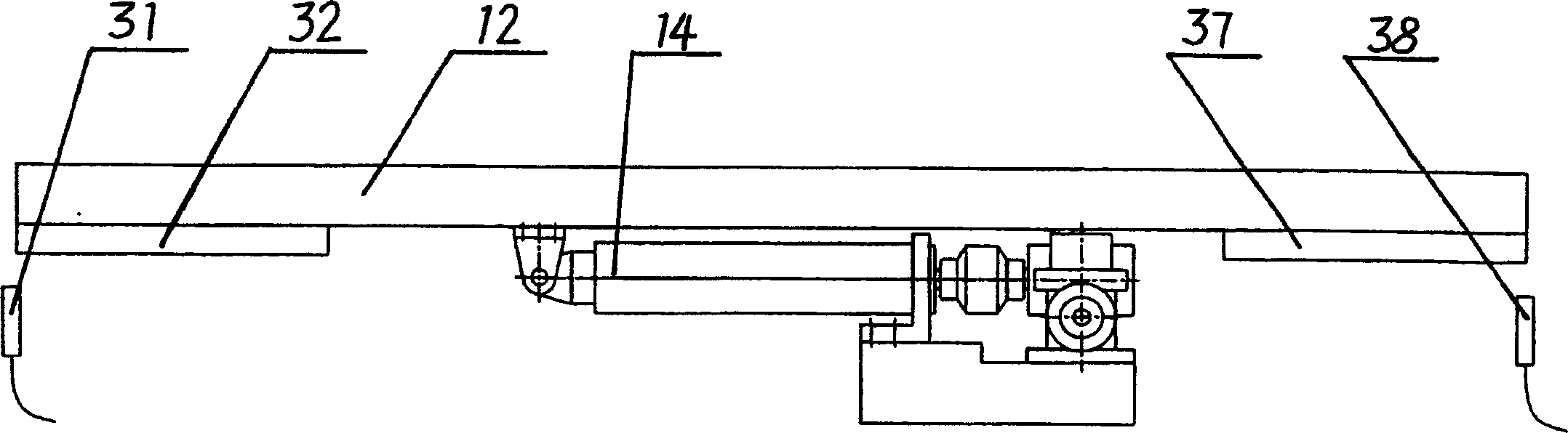

Material storing and cutting pulling device for automatic slitting machine

The invention discloses a material storing and cutting pulling device for an automatic slitting machine. The device is characterized by comprising a material storing device (1), and a cutting pulling device (2) positioned at the downstream of the material storing device (1); the material storing device (1) comprises a frame (11); a first vertical column (13) for fixing a first fixing roller (12) is arranged at the left side of the bottom end of the frame (11); a second vertical rod (14) for connecting the upper surface and the lower surface of the frame (11) is connected in parallel to the right side of the first vertical rod (13); a plurality of second fixing rollers (15) are arranged on the second vertical rod (14) from bottom to top in a sequence. According to the material storing and cutting pulling device for the automatic slitting machine, few parts are used, the structure is simple, the fault rate is low, the repair and maintenance are easy, and moreover, a combined film is free of damage due to being pulled, the quality is high, the pulling precision is high, the cost rate is high, and the device is suitable for wide popularization and application.

Owner:SUZHOU ACME MACHINERY

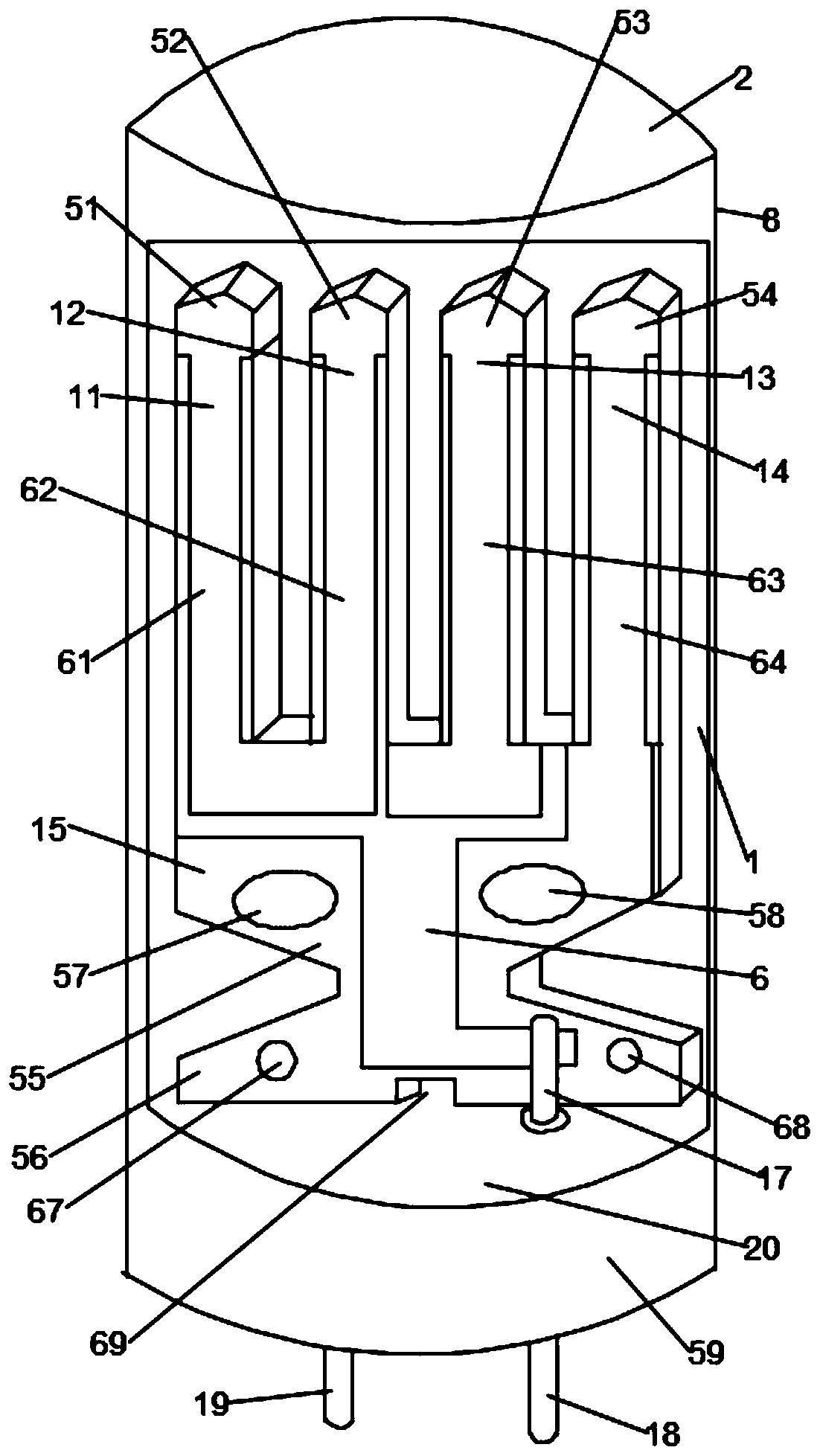

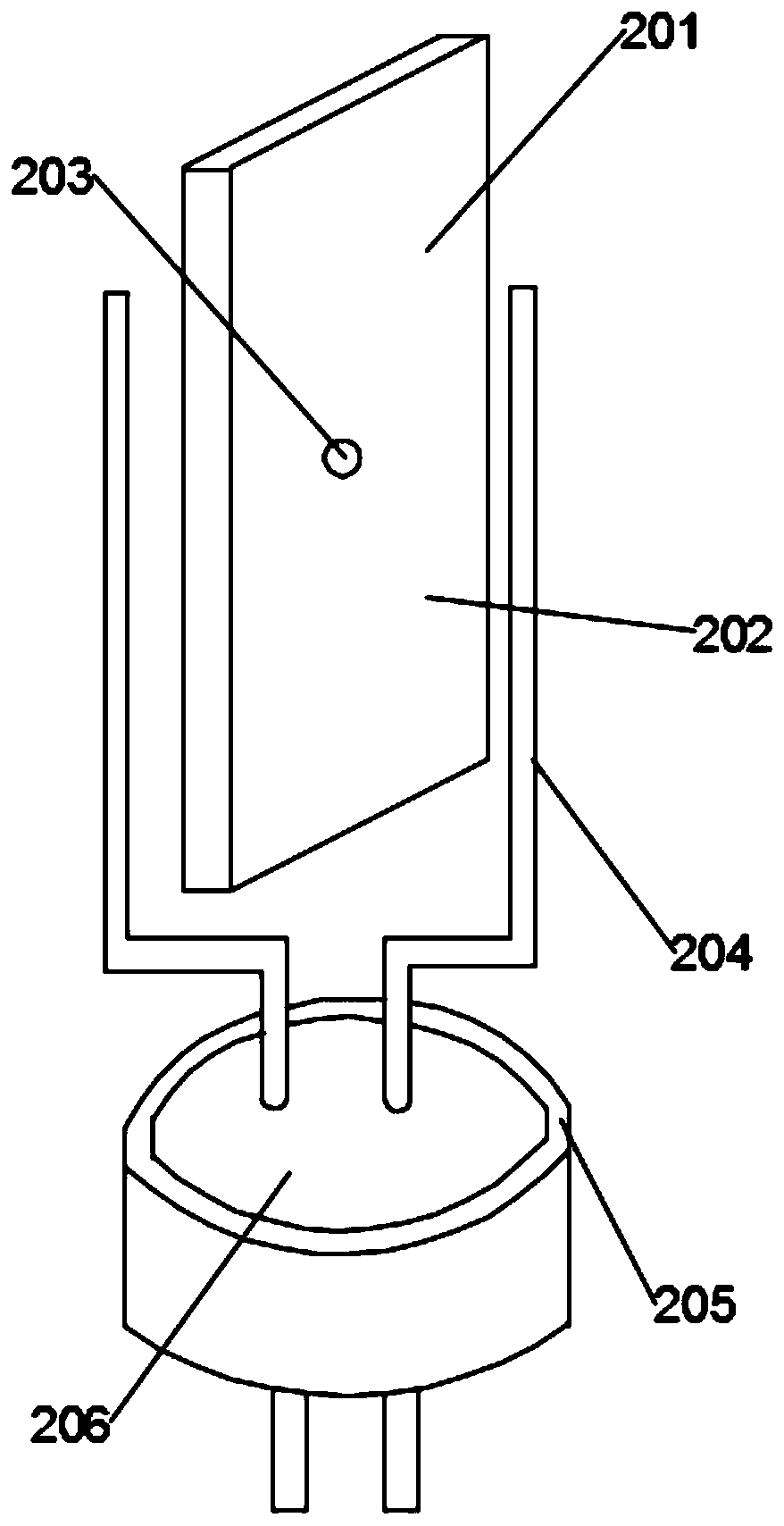

A high-precision resonant quartz temperature sensor with multiple arrow-shaped vibrating arms

ActiveCN109580030BIncentive strength is highReduce energy densityThermometers using electric/magnetic elementsUsing electrical meansInterference resistanceFrequency spectrum

Owner:哈尔滨华凡传感技术有限公司

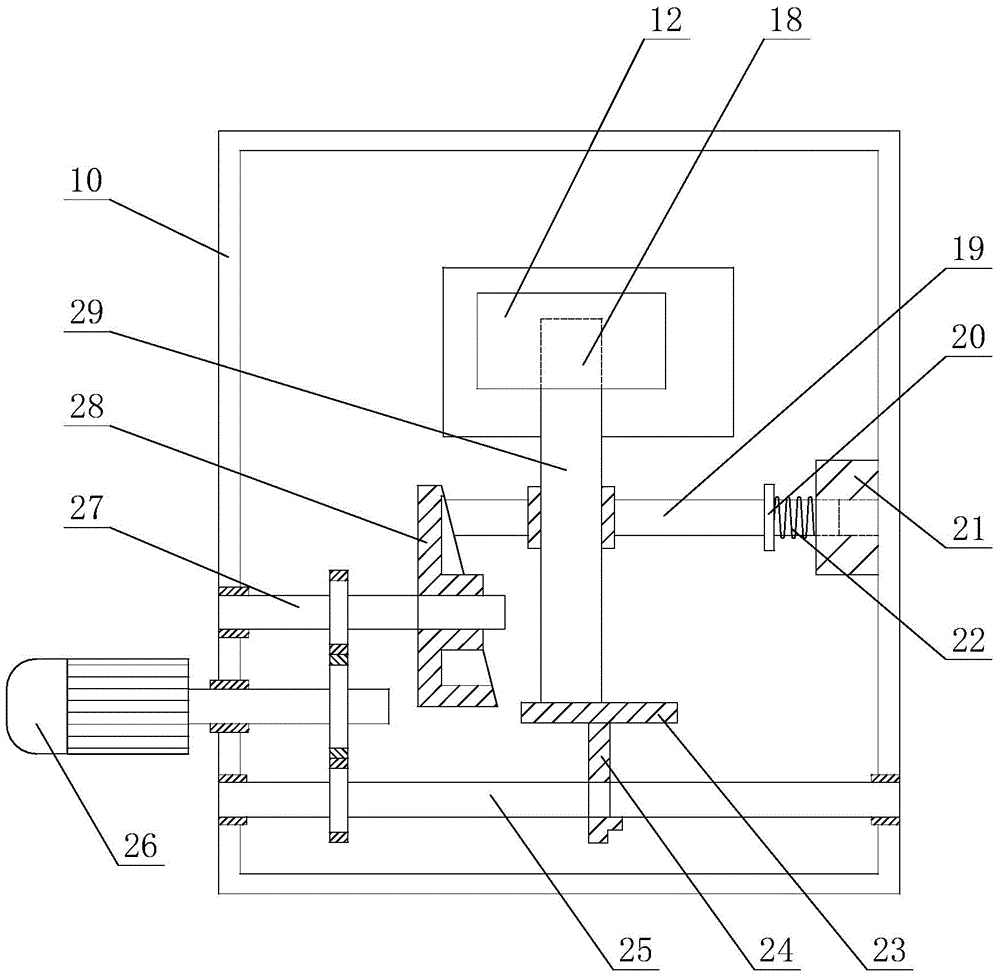

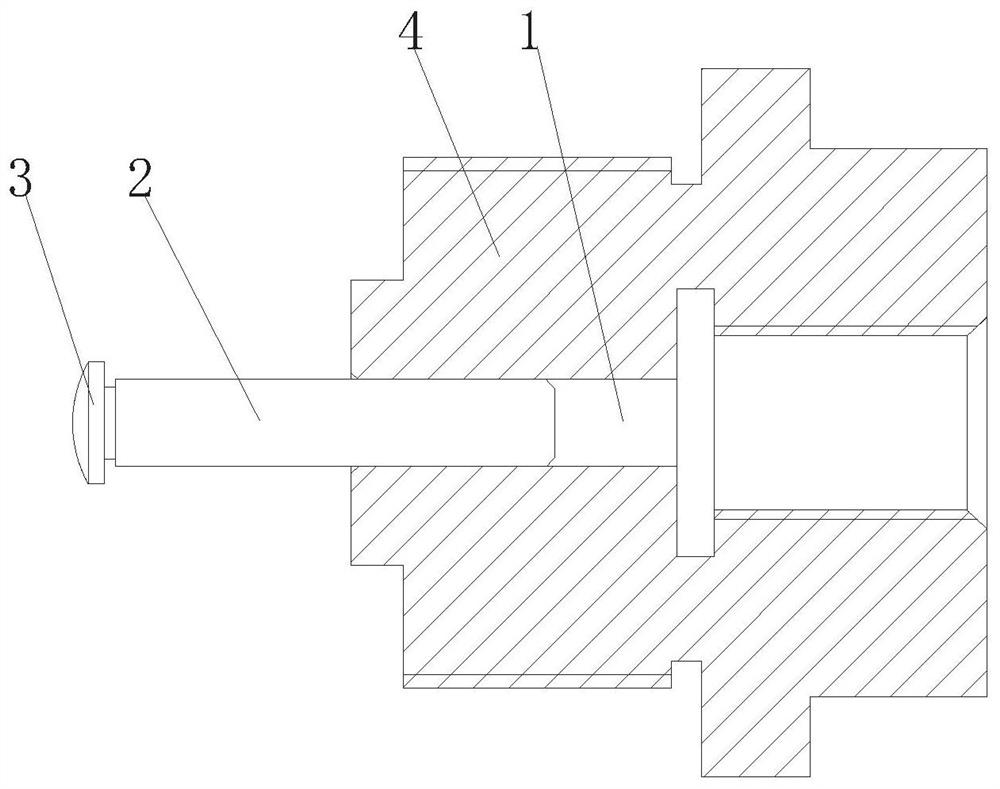

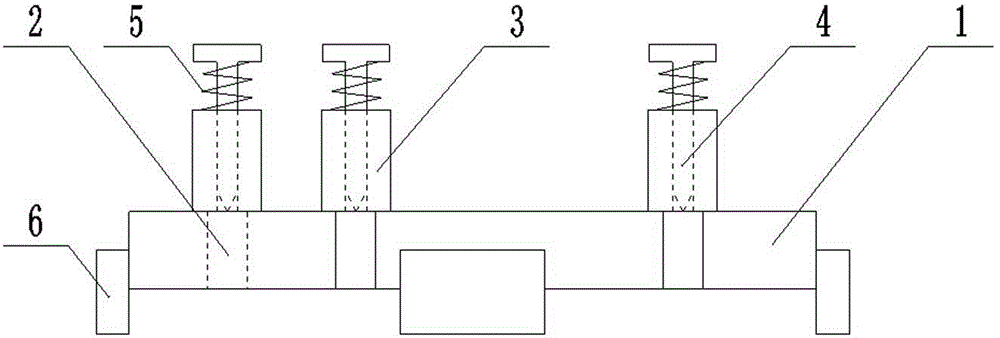

Cutting mechanism for battery case production

ActiveCN103531729BIncrease cost rateQuality improvementSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsTool bitElectrical battery

The invention discloses a cutting mechanism for battery case production, which comprises a bottom plate, a positioning mechanism is arranged at one end of the bottom plate, an outer cutter mechanism is arranged in the middle, and an inner cutter mechanism is arranged at the other end, the positioning mechanism includes a sliding The sliding seat on the bottom plate is provided with a notch for positioning the battery case. The upper end of the notch is provided with a pressing plate that can move up and down. The outer cutter mechanism includes an outer cutter plate fixed on the bottom plate. There is an outer knife edge that matches the outer contour of the battery case. The inner knife mechanism includes a base that is slidably set on the bottom plate. The base is provided with an inner knife head that is driven by a driving device to move along a rectangular trajectory. The inner knife head and the battery The inner contour of the shell matches. The inner cutter head of the present invention moves along a rectangular track, cooperates with the outer knife edge matching the outer contour of the battery case to cut the battery case, and the cut battery case has high cost rate and good quality.

Owner:无锡市金杨新材料股份有限公司

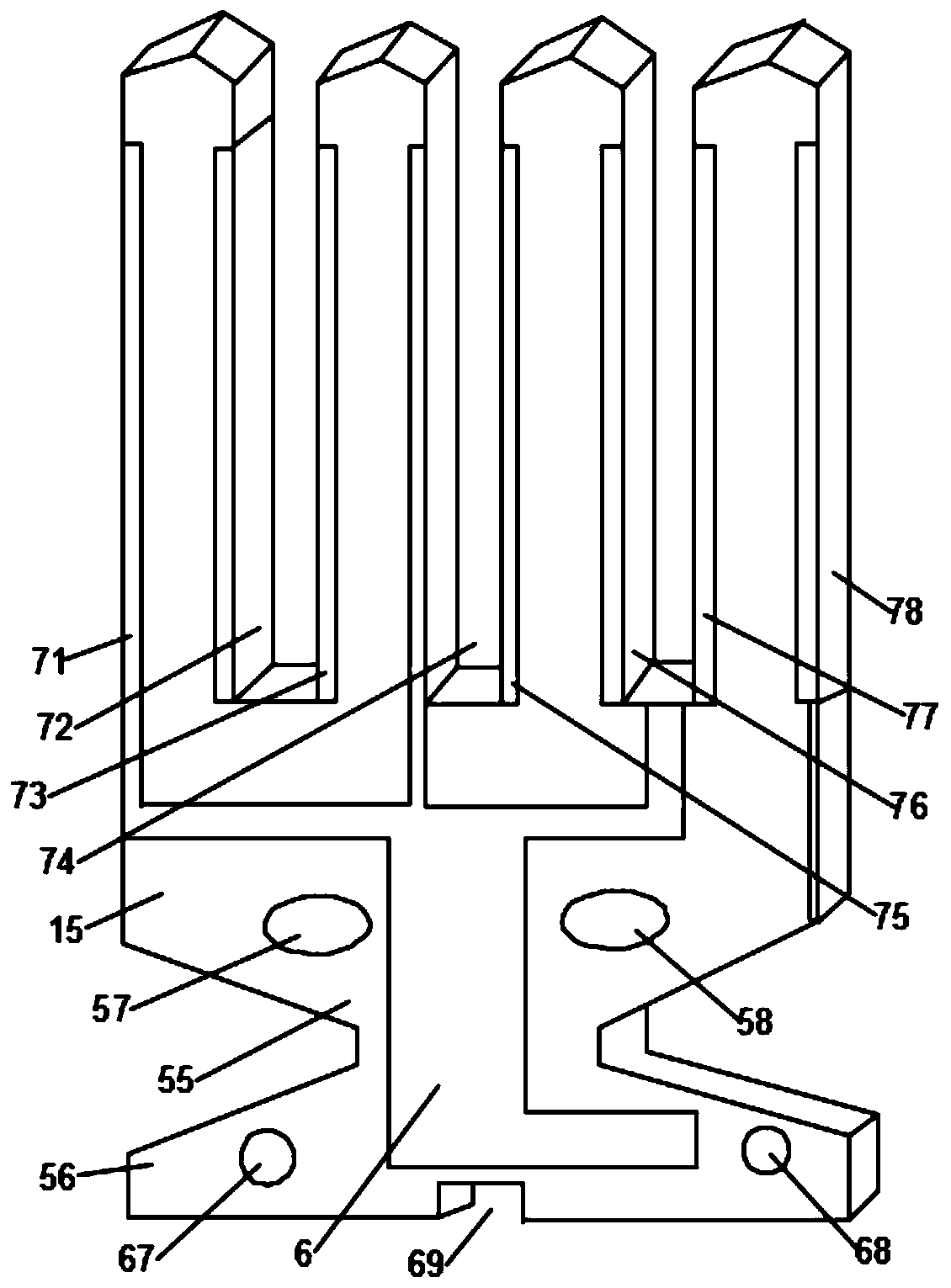

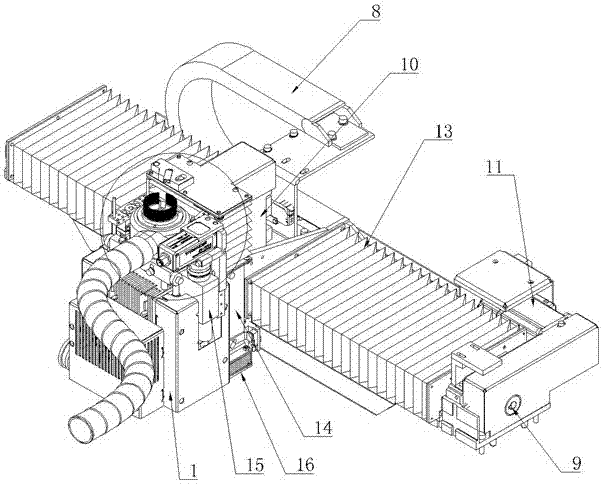

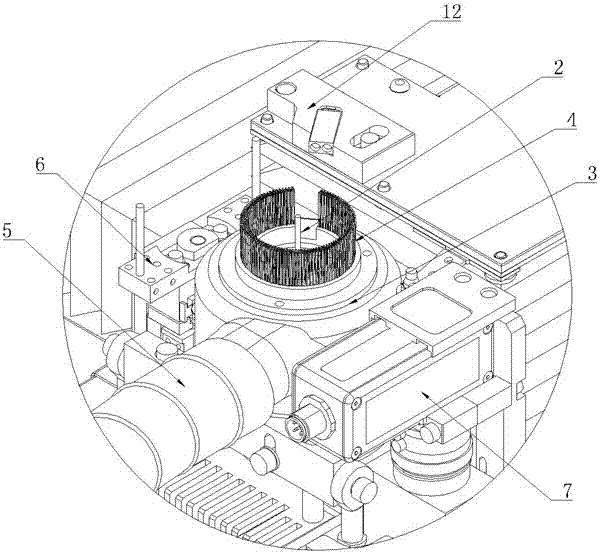

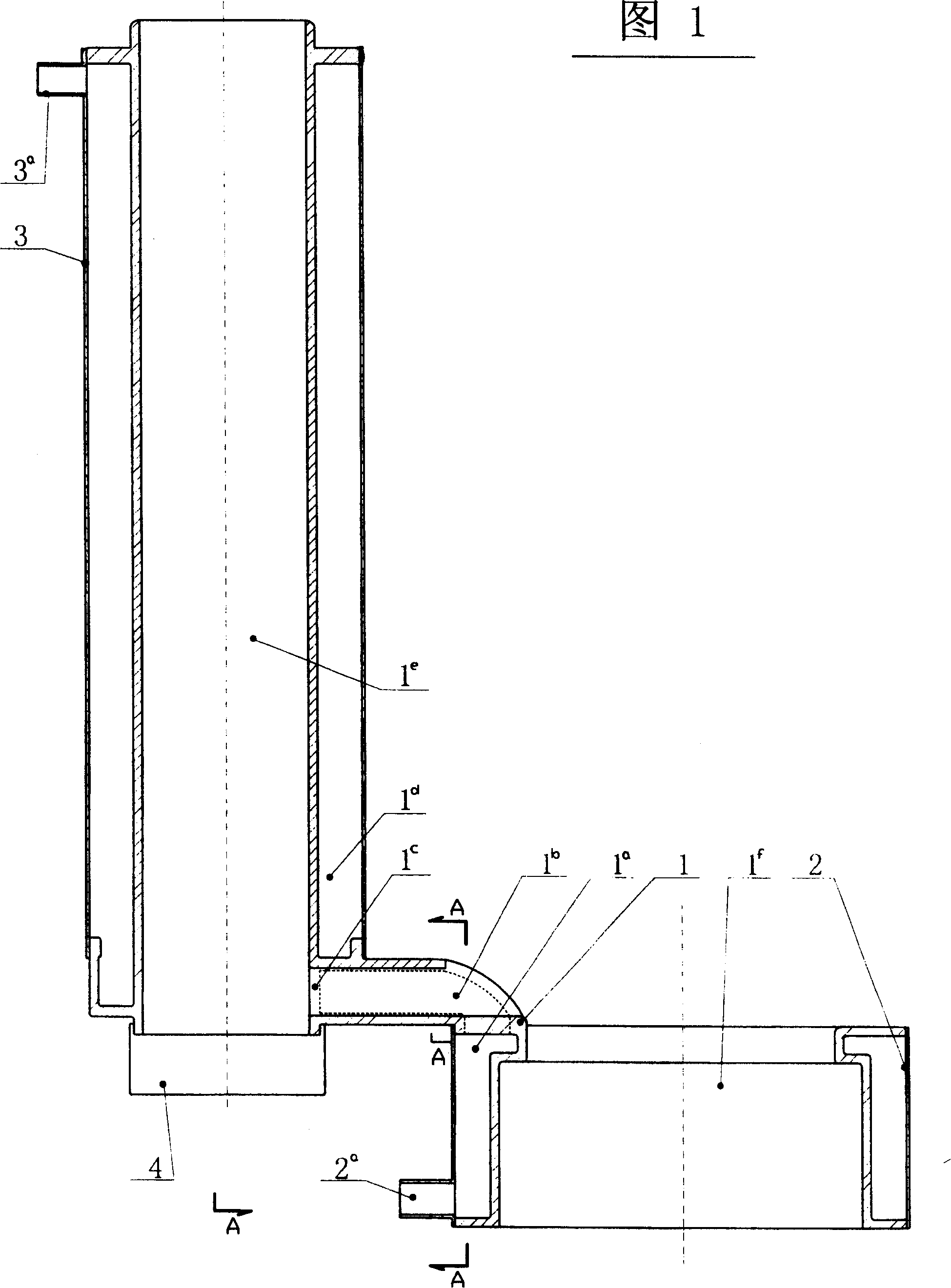

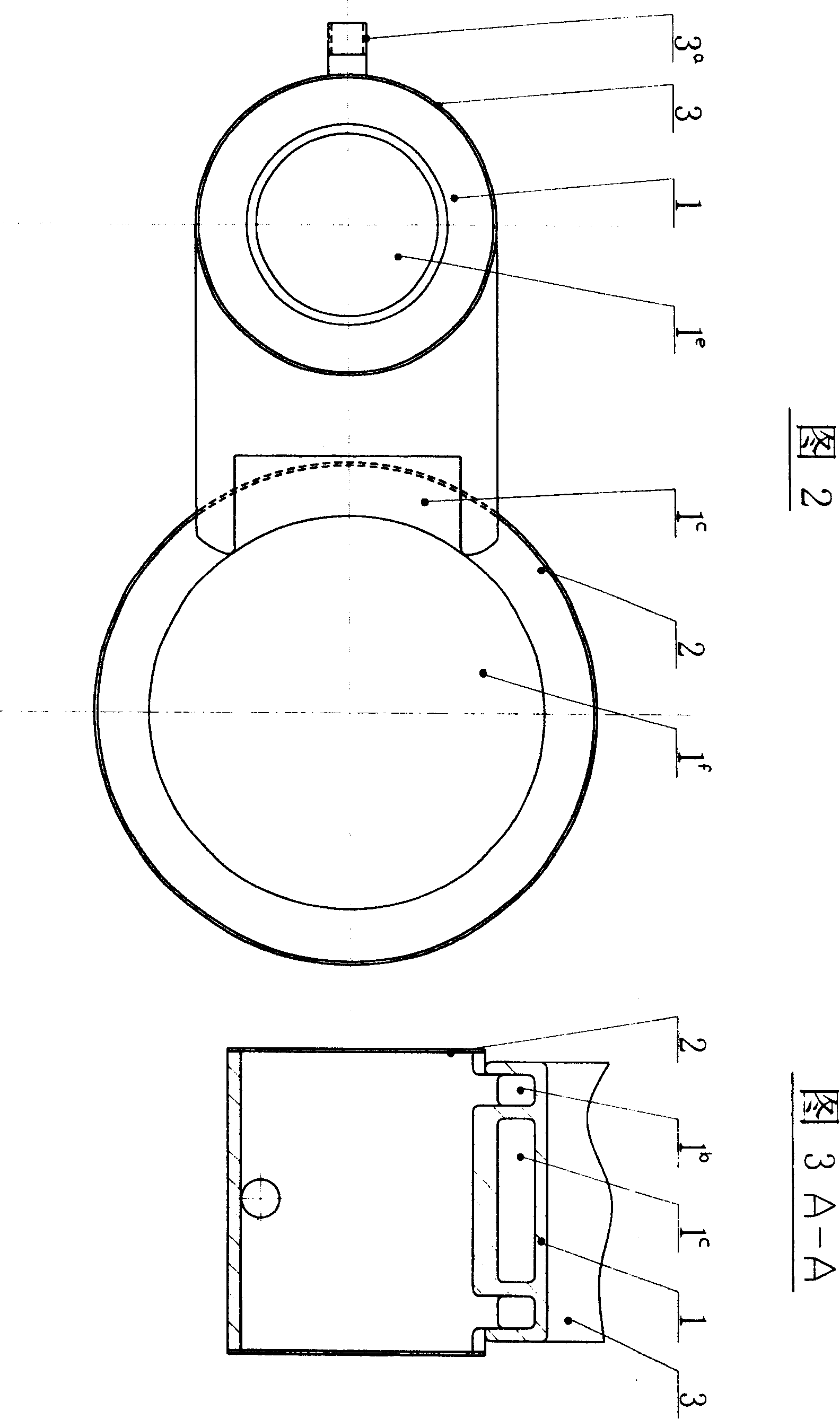

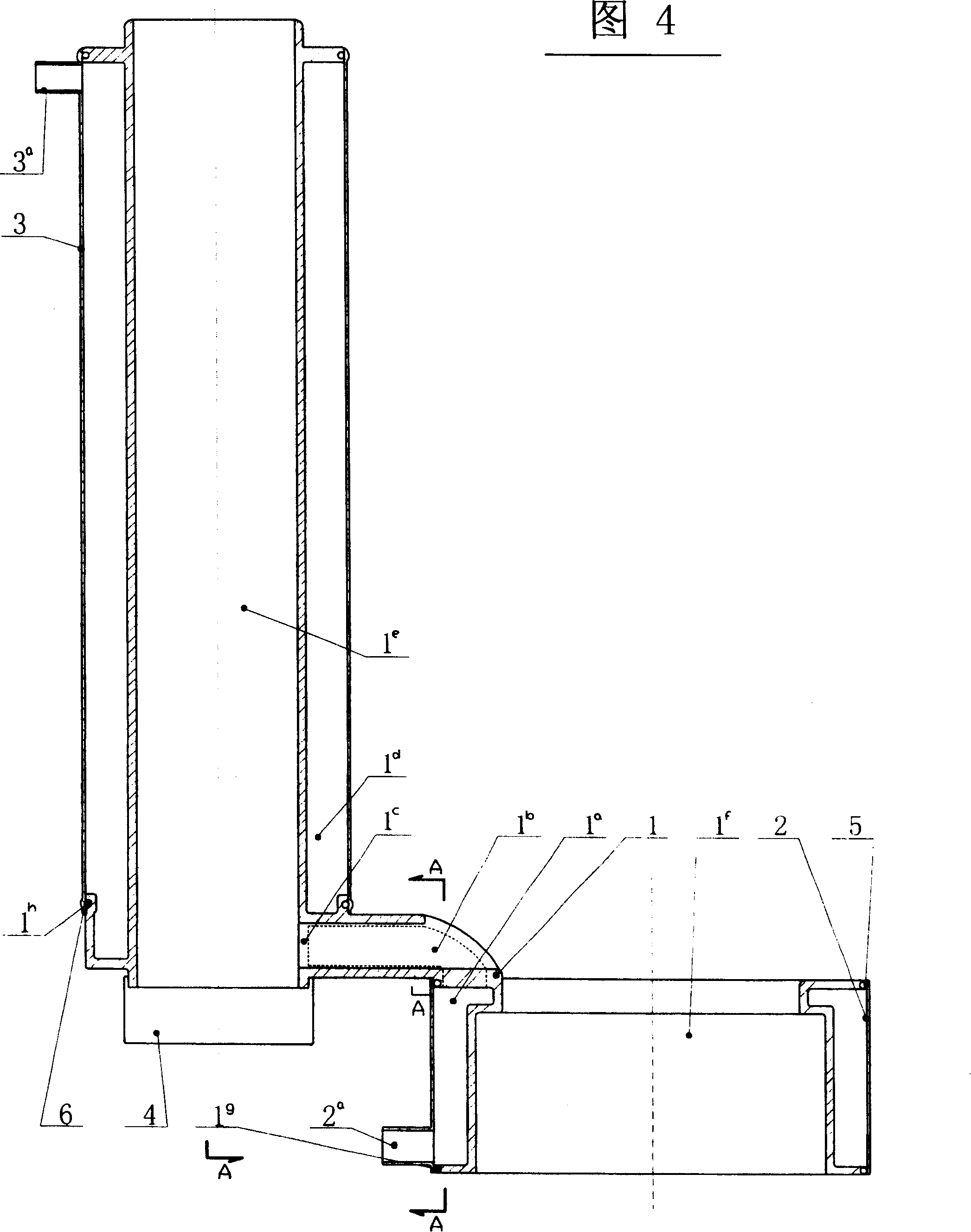

Separator Vacuum Milling Cutter

ActiveCN105499674BPrevent splashAvoid pollutionLarge fixed membersMilling equipment detailsMilling cutterEngineering

The invention discloses and provides a dust suction milling cutter for a depanel machine that has a simple structure, reduces production costs, realizes all-round dust collection, thereby reducing the defective rate, and effectively prevents static electricity at the same time. The invention includes a transverse moving device, a lifting device provided on the transverse moving device, and a milling cutter device provided on the lifting device, the lifting device and the transverse moving device, the milling cutter device and the The lifting device is in sliding fit. The milling cutter device includes a milling cutter seat (1) and a milling cutter (2) arranged on the top of the milling cutter seat (1). A suction device is also provided on the milling cutter seat (1). Dust chamber (3), the dust suction chamber (3) is wrapped around the milling cutter (1), and several anti-static brushes (4) are provided on the dust suction chamber (3), so The anti-static brush (4) is of the same height as the milling cutter (2), and the dust suction chamber (3) is also connected to the dust suction pipe (5). The invention is suitable for the field of depaneling machines.

Owner:珠海市申科谱工业科技有限公司

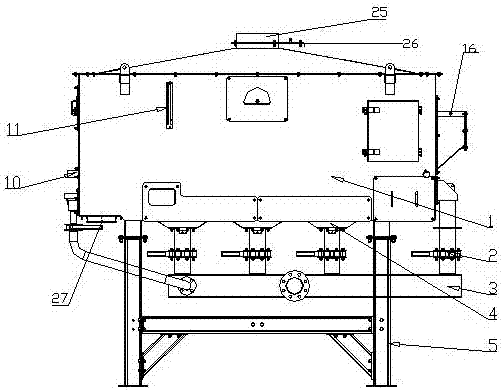

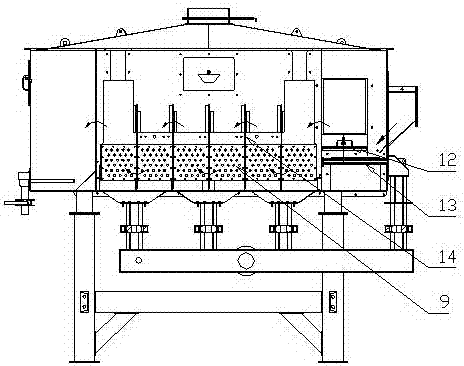

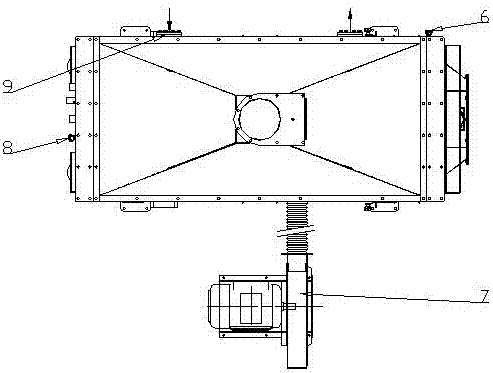

Efficient sand temperature adjuster with grading function

ActiveCN107127293AEfficient and uniform cooling effectQuality improvementMould handling/dressing devicesFluidized bedEngineering

The invention discloses an efficient sand temperature adjuster with a grading function. The adjuster comprises a machine body and a cooling unit tube bundle, the feeding end of one side of the machine body is provided with a quantitative feeder, and a bundle spraying air tube is arranged in the machine body and close to the feeding end of the machine body; a feeding screening plate is arranged above the bundle spraying air tube, a fluidized bed is arranged below the cooling unit tube bundle, a main air tube is arranged at the bottom of the fluidized bed, and the fluidized bed is arranged to communicate with the main air tube; a branch air tube is vertically arranged at one end of the main air tube in a communicating mode and connected with the bundle spraying air tube; a row of material flow guiding plates are arranged on the fluidized bed at equal intervals; and a dust collector is further arranged above the machine body, and the discharging end of the machine body is further provided with an on-line sampling device. The sand temperature adjuster is compact in outline size, easy to arrange on a site, high in temperature reducing efficiency, convenient to adjust the sand flow temperature and little in overhauling and maintaining, dust removal equipment is integrated so that fine powder in molding sand can be removed, the quantitative feeding mode can further be ensured, and thus the molding sand treated on the fluidized bed is more uniform and orderly.

Owner:南通凯斯辛普森机械科技有限公司

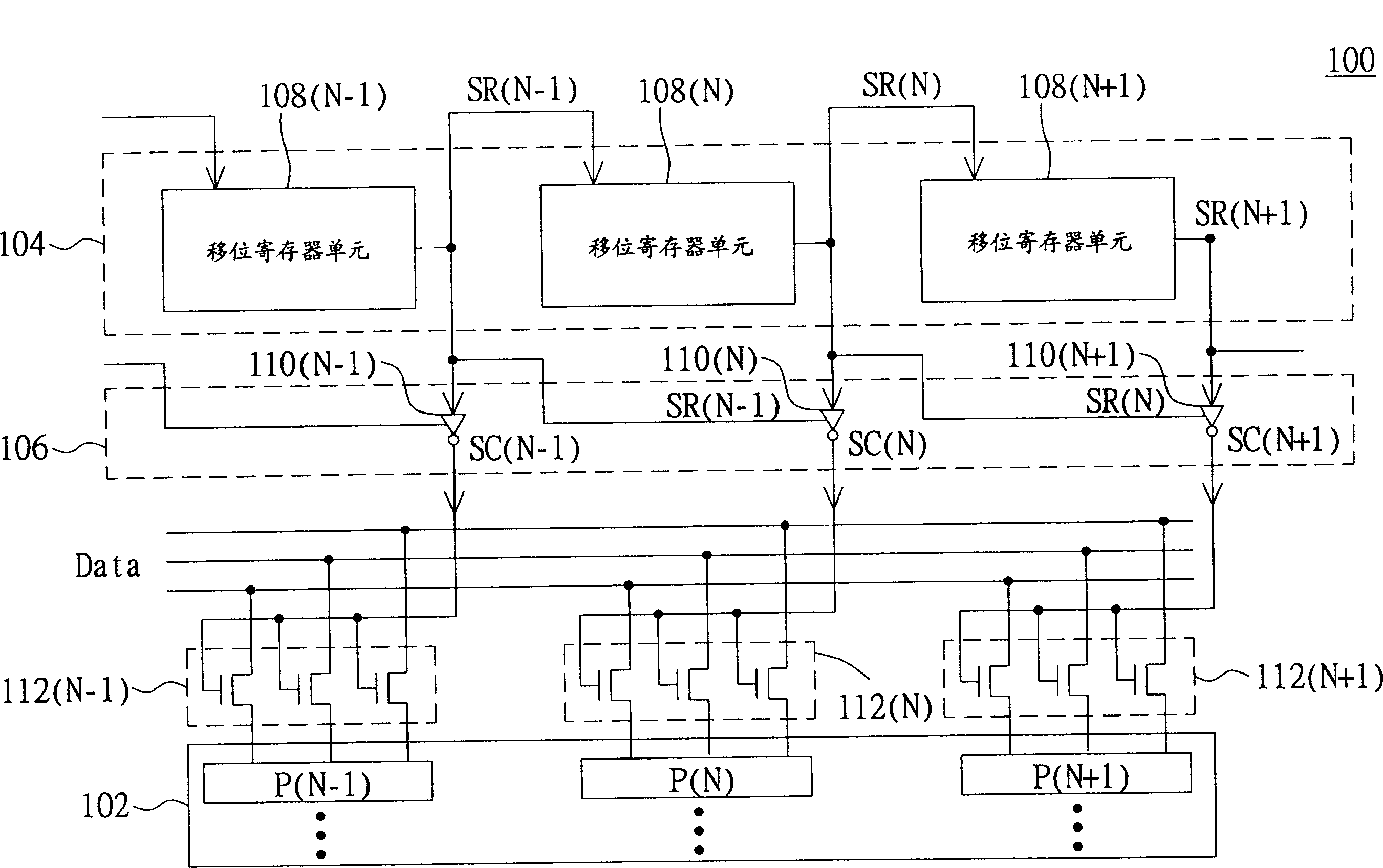

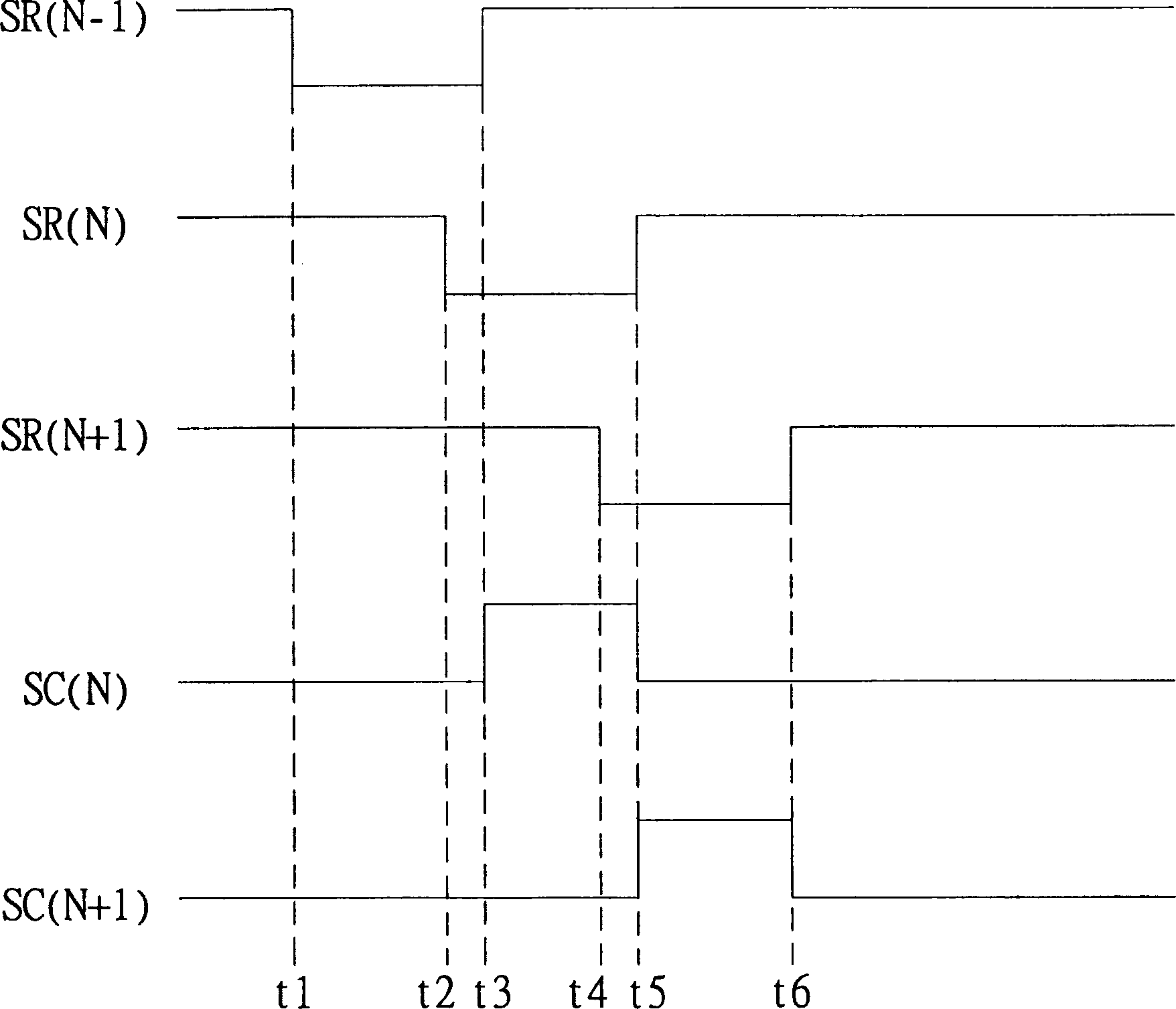

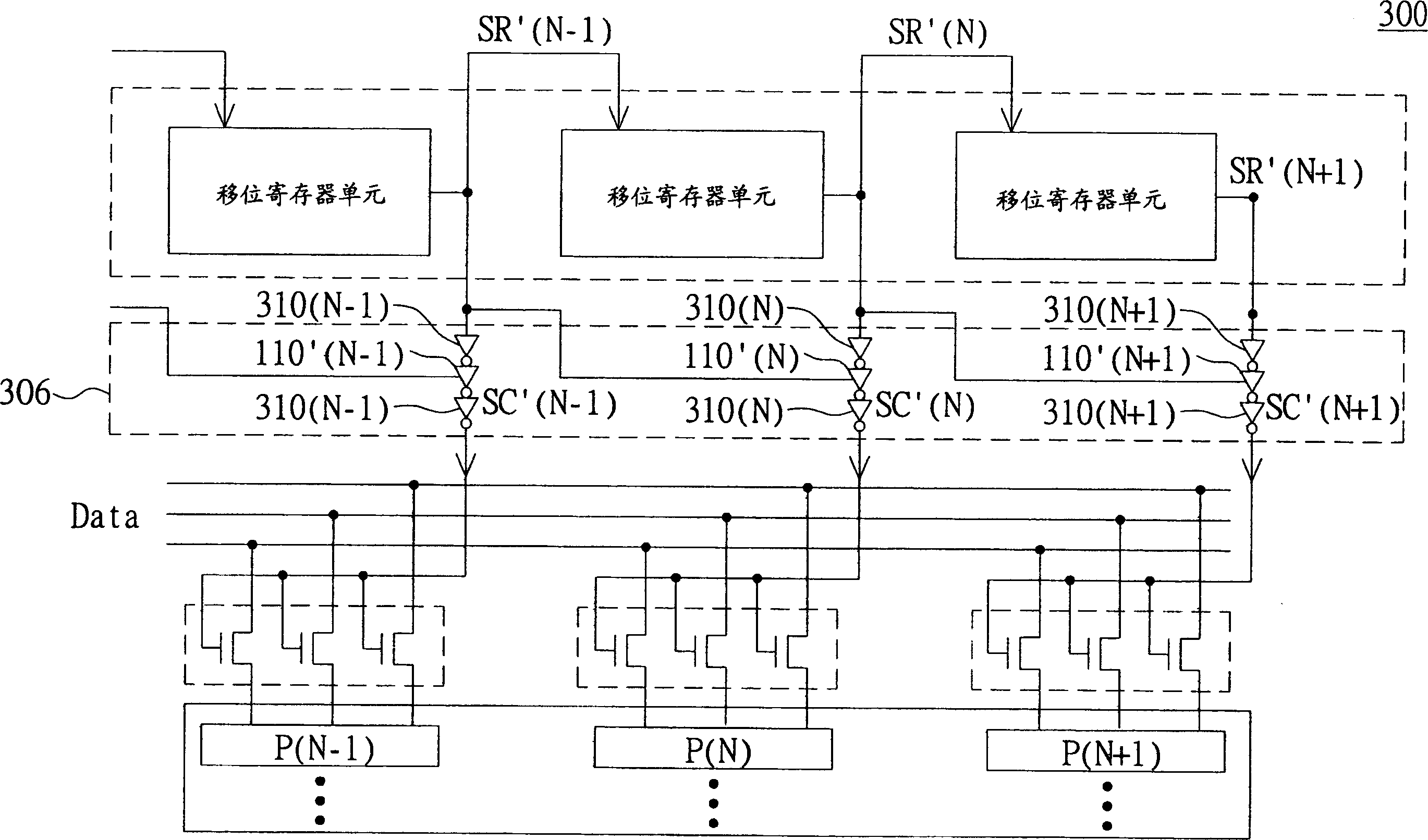

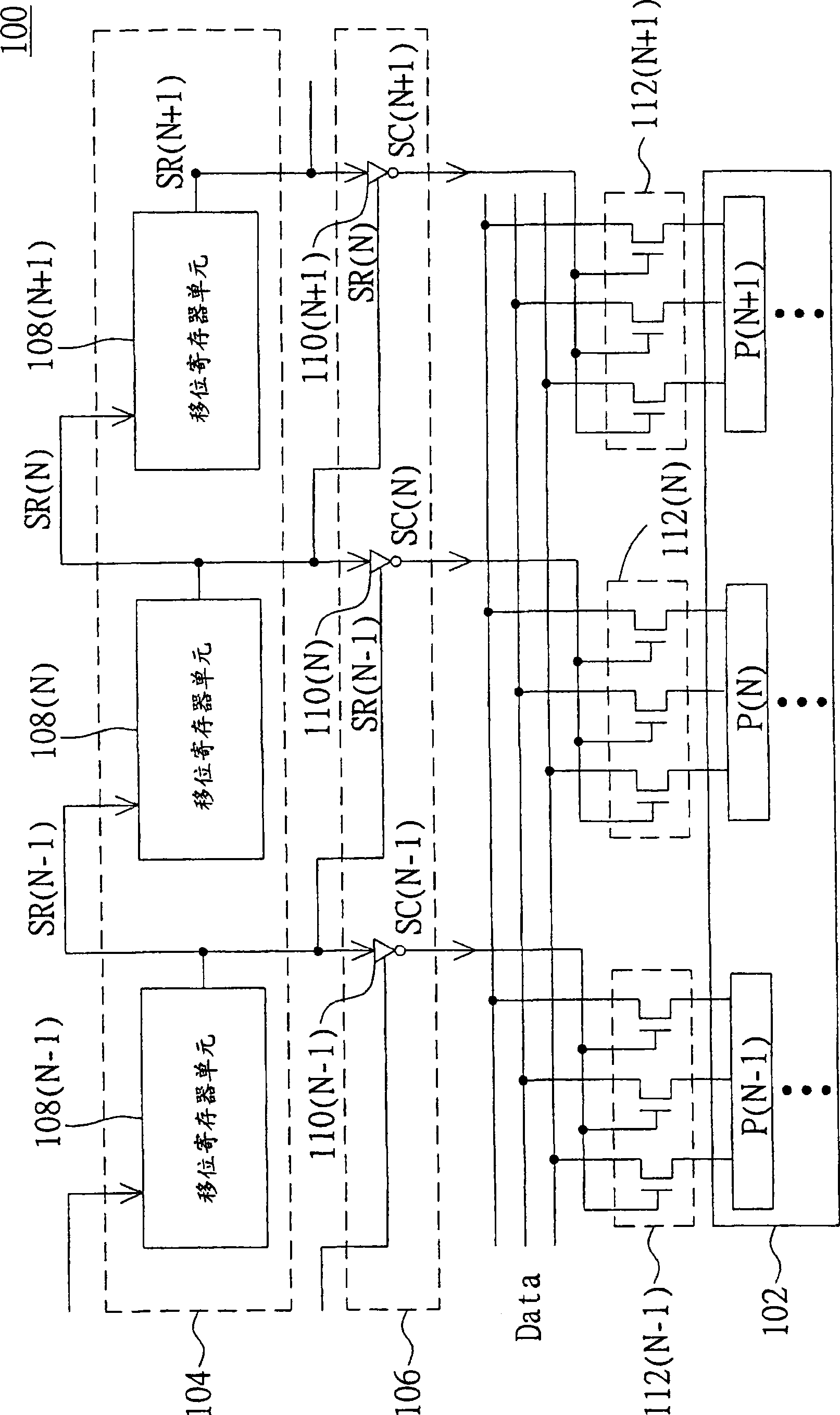

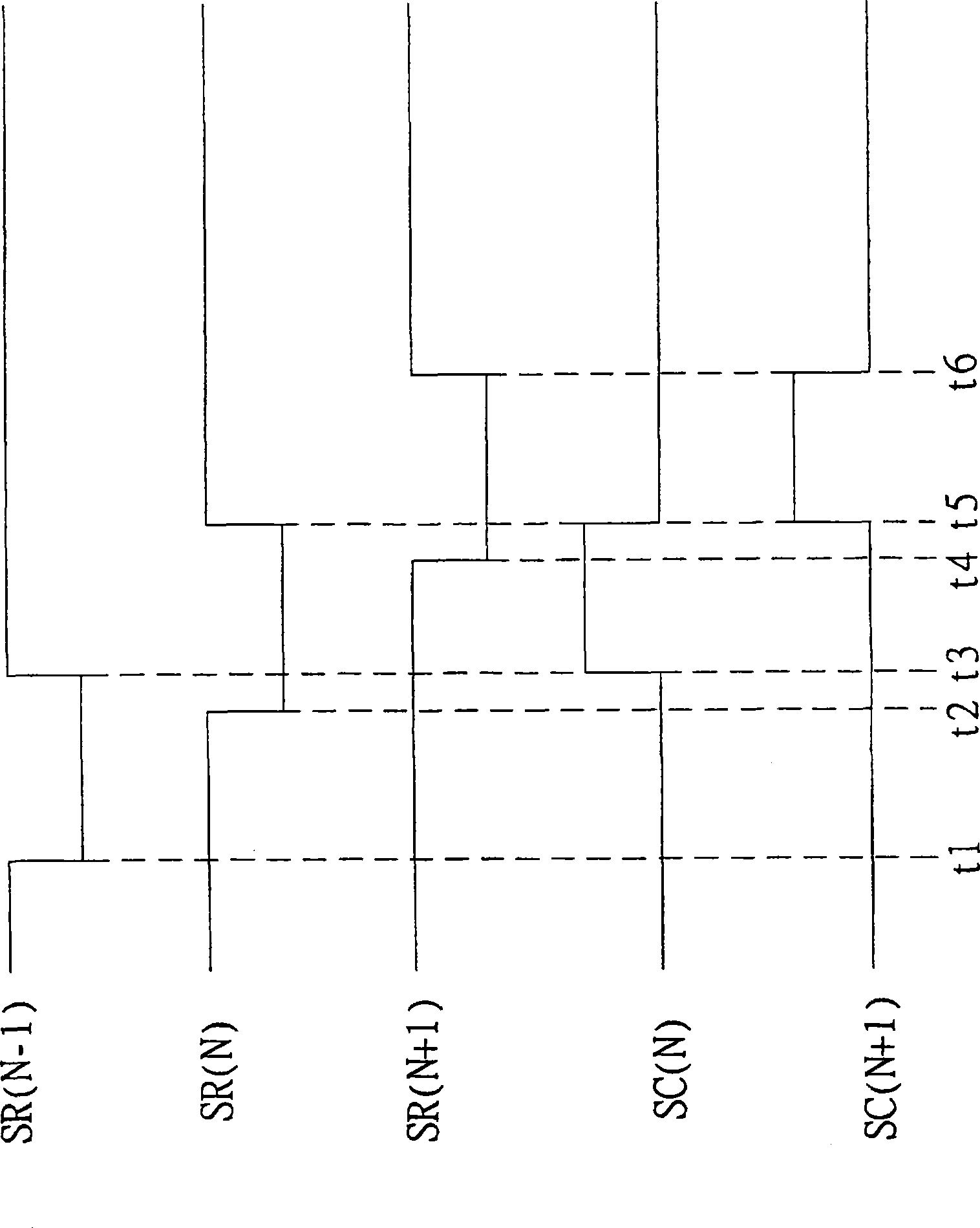

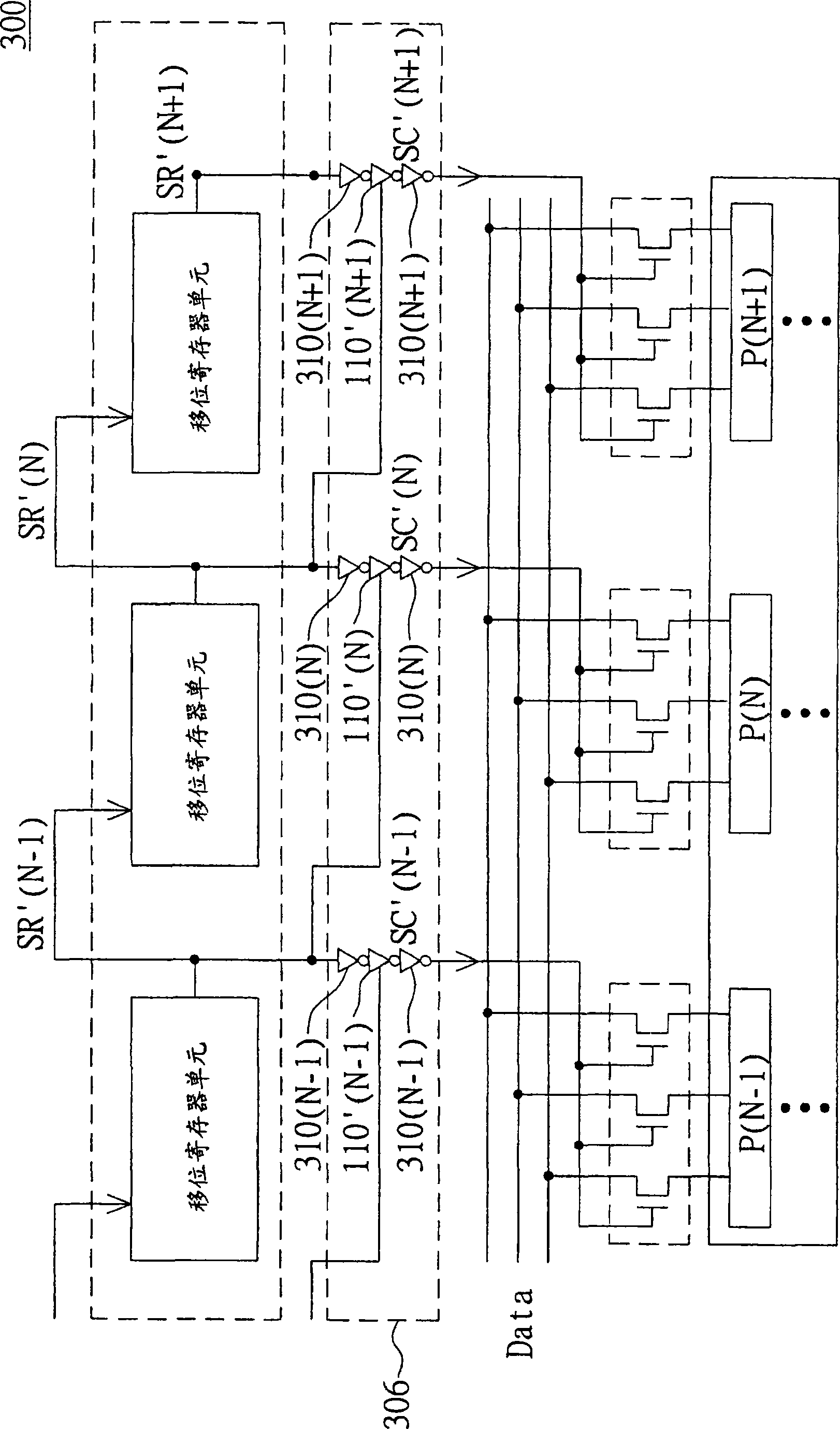

Drive circuit of picture element array for display panel

ActiveCN1609927ASolve overlapping issuesLow costTelevision system detailsStatic indicating devicesDriver circuitShift register

The driver circuit includes one shift register circuit and one output buffer circuit. The shift register circuit includes the first and the second shift register units to output the first and the second shift signals separately for use successively. The output buffer circuit include the first and the second output buffer units to receive the first and the second shift signals separately to output the first and the second switch controlling signals. The voltage supplying end of the second buffer unit receives the first shift signal. When the first shift signal is in the non-activation level, the second buffer unit is activated, so that the second buffer unit outputs the second switch control signal to output the first data signal the pixel array.

Owner:AU OPTRONICS CORP

Method for increasing kiln transmutation rate of Nixing pottery large vessel

The invention discloses a method for increasing the furnace transmutation rate of a Nixing pottery large vessel. The method comprises the following steps: preparing east clay; preparing western mud; preparing blank mud; forming a green body; drying the green body; firing the green body; and grinding and polishing the fired body. According to the method for increasing the kiln transmutation rate of the Nixing pottery large vessel, a proper amount of metal oxide is added into a traditional pottery blank; under the action of a reduction flame atmosphere, the surface of the Nixing pottery is influenced by pine branch oil smoke and the like, color variation is generated, and furnace transmutation occurs; the content of the metal oxide in the blank is directly increased when the blank is manufactured, so that the quantity of the metal oxide participating in the reduction reaction in the firing of the green body is increased; therefore, the probability of color variation is further improved, and the kiln transmutation rate of the Nixing pottery is improved; after different metal oxides are reduced, the Nixing pottery subjected to kiln change shows different colors or lines, and the variety of kiln change of the Nixing pottery is increased by adjusting the metal oxidation variety, so that the commercial value of the Nixing pottery is improved.

Owner:QINZHOU CITY HUAXIA TAIJIQUAN NINGXING POTTERY

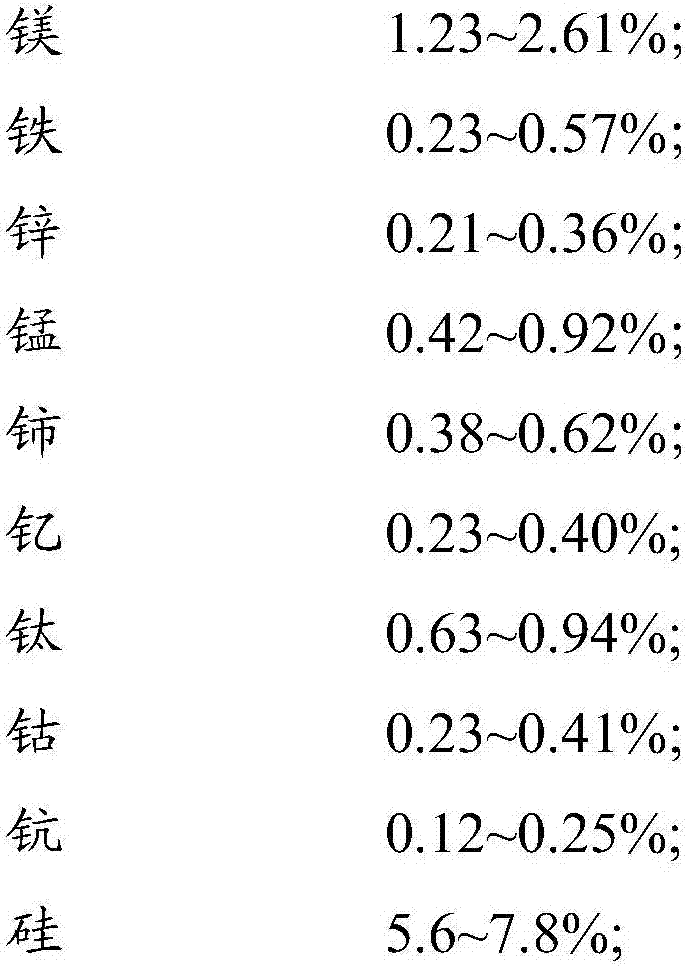

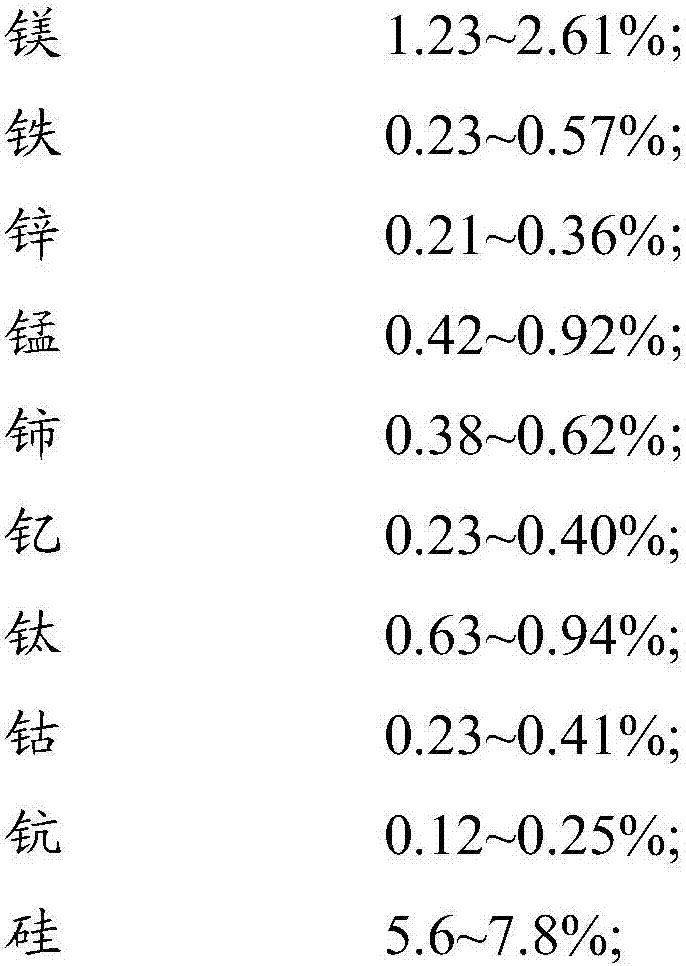

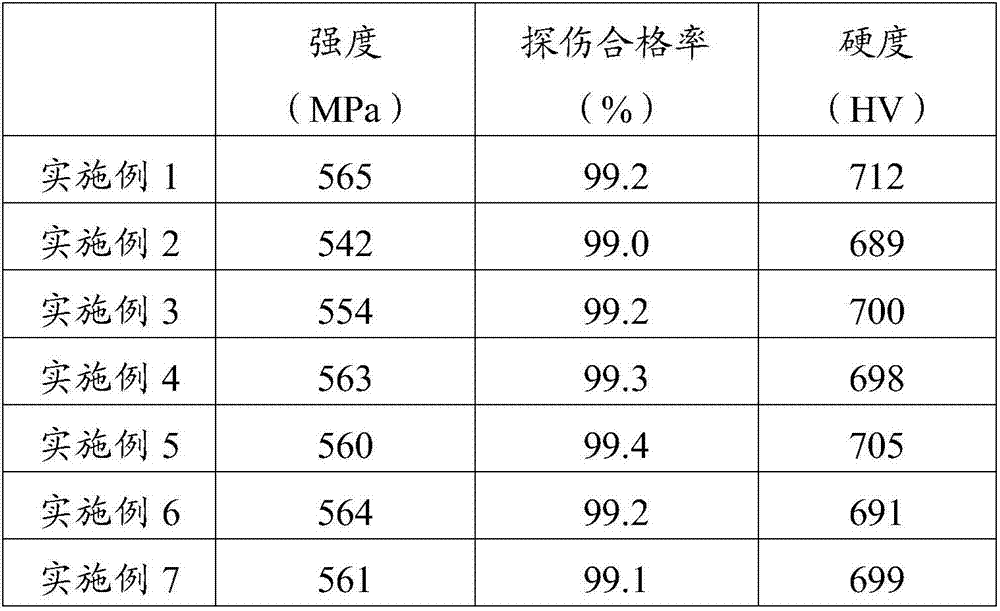

High-abrasive-resistance aluminum alloy material and preparation method thereof

The invention provides a high wear-resistant aluminum alloy material and a preparation method thereof. The high wear-resistant aluminum alloy material is composed of the following components by weight percentage: 1.23-2.61% of magnesium, 0.23-0.57% of iron, 0.21-0.36% zinc, 0.42-0.92% manganese, 0.38-0.62% cerium, 0.23-0.40% yttrium, 0.63-0.94% titanium, 0.23-0.41% cobalt, 0.12-0.25% scandium, 5.6- 7.8% silicon, the rest is aluminum and a small amount of unavoidable impurities. In the present invention, the addition of cerium and yttrium in the aluminum alloy material can improve the wear resistance of the aluminum alloy material; the addition of cobalt and scandium can improve the toughness of the aluminum alloy material, overcome casting cracks, improve the quality of the aluminum alloy, and improve the quality of the aluminum alloy. Product cost rate. According to the experimental results, the hardness of aluminum alloy products is above 689HV, the strength is above 542MPa, and the qualified rate of flaw detection is above 99%.

Owner:合肥饰界金属制品有限公司

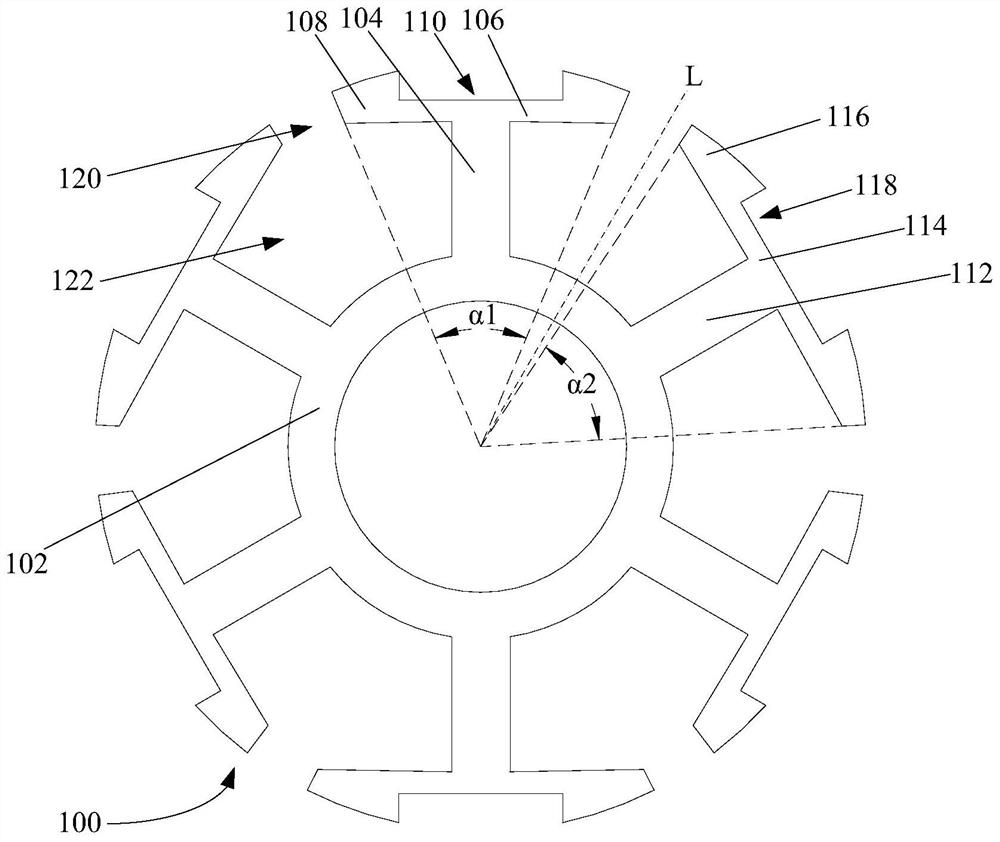

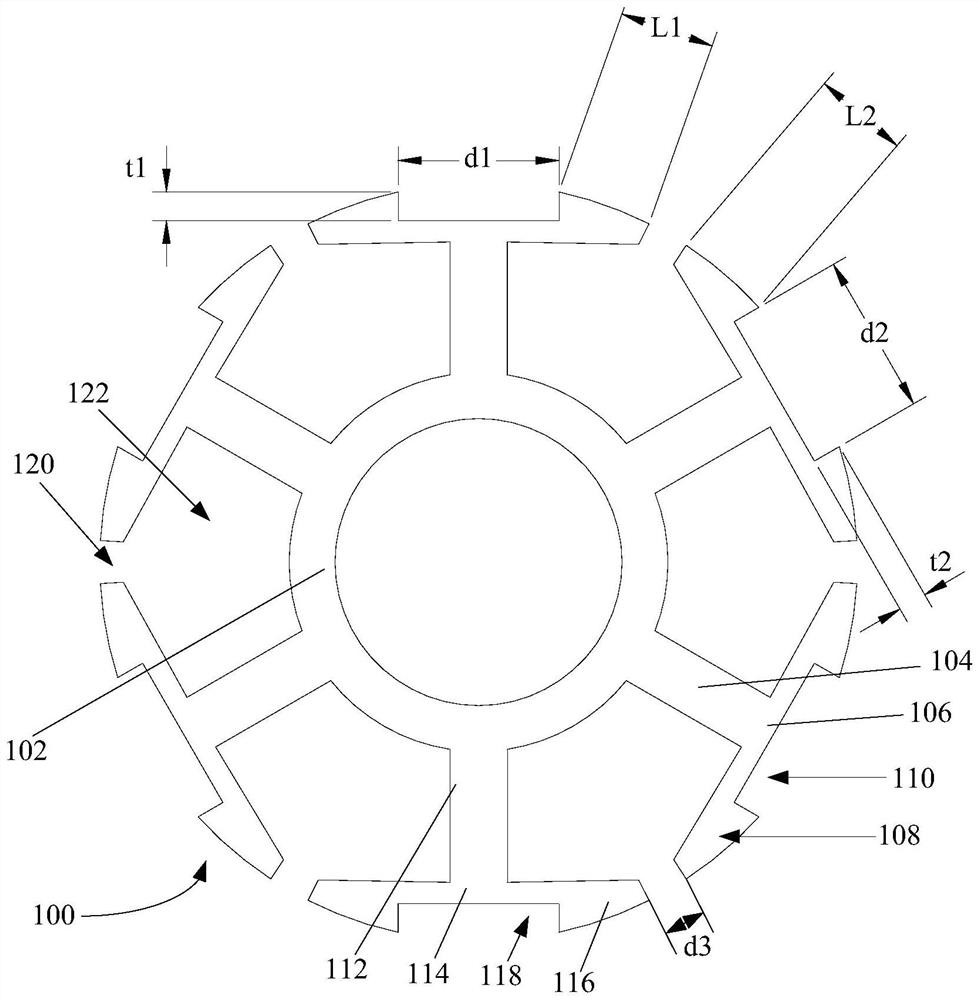

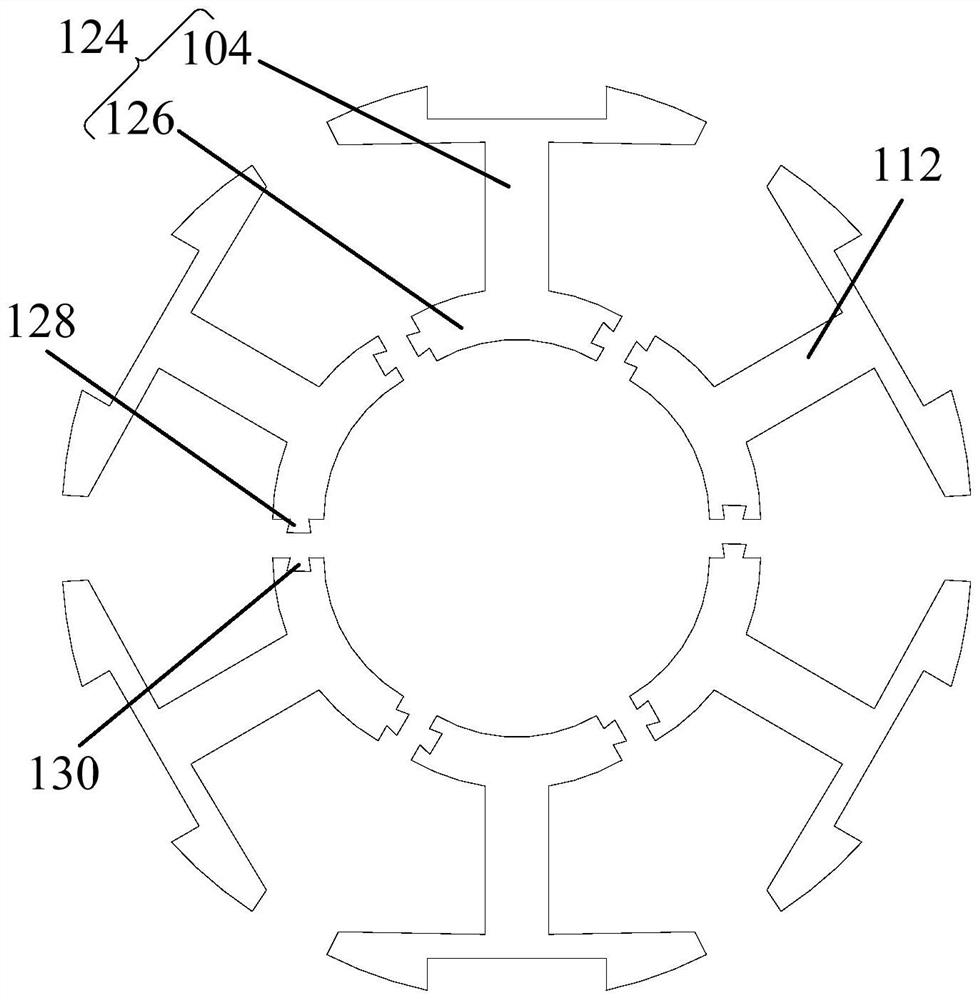

Stator assembly, motor and electrical equipment

PendingCN114069910AOperating space plusImprove work efficiencyWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineryEngineering

The invention provides a stator assembly, a motor and electrical equipment. The stator assembly comprises a stator iron core which comprises a yoke part, a first main tooth and a second main tooth, wherein the first main tooth and the second main tooth are arranged on the yoke part; the first main tooth comprises a first tooth boot and at least two first auxiliary teeth arranged on the first tooth boot, and a first groove is formed between every two adjacent first auxiliary teeth; the second main tooth comprises a second tooth boot and at least two second auxiliary teeth arranged on the second tooth boot, and a second groove is formed between every two adjacent second auxiliary teeth; wherein the angular bisector of the included angle formed between the first main tooth and the second main tooth is a reference line, and the first tooth boot and the second tooth boot are asymmetrically arranged relative to the datum line. According to the invention, the first tooth boot and the second tooth boot are asymmetrically arranged relative to the reference line, so that non-uniform distribution of air gap magnetic conductance is realized, and the number of air gap magnetic conductance cycles is reduced, thereby obtaining more working harmonics to improve the output torque of the motor.

Owner:WELLING WUHU MOTOR MFG +1

A kind of manufacturing method of high temperature and high pressure hydraulic components

ActiveCN112648422BIncrease cost rateImprove sealingSpindle sealingsSeat surface grinding machinesEngineeringMachining

The invention discloses a manufacturing method of a high temperature and high pressure resistant hydraulic component. The hydraulic component comprises a mounting shell, one end of the shell is provided with a valve hole, and the other end of the mounting shell is provided with a threaded hole which is communicated with the valve hole and is coaxial. The valve hole is provided with a valve core that fits with the valve hole. The clearance between the valve core and the valve hole is 0.001‑0.002mm. The roughness of the inner surface of the valve hole and the outer surface of the valve core are Ra0.4 and Ra0 respectively. .2; and prepared through the steps of material preparation, heat treatment, machining, fitter, surface treatment, grinding, and testing, the valve core and the valve hole can be sealed and fitted in a medium environment of 120‑130℃ and a pressure of 40‑45MP It has good sealing performance, and the preparation method of the present invention has a high yield.

Owner:新乡市平原工业滤器有限公司

Combined water jacket and manufacturing method

InactiveCN100410584CSimplify the molding casting processImprove product cost rateStove/ranges for heating waterSlagEngineering

A combined water jacket of heating furnace consists of internal water jacket, thin - wall external water jacket of firepot, thin- wall external water jacket of chimney, slag catcher, large rubber pad and small rubber pad. The method for preparing combined water jacket is also disclosed.

Owner:欧阳宝武

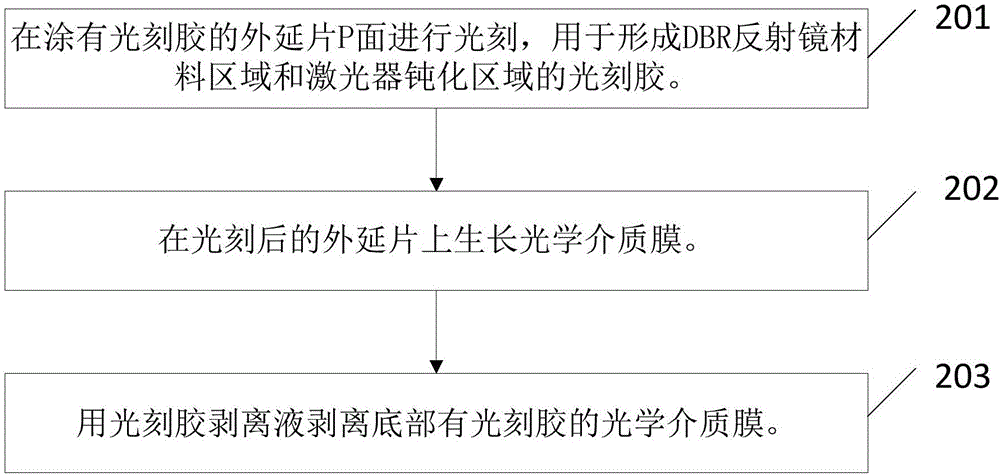

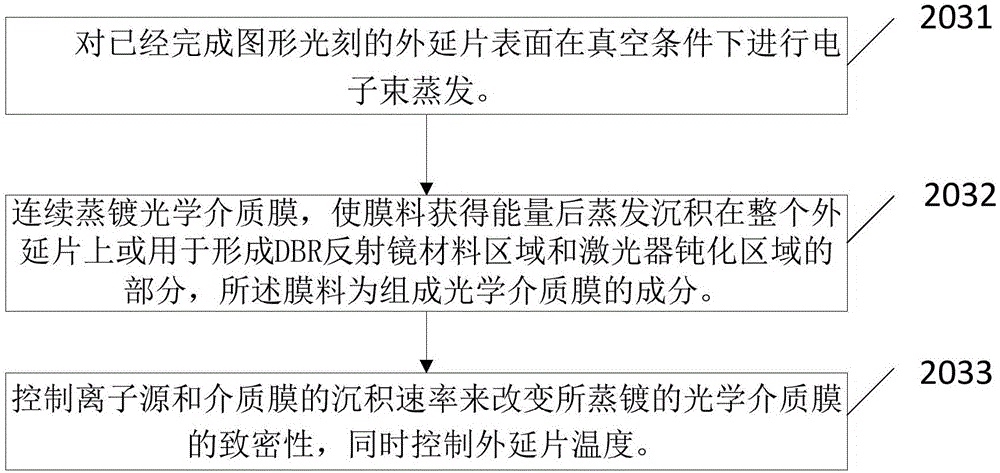

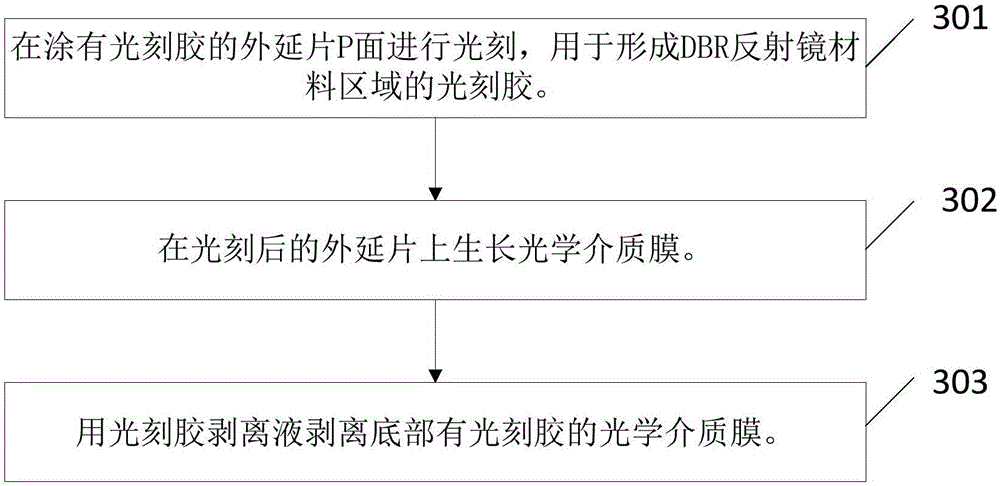

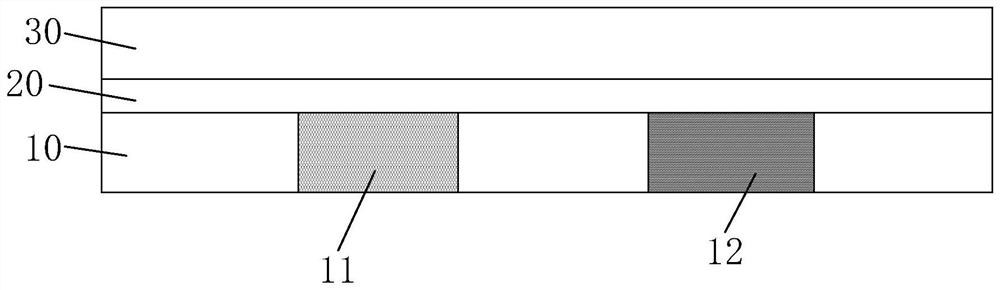

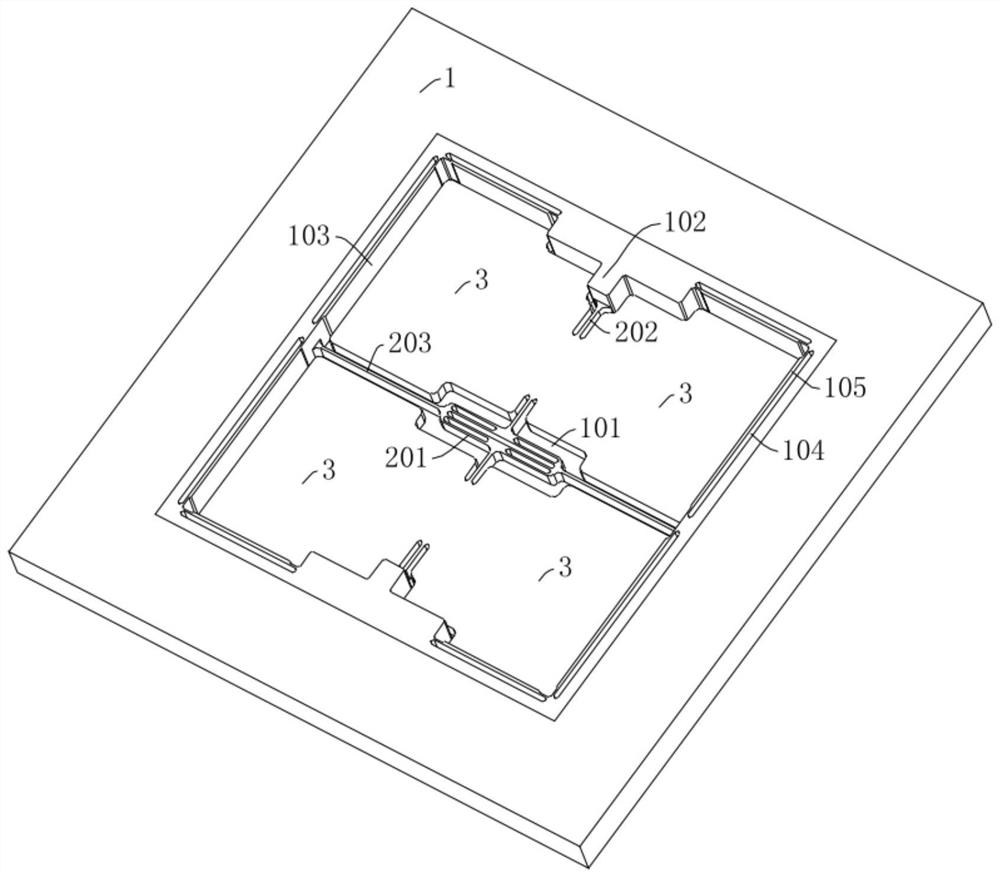

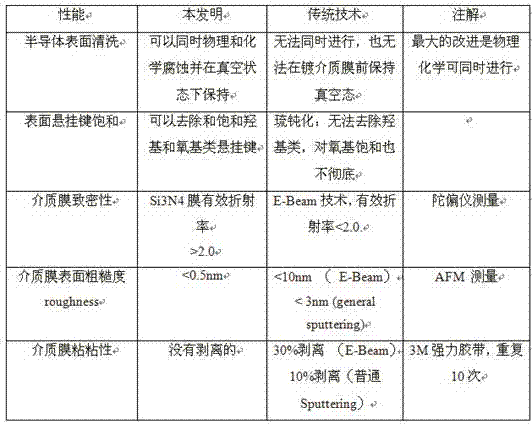

Optical dielectric film passivation-based vertical cavity surface laser and preparation method therefor

ActiveCN106207751AReduced series resistanceReduce absorption lossLaser detailsSemiconductor lasersDielectricDistributed Bragg reflector

The invention relates to the technical field of a semiconductor, and provides an optical dielectric film passivation-based vertical cavity surface laser and a preparation method therefor. The optical dielectric film is used as a DBR (distributed bragg reflector) reflective mirror material, and used as the passivation dielectric film of the cavity surface of the laser. By adopting the optical dielectric film to replace a conventional DBR reflective film, the series resistance, the absorption loss and the interface loss of the vertical cavity laser can be effectively lowered, thereby improving the thermal characteristics of the laser; the optical dielectric film is also a good electric dielectric film; and therefore, when the optical dielectric film is used for surface passivation of the laser, the process is simplified, the passivation cost is lowered, the cavity surface of the laser can be effectively protected, and the reliability of the laser is improved.

Owner:GUANGXUN SCI & TECH WUHAN +1

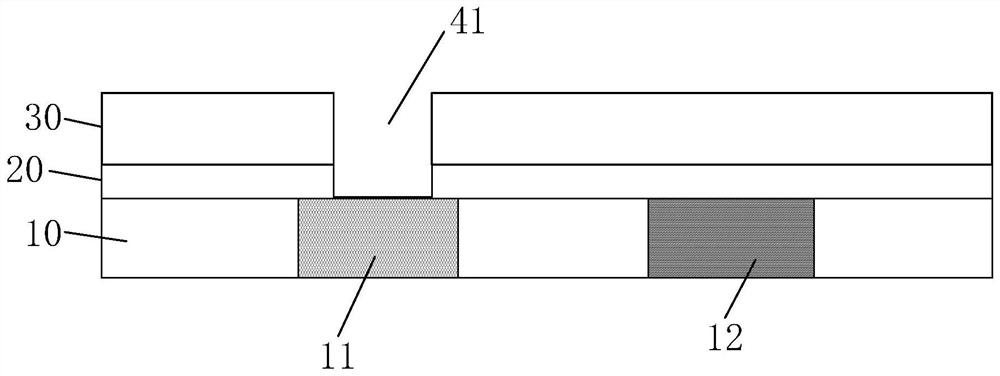

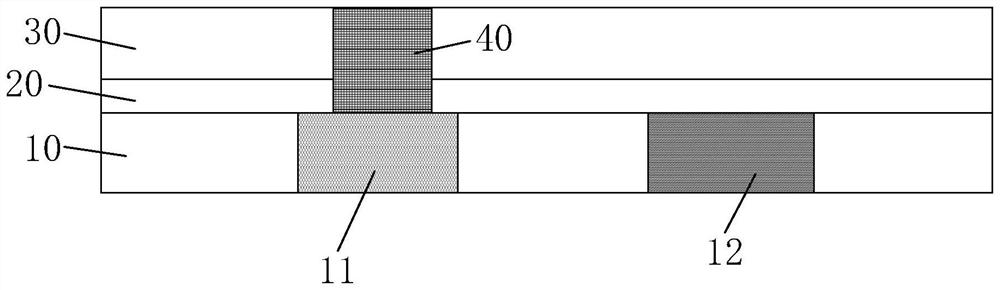

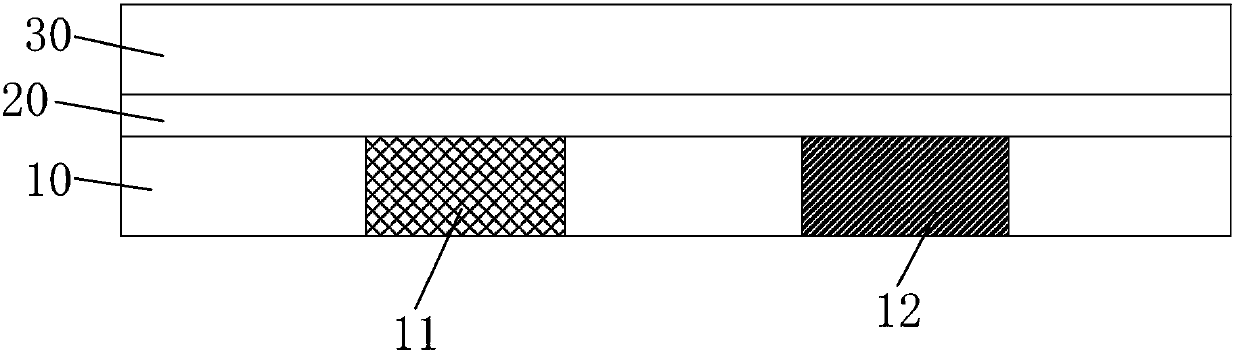

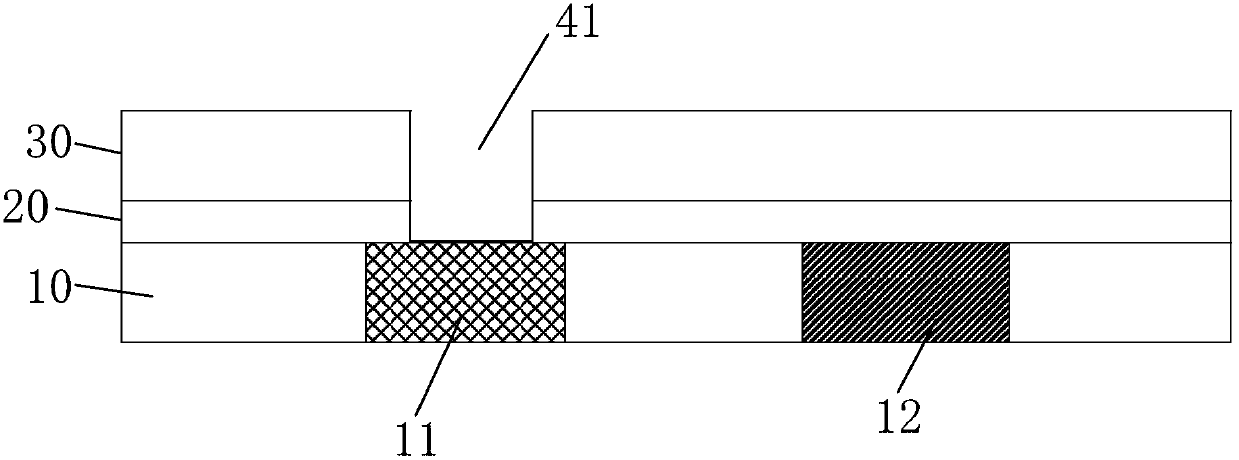

mram device and its manufacturing method

ActiveCN110648960BIncrease cost rateReduce processing difficultySemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Owner:CETHIK GRP +1

MRAM device and manufacturing method thereof

ActiveCN110648960AIncrease cost rateReduce processing difficultySemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

The invention provides an MRAM device and a manufacturing method thereof. The manufacturing method comprises the steps of S1, arranging a first interconnection part and a second interconnection part in an interconnection dielectric layer; S2, sequentially arranging a first etching barrier layer and a first dielectric layer on a surface of the interconnection dielectric layer; S3, forming first metal holes in the first etching barrier layer and the first dielectric layer above a first interconnection part; S4, sequentially arranging a bottom electrode, an MTJ unit, a top electrode and a secondetching barrier layer on a surface of the first dielectric layer above the first interconnection part; S5, sequentially arranging a third dielectric layer, a third etching barrier layer and a fourth dielectric layer on a surface, far away from the first dielectric layer, of the second dielectric layer; S6, forming a second through hole and a third through hole; and S7, filling the second through hole and the third through hole with metal. The manufacturing method is advantaged in that process difficulty is reduced, and the cost rate of the device is improved.

Owner:CETHIK GRP +1

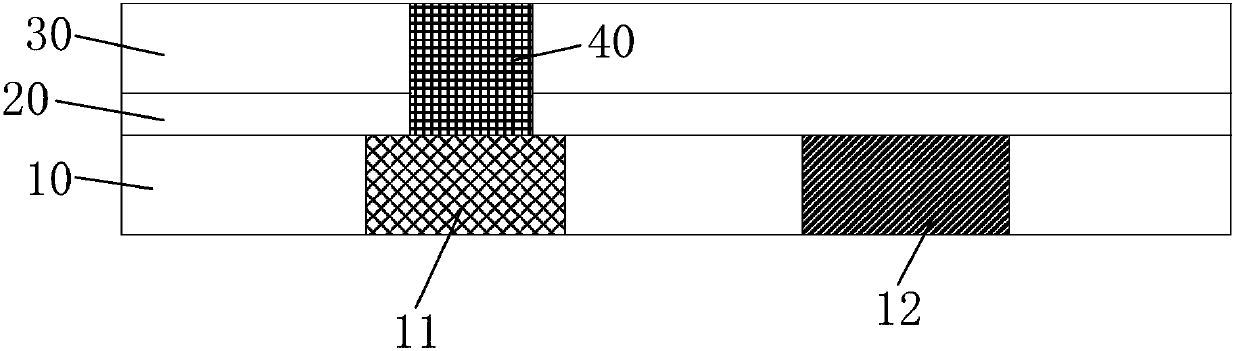

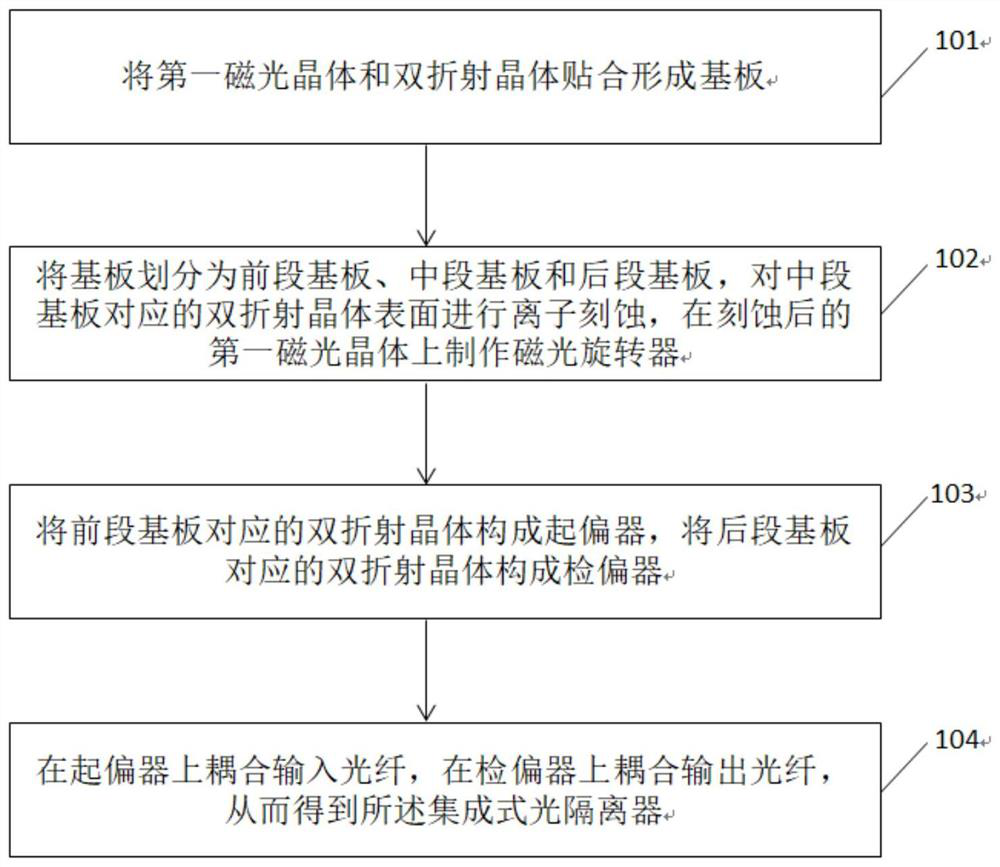

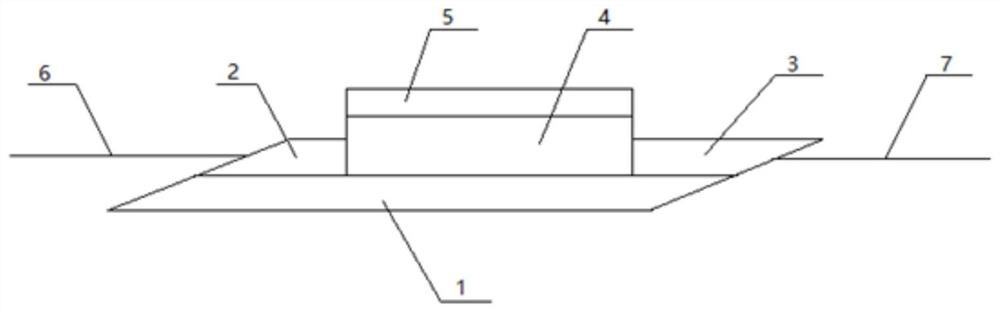

Packaging method of integrated optical isolator and integrated optical isolator

ActiveCN110687696BSimple processing technologyImprove processing efficiencyNon-linear opticsBirefringent crystalOptical isolator

The invention discloses a packaging method of an integrated optical isolator and the integrated optical isolator, and relates to the technical field of optical fiber communication. The method includes: laminating the first magneto-optic crystal and the birefringent crystal to form a substrate; dividing the substrate into a front substrate, a middle substrate and a rear substrate, performing ion etching on the surface of the birefringent crystal corresponding to the middle substrate, and Make a magneto-optical rotator on the first magneto-optic crystal after etching; use the birefringent crystal corresponding to the front substrate to form a polarizer, and use the birefringent crystal corresponding to the rear substrate to form a polarizer; couple the polarizer to the optical fiber , coupled to the output fiber on the analyzer to obtain an integrated optical isolator. In the present invention, the first magneto-optic crystal is pasted with birefringent crystal, and the polarizer and the polarizer are prepared at the same time, so the product quality is high, the processing technology is simple, the processing efficiency is high, and the processing cost is reduced.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

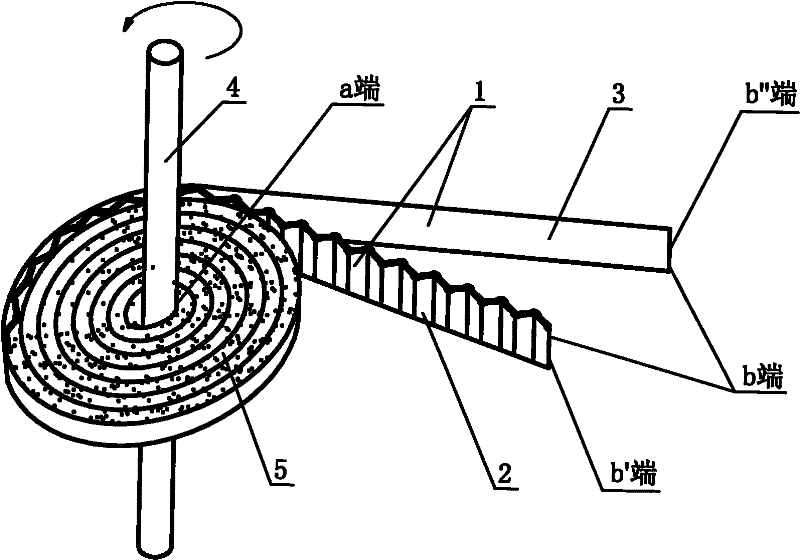

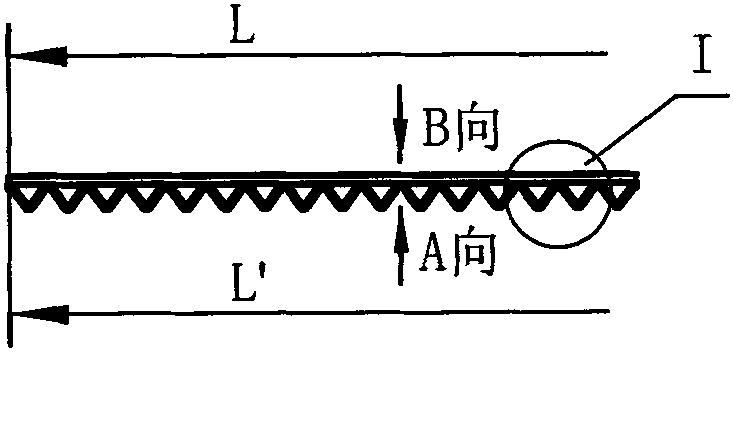

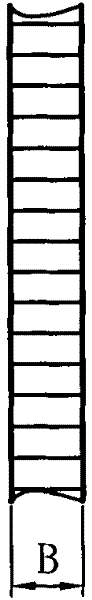

Equipment for continuous automatic measuring resistance of conducting material

InactiveCN1281967CEvenly distributedReduce density unevennessResistance/reactance/impedenceMeasurement deviceEngineering

The invention relates to a device for continuously and automatically measuring the resistance value of conductive materials, which belongs to the field of electrical measurement technology, and mainly solves the problem of multi-point monitoring of the resistance value of conductive materials. It is mainly composed of a resistance multi-point cycle detection system, a winding system, a deviation correction mechanism and a support plate; the support plate is provided with a deviation correction mechanism pressure roller, and a deviation correction mechanism is provided below, and is controlled by a central controller; The material board and the deviation correction mechanism are installed on the support frame; the detection system and the winding system are installed on the winding frame, and the detection system is located between the deviation correction mechanism and the winding system. Due to the continuous multi-point cyclic detection of the resistance value, and the multi-point horizontal distribution of the detection points, the uniform distribution of the resistance value after the conductive treatment of the material is ensured, and the uneven density of the later electroplated metal surface caused by the uneven resistance value of the material is reduced. The cost rate of production is improved, and the product quality is guaranteed. It is suitable for measuring the resistance of materials such as conductive sponges.

Owner:HEZE TIANYU TECH DEV CO LTD

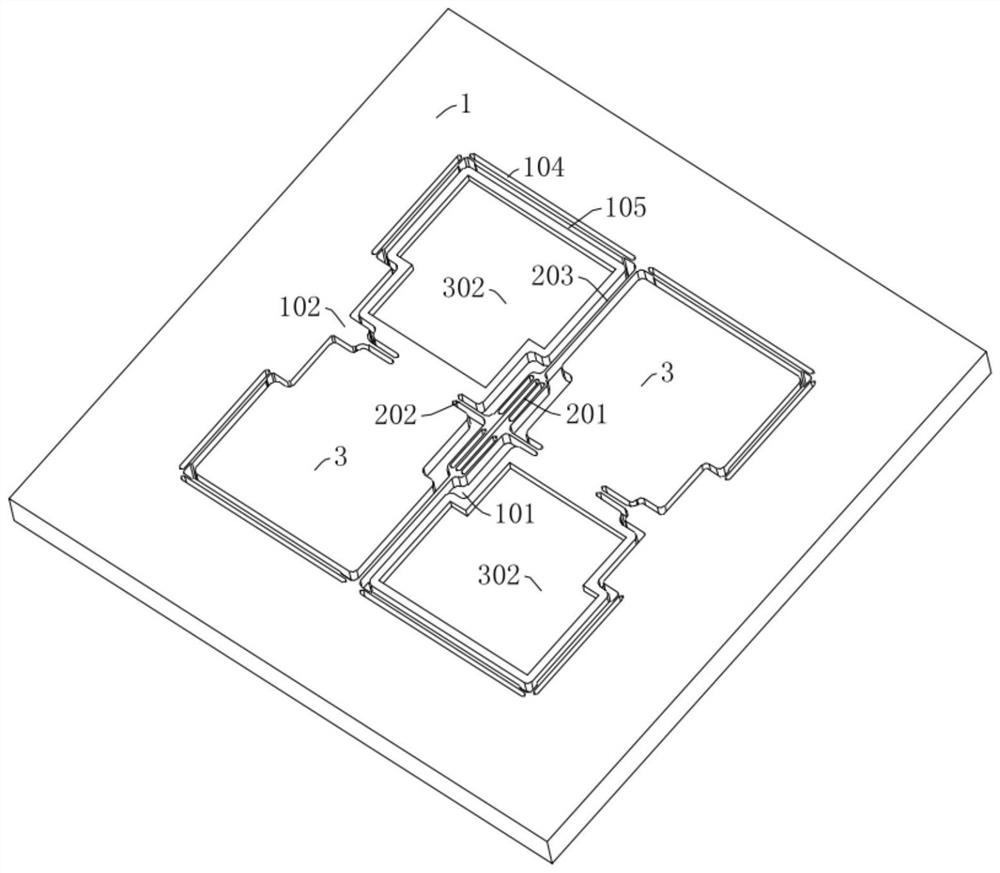

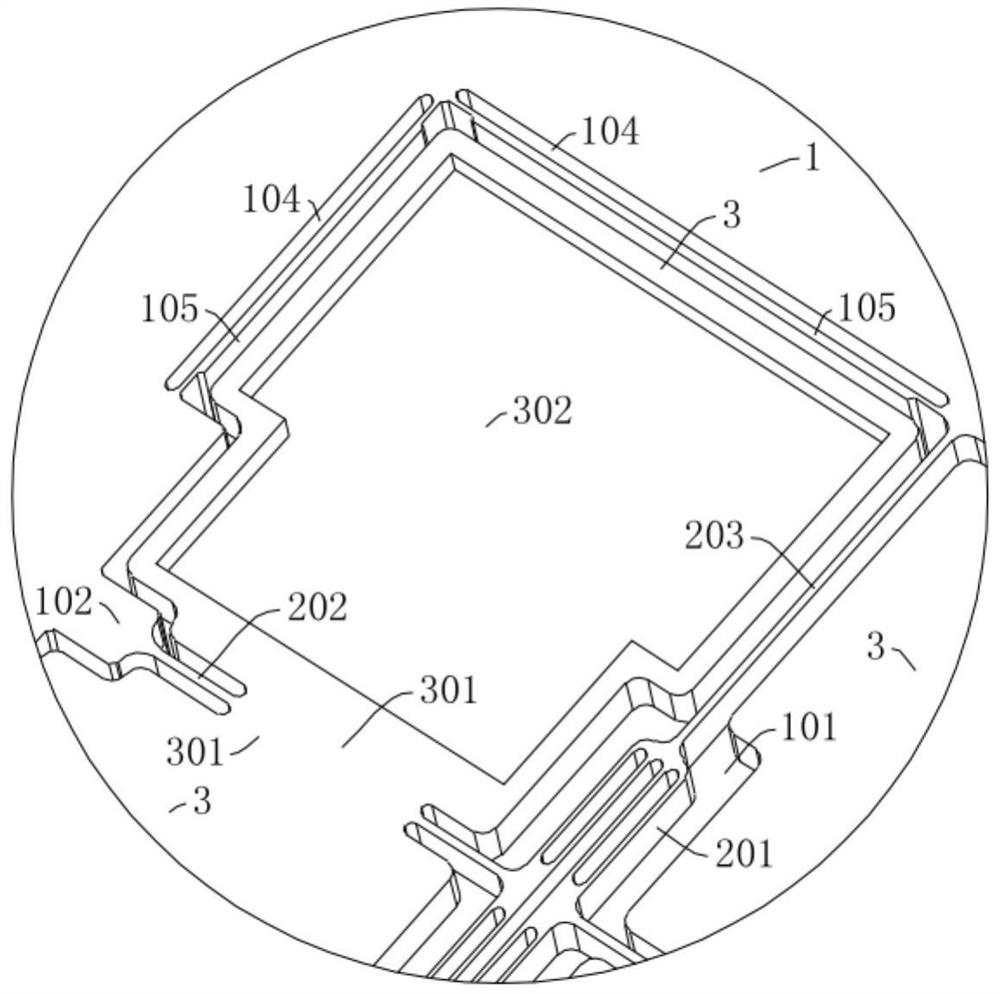

High-overload-resistant silicon sensing unit, micro-accelerometer and preparation method of high-overload-resistant silicon sensing unit

PendingCN114348951AIncrease stiffnessImprove structural rigidityDecorative surface effectsAcceleration measurementAccelerometerStructural engineering

The invention discloses a high-overload-resistant silicon sensing unit, a micro-accelerometer and a preparation method of the high-overload-resistant silicon sensing unit. The silicon sensing unit comprises an outer frame, a composite beam structure and a mass block assembly, the composite beam structure comprises a beam stress releasing structure, sensitive beams and displacement limiting beams, the two sides of the beam stress releasing structure are connected with the outer frame through the sensitive beams, and the two ends of the beam stress releasing structure are connected with the outer frame through the displacement limiting beams. The two sensitive beams and the two displacement limiting beams are in a cross-shaped symmetrical structure by taking the beam stress release structure as the center and are positioned in the spaced hollow-out grooves of the mass block assembly; the outer frame comprises a buffer stop structure. The micro-accelerometer is applied to the technical field of silicon micro-sensors, the displacement limiting beam and the buffer stop structure are additionally arranged, and the displacement limiting beam can improve the rigidity of the sensitive beam and the rigidity of the whole sensitive unit when the micro-accelerometer is impacted under the condition that the working mode of the micro-accelerometer is not influenced; and the buffer stop structure on the outer frame can perform blocking and buffer protection when the mass block collides with the outer frame, so that the overload resistance of the micro accelerometer is improved.

Owner:NAT UNIV OF DEFENSE TECH

A vertical cavity surface laser based on optical dielectric film passivation and its preparation method

ActiveCN106207751BReduced series resistanceReduce absorption lossLaser detailsSemiconductor lasersDielectricDistributed Bragg reflector

The invention relates to the technical field of a semiconductor, and provides an optical dielectric film passivation-based vertical cavity surface laser and a preparation method therefor. The optical dielectric film is used as a DBR (distributed bragg reflector) reflective mirror material, and used as the passivation dielectric film of the cavity surface of the laser. By adopting the optical dielectric film to replace a conventional DBR reflective film, the series resistance, the absorption loss and the interface loss of the vertical cavity laser can be effectively lowered, thereby improving the thermal characteristics of the laser; the optical dielectric film is also a good electric dielectric film; and therefore, when the optical dielectric film is used for surface passivation of the laser, the process is simplified, the passivation cost is lowered, the cavity surface of the laser can be effectively protected, and the reliability of the laser is improved.

Owner:GUANGXUN SCI & TECH WUHAN +1

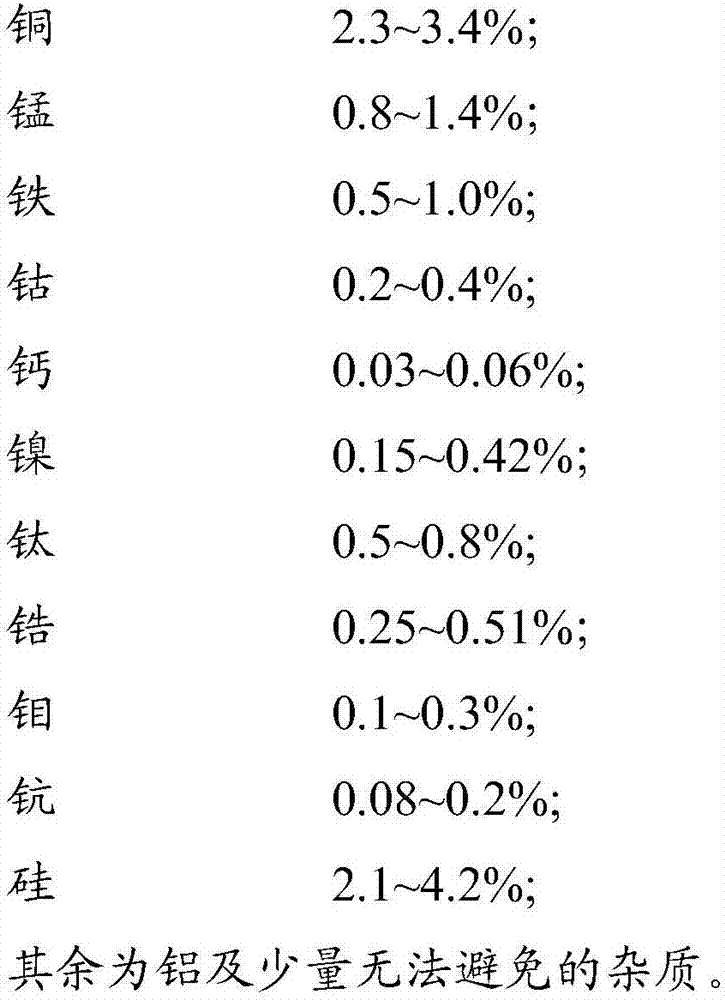

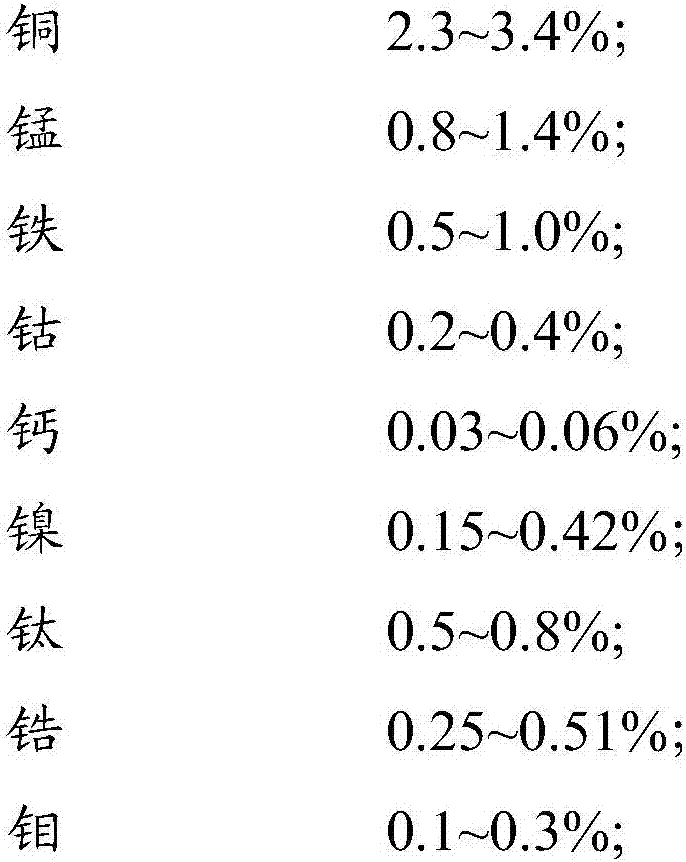

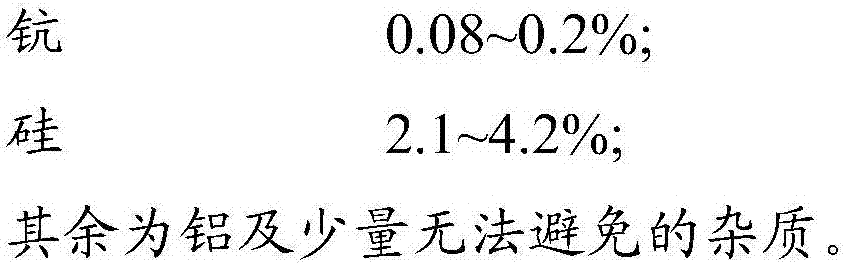

High-strength aluminum alloy material and preparation method thereof

The invention provides a high-strength aluminum alloy material and a preparation method thereof. The high-strength aluminum alloy material is composed of the following components by weight percentage: 2.3-3.4% copper, 0.8-1.4% manganese, 0.5-1.0% iron, 0.2-0.4% cobalt, 0.03-0.06% calcium, 0.15-0.42% nickel, 0.5-0.8% titanium, 0.15-0.42% nickel, 0.25-0.51% zirconium, 0.1-0.3% Molybdenum, 0.08-0.2% scandium, 2.1-4.2% silicon. In the present invention, the strength and plasticity of the aluminum alloy material are improved by adding zirconium and molybdenum to the aluminum alloy material, and the addition of cobalt and scandium to the aluminum alloy material can effectively overcome casting cracks, improve the quality of the aluminum alloy, and improve the quality of the aluminum alloy product. Cost rate. According to the experimental results, the strength of aluminum alloy products is above 547MPa, the elongation rate is above 7.9%, and the qualified rate of flaw detection is above 99%.

Owner:合肥饰界金属制品有限公司

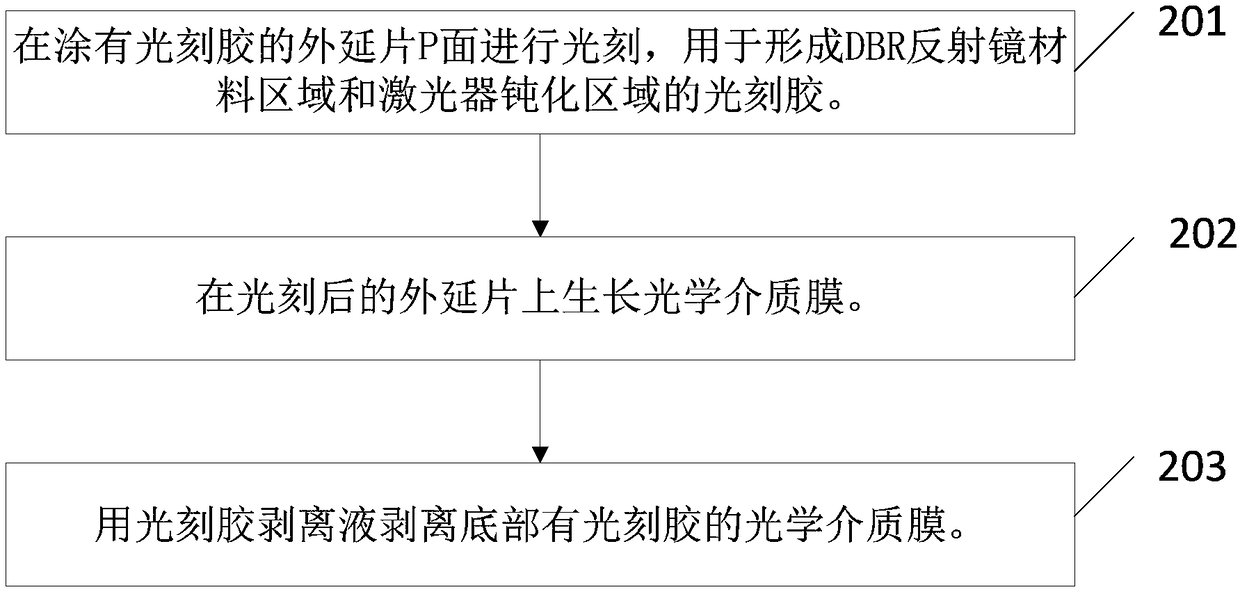

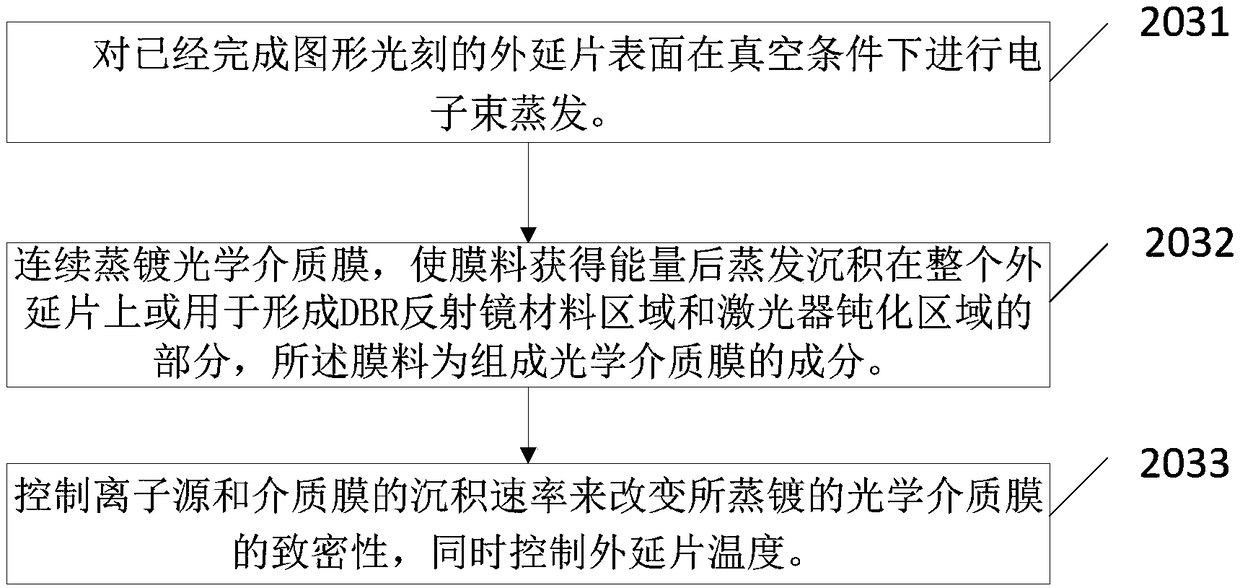

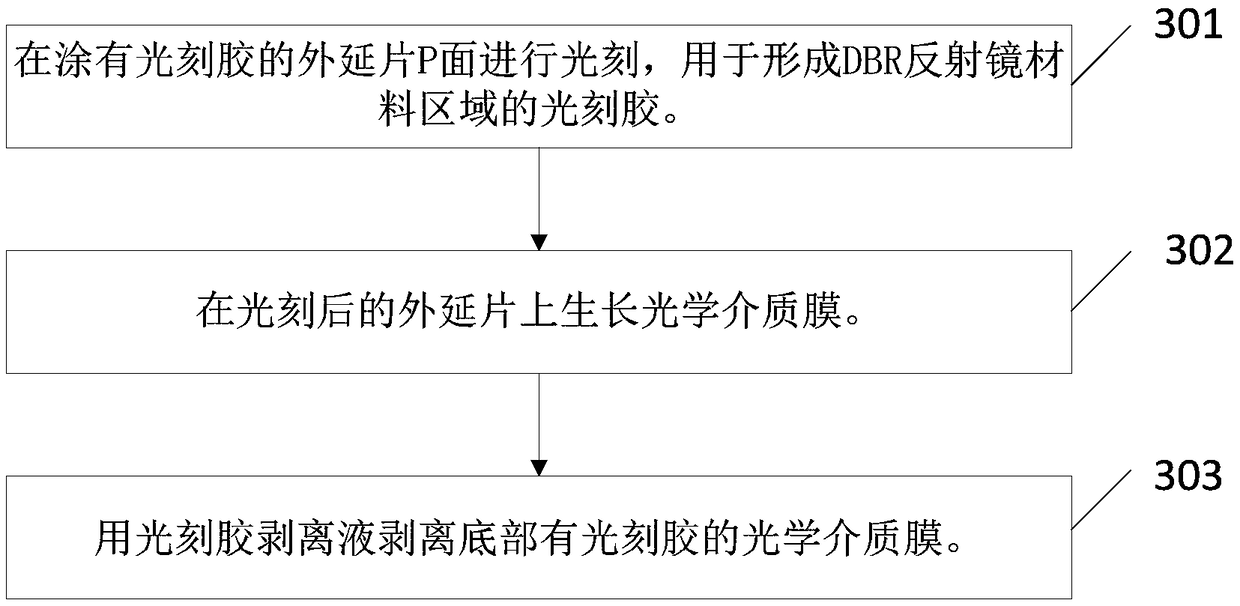

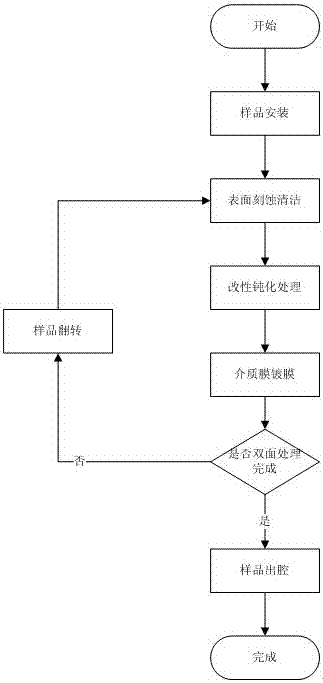

A kind of preparation method of semiconductor laser cavity mirror

ActiveCN104377543BImprove performanceImprove yieldLaser detailsVacuum evaporation coatingDielectricBatch processing

The invention belongs to the technical field of semiconductor surface modification, and specifically relates to a method for preparing a semiconductor laser cavity mirror, comprising the following steps: Step 1, cleaning; Step 2, passivation modification; Step 3, dielectric film coating; Step 4, flipping, Repeat step 1 to step 3, step 5, remove; the semiconductor laser cavity mirror modification method can be compatible with chemical and physical surface modification technology, which improves the selectivity and integrity of surface treatment; makes the surface clean and passivation modified The dielectric film coating of the double-sided cavity mirror is completed in the same vacuum chamber at one time, which reduces the number of sample entry and exit operations and possible pollution and damage, improves the cost rate, and greatly improves production efficiency; this method is based on the same equipment. Surface cleaning, modified passivation and dielectric film technology are integrated on the surface, so that the various steps of surface treatment are seamlessly connected, and the performance and yield of the finished product are improved; further, the treatment of the double-sided dielectric film cavity mirror is also completed in one step. The production efficiency and quality stability are further enhanced; the method is suitable for batch processing, has high production efficiency and low comprehensive cost.

Owner:XIAN LIXIN PHOTOELECTRIC SCI & TECH

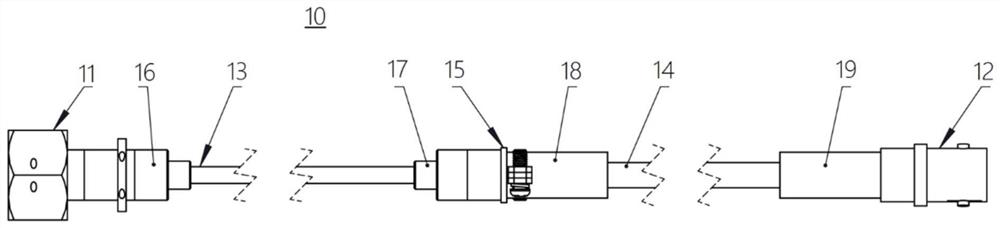

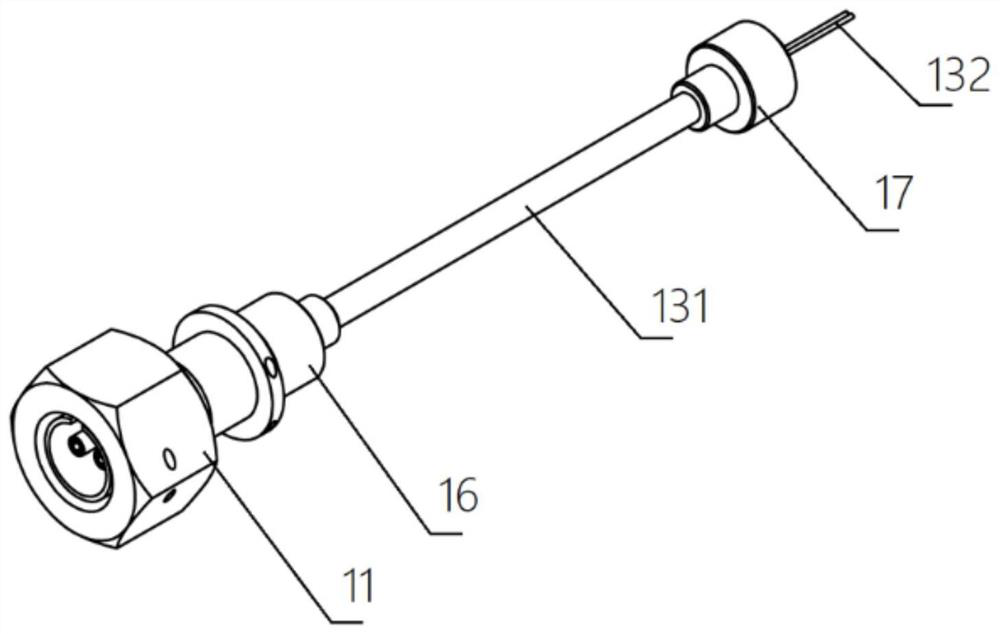

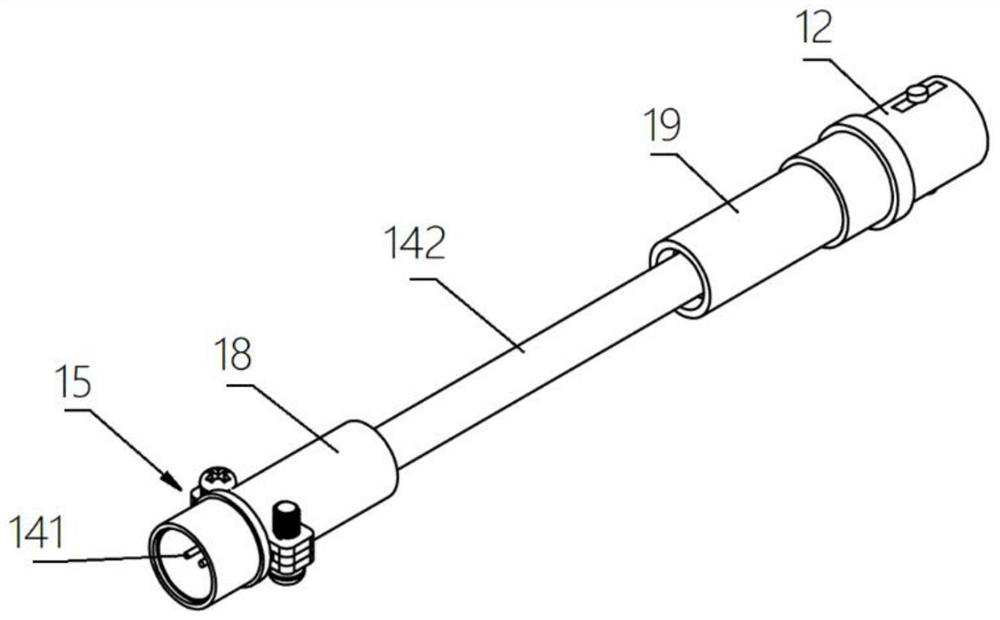

Armored cable, jig, assembling method of armored cable and sensor

PendingCN112735646ASolve the problem of low yieldAchieve receptionContact member assembly/disassemblySubsonic/sonic/ultrasonic wave measurementStructural engineeringMechanical engineering

The invention discloses an armored cable, a jig, an assembling method of the armored cable and a sensor. The armored cable comprises a high-temperature device, a low-temperature device, a high-temperature line segment and a low-temperature line segment, the high-temperature line segment and the low-temperature line segment are located between the high-temperature device and the low-temperature device, the high-temperature device is connected to the high-temperature line segment, and the low-temperature device is connected to the low-temperature line segment. And the high-temperature line segment is connected with the low-temperature line segment through a connecting device. According to the invention, the overall cost of the armored cable is reduced, the low-temperature line segment is easy to process, the cost rate is high, and the problem that the yield of the armored cable with a single high-temperature line segment is low is solved.

Owner:FATRI UNITED TESTING & CONTROL QUANZHOU TECH CO LTD

Manufacturing method for aircraft steering engine body

InactiveCN109514339AAvoid pollutionGuarantee product qualityMaintainance and safety accessoriesWaxContamination

The invention relates to a manufacturing method for an aircraft steering engine body. The manufacturing method comprises the steps that firstly, a gas pipeline of a casting for manufacturing the aircraft steering engine body is filled with pasty wax, and cooling is conducted; and secondly, rough machining treatment, fine machining treatment and dewaxing treatment are sequentially conducted on thecasting filled with the wax, and the aircraft steering engine body is obtained. According to the manufacturing method for the aircraft steering engine body, the technological method of sequentially conducting plugging, machining and dredging is innovatively proposed, the gas pipeline is filled with the wax before machining is conducted, therefore, gas outlet pipeline cutting contamination can be effectively prevented, the product quality is guaranteed, and the machining cost is greatly reduced.

Owner:江南工业集团有限公司

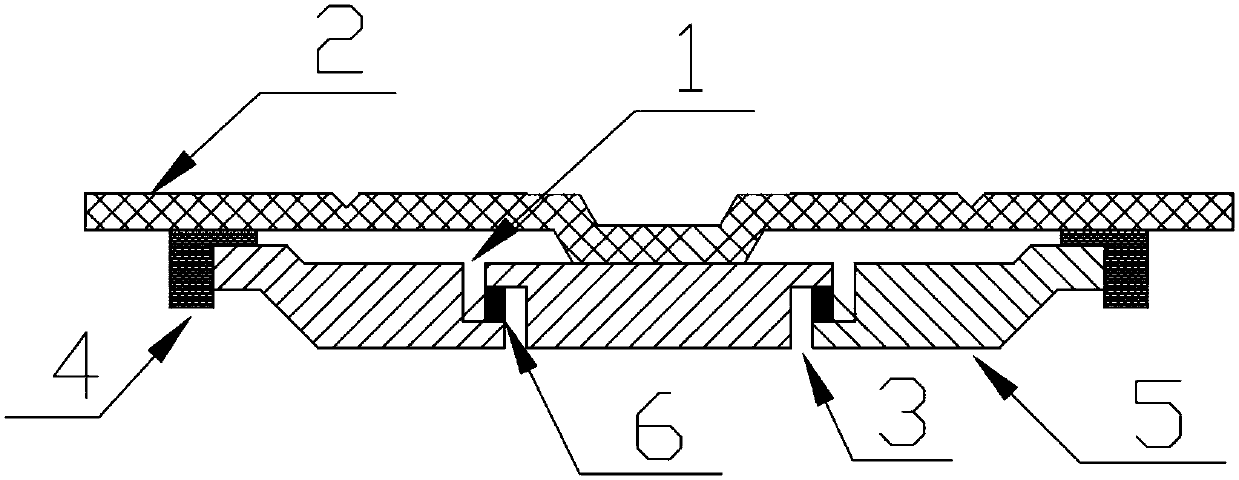

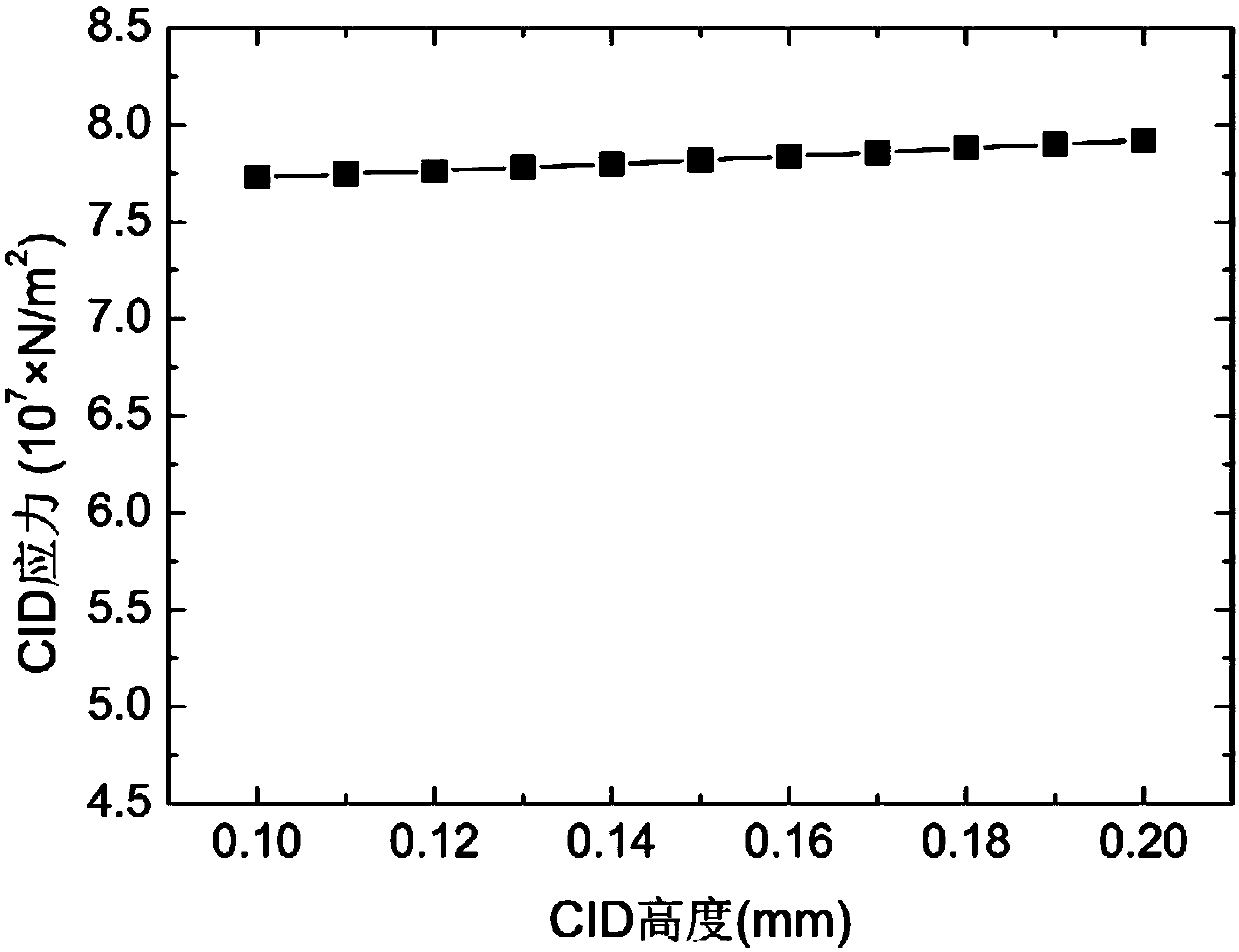

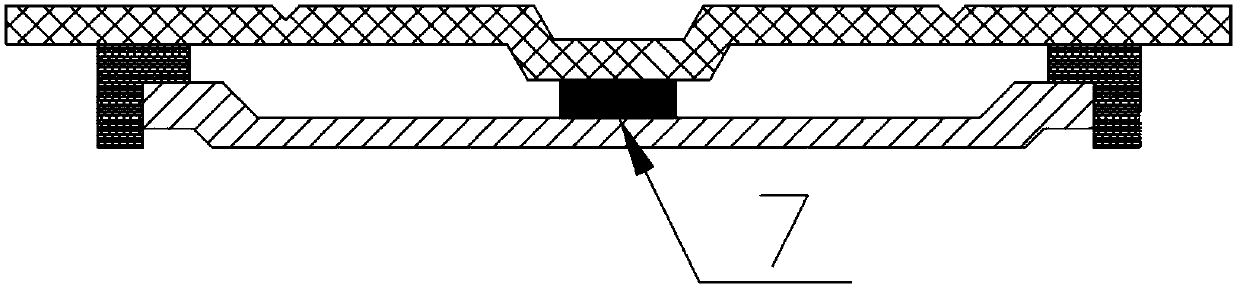

Porous plate and current blocking structure of lithium-ion battery

ActiveCN105826504BReduce dependenceEasy to processCell seperators/membranes/diaphragms/spacersStructural engineeringLithium-ion battery

The invention discloses an orifice plate. An upper ring score and a lower ring score are respectively arranged on the upper surface and the lower surface of the orifice plate. The upper ring score and the lower ring score are coaxial but have a diameter of different. At the same time, the current blocking structure of the lithium-ion battery is disclosed, which includes a fixedly connected orifice plate and an explosion-proof sheet, and an upper ring score and a lower ring score are respectively formed on the upper surface and the lower surface of the orifice plate. The upper and lower ring scores are coaxial but have different diameters. In the orifice plate of the present invention, the interval 6 of the overlapping portion of the upper ring score and the lower ring score is used as a CID structure, and the processing is simple. The current blocking is realized by the current blocking structure on the orifice plate perpendicular to the direction of the battery cover, that is, the tearing of the spacer 6 . The reduction of the tolerance dependence of the upper ring notch and the lower ring notch, first of all, greatly reduces the processing cost, and the stability of the product, especially the stability of the explosion-proof performance.

Owner:力神电池(苏州)有限公司

Standard punching sample plate

InactiveCN104550430AReasonable and reliable structural designTime-saving and labor-saving punching processPerforating toolsOther workshop equipmentProblem of timePunching

The invention relates to a punching device applied to the electric power industry and specifically relates to a standard punching sample plate. The problems of time and labor waste, low production efficiency and influence on drilling quality of the present punching plate during a sampling process are solved. The standard punching sample plate comprises a sample plate main body, wherein the sample plate main body is identical to the horizontal cross section of the punching plate; a through hole corresponding to a sampling position on the punching plate is formed in the sample plate main body; a guide sleeve corresponding to the position of the through hole is arranged on the upper surface of the punching plate; a punching steel nail in close fit with the guide sleeve penetrates through the guide sleeve; a reset spring sleeving the punching steel nail is arranged between the tail end of the punching steel nail and the upper end face of the guide sleeve. The standard punching sample plate is reasonable and reliable in structure design, is time-saving and labor-saving during a punching process, is capable of relieving the labor intensity and increasing the operation effect, is capable of ensuring the punching precision and greatly increasing the cost rate and has the advantages of simple structure, convenience in operation and low cost.

Owner:STATE GRID CORP OF CHINA +1

Drive circuit of picture element array for display panel

ActiveCN100527198CSolve overlapping issuesLow costTelevision system detailsStatic indicating devicesShift registerProcessor register

A driving circuit includes a shift register circuit and an output buffer circuit. The shift register circuit includes first and second shift register units. The first and second shift register units respectively output first and second shift signals, and the first and second shift signals are enabled sequentially. The output buffer circuit includes first and second output buffer units. The first and second output buffer units respectively receive the first and second shift signals to output a first switch control signal and a second switch control signal. The voltage supply end of the second output buffer unit receives the first shift signal. When the voltage of the first shift signal turns inactive, the second output buffer unit is enabled, so that the second output buffer unit outputs the second switch control signal, so that a data signal is input into the pixel array.

Owner:AU OPTRONICS CORP

Process for overlaying stainless steel sealing face on nodular cast iron valve substrate

InactiveCN104959711AStrong heat resistanceIncrease profitArc welding apparatusWelding/soldering/cutting articlesButt weldingSS - Stainless steel

The invention discloses a process for overlaying a stainless steel sealing face on a nodular cast iron valve substrate. The process comprises the steps that firstly, the valve substrate is cleaned; pulse gas metal arc welding is adopted; full-automatic welding is adopted, pulsed direct currents are adopted, an anode is reversely connected, inert gas shielding is achieved, and flow ranges from 10 L / min to 17 L / min; welding speed ranges from 8 cm / min to 15 cm / min; after welding is completed, the position, to be welded, of the valve substrate is wrapped by a stainless steel overlaying layer of 2 mm to 4 mm; and heat preservation and preheating are omitted. The process has the advantages that the welded sealing face is reliable in strength and stable in performance, the defects of air holes, cracks and the like are overcome, and the utilization rate of materials is high; the process is simple, operation is convenient, and automation can be achieved. Compared with a stainless steel ring spinning, contour welding and embedding process, a plurality of procedures such as line drawing, blanking, plate rolling, butt welding and spinning are omitted, and the process is suitable for automatic welding and volume production.

Owner:HEBEI HENGTONG VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com