Material storing and cutting pulling device for automatic slitting machine

A pulling device and cutting machine technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve the problems of high maintenance cost, numerous parts and high cost rate, and achieve high cost rate and traction. High precision and good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

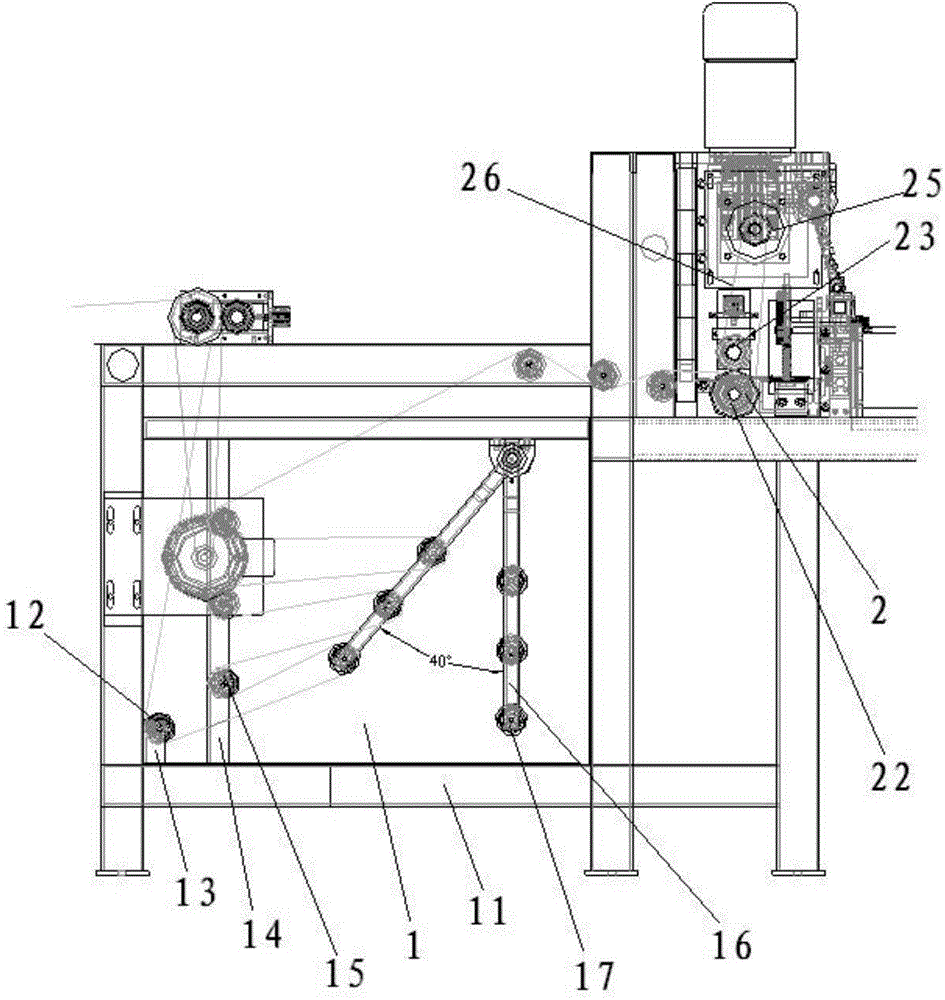

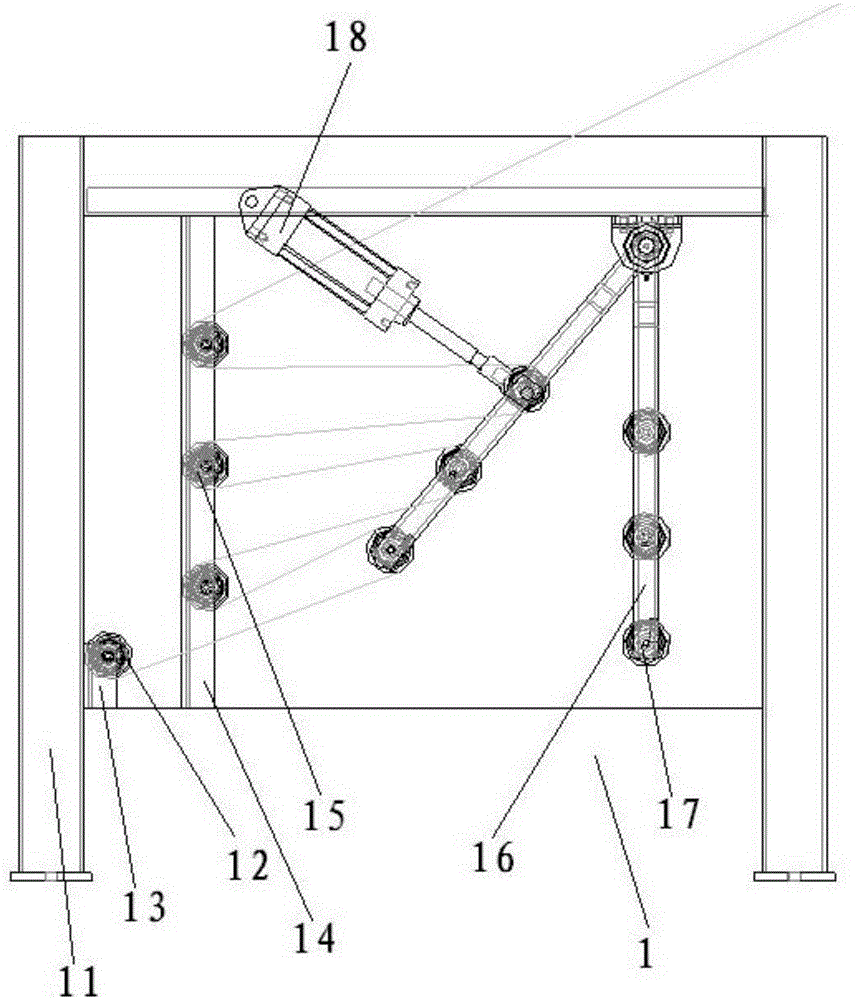

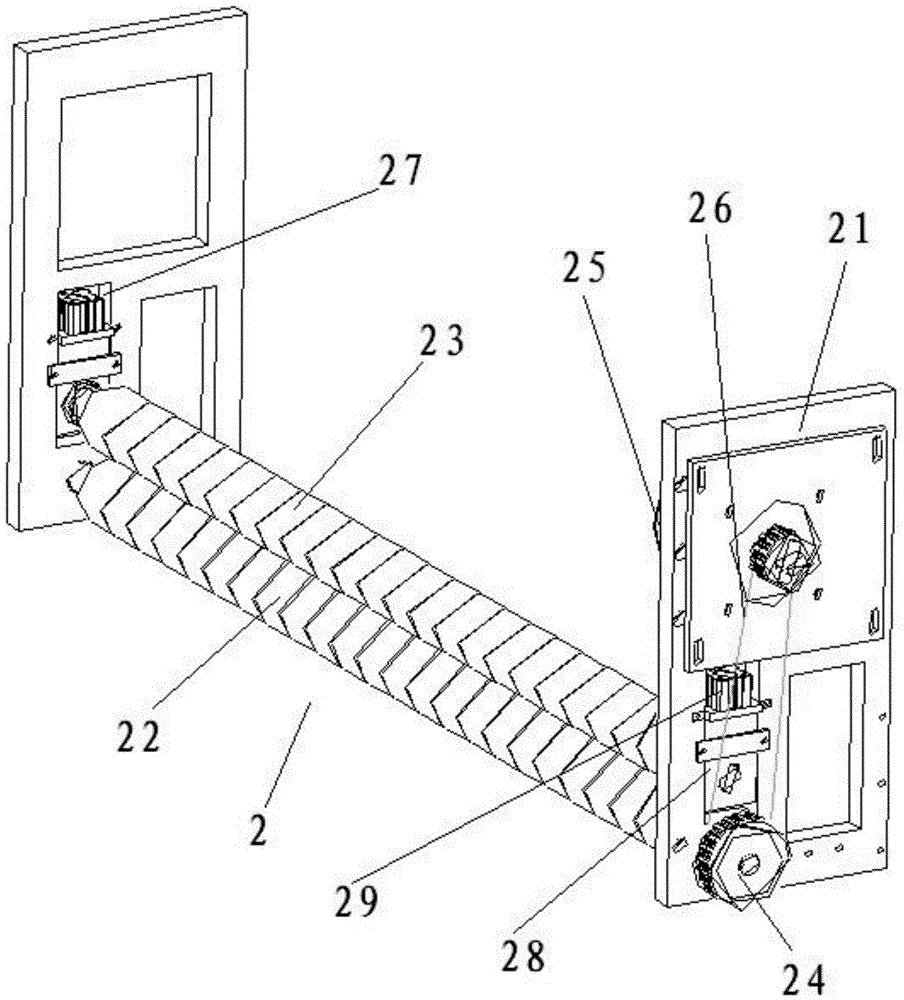

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figure 1~3 As shown, a material storage device and cutting traction device of an automatic cutting machine is characterized in that: it includes: a material storage device 1 and a cutting and traction device 2 located at the off-line of the storage device 1; The device 1 includes a frame 11, the left side of the bottom end of the frame 11 is provided with a first pole 13 for fixing the first fixed roller 12, and the right side of the first pole 13 is arranged in parallel to connect the frame 11 up and down. The second pole 14 on the surface, on the second pole 14, several second fixed rollers 15 are arranged sequentially from bottom to top, the top right side of the frame 11 is movably connected with the top of the swing arm 16, the swing On the arm 16, several swing rollers 17 are sequentially arranged from top to bottom, the middle part of the swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com