Integral metal-based polymer composite self-lubricating bearing and manufacturing method thereof

A self-lubricating bearing and polymer-based technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of Green column strain, high cost, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

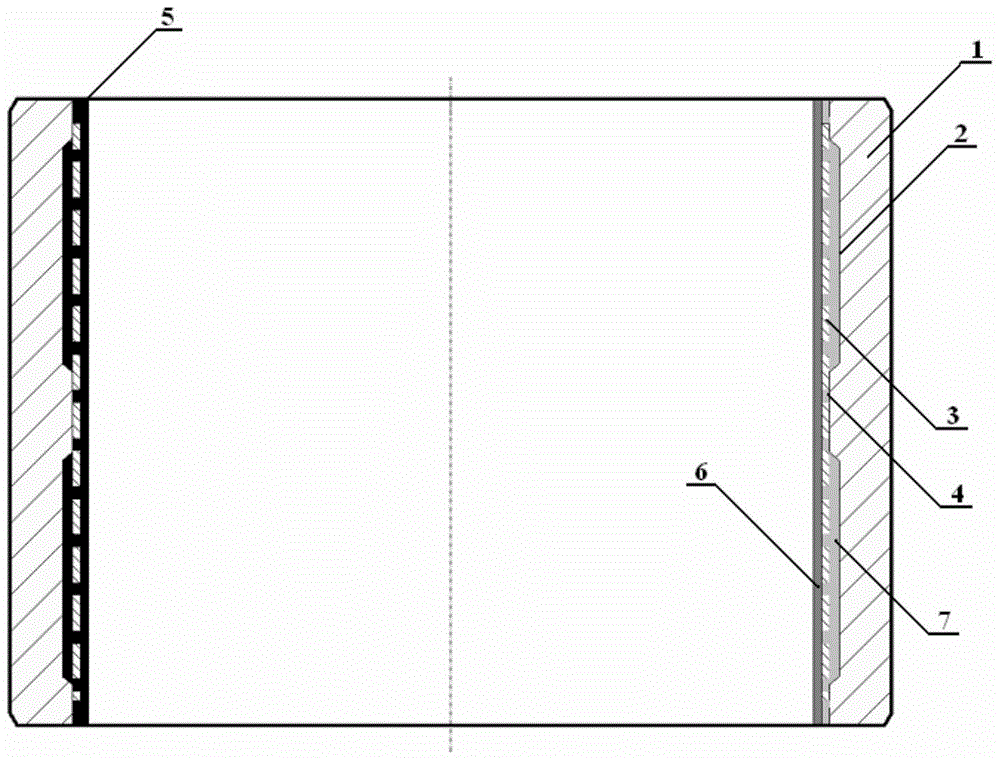

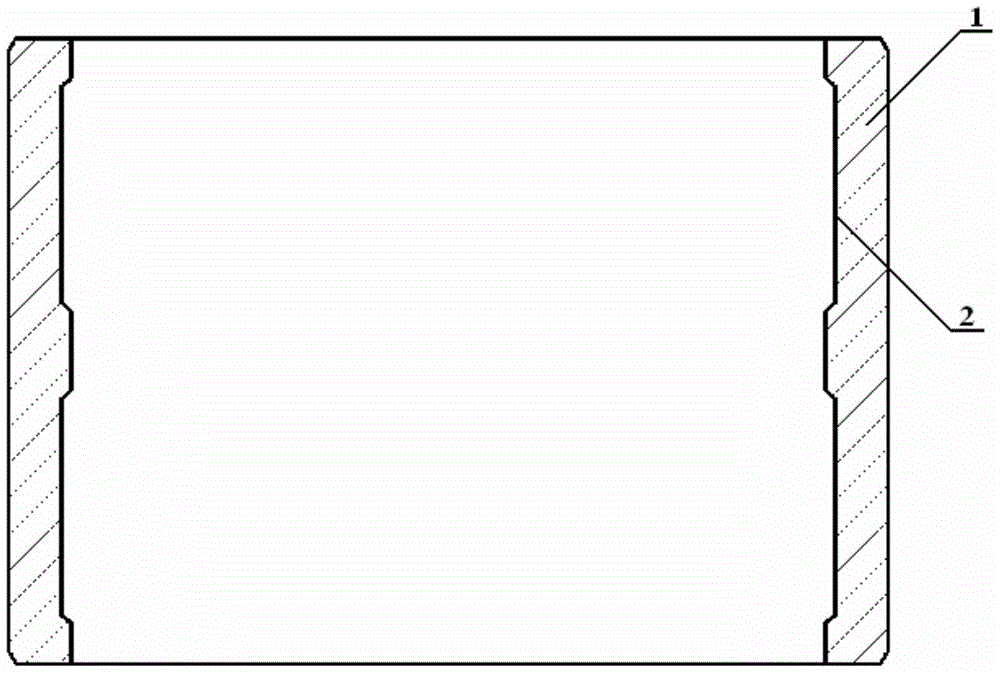

[0059] (1) Machining the inner surface of the 45# steel shaft sleeve to obtain an outer circular metal bushing with an inner diameter of 75mm, an outer diameter of 85.3mm, and a height of 59mm; the inner surface of the outer metal bushing is provided with 2 inner diameter rings Groove, the depth of the inner diameter ring groove is 1mm, and the width is 21.5mm.

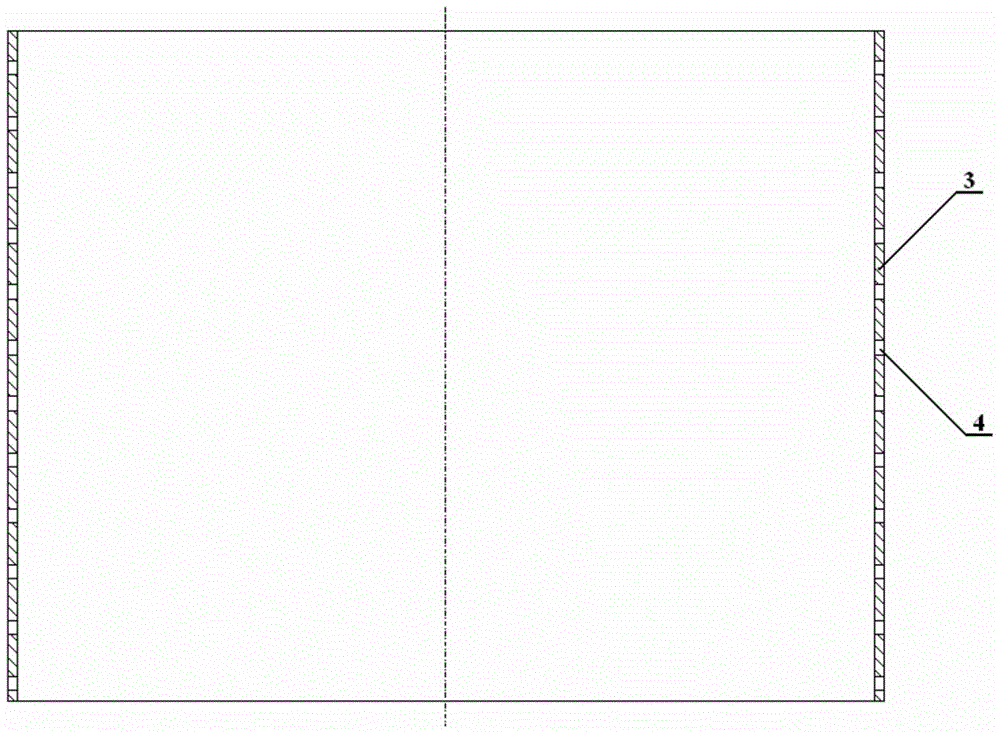

[0060] (2) The cold-rolled low-carbon steel plate with the grade SPCC and a thickness of 1.5mm is in accordance with Figure 5 The distribution of the through holes shown is punched, and then the plate is cut, rolled and machined to obtain a steel plate layer with an inner diameter of 72 mm, a thickness of 1.5 mm, and a height of 52 mm; the steel plate layer has a plurality of through holes, and the multiple The diameter of each hole is 3mm.

[0061] (3) Press the steel plate layer obtained in step (2) into the outer circular metal bushing obtained in step (1) under the press-in force condition of 200kg. Spot weldin...

Embodiment 2

[0064] (1) The inner surface of the 45# steel shaft sleeve is machined to obtain an outer metal shaft sleeve with an inner diameter of 44.5mm, an outer diameter of 50.3mm, and a height of 33mm; the inner surface of the outer metal shaft sleeve is provided with 2 inner diameters Ring groove, the depth of the inner diameter ring groove is 1mm, and the width is 7.5mm.

[0065] (2) The cold-rolled low-carbon steel plate with the grade SPCC and a thickness of 1.5mm is in accordance with Figure 5 The distribution of the through holes shown is punched, and then the plate is cut, rolled and machined to obtain a steel plate layer with an inner diameter of 41.5mm, a thickness of 1mm, and a height of 26mm; the steel plate layer has a plurality of through holes, and the multiple The diameter of each hole is 3mm.

[0066](3) Press the steel plate layer obtained in step (2) into the outer circular metal bushing obtained in step (1) under the press-in force condition of 100kg. Spot weldin...

Embodiment 3

[0069] (1) The inner surface of the 45# steel shaft sleeve is machined to obtain an outer metal shaft sleeve with an inner diameter of 85mm, an outer diameter of 95.6mm, a flange outer diameter of 101.5mm, and a height of 83mm; the outer metal shaft Two inner diameter ring grooves are provided on the inner surface of the sleeve, the depth of the inner diameter ring grooves is 1mm, and the width is 27.5mm.

[0070] (2) The cold-rolled low-carbon steel plate with the grade SPCC and a thickness of 1.5mm is in accordance with Figure 5 The distribution of the through holes shown is punched, then sheared, rounded and machined to obtain a steel plate layer with an inner diameter of 82 mm, a thickness of 1.5 mm, and a height of 71 mm; the steel plate layer has a plurality of through holes, and the multiple The diameter of each hole is 3mm.

[0071] (3) Press the steel plate layer obtained in step (2) into the outer circular metal bushing obtained in step (1) under the press-in force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com