Patents

Literature

56results about How to "No strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

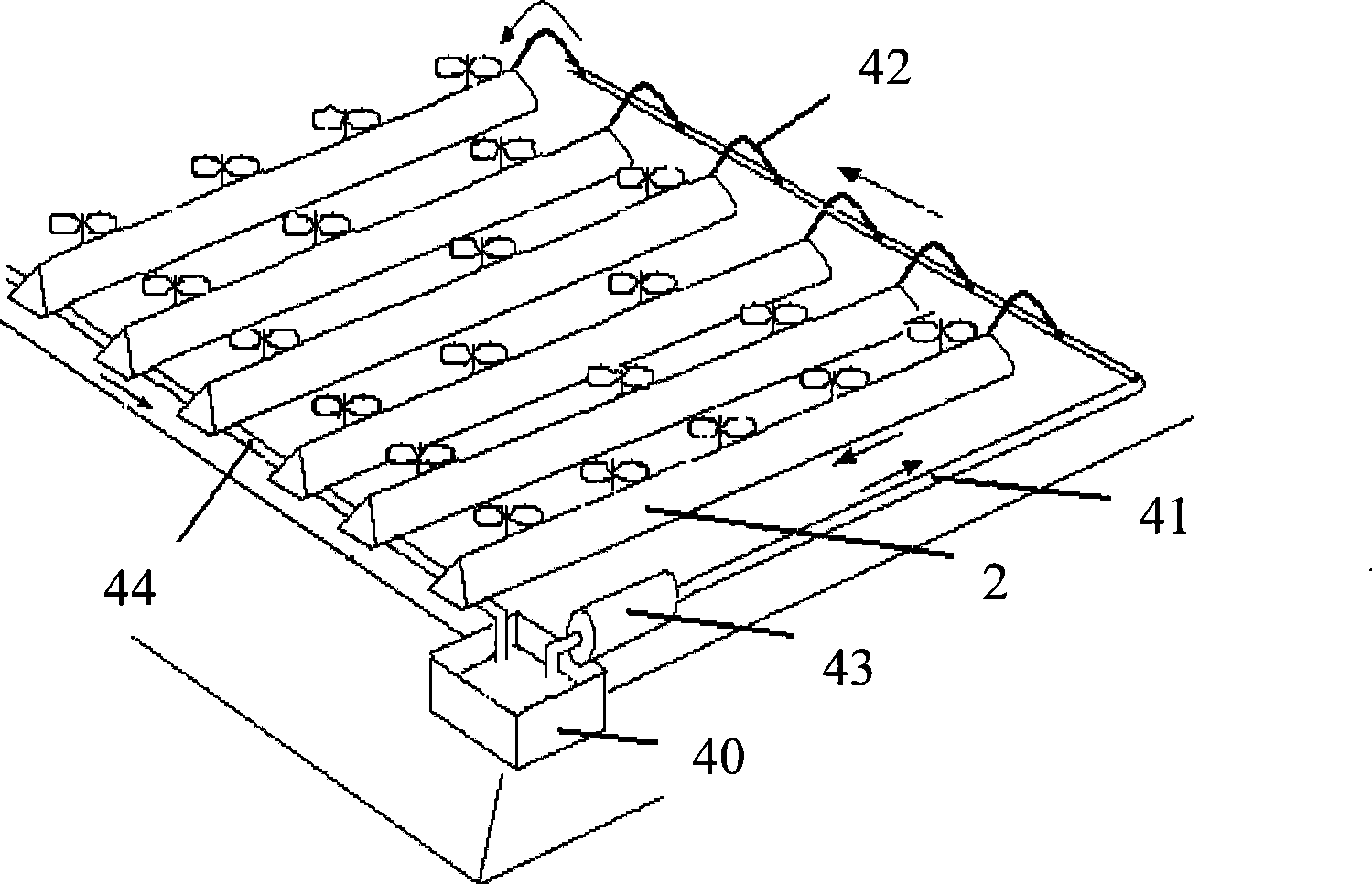

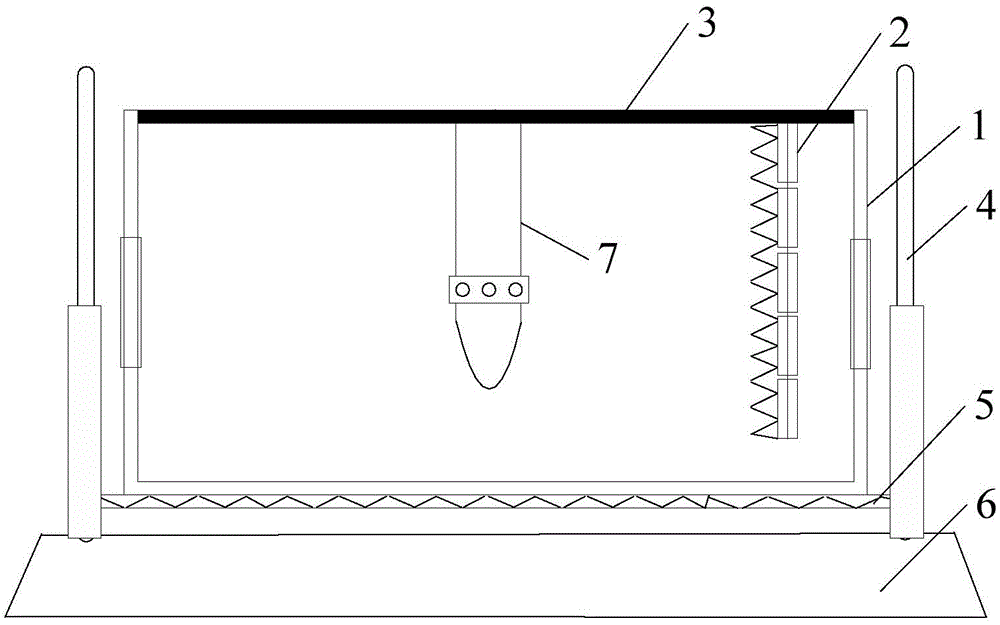

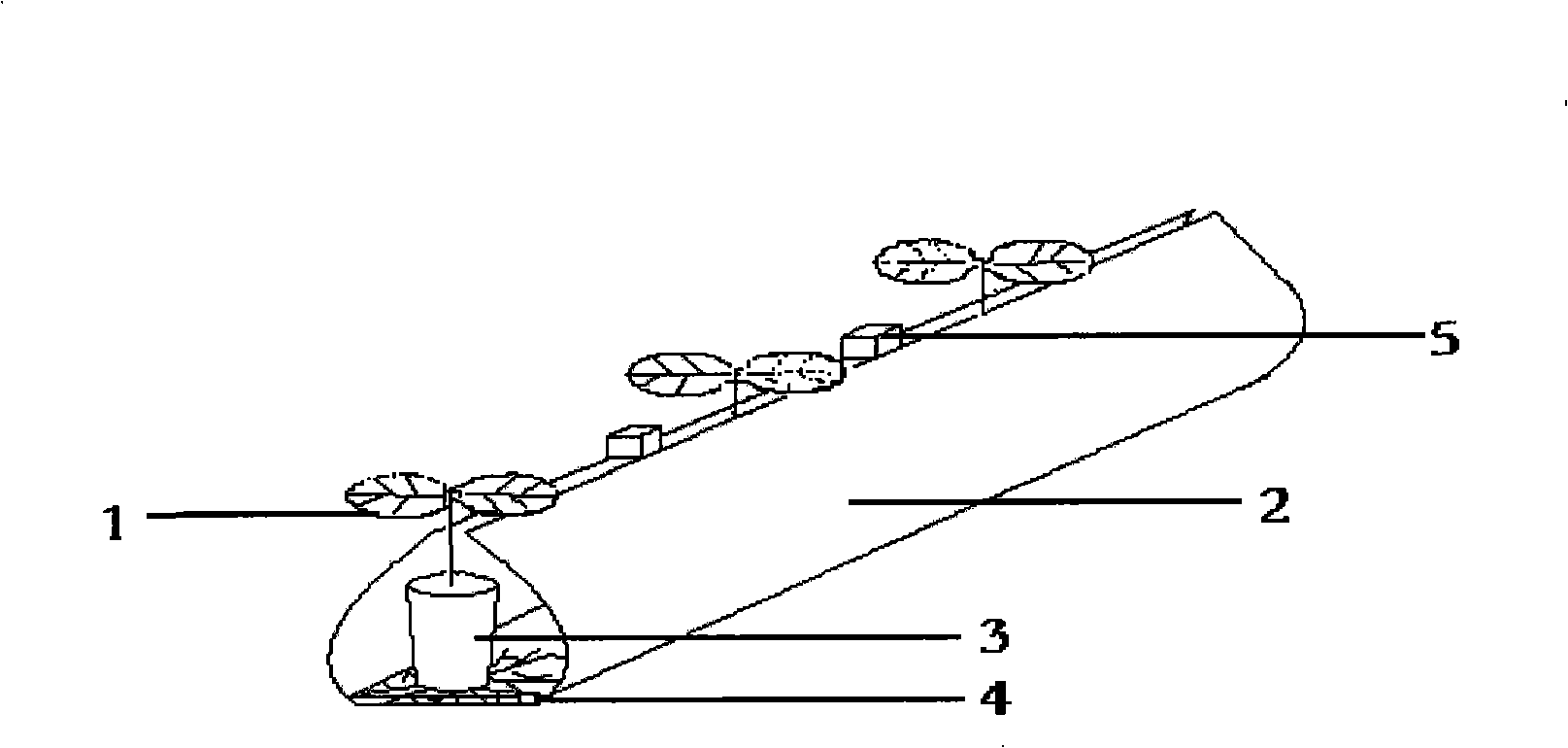

Soilless capillary hydroponics rearing system

InactiveCN101416605ANo strainReduce labor intensityAgriculture gas emission reductionCultivating equipmentsWater filterLiquid storage tank

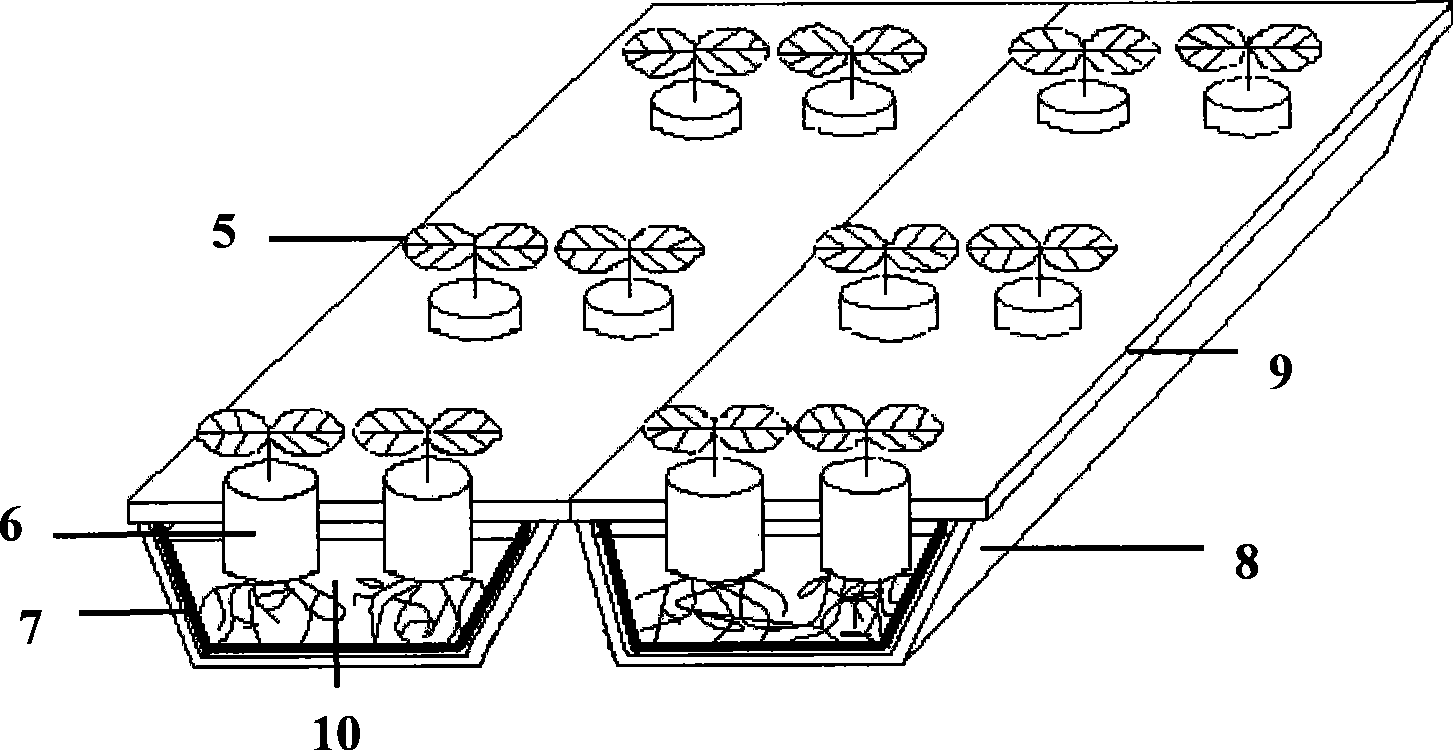

The invention relates to a soilless cultivation system of capillary hydroponics, comprising a plurality of culturing grooves, a liquid storage tank, a liquid feeding pipe, a water pump, a flowmeter, a timer, a first backflow pipe, a second backflow pipe, a backflow tank, a pressure pump, a water filtering and disinfecting device, and a fertilizer blending tank. The tables for fixing and putting plants in the culturing grooves of the soilless cultivation system of capillary hydroponics are set fixedly, such that there is no damage to the roots of plants because of the liquid level changes of the nutrient solution and no worry about water or power cut because of the 5cm height of the nutrient solution. The invention adopts the root separating method to solve the conflict of oxygen uptake and liquid supplement with low consumption of energy. in addition, The bottom of the culturing groove can be provided with a culturing frame having the function of supporting to completely change the traditional stooping or squatting working way of the workers in the past, which is not only good for easy operation and management, but also for easy cleaning of the residue roots after harvesting. So the labor intensity can be reduced.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

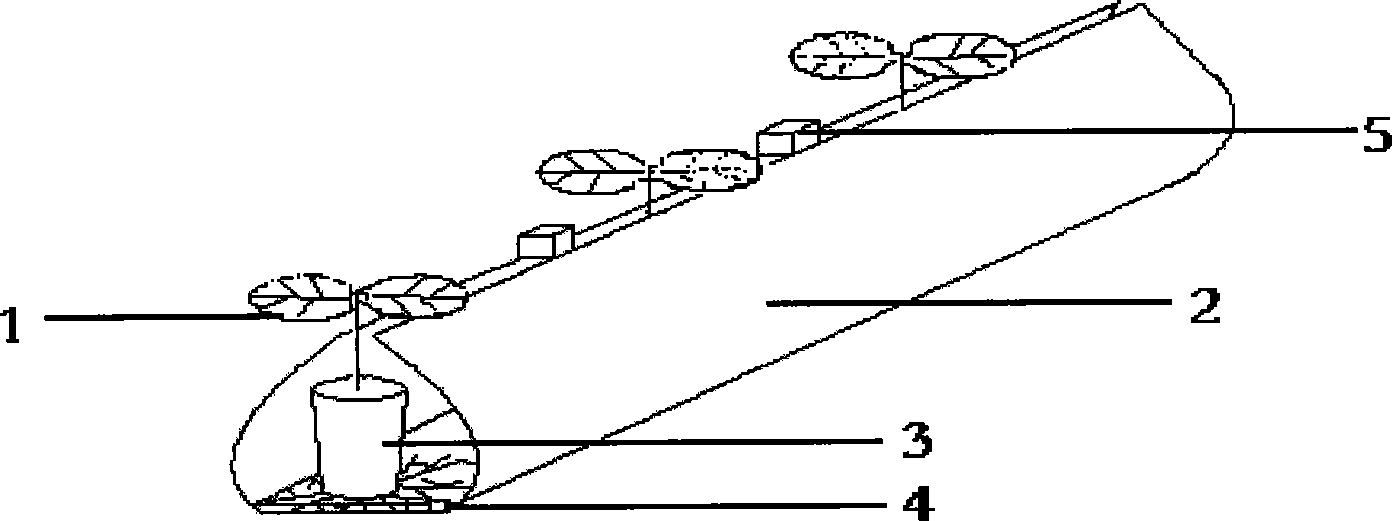

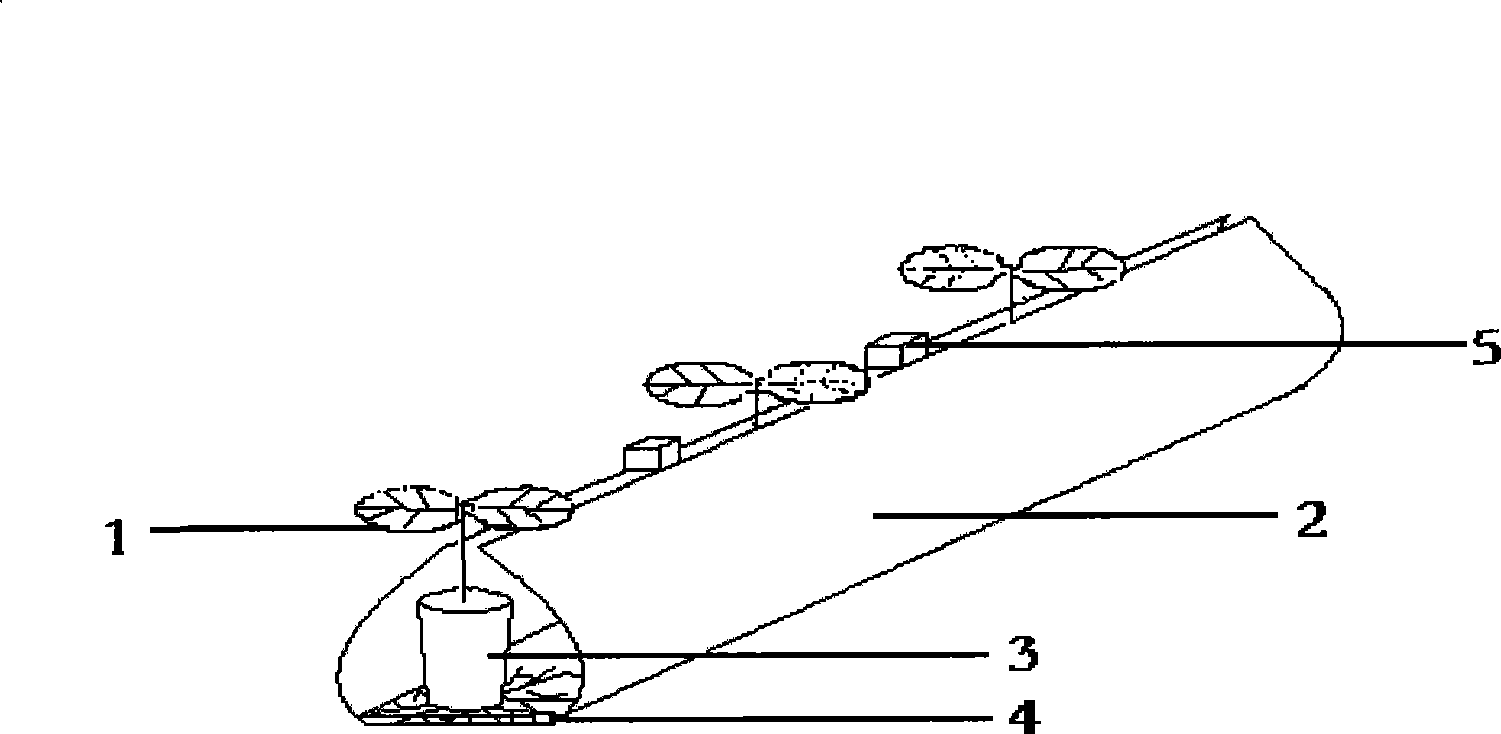

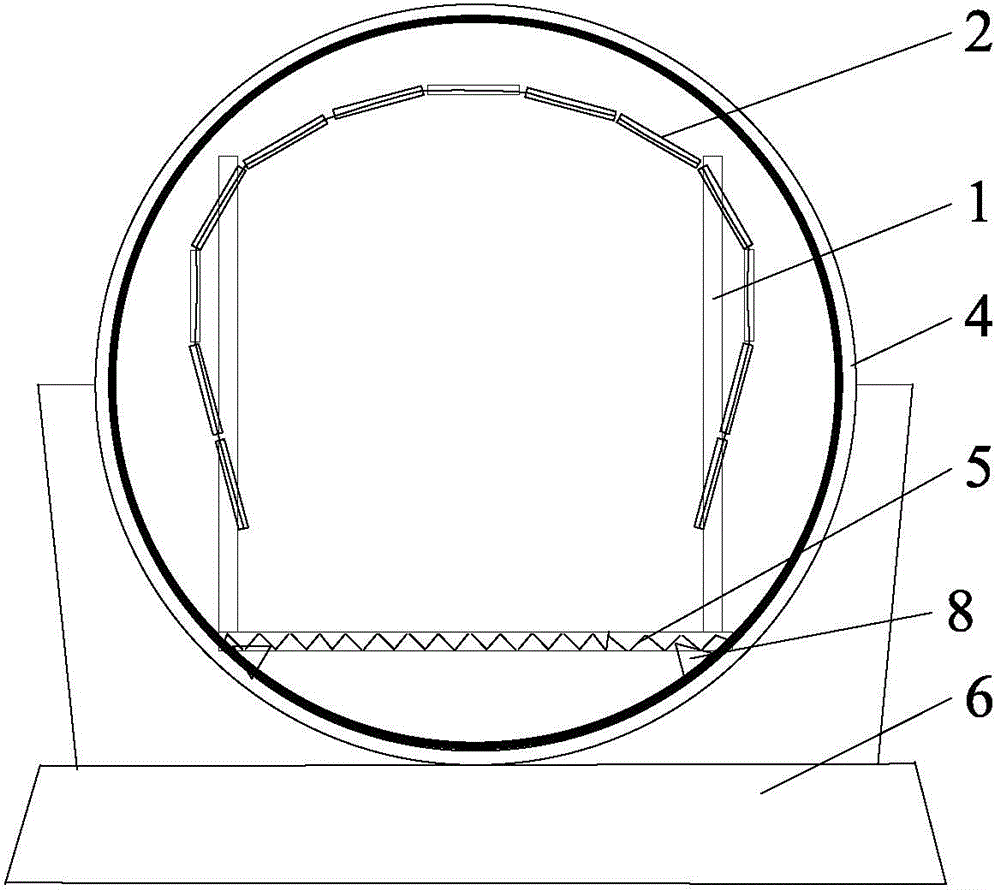

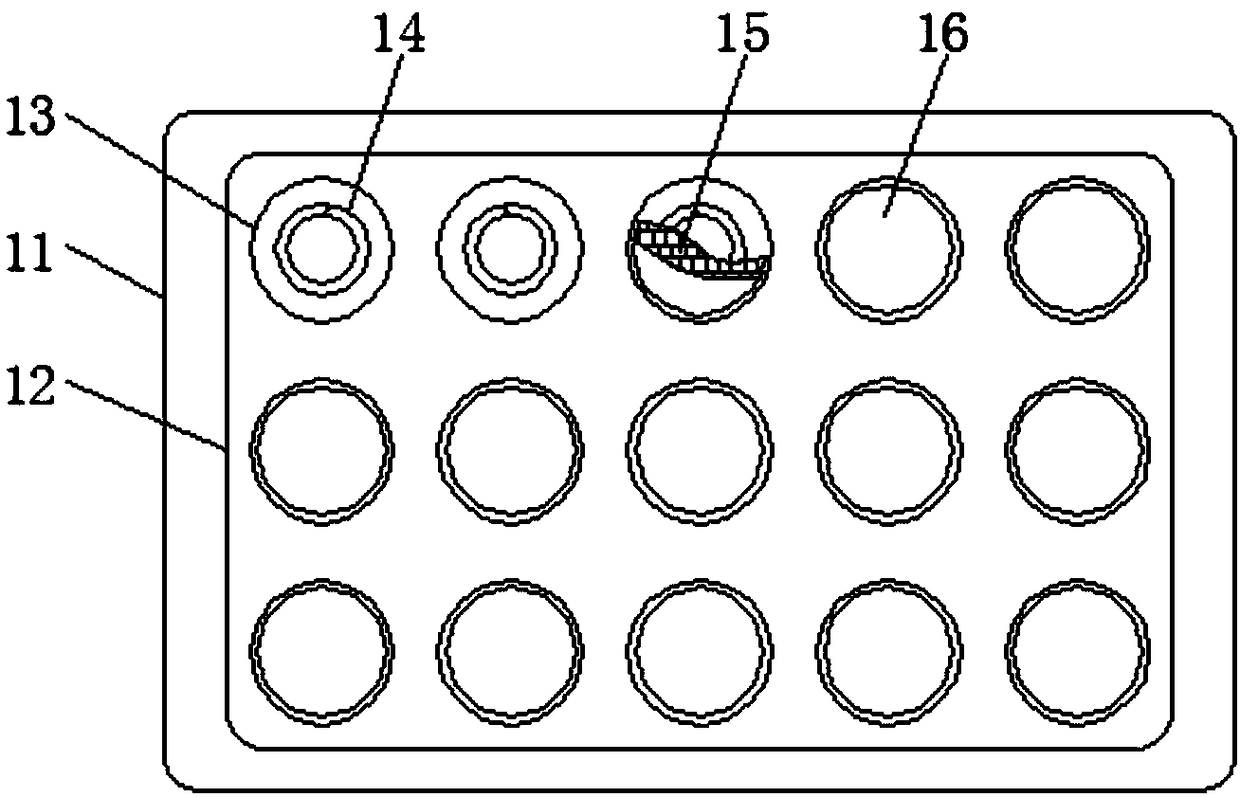

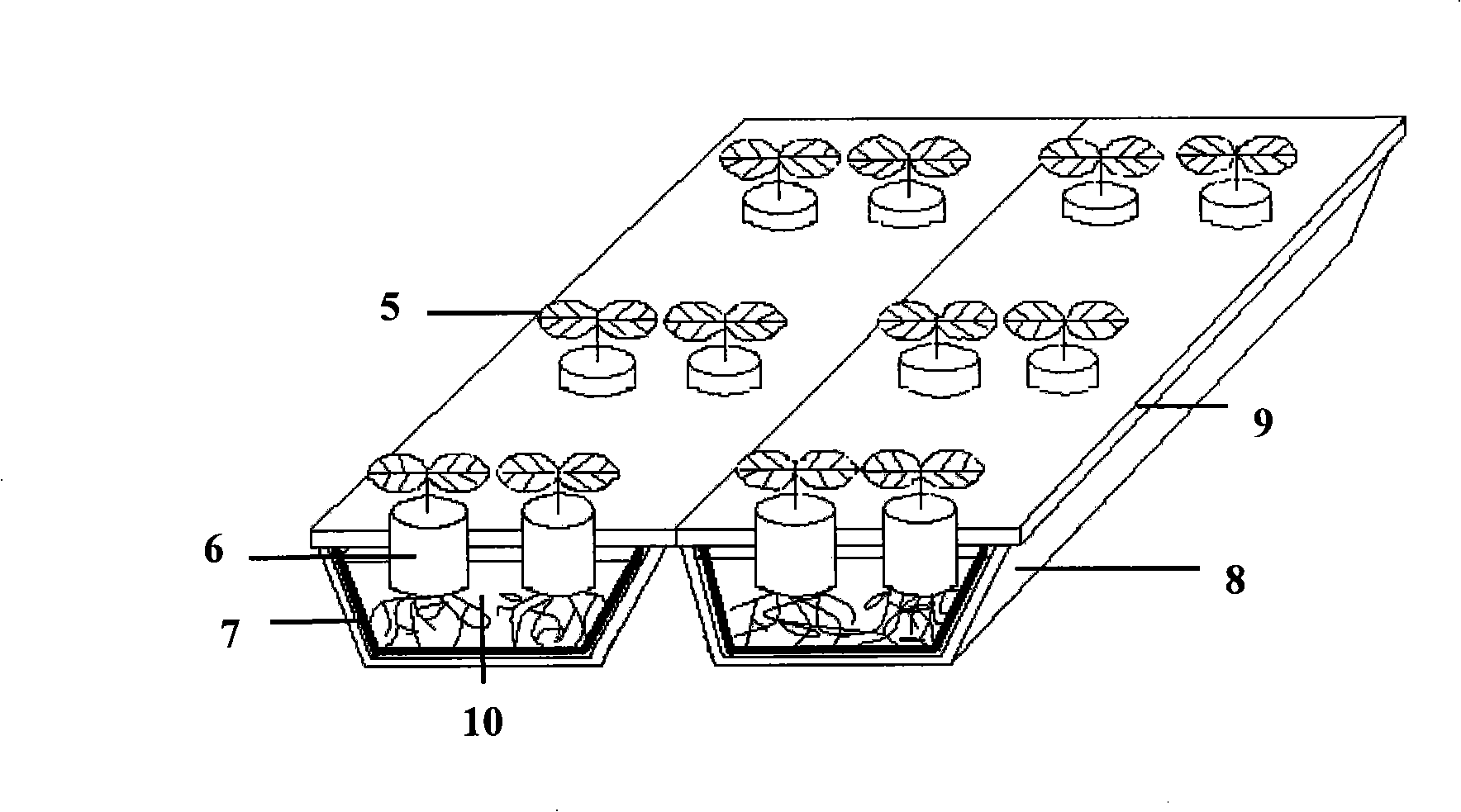

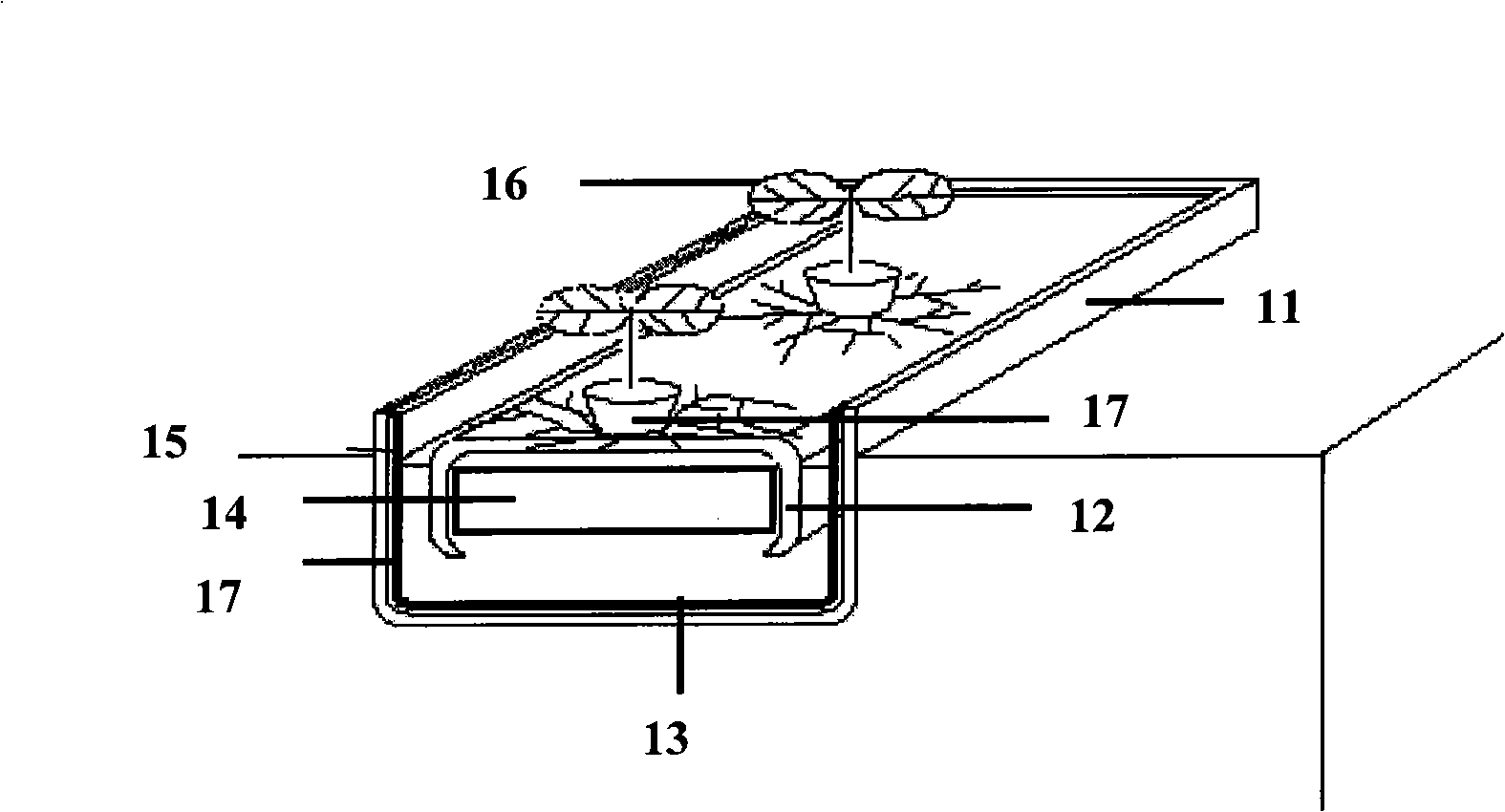

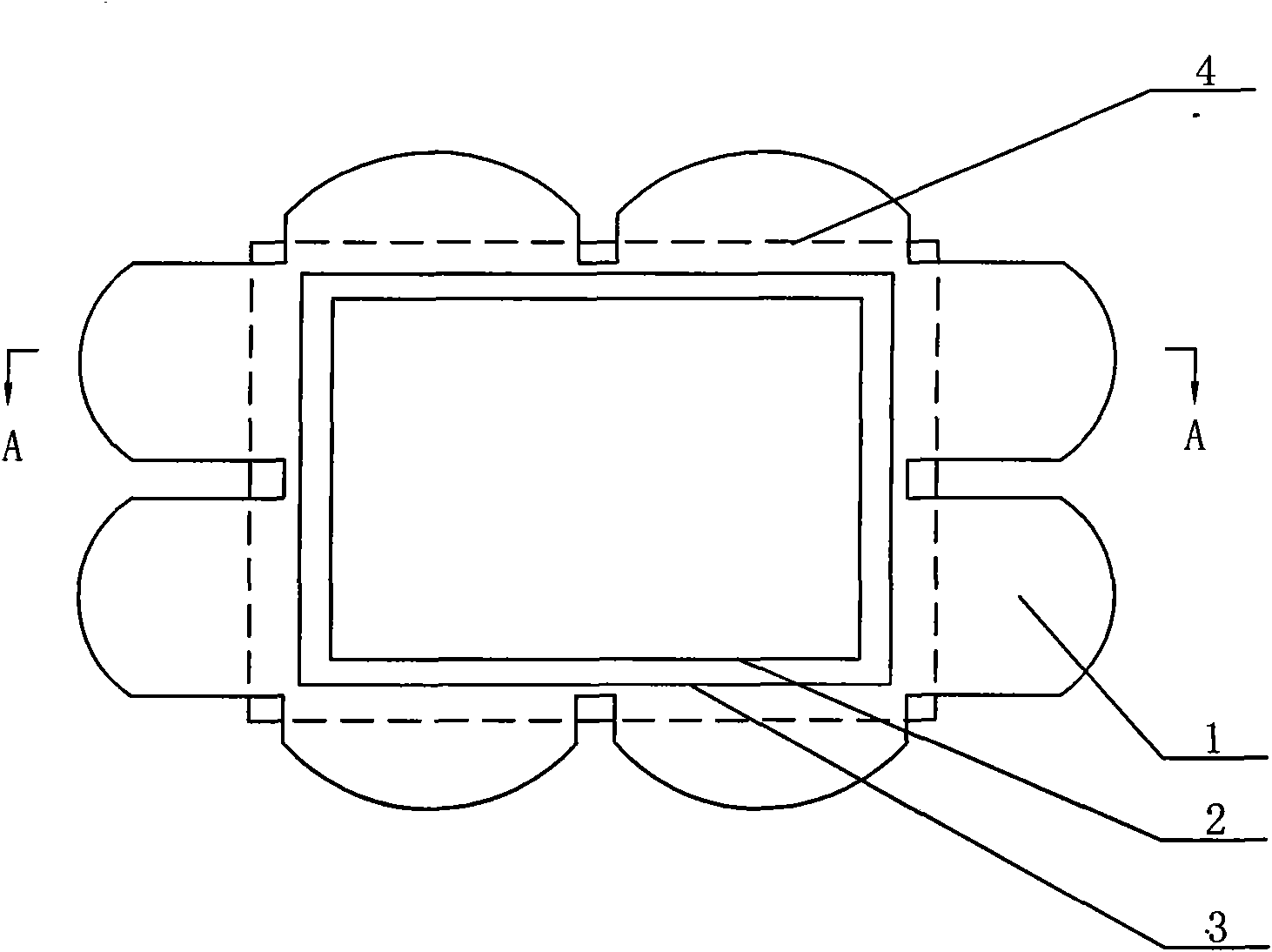

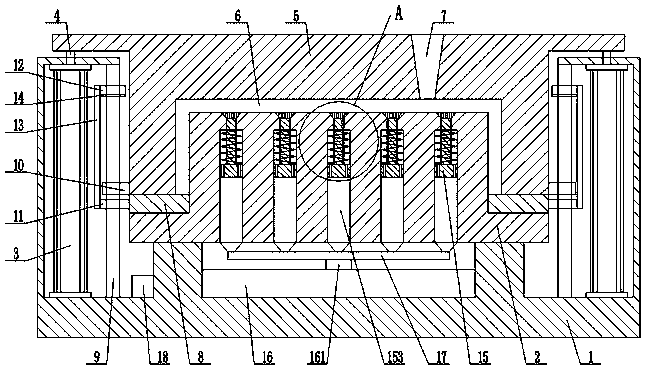

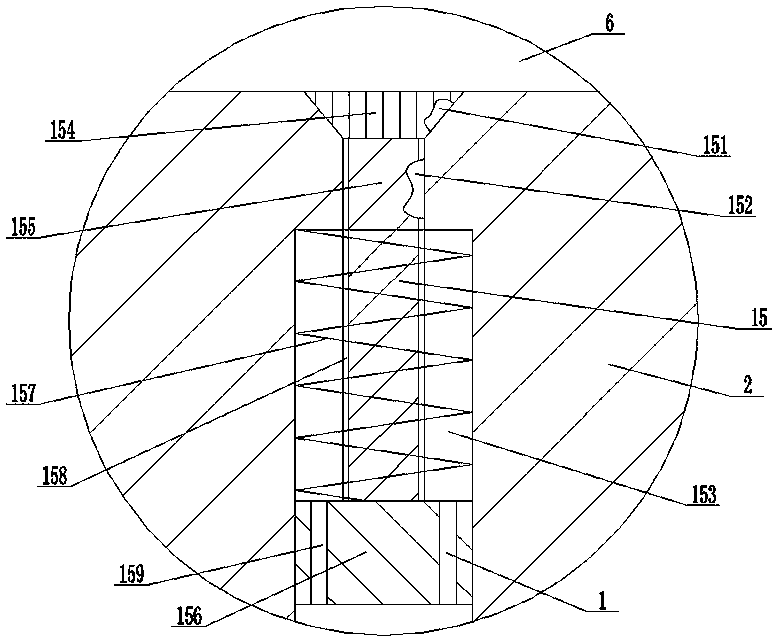

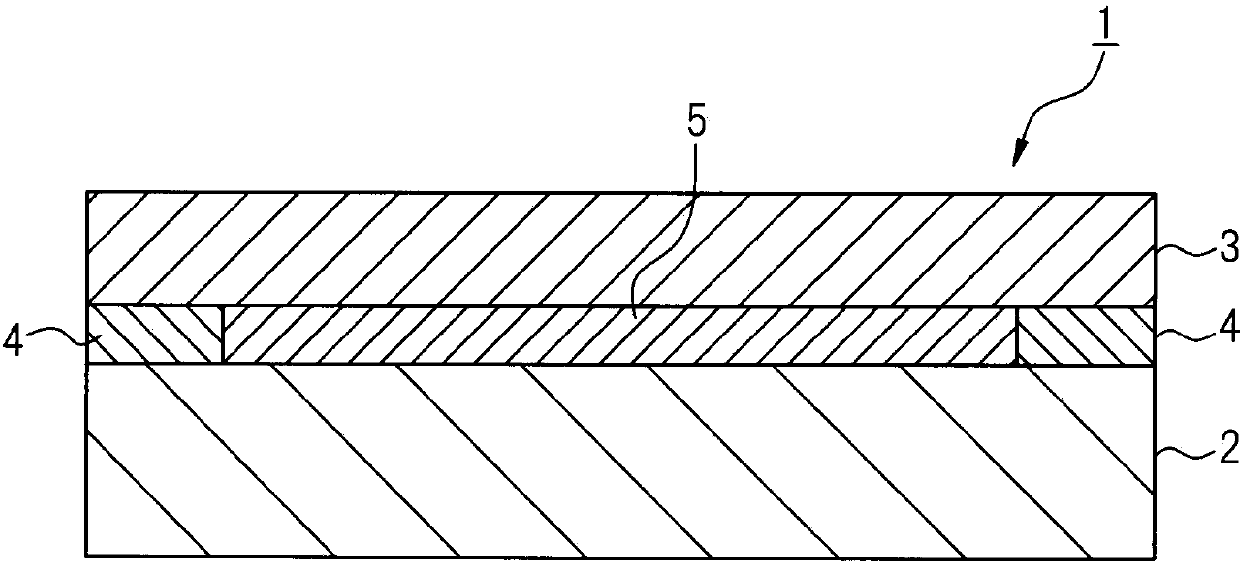

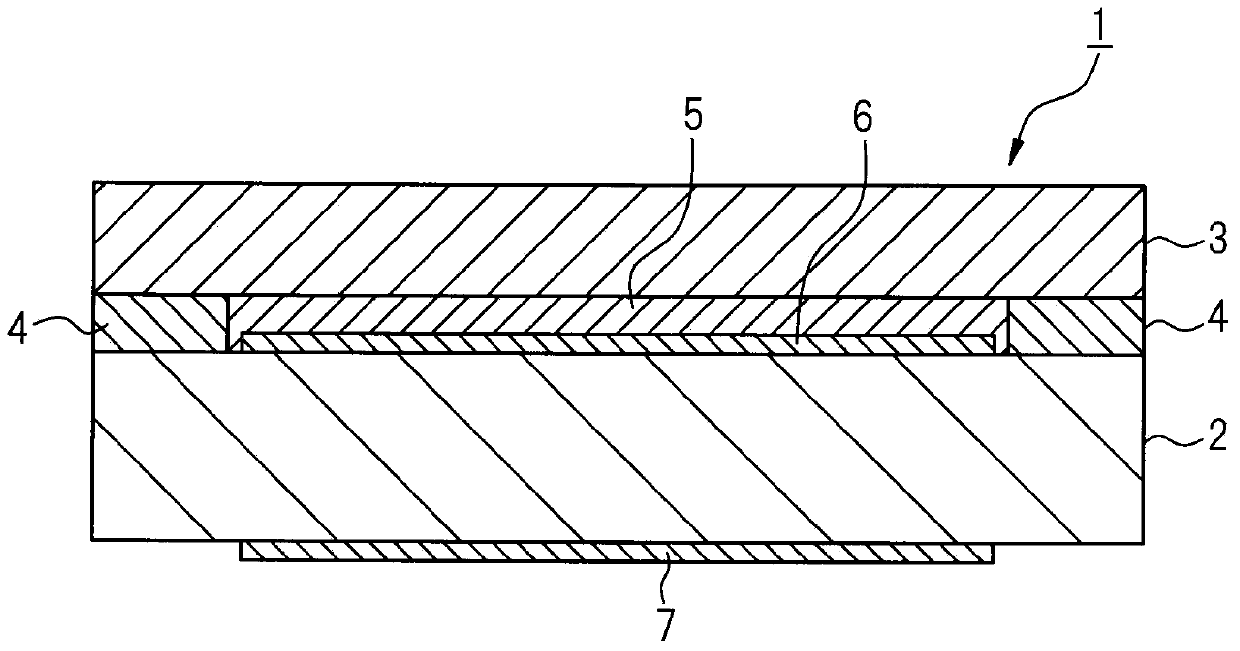

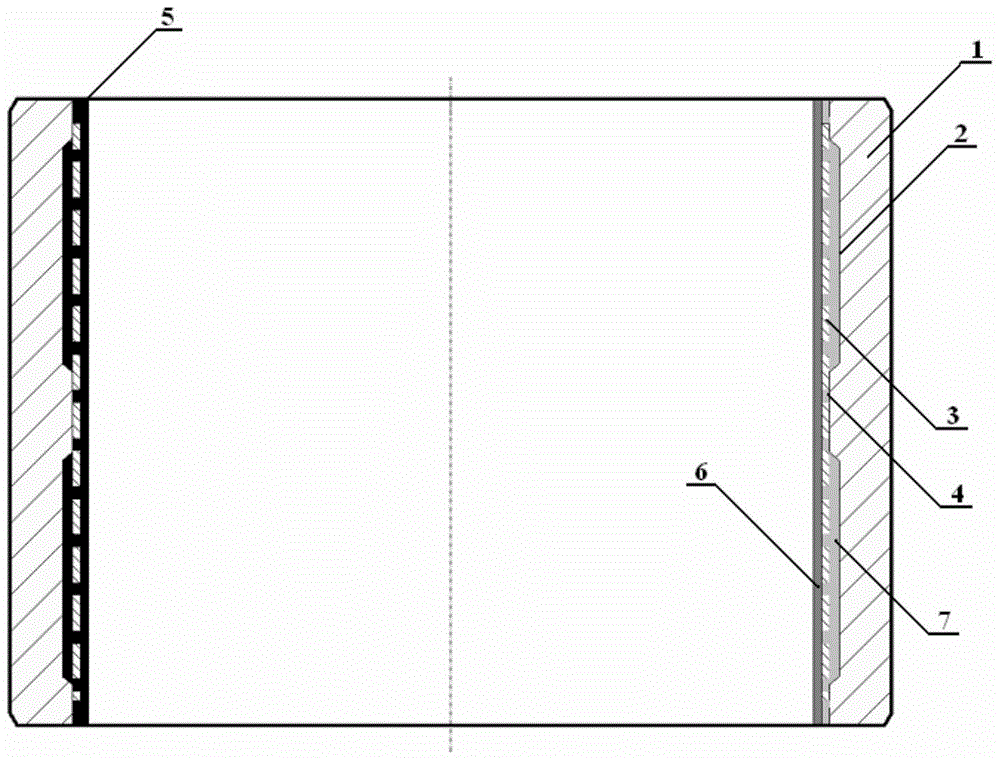

Soilless capillary hydroponics rearing groove

InactiveCN101416606ANo strainReduce labor intensityAgriculture gas emission reductionCultivating equipmentsNutrient solutionEngineering

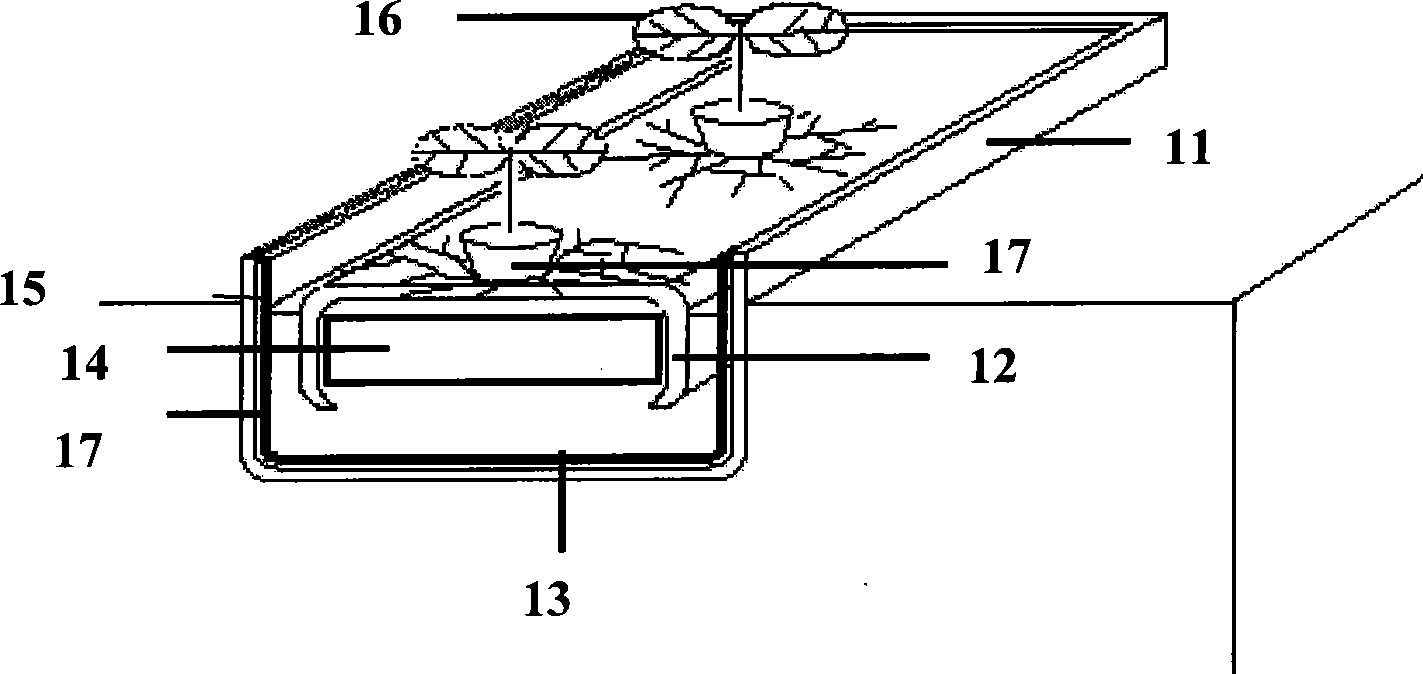

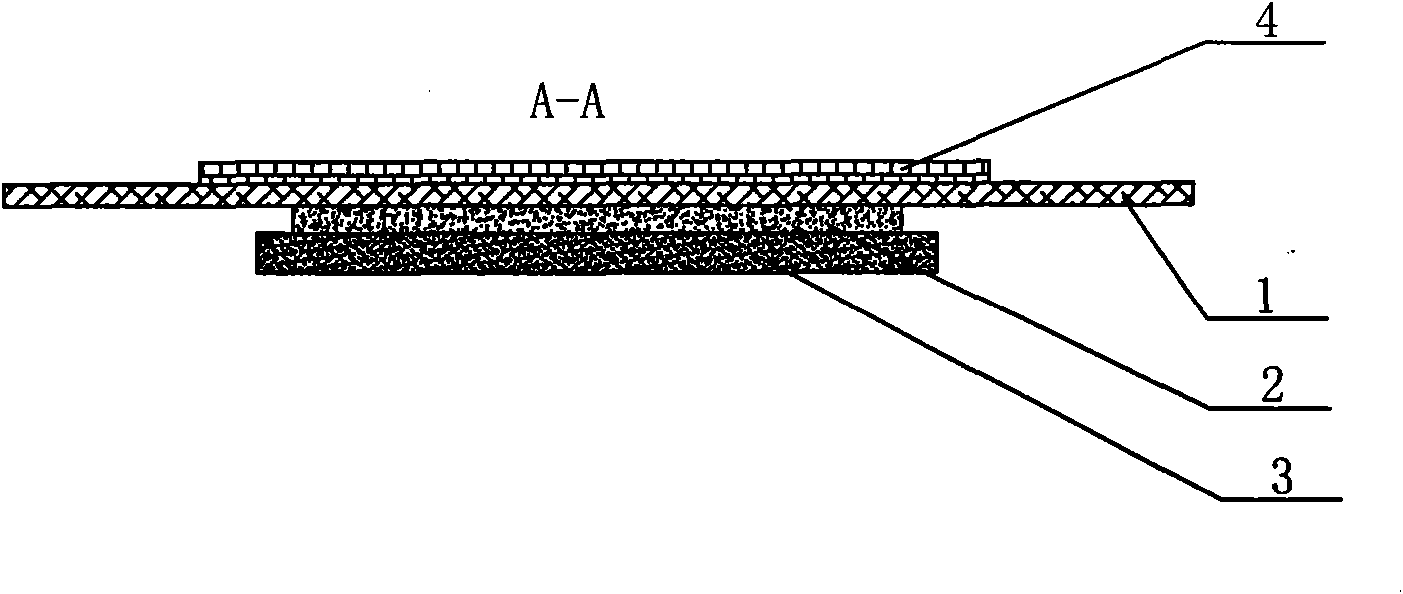

The invention relates to a soilless cultivation groove of capillary hydroponics, comprising a groove body, a seepage prevention film, a table for fixing plant, a hydrophilic non-woven fabric, and a groove cover. The table for fixing and putting plants in the culturing groove of the soilless cultivation system of capillary hydroponics is set fixedly, such that there is no damage to the roots of plants because the liquid level of the nutrient solution is changed by the influence of external temperature and no worry about water or power cut because of the 5cm height of the nutrient solution. The invention adopts the root separating method to solve the conflict of oxygen uptake and liquid supplement in the way of making one part of roots on the surface of the non-woven cloth to adsorb oxygen in air and the other part in nutrient fluid to adsorb nutrition and water. The bottom of the culturing groove can be provided with a culturing frame having the function of supporting to completely change the traditional stooping or squatting working way of the workers in the past, which is not only good for easy operation and management, but also for easy cleaning of the residue roots after harvesting. So the labor intensity can be reduced.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

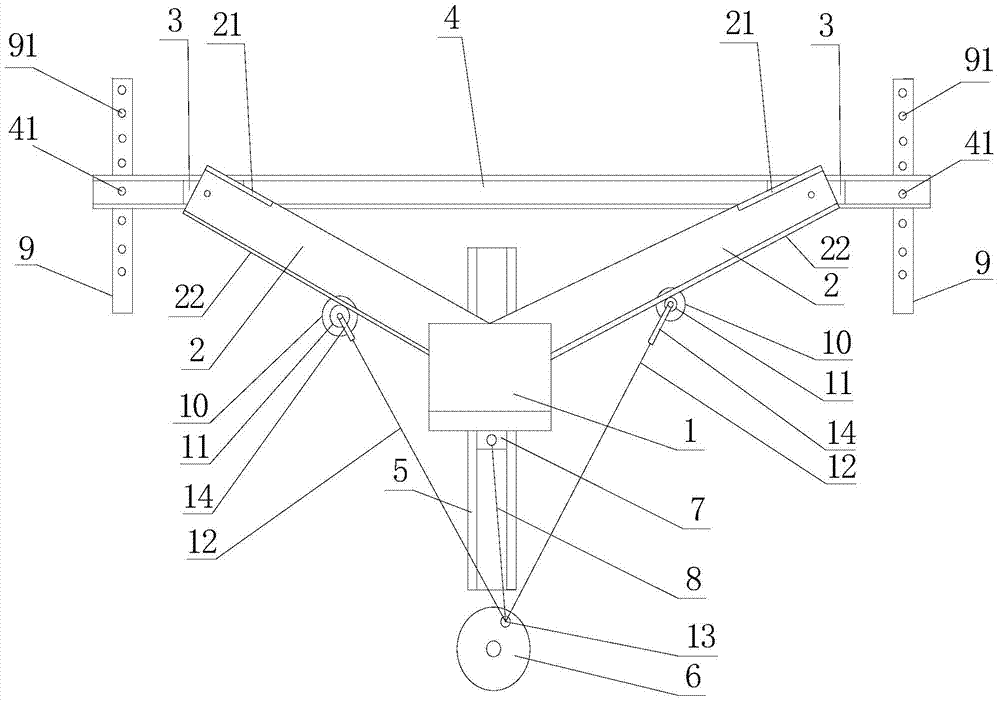

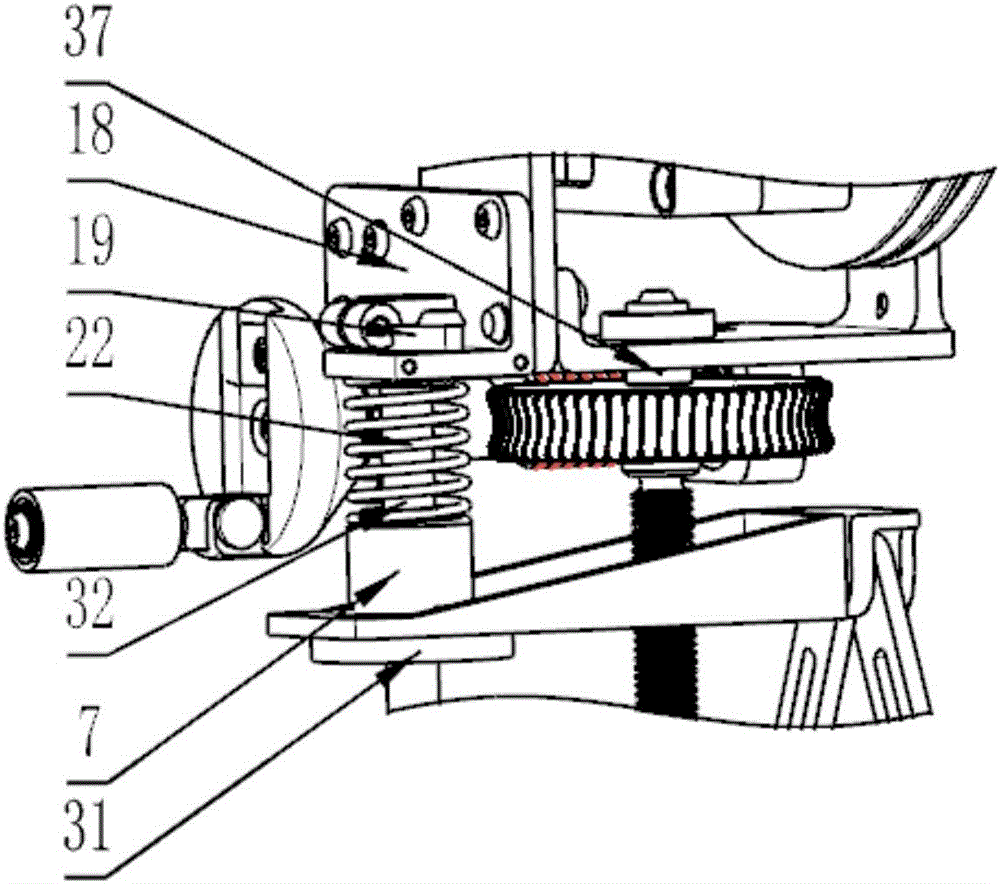

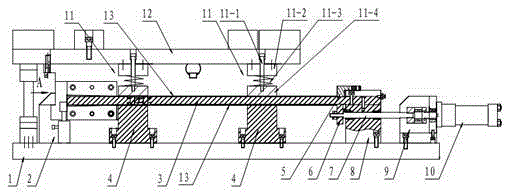

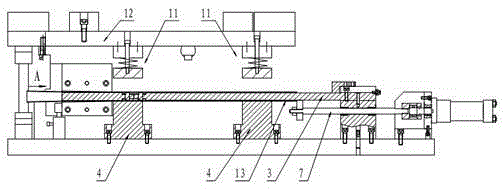

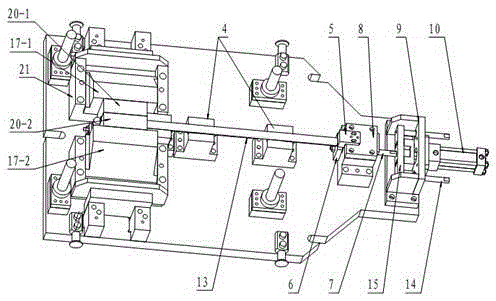

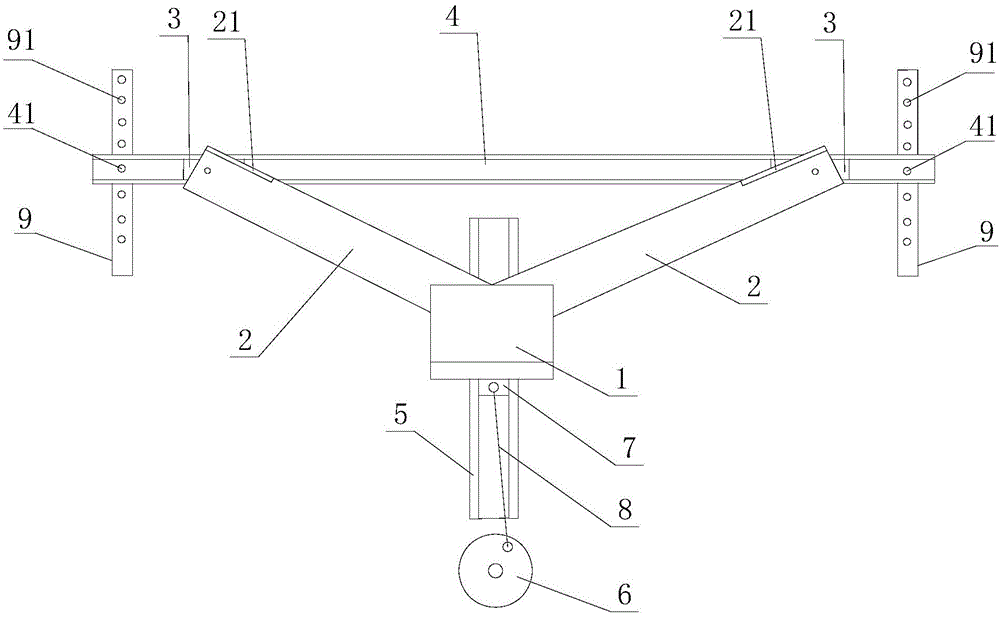

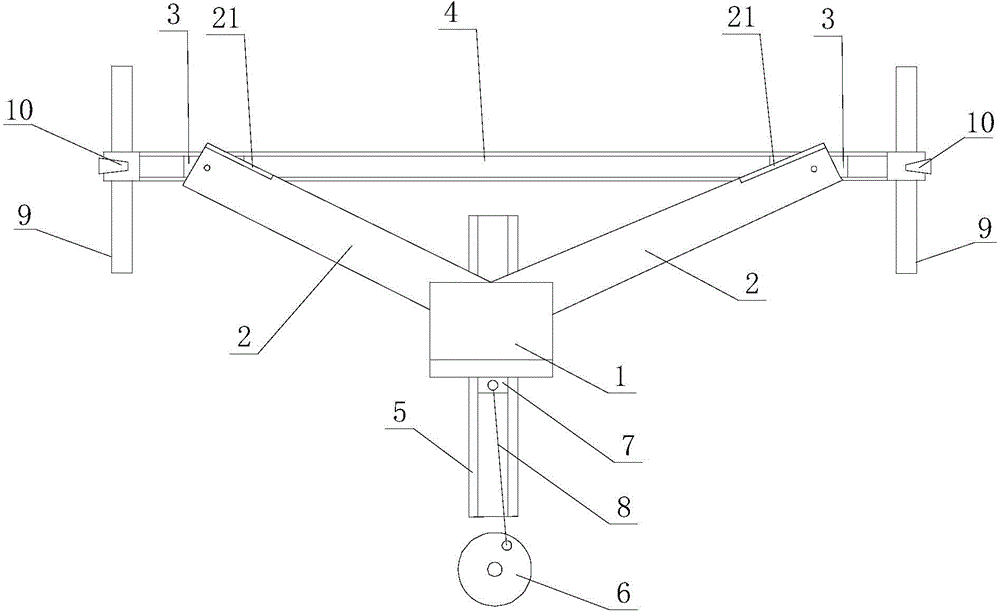

Lateral spilt trainer with massaging devices

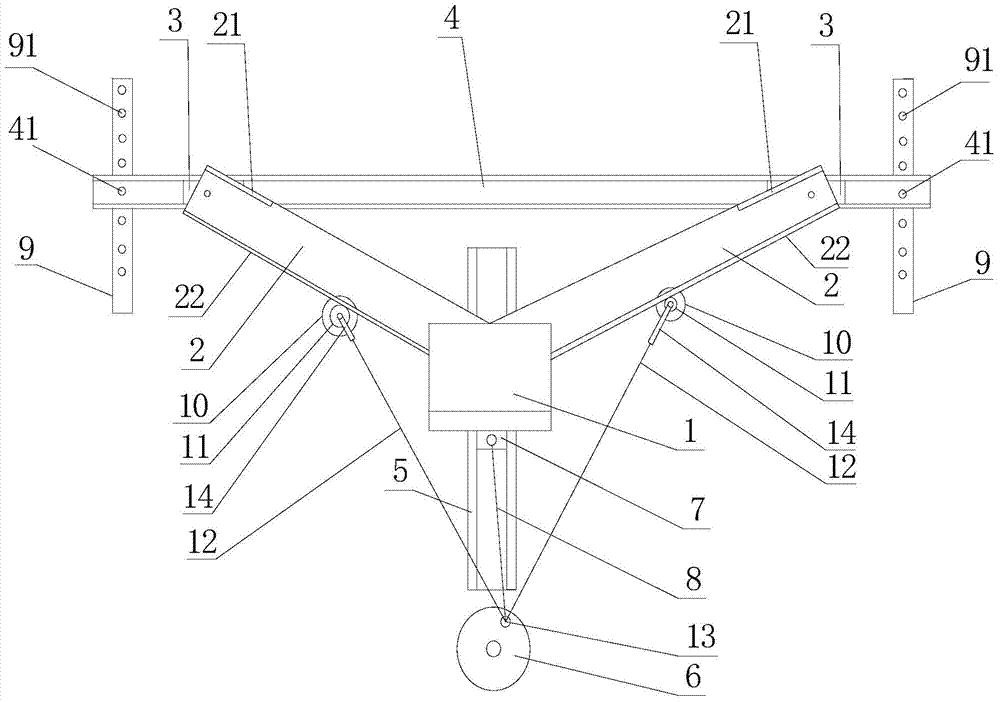

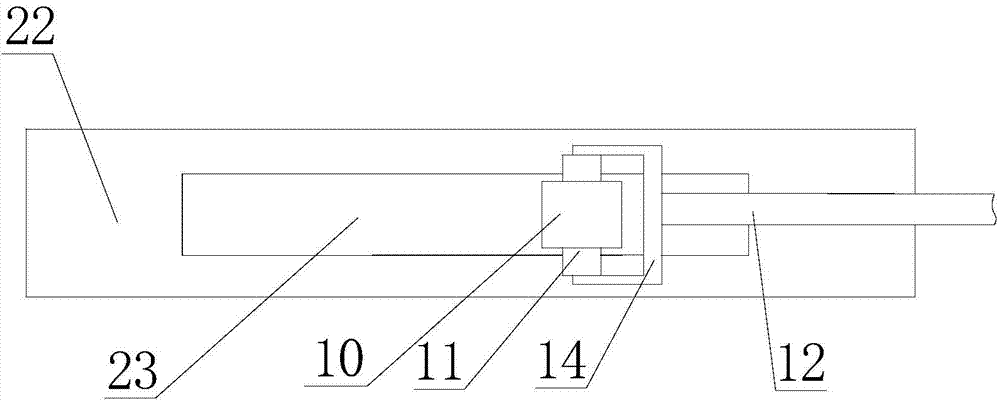

InactiveCN104841097ANo strainEasy to open and close automaticallyGymnastic exercisingRoller massageLeg pressReciprocating motion

The invention relates to sport equipment, in particular to a lateral split exercise device with massage devices. The lateral split exercise device aims at solving the problems that when the two legs of an exerciser are split to the extent approaching the limit that the exerciser can reach, the two legs cannot conveniently open, close or swing in a small range at the limit position, massage cannot be carried out and the exercise effect is poor. The lateral split exercise device comprises a seat and two leg frames, wherein the seat is provided with a seat wheel; one end of each leg frame is hinged to the seat, the other end of each leg frame is provided with a leg frame wheel, and each leg frame wheel is arranged in a transverse rail. The seat wheel is arranged in a seat rail vertical to the transverse rails, the back of the seat is connected with a first crank sliding block mechanism used for driving the seat to move in a reciprocating mode, and each leg frame is provided with one massage device used for massaging the corresponding leg. The lateral split exercise device is provided with the massage devices, the legs can be massaged when lateral split is carried out, and the leg pressing effect is better.

Owner:SHAOXING TEXTILE MACHINERY GRP

Lateral split exercise device with massage devices

ActiveCN103611271ANo strainEasy to open and close automaticallyGymnastic exercisingRoller massageReciprocating motionLeg press

The invention relates to sport equipment, in particular to a lateral split exercise device with massage devices. The lateral split exercise device aims at solving the problems that when the two legs of an exerciser are split to the extent approaching the limit that the exerciser can reach, the two legs cannot conveniently open, close or swing in a small range at the limit position, massage cannot be carried out and the exercise effect is poor. The lateral split exercise device comprises a seat and two leg frames, wherein the seat is provided with a seat wheel; one end of each leg frame is hinged to the seat, the other end of each leg frame is provided with a leg frame wheel, and each leg frame wheel is arranged in a transverse rail. The seat wheel is arranged in a seat rail vertical to the transverse rails, the back of the seat is connected with a first crank sliding block mechanism used for driving the seat to move in a reciprocating mode, and each leg frame is provided with one massage device used for massaging the corresponding leg. The lateral split exercise device is provided with the massage devices, the legs can be massaged when lateral split is carried out, and the leg pressing effect is better.

Owner:浙江惠通全成重工机械科技有限公司

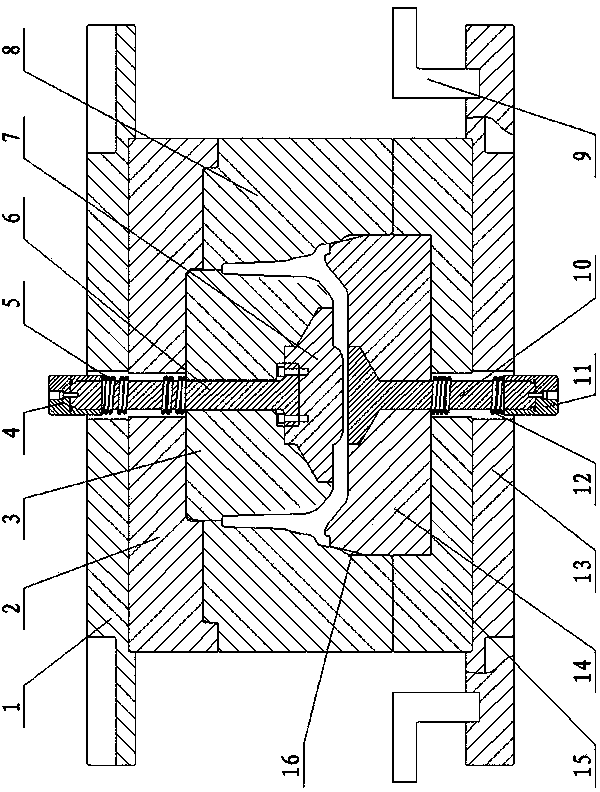

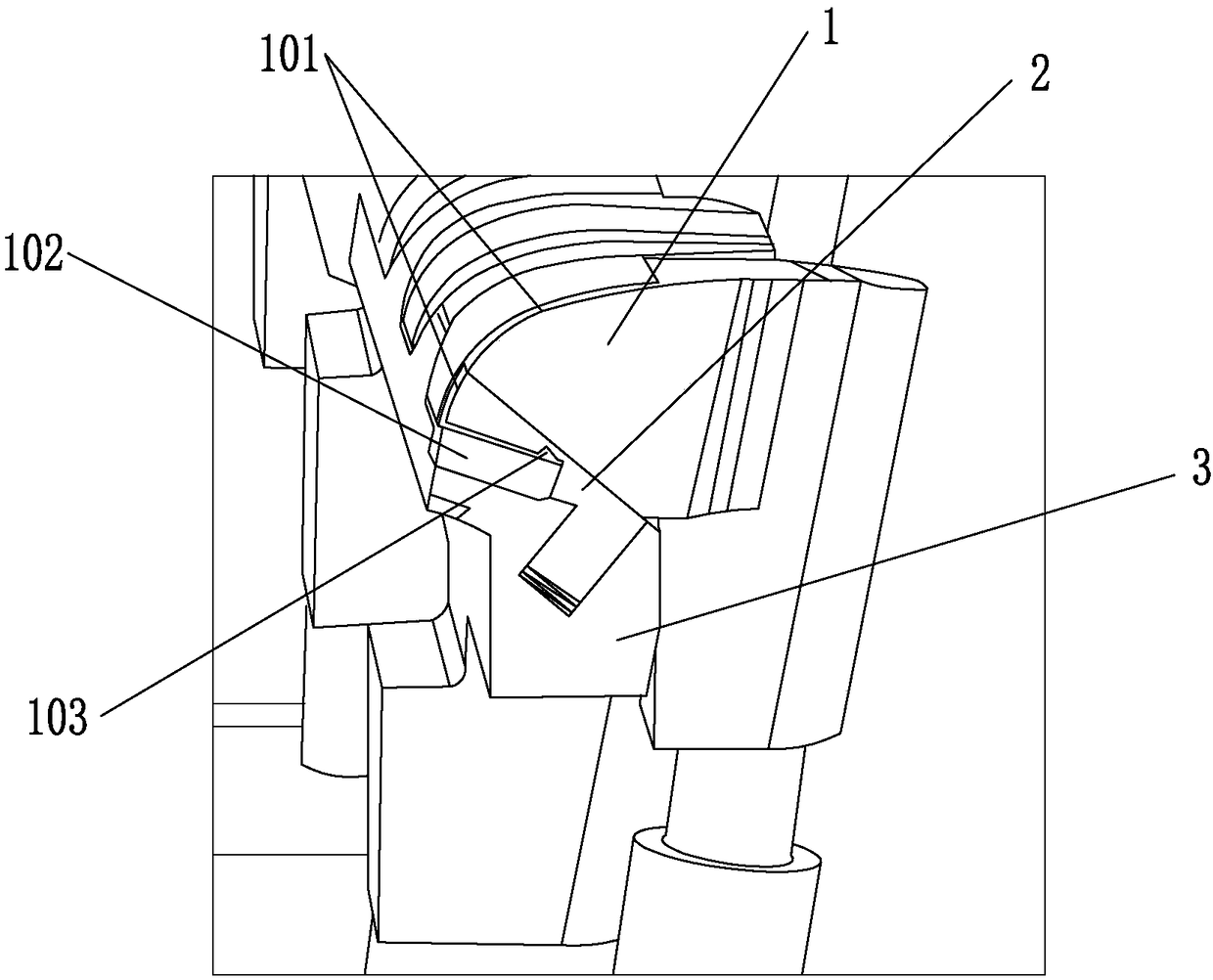

Finish forging die for forging aluminum alloy wheel

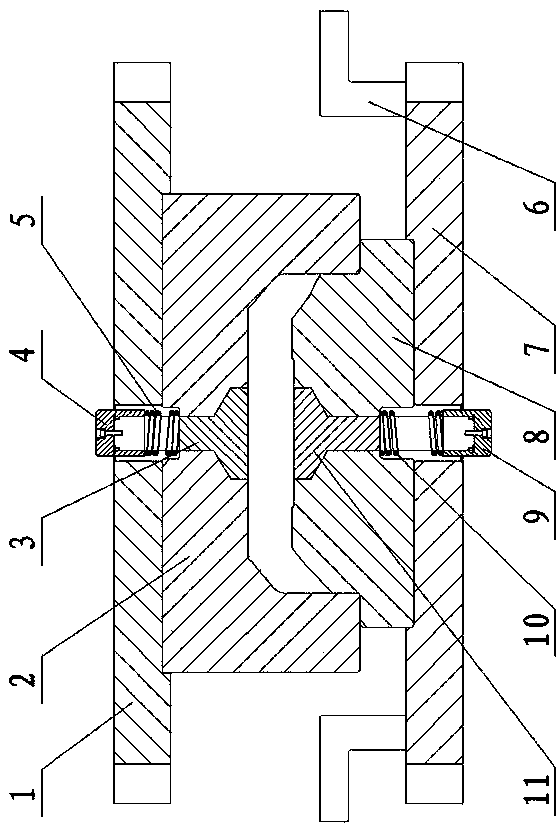

InactiveCN103752752ASolve uneven iron materialEasy loading and unloadingForging/hammering/pressing machinesAluminium alloyMaterials science

A finish forging die for forging an aluminum alloy wheel comprises an upper die plate and a lower die plate. A lower die is fixed above the lower die plate. An upper die is fixed below the upper die plate. The upper die comprises an upper die core, and the upper die core is sleeved with an upper die sleeve. A circle of notch is formed in the outer wall of the upper portion of the lower die. A flash reserving cavity is formed between the inner wall of the upper die sleeve and the notch of the lower die. A lower ejector rod is arranged at the center of the lower die. An upper ejector rod is arranged at the center of the upper die core. The problems that iron materials are not even and a die is not in place when the quantity of materials is large are solved through the flash reserving cavity formed between the inner wall of the upper die sleeve and the notch of the lower die; a workpiece can be pressed on a lower die core through the upper ejector rod arranged right at the center of the upper die core so that the die can be released, and damage caused when the workpiece collides with the die is avoided; the workpiece is ejected out of the lower die core through the lower ejector rod arranged right at the center of the lower die core, and therefore the forging process is achieved; compared with a traditional die, the finish forging die has the advantages of being free of die holding, easy to release and not prone to strain.

Owner:连云港宝石精密重工科技有限公司

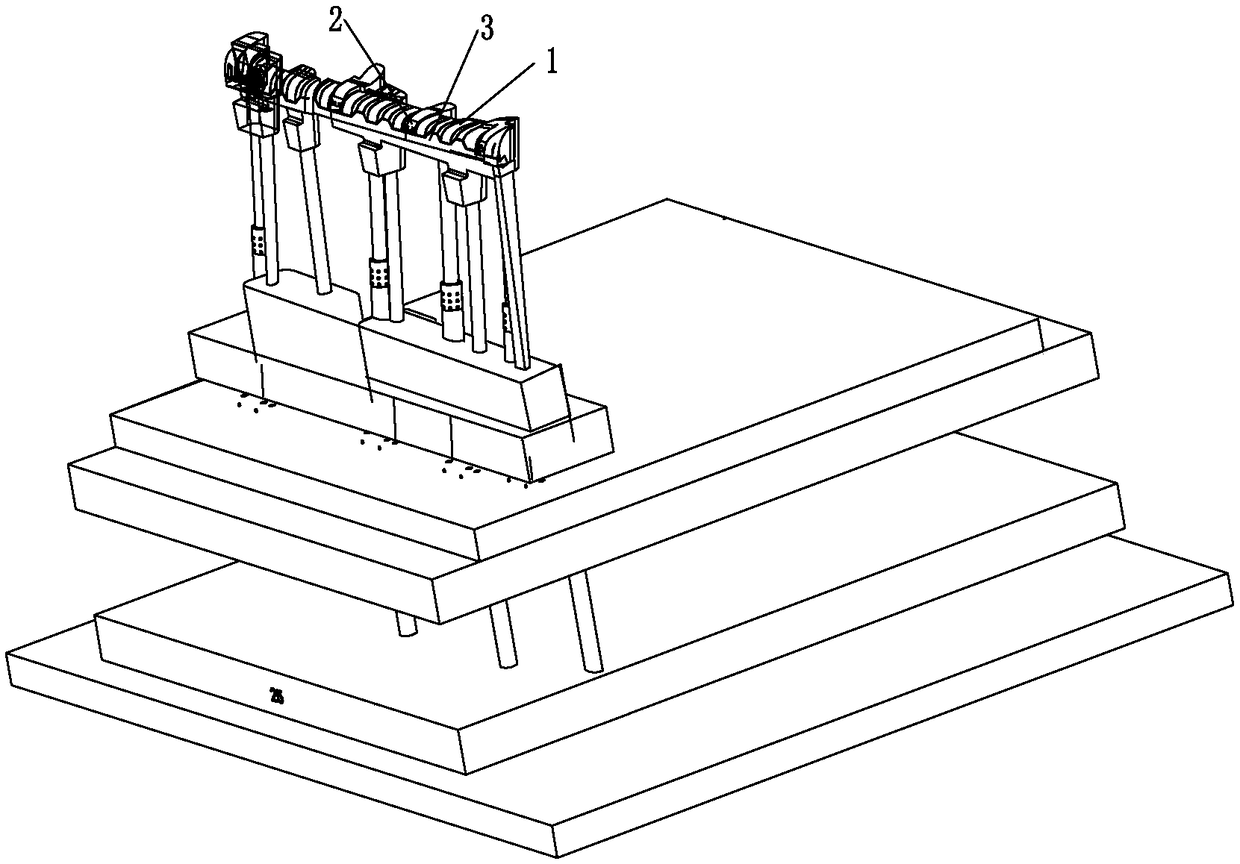

Device for removing wool from sheep

ActiveCN104082172ASave human resourcesSave power resourcesOther apparatusGrooming devicesFixed frameEngineering

The invention discloses a device for removing wool from sheep. The device is characterized by comprising a sheep fixing device, two first guide rails and a leg fixing device, wherein the sheep fixing device comprises a first support and a bottom plate, the first support comprises two rectangular fixing frames which are arranged at the upper end of the bottom plate in parallel in a spaced mode, the first support is parallel with the bottom plate in the axial direction, the two first guide rails are arranged along the two fixing frames of the first support respectively, the leg fixing device is of a semispherical structure, the spherical surface of the semispherical structure is movably embedded in the bottom plate downwards, and a clamping groove is formed in a plane, facing upwards, of the semispherical structure; the device for removing the wool from sheep comprises multiple shavers which are jointed mutually to form a strip-shaped shaver body in the perpendicular direction of the operation direction of the shavers. The device can clear up the wool under the condition of low power consumption, is simple in structure, convenient to use and practical, saves time and labor, saves energy and protects environment.

Owner:邓雪明

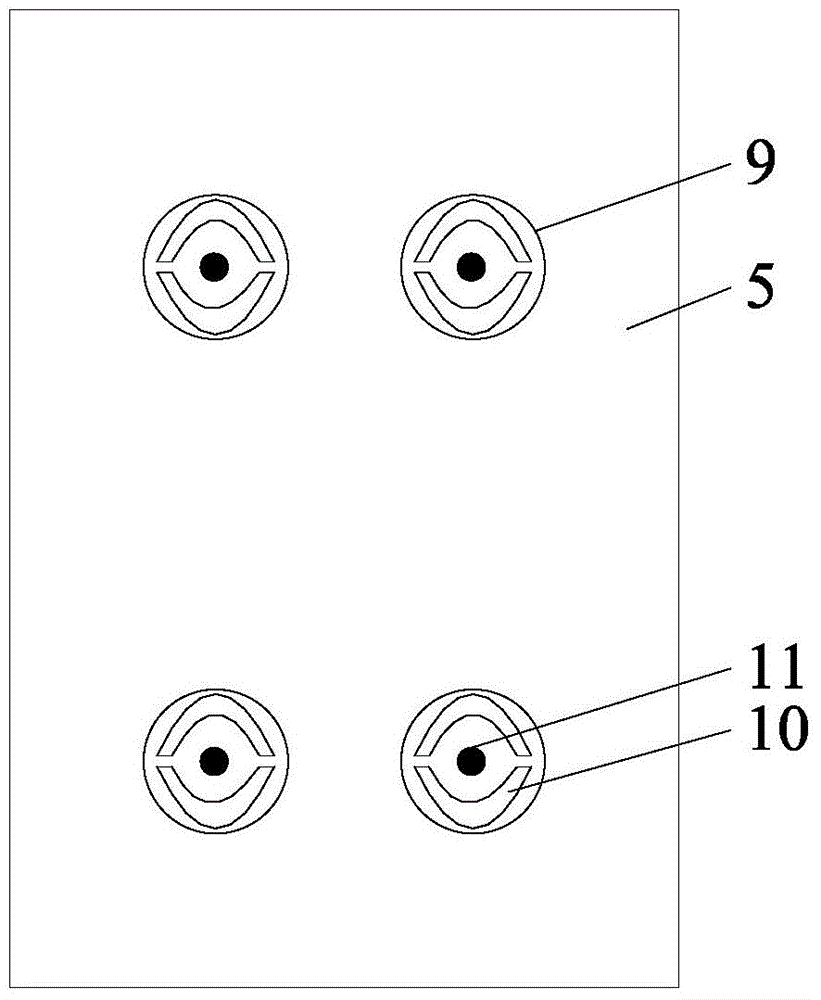

Filter plate comprising a temperature control body and filter cartridge comprising such a filter plate

ActiveCN102686292ANo strainThermal Dimensional Change CompensationFiltration separationTemperature controlPhysics

The invention relates to a filter plate comprising a main body and an elastic element, which is fastened to the main body in an annular and fluid-tight manner. The filter plate is characterized in that a temperature control plate is fastened to the elastic element.

Owner:JVK FILTRATION SYST

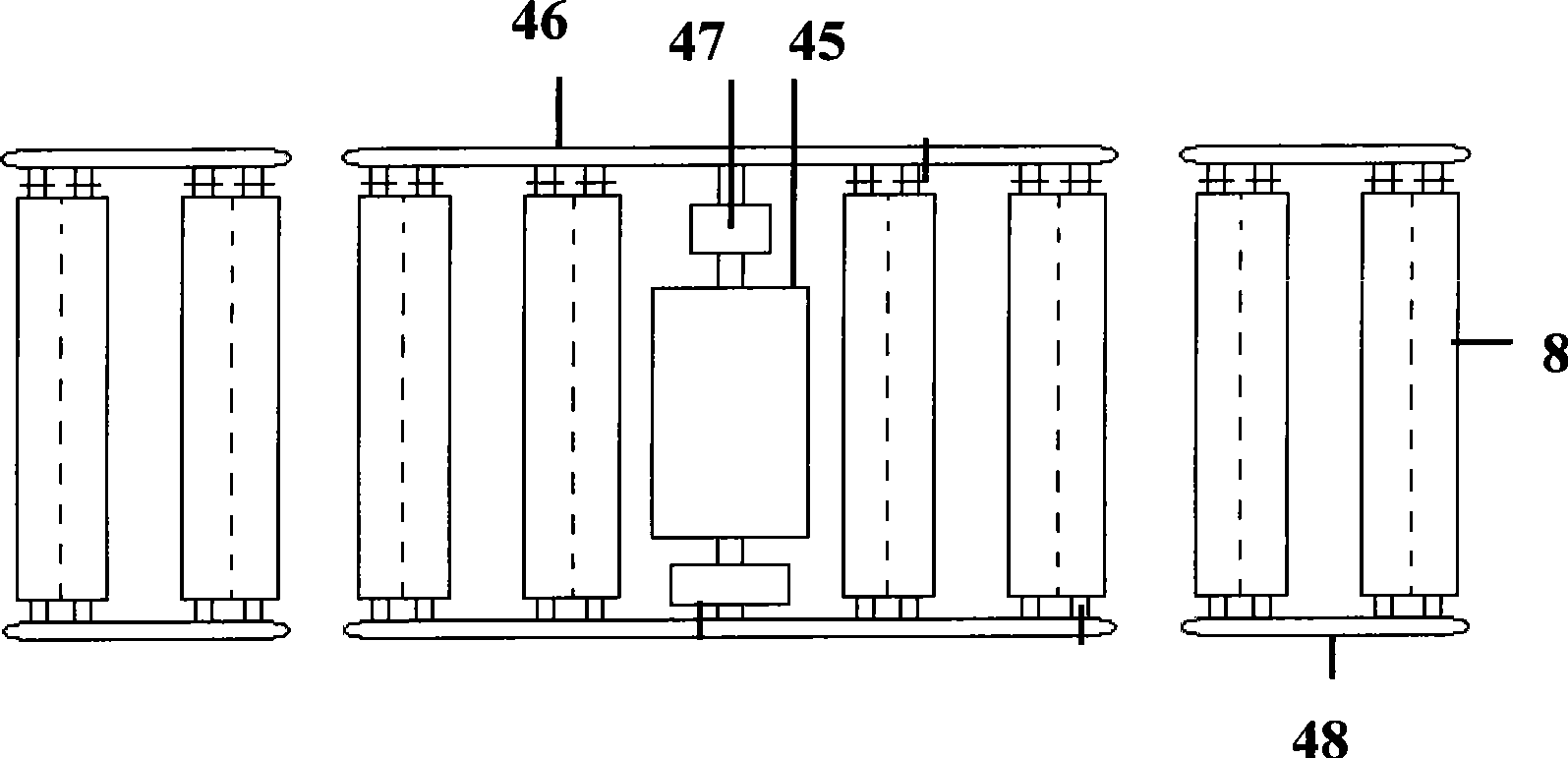

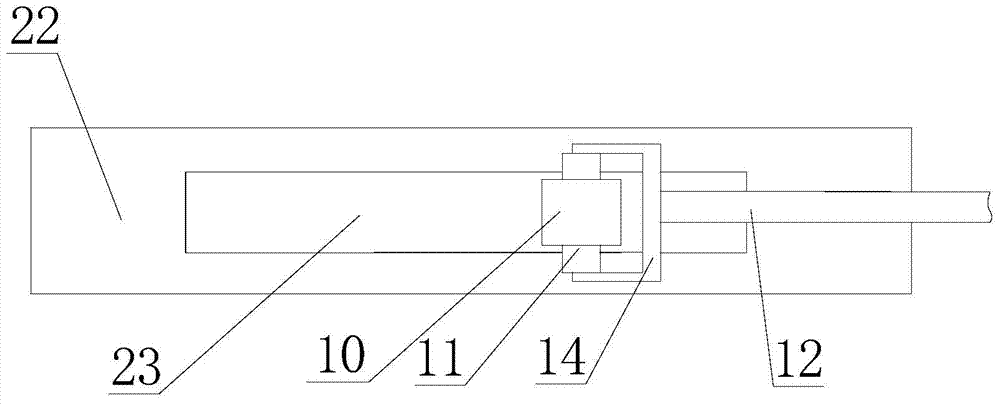

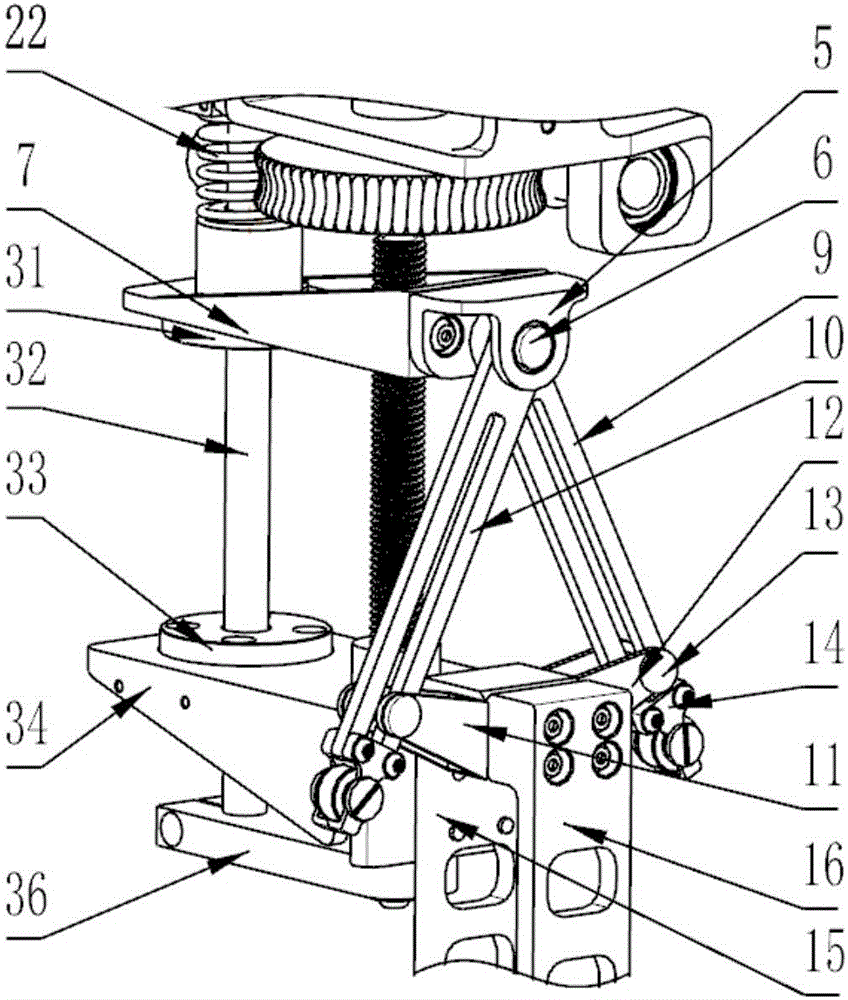

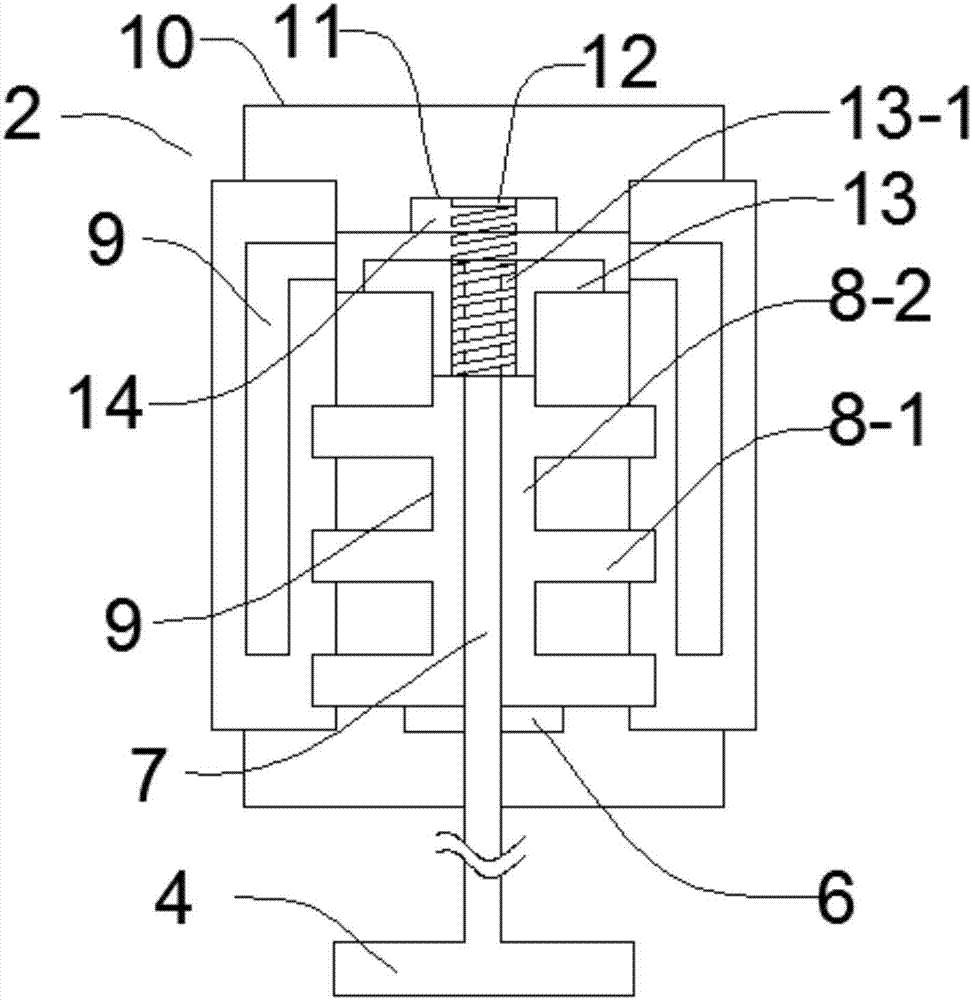

Arm length adjusting device for upper limb exoskeleton rehabilitation robot

ActiveCN106551777ARealize arm length adjustment functionEffective trainingChiropractic devicesEngineeringUpper limb

The invention belongs to the related field of medical rehabilitation training equipment, and particularly discloses an arm length adjusting device for an upper limb exoskeleton rehabilitation robot. The arm length adjusting device comprises an upper left bracket, an upper right bracket, a lower bracket and a worm and gear assembly. The worm and gear assembly is arranged between the upper bracket and the lower bracket, and comprises a worm wheel, a worm and a screw rod. The screw rod is fixed between the upper left bracket and the upper right bracket in the axial direction. The screw rod is mounted between the upper left bracket and the lower bracket. The worm wheel is coaxially mounted above the screw rod. A rocker component is arranged at the right end of the upper right bracket and is connected with the right end of the worm. A polished rod is arranged between the upper right bracket and the lower bracket. The screw rod and the polished rod penetrate through a horizontal connecting plate and a lower movable rack between the upper bracket and the lower bracket. An up-down moving component is fixedly mounted on the same sides of the horizontal connecting plate and the lower movable rack. The arm length adjusting device can realize the arm length adjusting function of the shoulder-elbow part of the upper limb exoskeleton rehabilitation robot, and is suitable for upper limb sizes of different patients, and the adjusting step is simple and easy.

Owner:HUAZHONG UNIV OF SCI & TECH

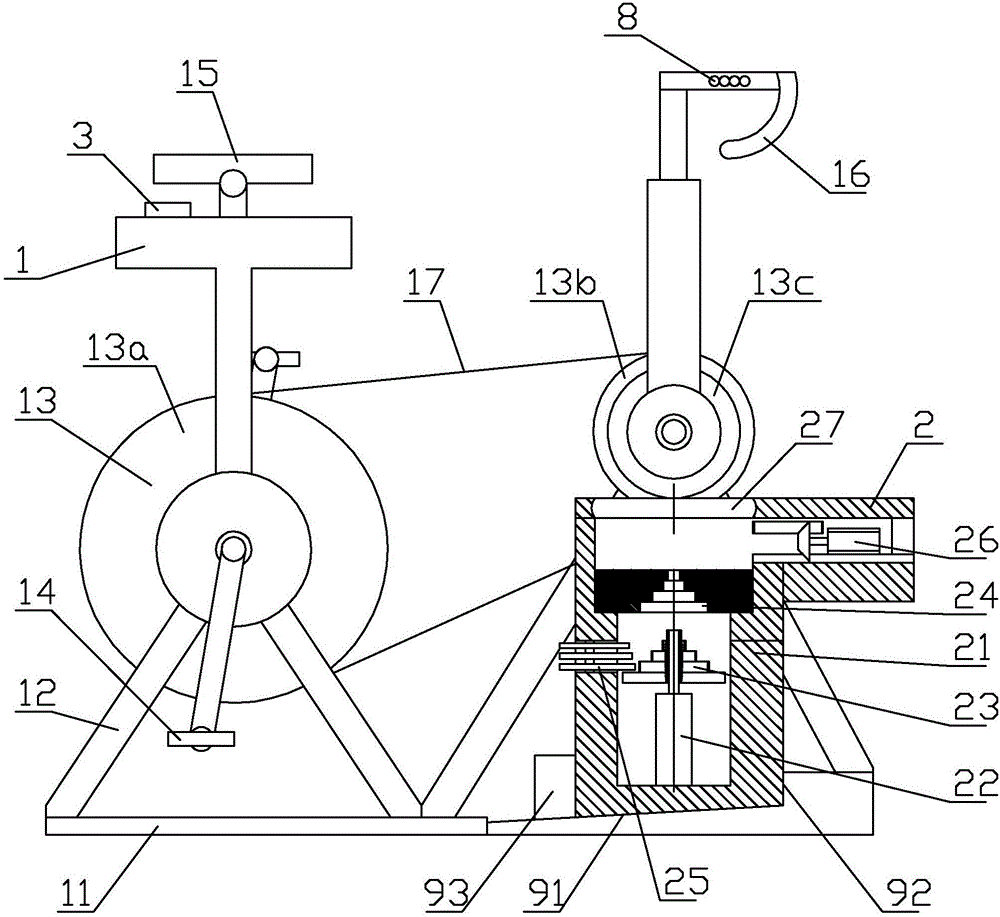

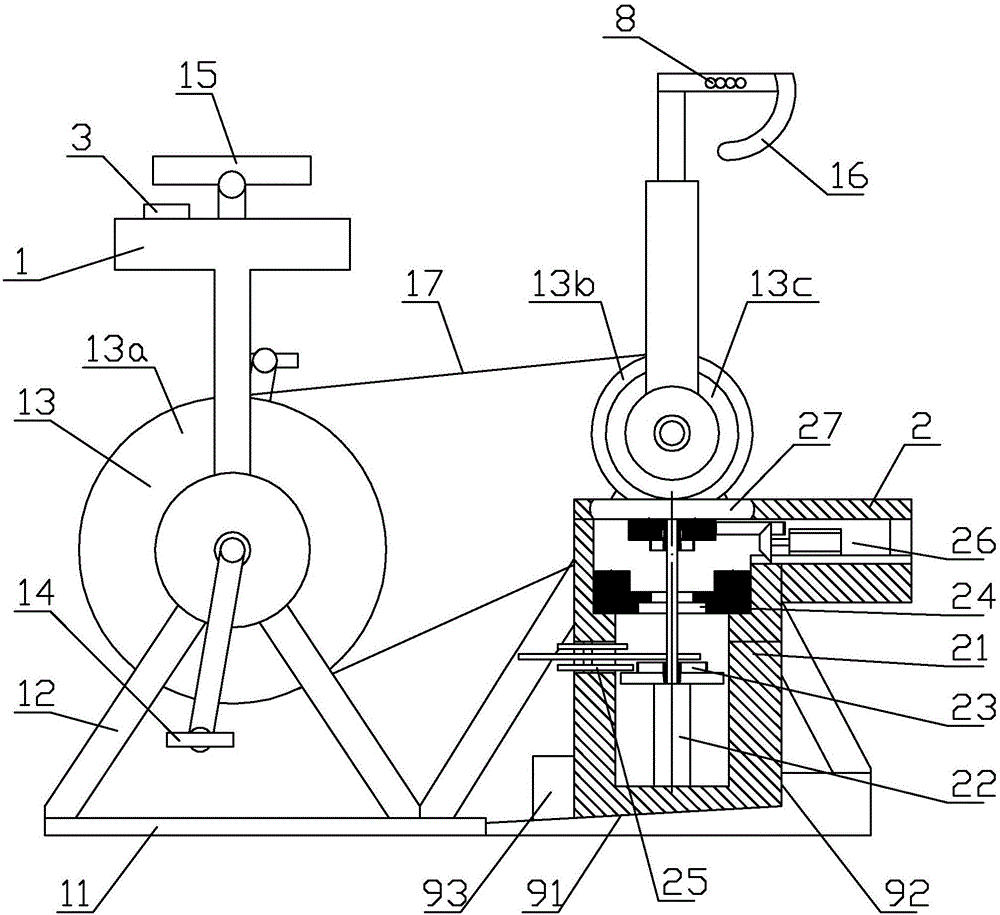

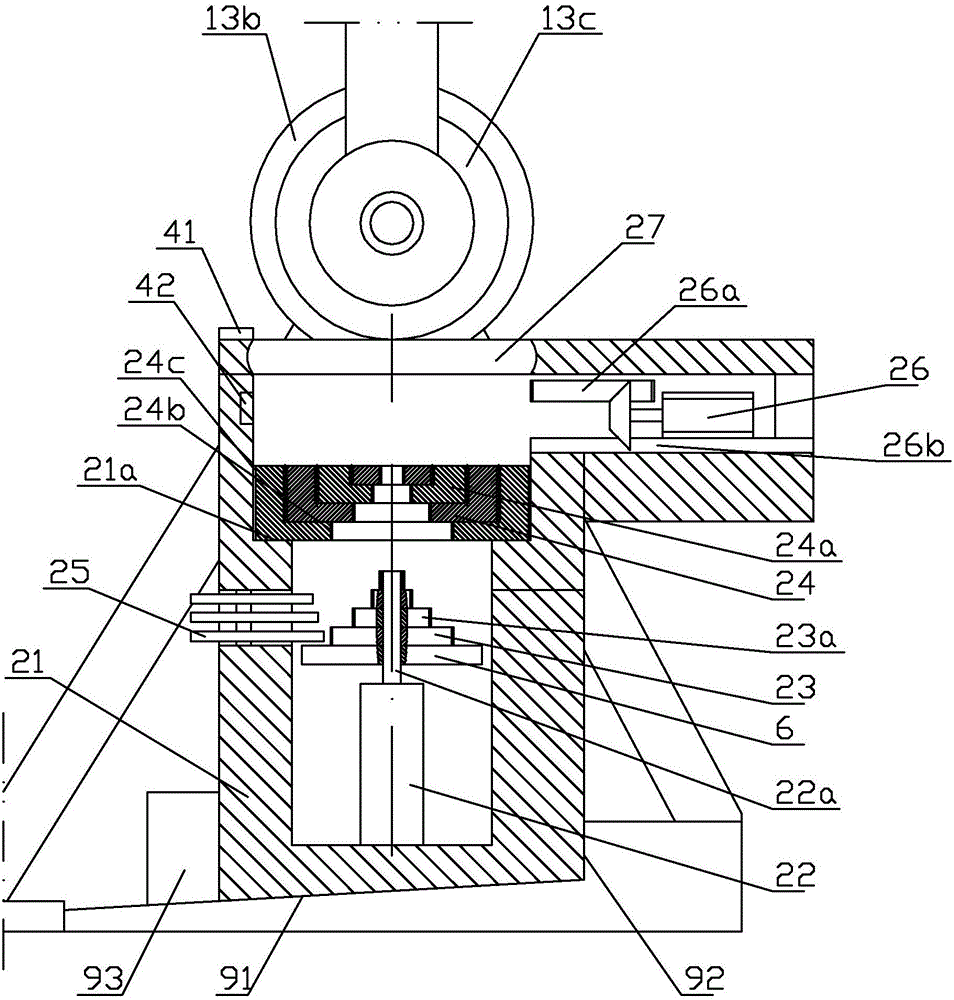

Exercise frequency induction based spinning protection system

ActiveCN106215375ANo crampingNo sports injuries such as strainsChiropractic devicesMuscle exercising devicesRough surfaceTransducer

The invention discloses a protection system for an exercise frequency induction based spinning protection system. On the basis of a spinning bicycle, a frequency regulation box for driven riding is additionally arranged on the protection system; an exerciser can change self-riding to passive riding under the driving of a motor; a friction driving mode of a rough surface is adopted; when the exerciser applies force to stop pedaling and two sets of driving components have a certain speed difference, a transducer can induce and then feed back to the motor for relieving the driving, so that the potential safety hazard caused by continuous force application of the exerciser can be reduced, the long-term resistance abrasion between the parts can be avoided and the service life of the parts can be prolonged; a hinged cushion is matched with a trigger switch; when the exerciser leans back and drives the cushion to rotate so as to press the trigger switch, the box can be driven to move downward so as to release the driving between the gears, so that the passive suspension of the motion can be realized; the protection effect of the mechanical automatic and manual starting multi-aspect system is achieved; the exerciser can be effectively protected from being hurt in the motion process; the safety is higher.

Owner:WENZHOU MEDICAL UNIV

Vehicle door sheet injection mold demolding mechanism

Owner:NINGBO FANGZHENG TOOL

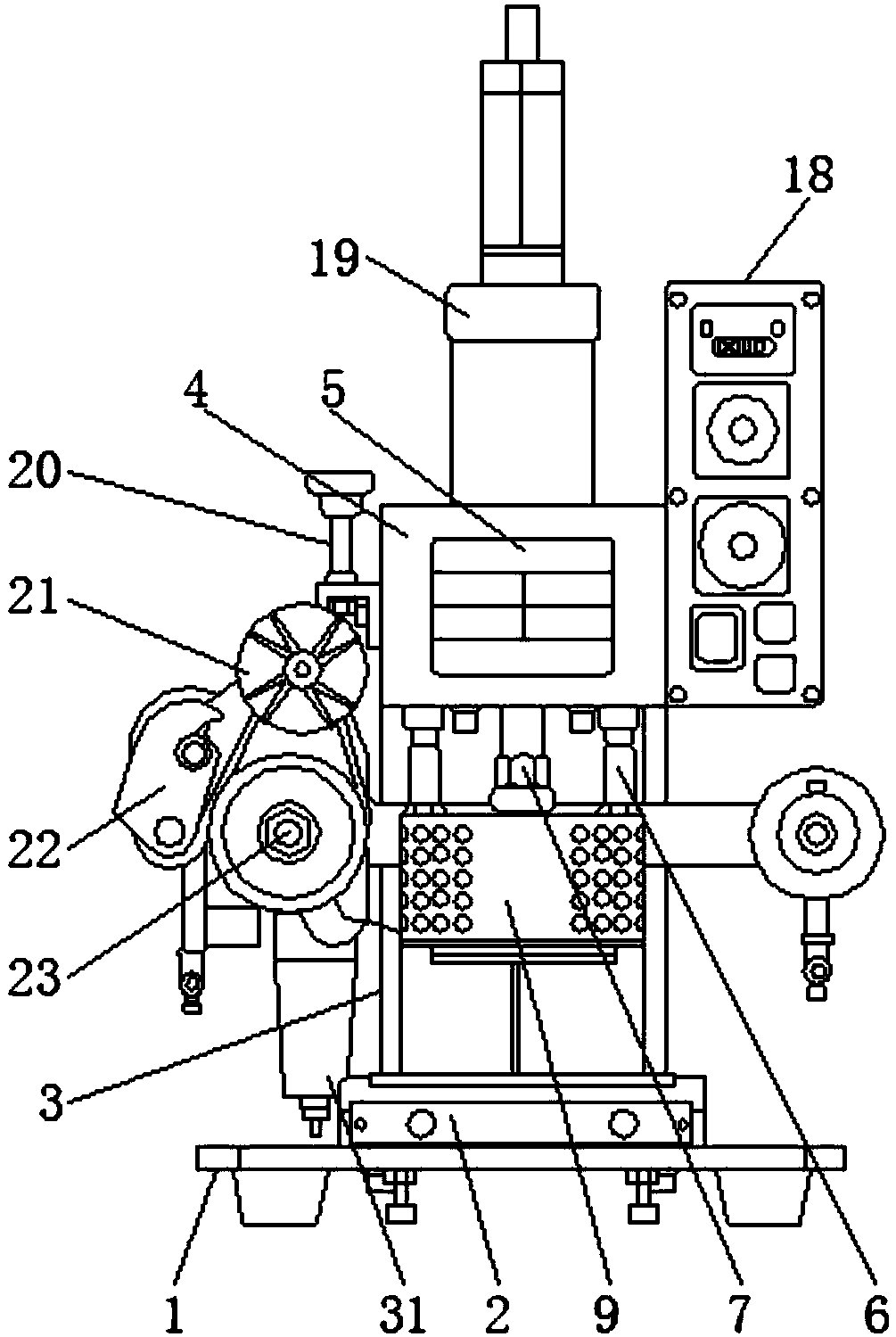

Full-automatic rotary type indentation gold stamping equipment

The invention discloses full-automatic rotary type indentation gold stamping equipment. The full-automatic rotary type indentation gold stamping equipment comprises a workbench, an object printing frame and a conveying wheel, wherein a horizontal substrate is installed on the workbench, and a support is fixed above the rear side of the horizontal substrate; a bearing seat is welded to the front side of the upper part of the support, and a sign is arranged on the front side of the bearing seat; the left side and the right side of the lower part of the bearing seat are correspondingly provided with fixed printing shafts, a supporting shaft is arranged between the fixed printing shafts, and a is installed below the fixed printing shafts; a protective plate is arranged below the supporting shaft, a heating block is arranged below the object printing frame, and the object printing frame is located on the back side of the protective plate; and a wheel middle shaft is fixed in the middle of the conveying wheel, and the conveying wheel is located at the right lower part of a traction wheel. When gold paper is transmitted by the full-automatic rotary type indentation gold stamping equipment, the gold paper can be subjected to synchronous smoothing operation, heating is uniform, heating uniformity can be ensured after the equipment is used for a long period of time, and the service lifeis relatively long.

Owner:方圆塑胶彩印制品(江西)有限公司

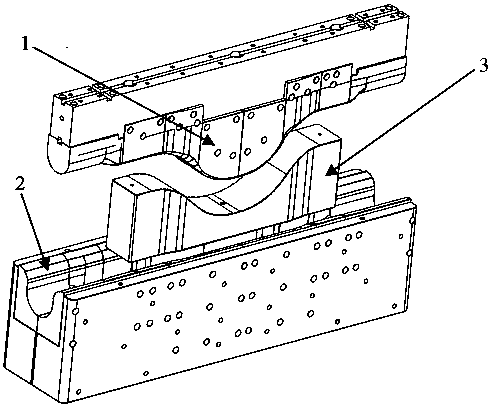

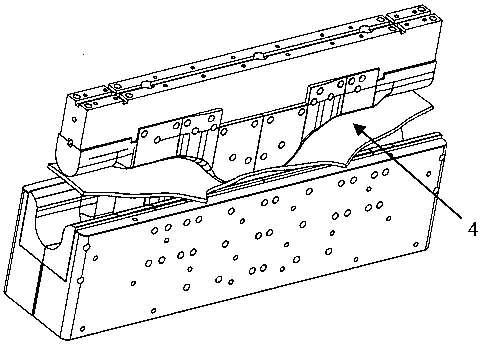

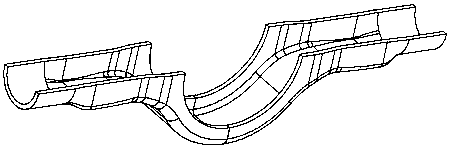

Forming die for half-housing body of axle housing and machining technology

The invention relates to a forming die for a half-housing body of an axle housing and a machining technology. The forming die for the half-housing body of the axle housing is characterized in that thetops of the upper end faces of the two side walls of a female die body of the die are on the same plane and are the same in height, and the upper end faces and the inner walls of the female die bodyare in smooth transition; the side walls of the female die body are in the same cross-section shape in the length direction; an ejector is located at the bottom of the die; and the upper surface of the ejector and the bottom profile of the female die body of the die jointly form the shape of the outer surface of the bottom of the half-housing body. According to the forming die for the half-housingbody of the axle housing and the machining technology, the quality problems of unevenness, severe strain and severe gnawing of the plate surface in the stamping forming process of the half-housing body of the axle housing are solved, and in addition, the problems that due to an existing technology and an existing die structure, galling and strain of an opening of the female die body of the die are likely to occur, and built-up edges are likely to be formed at the opening of the female die body of the die are solved; and by changing the die structure, the half-housing body forming technological process is adjusted, namely the forming process of the half-housing body is changed from the original process that longitudinal bending is conducted first and then two-side edge turning is conductedto the technological process that forming is conducted gradually with two-side edge turning as the main step and longitudinal bending as the auxiliary step, so that the bending process of the axle housing is completed under the constraint condition of the die, and it is guaranteed that wrinkling, strain and gnawing of the plate surface of the half-housing body are avoided.

Owner:CHINA FIRST AUTOMOBILE

Soilless capillary hydroponics rearing groove

InactiveCN101416606BNo strainReduce labor intensityAgriculture gas emission reductionCultivating equipmentsEngineeringNutrient solution

The invention relates to a soilless cultivation groove of capillary hydroponics, comprising a groove body, a seepage prevention film, a table for fixing plant, a hydrophilic non-woven fabric, and a groove cover. The table for fixing and putting plants in the culturing groove of the soilless cultivation system of capillary hydroponics is set fixedly, such that there is no damage to the roots of plants because the liquid level of the nutrient solution is changed by the influence of external temperature and no worry about water or power cut because of the 5cm height of the nutrient solution. Theinvention adopts the root separating method to solve the conflict of oxygen uptake and liquid supplement in the way of making one part of roots on the surface of the non-woven cloth to adsorb oxygen in air and the other part in nutrient fluid to adsorb nutrition and water. The bottom of the culturing groove can be provided with a culturing frame having the function of supporting to completely change the traditional stooping or squatting working way of the workers in the past, which is not only good for easy operation and management, but also for easy cleaning of the residue roots after harvesting. So the labor intensity can be reduced.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

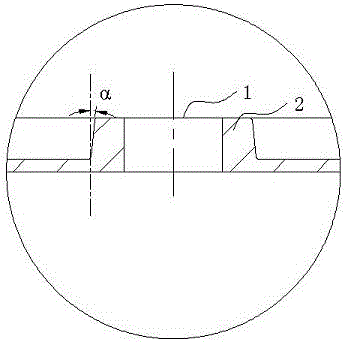

Precision bright press-trimming method for forging burrs

A precision bright press-trimming method for forging burrs, which is disclosed by the invention, relates to the technical field of non-cutting metal machining and precision forging. By introducing the steps of pressing and trimming on the basis of conventional process steps and equipment, the method increases the quality of precision-forged products, reduces the production cost, sufficiently exerts the existing equipment conditions of medium and small factories, prolongs the service lives of dies, and saves the expenditure on dies.

Owner:QINHAN PRECISION IND CO LTD

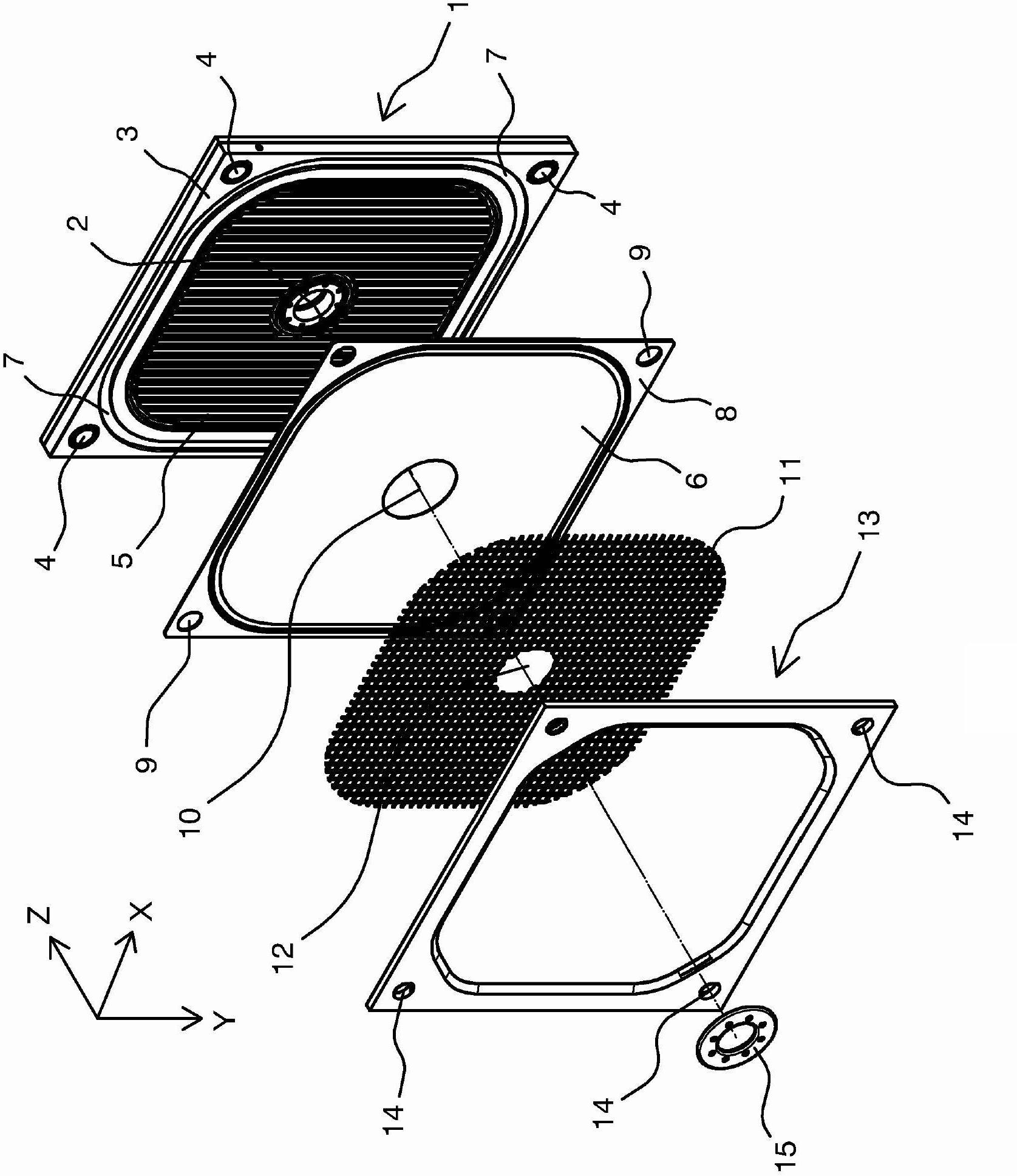

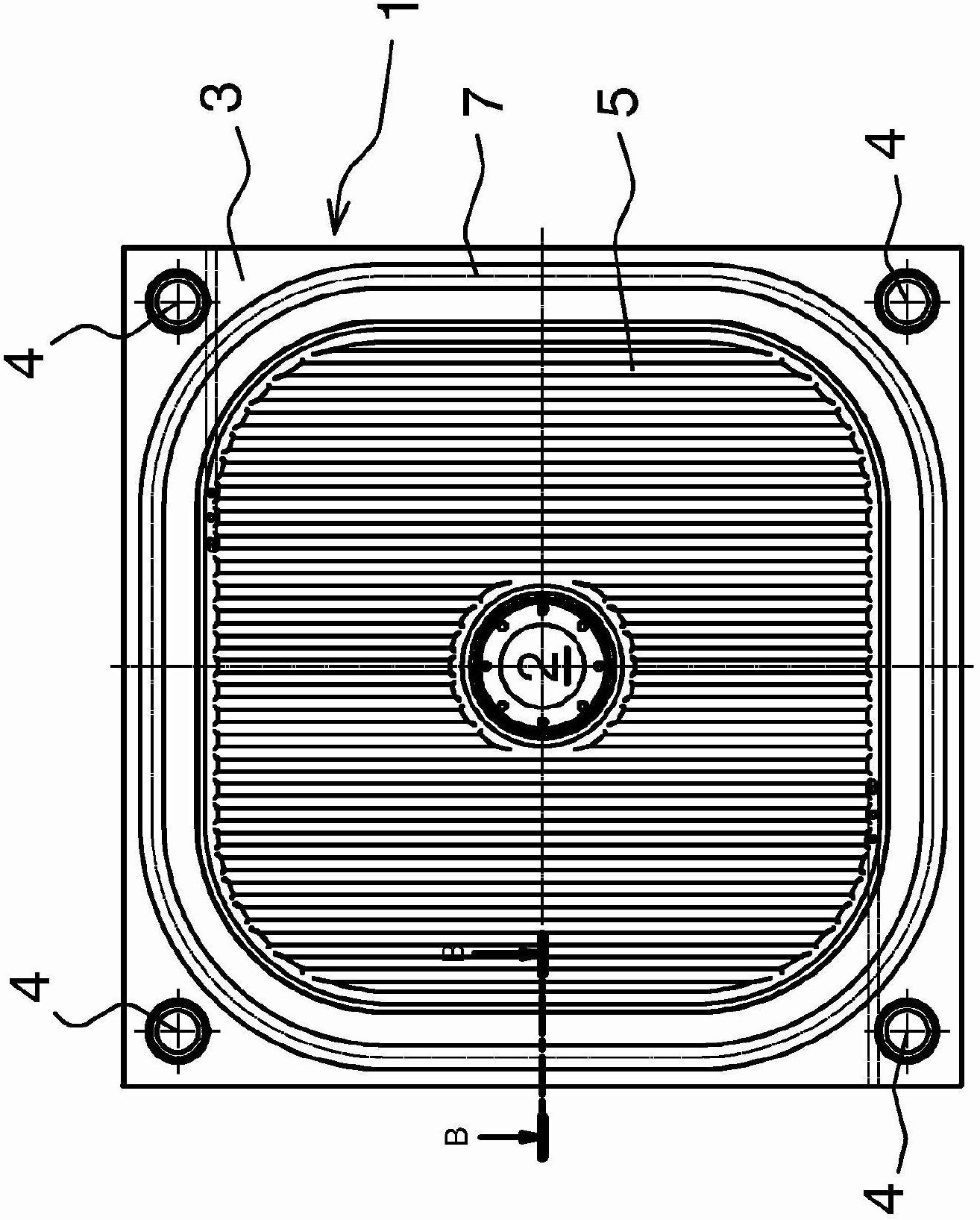

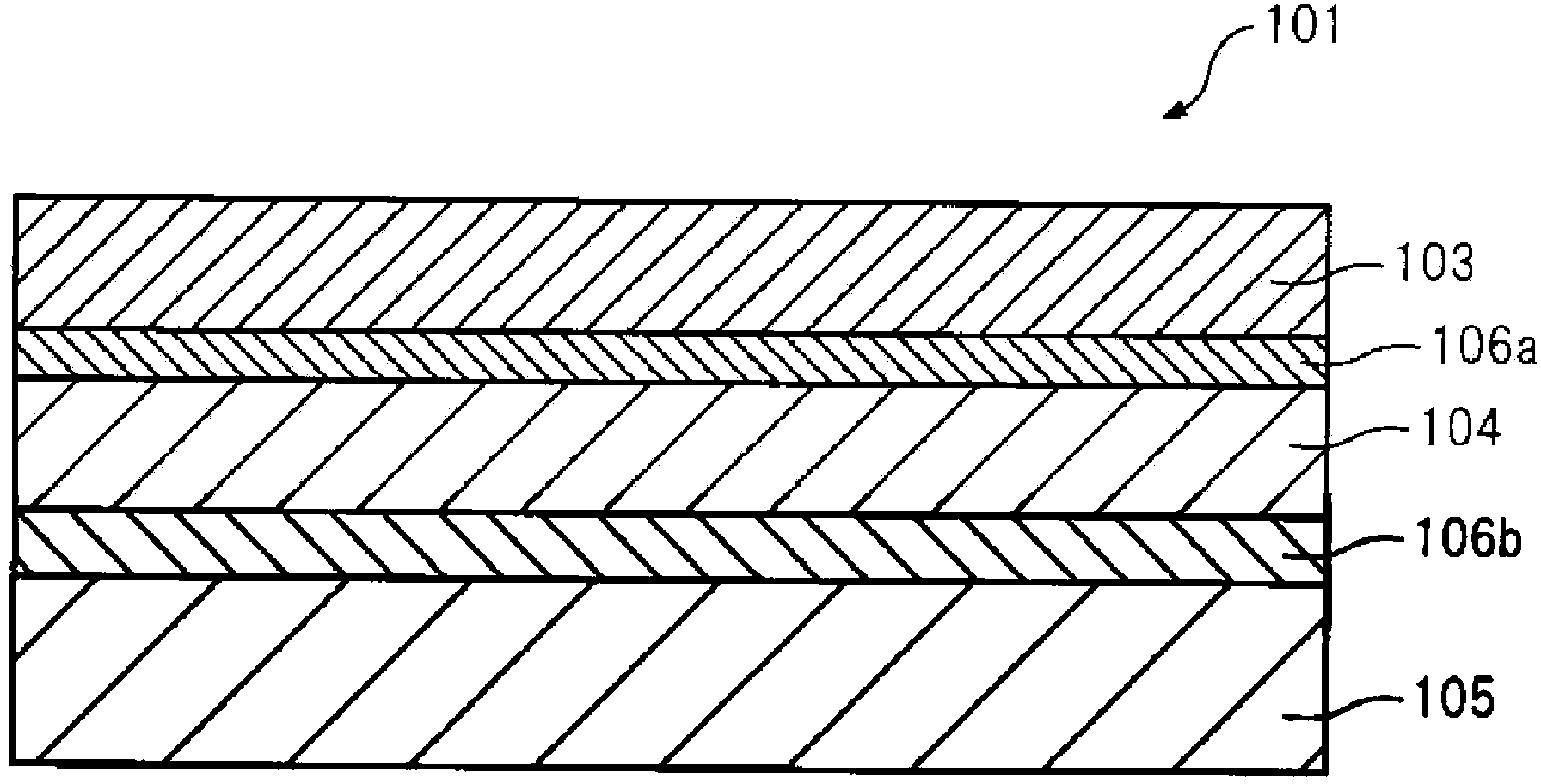

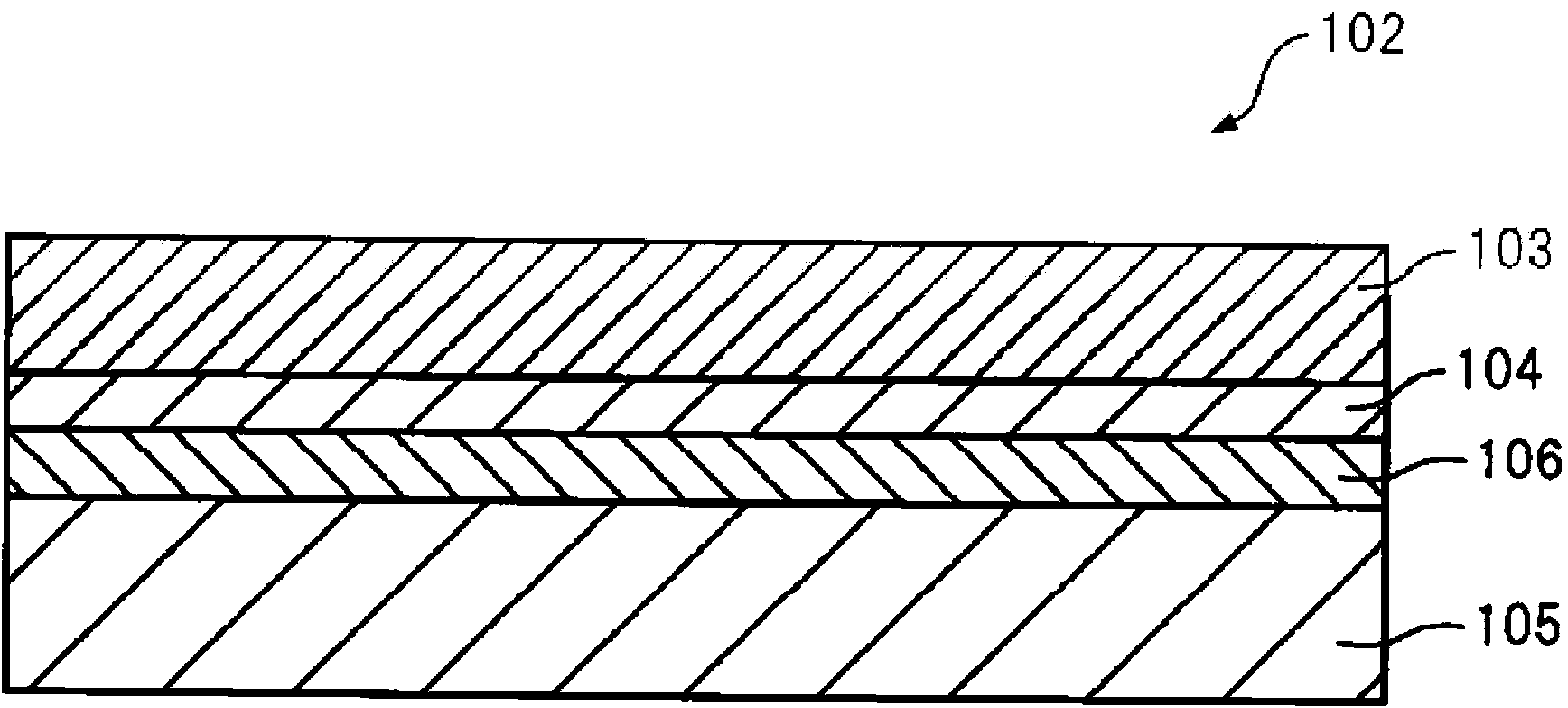

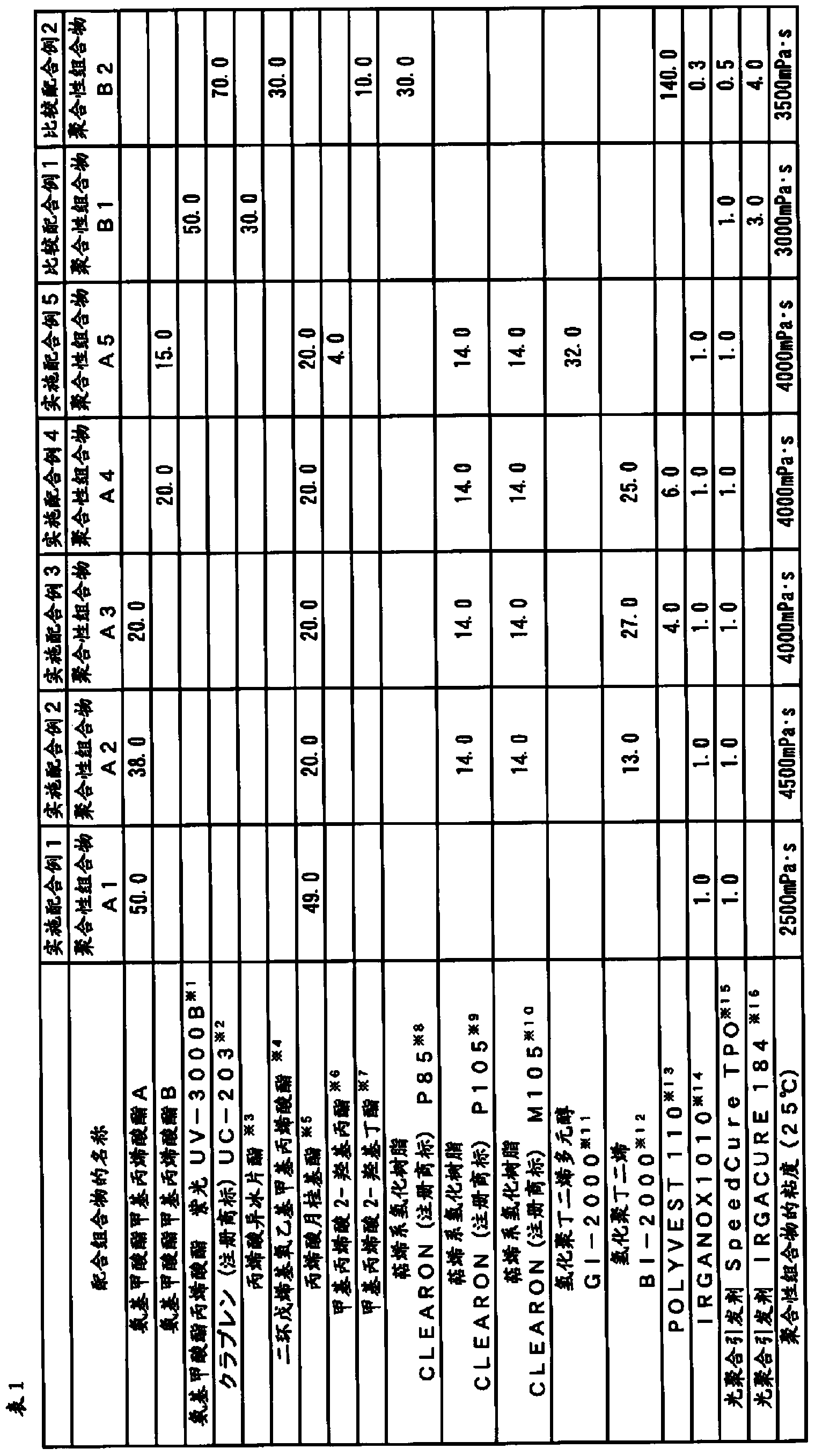

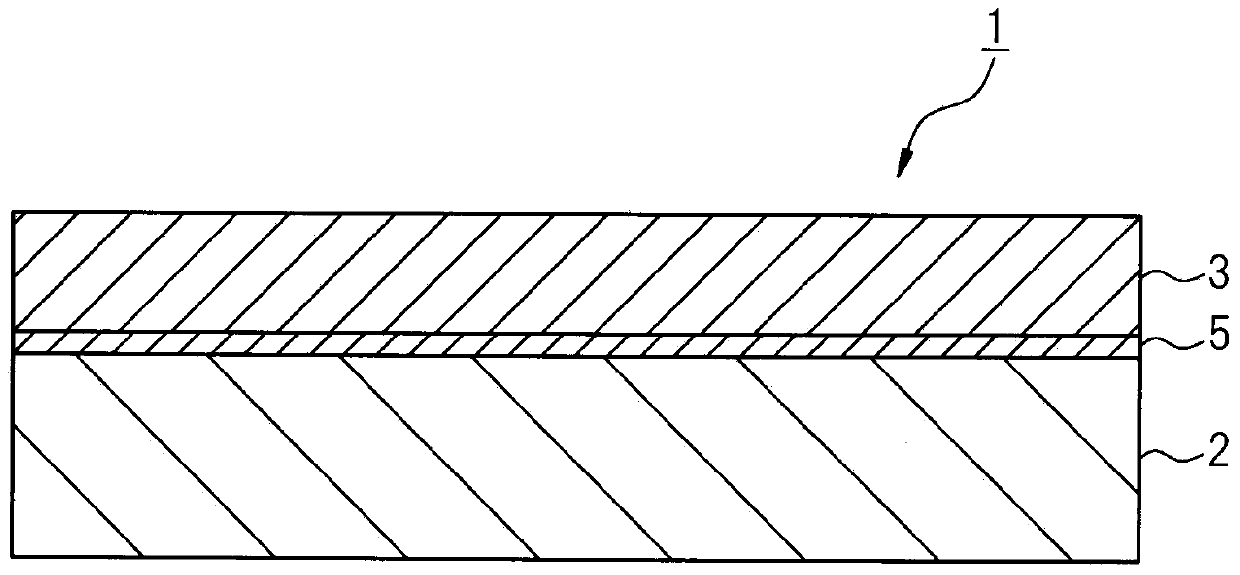

Polymerizable composition, polymer, image display device, and method for producing same

In relation to a polymerizable composition for forming a transparent optical resin layer to be interposed between an image display section of an image display device and a light-transmissive protective section thereof, the present invention provides a polymerizable composition that does not give rise to display defects caused by the deformation of the image display section, enables high-luminance, high-contrast image displaying, has excellent heat resistance, and also has a low dielectric constant. This polymerizable composition comprises: (1) a urethane (meth)acrylate obtained by reacting a hydrogenated polyolefin polyol and a compound having an isocyanato group and a (meth)acryloyl group; (2) a (meth)acryloyl-group-containing compound having a hydrocarbon group with a carbon number of 6 or greater; and (3) a photopolymerization initiator.

Owner:RESONAC CORPORATION

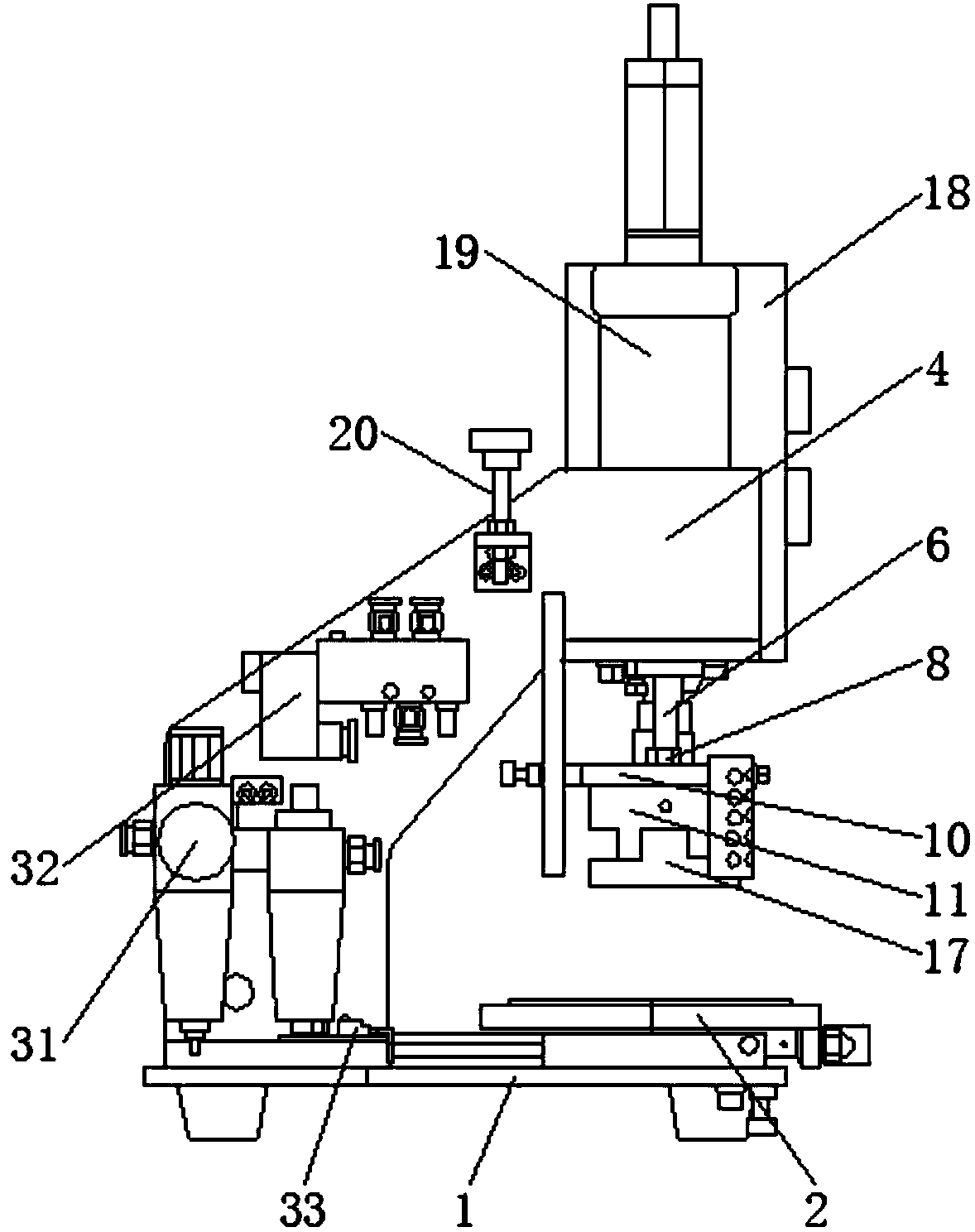

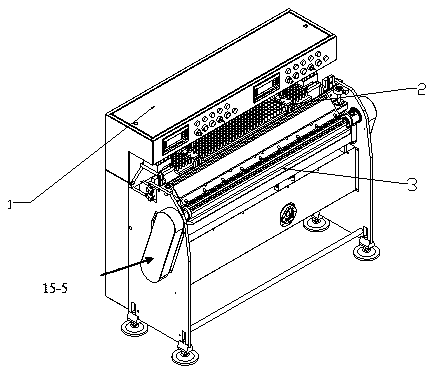

Numerical control corner cutting and edge folding machine equipment

InactiveCN109290414AEasy to operateSave manpower and material resourcesMetal-working feeding devicesPositioning devicesNumerical control systemScratching

The invention relates to the field of mechanical automation, in particular to numerical control corner cutting and edge folding machine equipment. The numerical control corner cutting and edge foldingmachine equipment comprises a numerical control system electric appliance cabinet, numerical control air cylinder corner cutting equipment and numerical control edge folding machine equipment. The numerical control air cylinder corner cutting equipment comprises a brush tabletop capable of avoiding material surface scratching. Numerical control air cylinder corner cutting devices are further arranged on the two sides of the brush tabletop. A first linear lead screw module is arranged beside each numerical control air cylinder corner cutting device and provided with an air cylinder induction clamping sliding table. A numerical control edge folding machine comprises an edge folding machine main rack. The rear side of the edge folding machine main rack is provided with an edge folding machine lifting rear gear. Edge folding upper pressing plate lifting lead screw motors are arranged on the two sides of the edge folding machine main rack. An edge folding overturning plate speed reducer isarranged below the edge folding machine main rack. The numerical control corner cutting and edge folding machine equipment has the beneficial effects that a corner cutting machine and the edge folding machine are combined, operation is simple and convenient, manpower and material resources are saved, material surface pulling damage cannot be caused during remanufacturing, die folding marks are avoided, meanwhile, special dies are not needed for small-angle edge folding, and the die cost is saved.

Owner:优尔屋面科技(苏州)有限公司

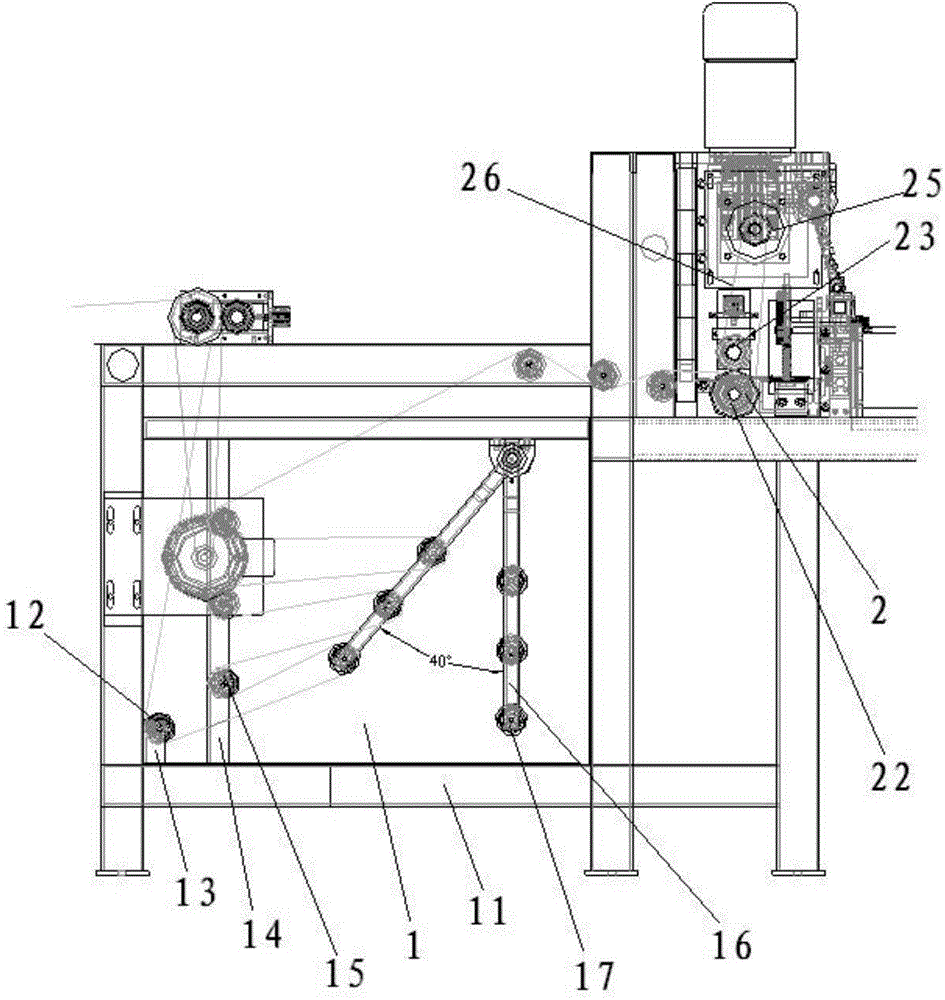

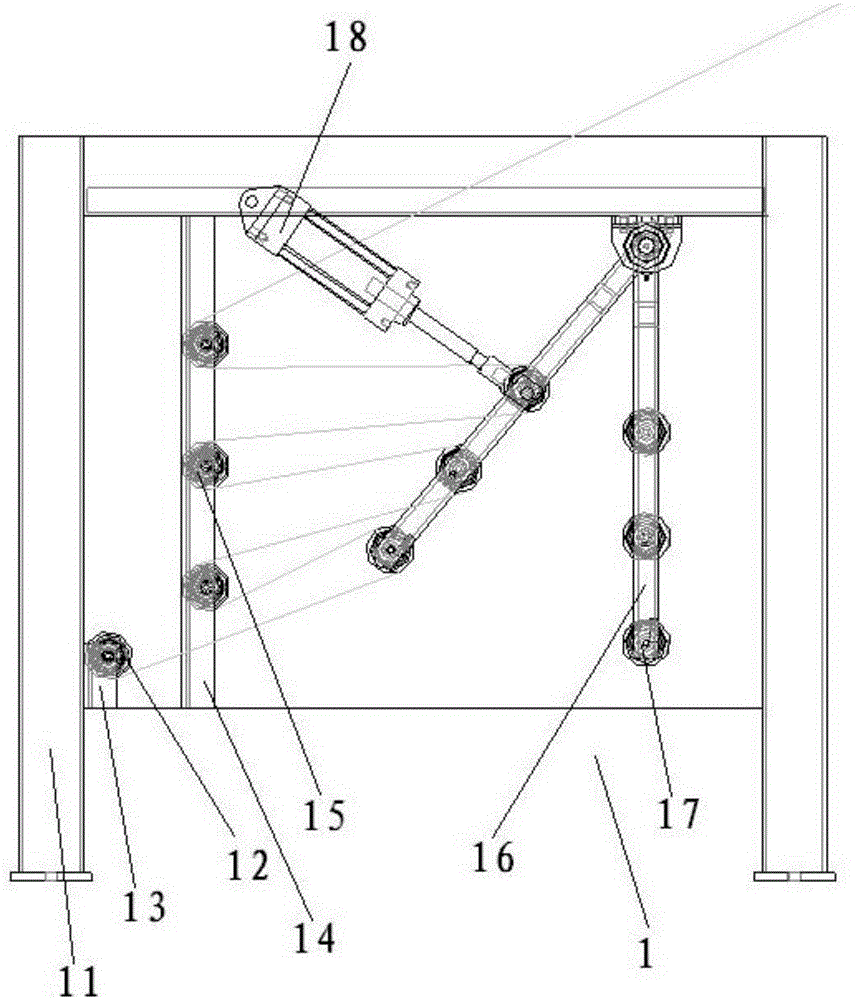

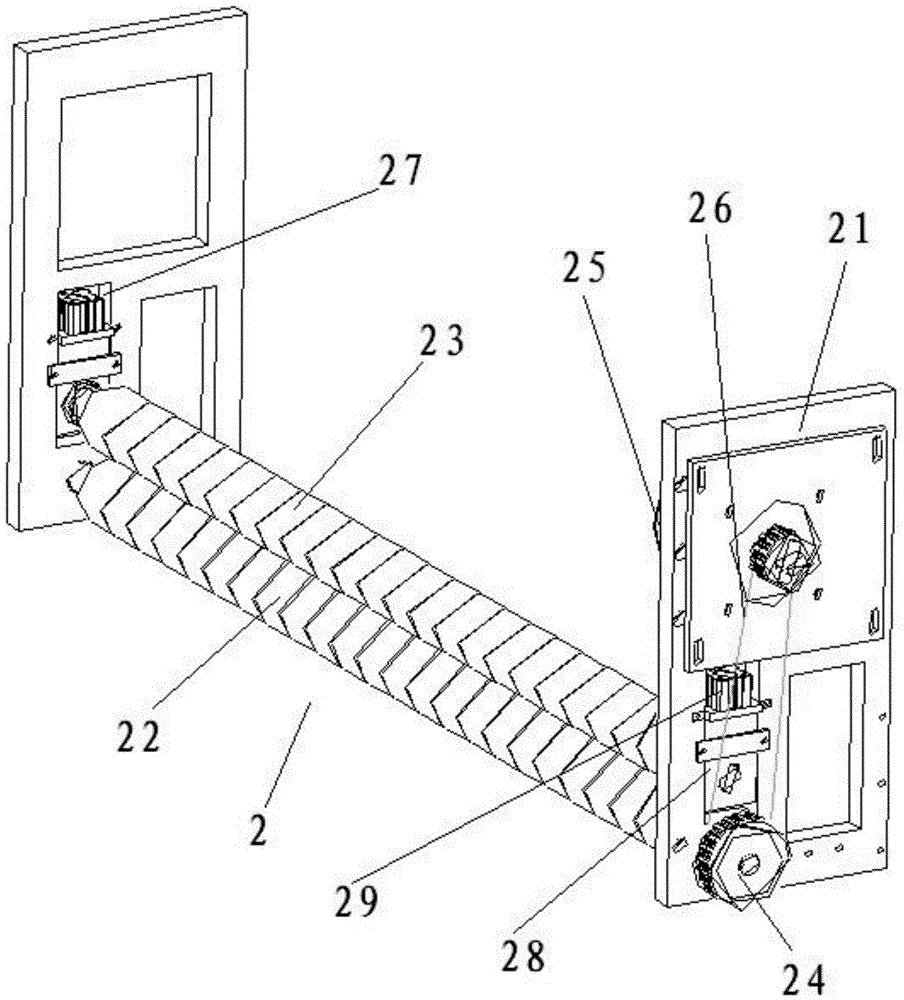

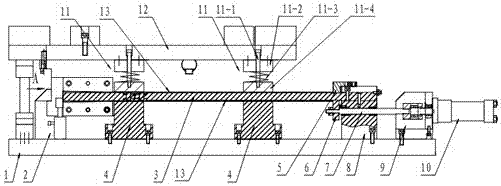

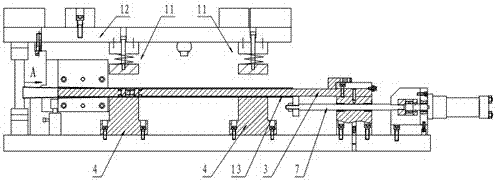

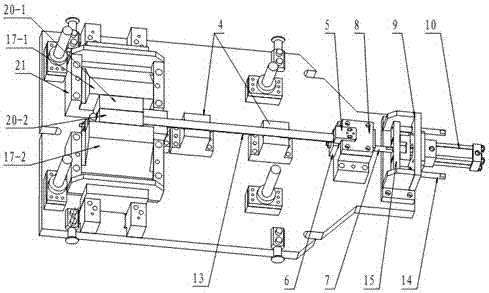

Material storing and cutting pulling device for automatic slitting machine

The invention discloses a material storing and cutting pulling device for an automatic slitting machine. The device is characterized by comprising a material storing device (1), and a cutting pulling device (2) positioned at the downstream of the material storing device (1); the material storing device (1) comprises a frame (11); a first vertical column (13) for fixing a first fixing roller (12) is arranged at the left side of the bottom end of the frame (11); a second vertical rod (14) for connecting the upper surface and the lower surface of the frame (11) is connected in parallel to the right side of the first vertical rod (13); a plurality of second fixing rollers (15) are arranged on the second vertical rod (14) from bottom to top in a sequence. According to the material storing and cutting pulling device for the automatic slitting machine, few parts are used, the structure is simple, the fault rate is low, the repair and maintenance are easy, and moreover, a combined film is free of damage due to being pulled, the quality is high, the pulling precision is high, the cost rate is high, and the device is suitable for wide popularization and application.

Owner:SUZHOU ACME MACHINERY

Pressing mold for round tube class car bumper

ActiveCN105414335AIncrease productivityEliminate time-consuming and laboriousShaping toolsEjection devicesBatch productionStamping press

A pressing mold for a round tube class car bumper comprises a pressing device, a pressing mechanism and a core shaft. The pressing device comprises an upper mold plate, a left wedged pressing block, a right wedged pressing block, a left wedged sliding block, a right wedged sliding block, a left pressing block, a right pressing block, a lower mold plate and a sliding block seat, wherein the upper mold plate is pressed down along with a punch machine; the left and right wedged pressing blocks fit and press the left and right wedged sliding blocks respectively; the left and right wedged sliding blocks push the left and right pressing blocks to close respectively; grooves of the left and right pressing blocks are closed and form a flat round hole matched with the outline of a flat round section of a bumper product to be machined. The pressing mechanism is provided with a pressing fixing seat and a pressing assembly which vertically correspond in position. The rear portion of the core shaft is fixed, the front portion of the core shaft extends to the position between the grooves of the left and right pressing blocks, and the section of the front section of the core shaft is changed from a round shape to a flat round shape. The pressing mold for the round tube class car bumper meets the machining requirements of the product through one time of pressing, obviously improves production efficiency, guarantees product quality, relieves labor intensity, reduces production cost and meets the batched production requirement.

Owner:LINGYUN INDAL CORP

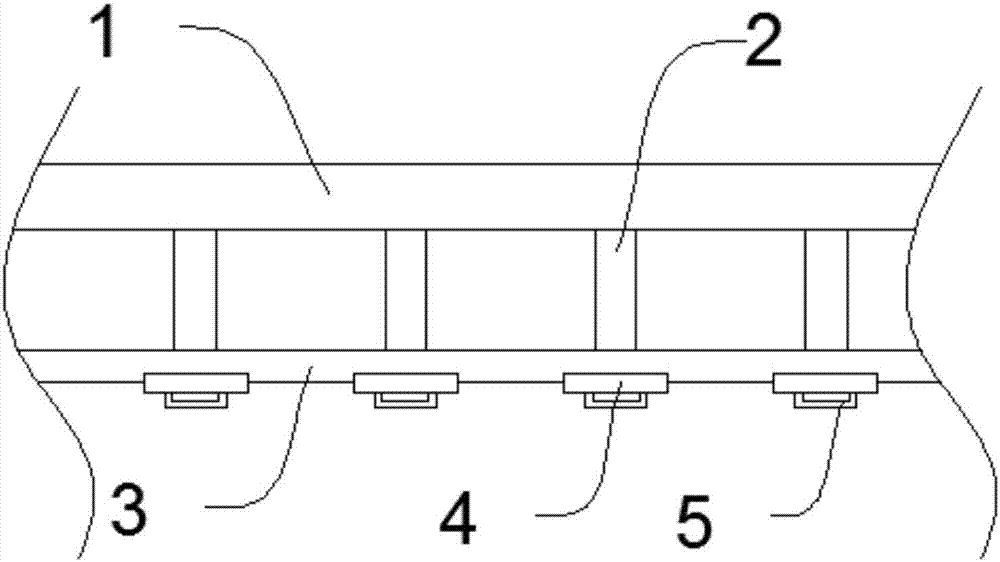

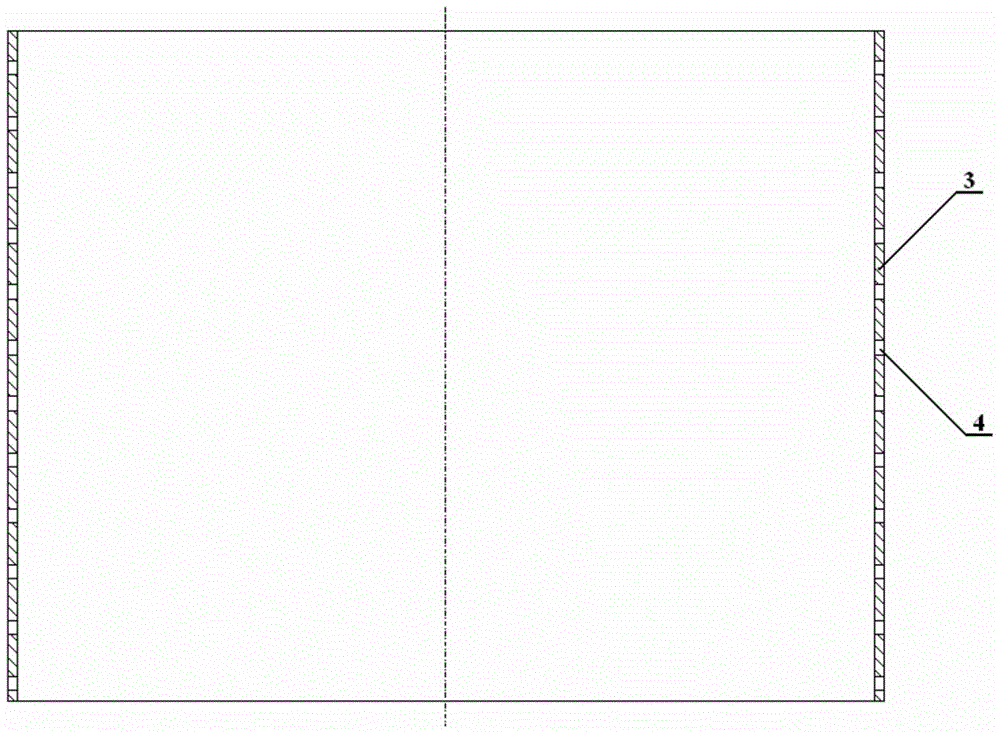

An externally-applied patch

InactiveCN101675920AFast absorptionPromote absorptionSkeletal disorderSheet deliveryThermostatPlastic film

An externally-applied patch relates to an externally-applied patch, which is composed of nonwoven (1), automatic thermostat heater (2), hydrogel transdermal ointment (3) and plastic film (4). The nonwoven (1) and the automatic thermostat heater are tightly connected, the hydrogel transdermal ointment is coated on the back line of the nonwoven, the automatic thermostat heater is arranged in the middle, and the surface of the hydrogel transdermal ointment (3) is covered with the plastic film. The present invention makes the hydrogel transdermal ointment enable to play medical action for a long time at a certain temperature by the continuous heating of the automatic thermostat heater, thereby reducing the effective time of the medicine, and improving the effect of medicine absorption; and thepresent invention has the advantages of convenient and comfortable use, large drug loading, strong penetrability, easy absorption, no residue, and no contaminated clothing.

Owner:倪海军

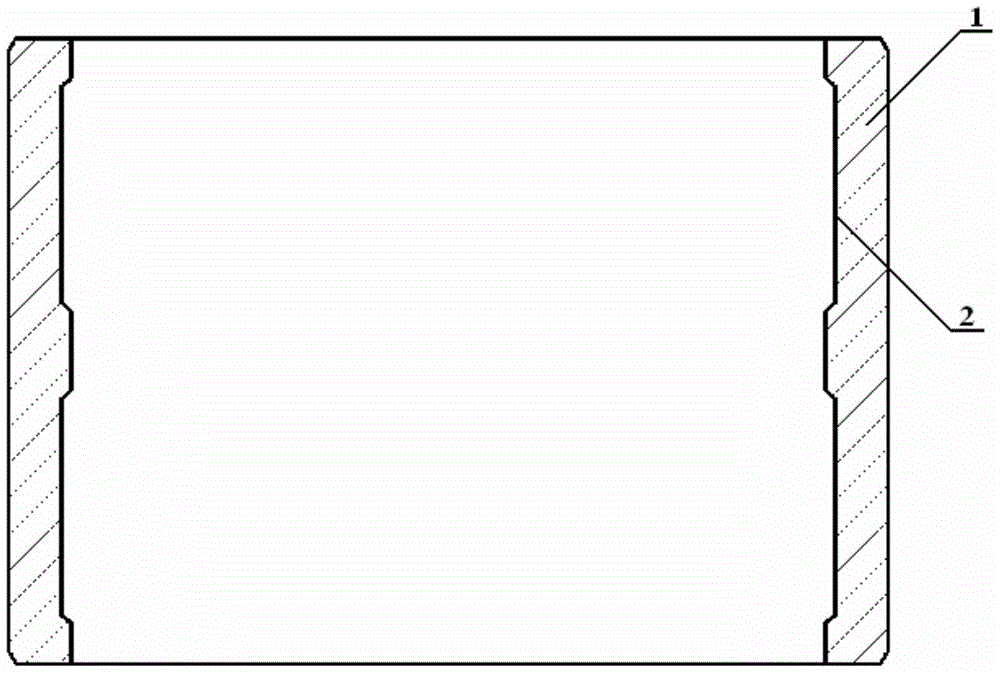

Pre-forging die for forging aluminum alloy wheel

InactiveCN103752751AEasy loading and unloadingGuaranteed mechanical propertiesForging/hammering/pressing machinesForgingAluminium alloy

A pre-forging die for forging an aluminum alloy wheel comprises an upper die plate and a lower die plate. A female die is downward fixed to the upper die plate. A male die is upward fixed to the lower die plate. A circle of a spigot boss is arranged on the periphery of the male die. A positioning edge matched with the spigot boss of the male die is arranged on the periphery of the female die. A closed forging cavity is formed between the female die and the male die. A lower ejector rod which upward ejects a workpiece is arranged right at the center of the male die. An upper ejector rod which downward ejects the workpiece is arranged right at the center of the female die. The workpiece can be pressed on the male die through the upper ejector rod arranged right at the center of the female die, the female die retreats, and therefore the die releasing process is achieved, the traditional method that a die is first lifted and then released is avoided, and damage caused when the workpiece collides with the die is avoided; the workpiece is ejected out of the male die through the lower ejector rod arranged right at the center of the male die, and therefore the forging process is achieved; compared with a traditional die, the pre-forging die has the advantages of being free of die holding, easy to release and not prone to strain. By means of the pre-forging die, materials are saved, abraded pieces can be conveniently loaded and unloaded, and mechanical performance of products can be ensured.

Owner:连云港宝石精密重工科技有限公司

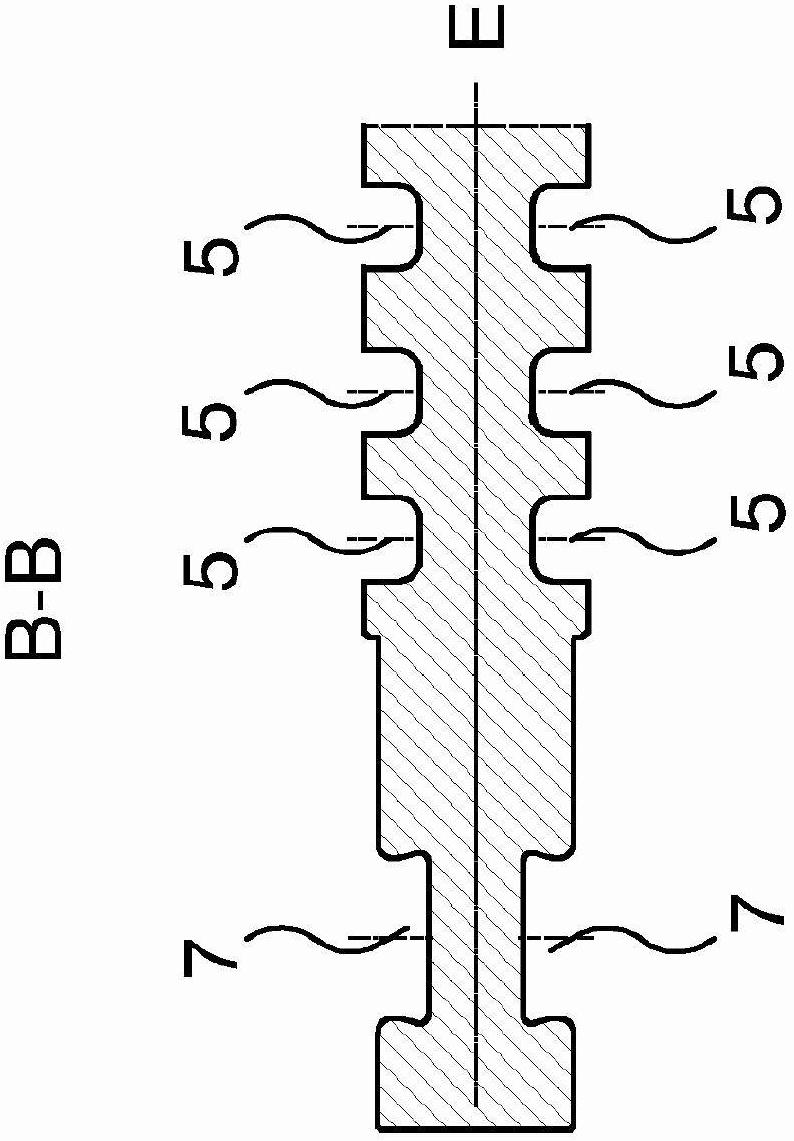

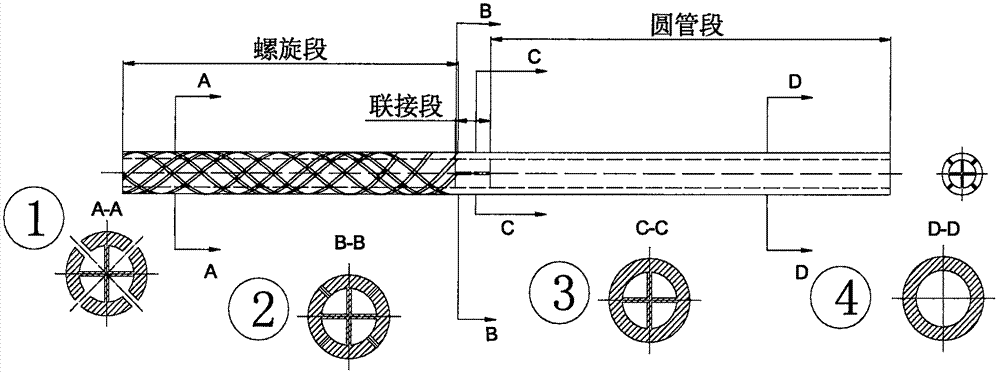

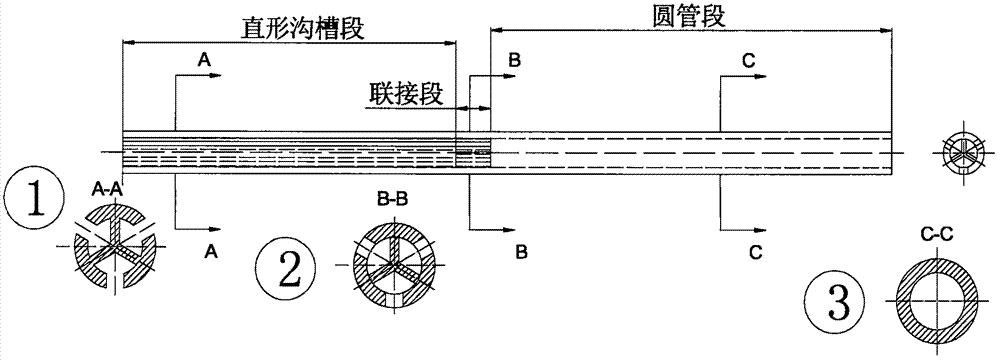

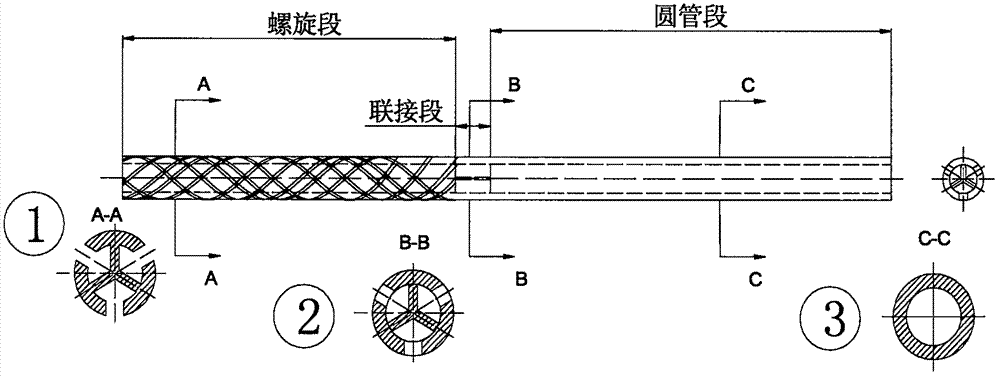

Drainage tubes

The invention relates to five shaped multichannel spiral or straight form pored equal-diameter drainage tubes. Each drainage tube is characterized in that a grooved section, a connection section and a circular tube section of the drainage tube are prepared by silica gel materials having the same diameter. Two cut planes meet in a line at parallel connection positions of the channel grooved section and the connection section. Semicircles are intersected at parallel connection positions of the channel grooved section and the connection section. Rectangles are intersected at parallel connection positions of the channel grooved section and the connection section. Crossed four-channel spiral, equant three-channel straight form and equant three-channel spiral equal-diameter drainage tubes are provided. The crossed four-channel spiral drainage tube comprises the crossed four-channel spiral grooved section, the connection section and the circular tube section. The equant three-channel straight form and spiral form pored equal-diameter drainage tubes are characterized in that a wall of a hole of the equant three-channel straight form pored equal-diameter drainage tube is a sealed hole, and an opening of the hole is positioned at an insertion end for inserting an indwelling needle from an outer end.

Owner:罗顺莲

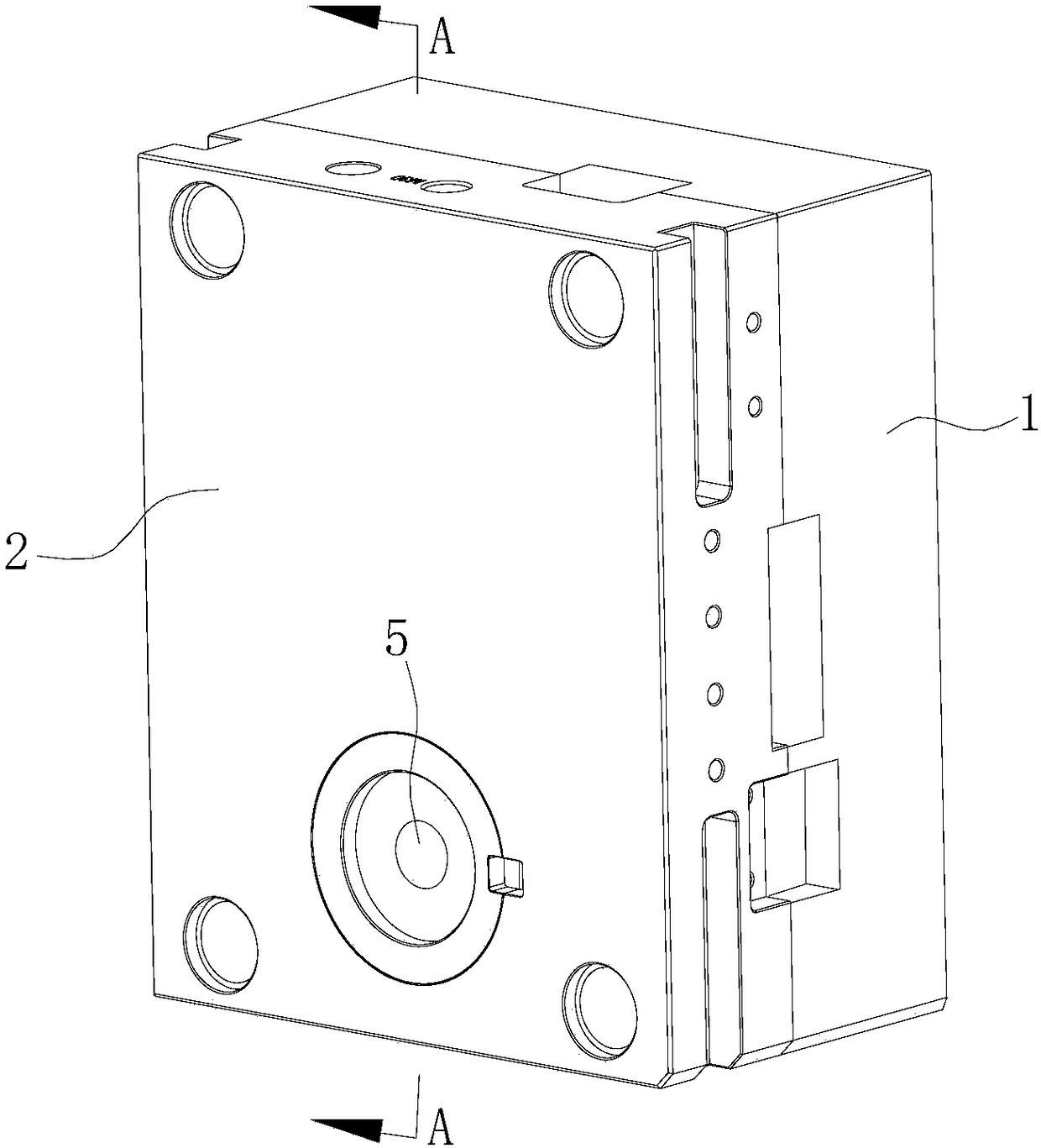

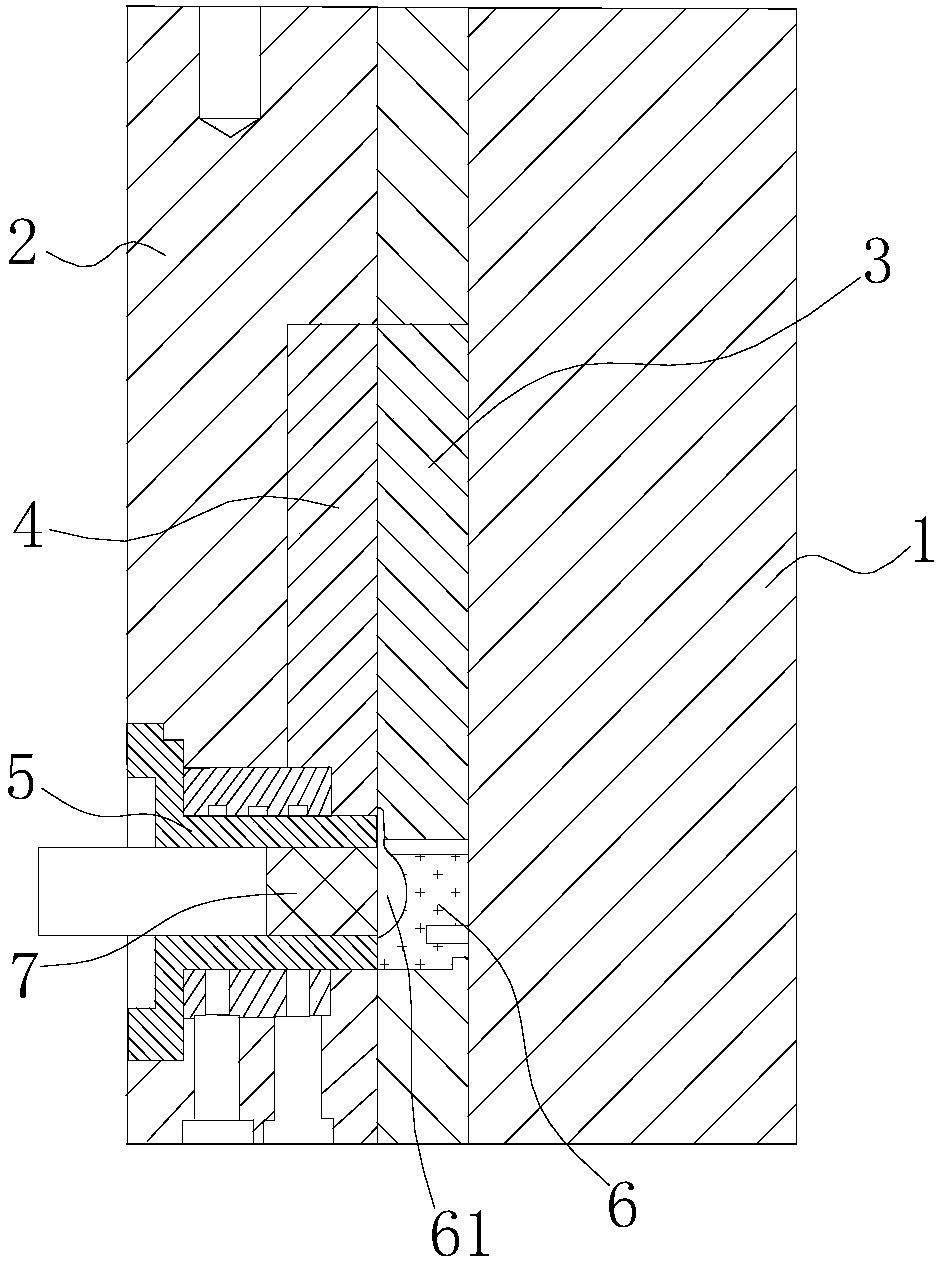

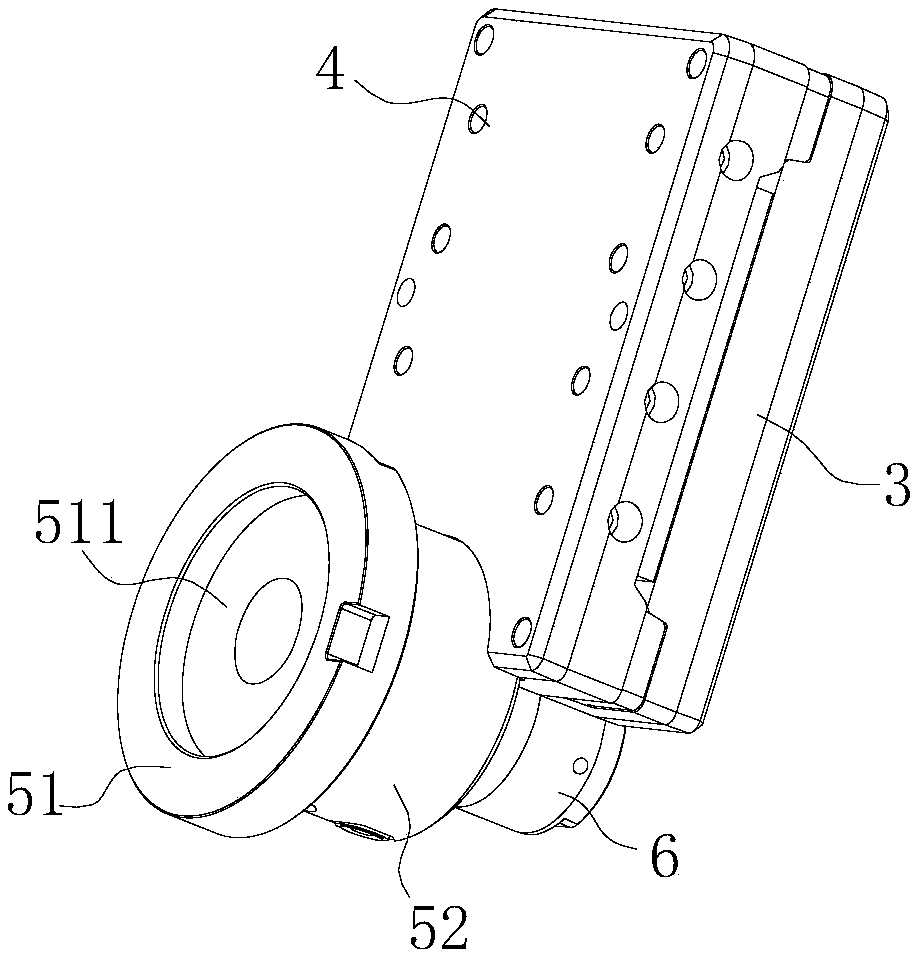

Pressure casting mould and pressure casting device

The invention provides a pressure casting mould and a pressure casting device, and relates to the technical field of moulding. The pressure casting mould comprises a male mould plate and a female mould plate which are matched with each other; a moving mould core is arranged on the male mould plate; a fixed mould core is arranged on the female mould plate; when the male mould plate and the female mould plate are closed, the moving mould core and the fixed mould core form a mould cavity; a sprue bush is arranged on the female mould plate; a spure spreader is arranged on the male mould plate; a groove and a flow distributing channel which communicate with each other are formed in the spure spreader; when the male mould plate and the female mould plate are closed, the spure spreader is positioned out of the sprue bush; the groove of the spure spreader communicates with a pressure injection flow channel; the flow distributing channel of the spure spreader communicates with the mould cavity;the pressure casting device comprises a pressure casting machine and the pressure casting mould; a pressure injection head of the pressure casting machine is inserted into the sprue bush in a matchedmanner; and the stroke of the pressure injection head in the pressure injection flow channel is not less than the length of the pressure injection flow channel. According to the pressure casting mould and the pressure casting device, the sprue bush is not affected by the formation and separation of a material handle; the situations of sprue bush damages caused by tearing are reduced; the servicelife of the sprue bush is long; and the situations that the pressure injection head is clamped in the sprue bush are also reduced.

Owner:JIANGSU HAIJIN METALLIC GLASS TECH CO LTD

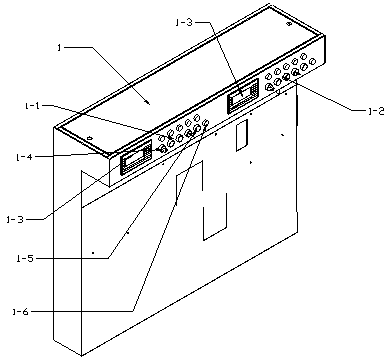

Plastic panel injection mold for water purifier

The invention discloses a plastic panel injection mold for a water purifier. The injection mold comprises a base, wherein a lower mold is fixedly arranged on the base, jacking air cylinders are symmetrically arranged on the two sides of the base, and an upper mold matched with the lower mold is arranged at the upper ends of piston rods of the jacking air cylinders; a plastic panel injection mold cavity is arranged between the inner part of the upper mold and the lower mold, and an injection molding opening communicated with the plastic panel injection mold cavity is formed in the upper end ofthe upper mold; a mold stripping plate is arranged between the lower end of the upper mold and the lower mold, and the mold stripping plate is positioned at the lower end of the plastic panel injection mold cavity; and vertical sliding rods are symmetrically arranged on the bases on the two sides of the lower mold, the two sides of the lower end of the upper mold are arranged on the vertical sliding rods in a sliding mode through middle sliding blocks, the two sides of the mold stripping plate are arranged on the vertical sliding rods in a sliding mode through lower sliding blocks, and upper sliding blocks are arranged on the vertical sliding rods at the upper end of the middle sliding blocks in a sliding mode.

Owner:江苏宇豪新材料科技有限公司

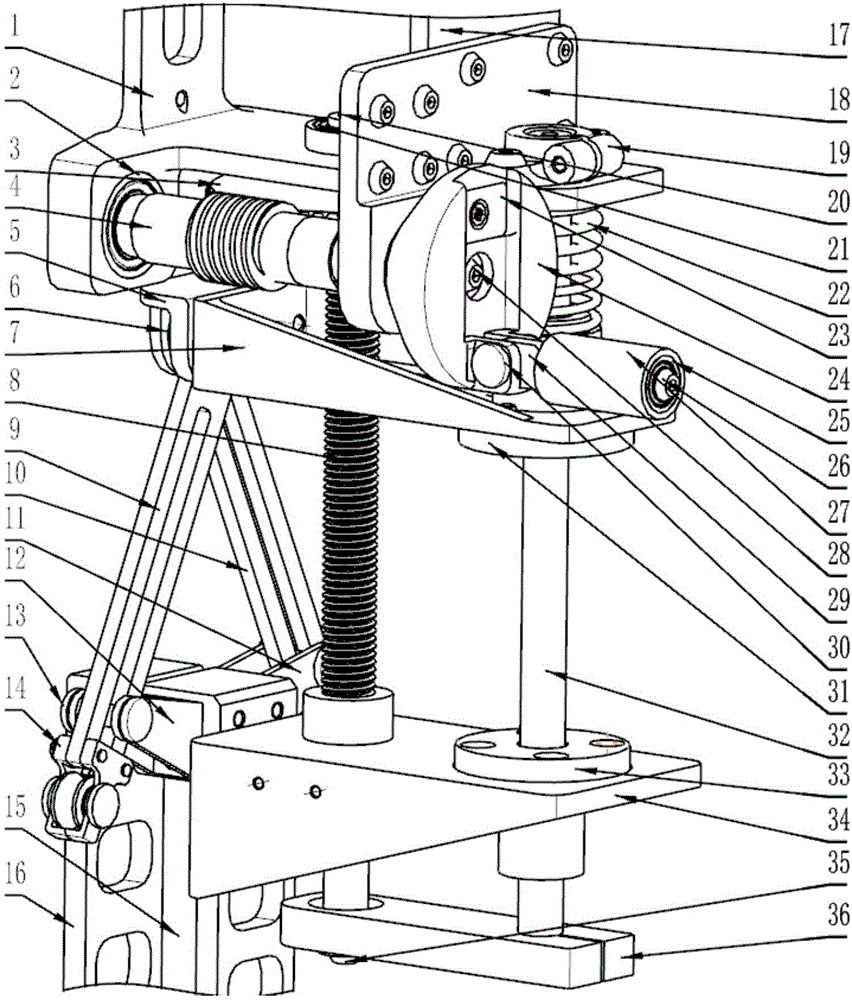

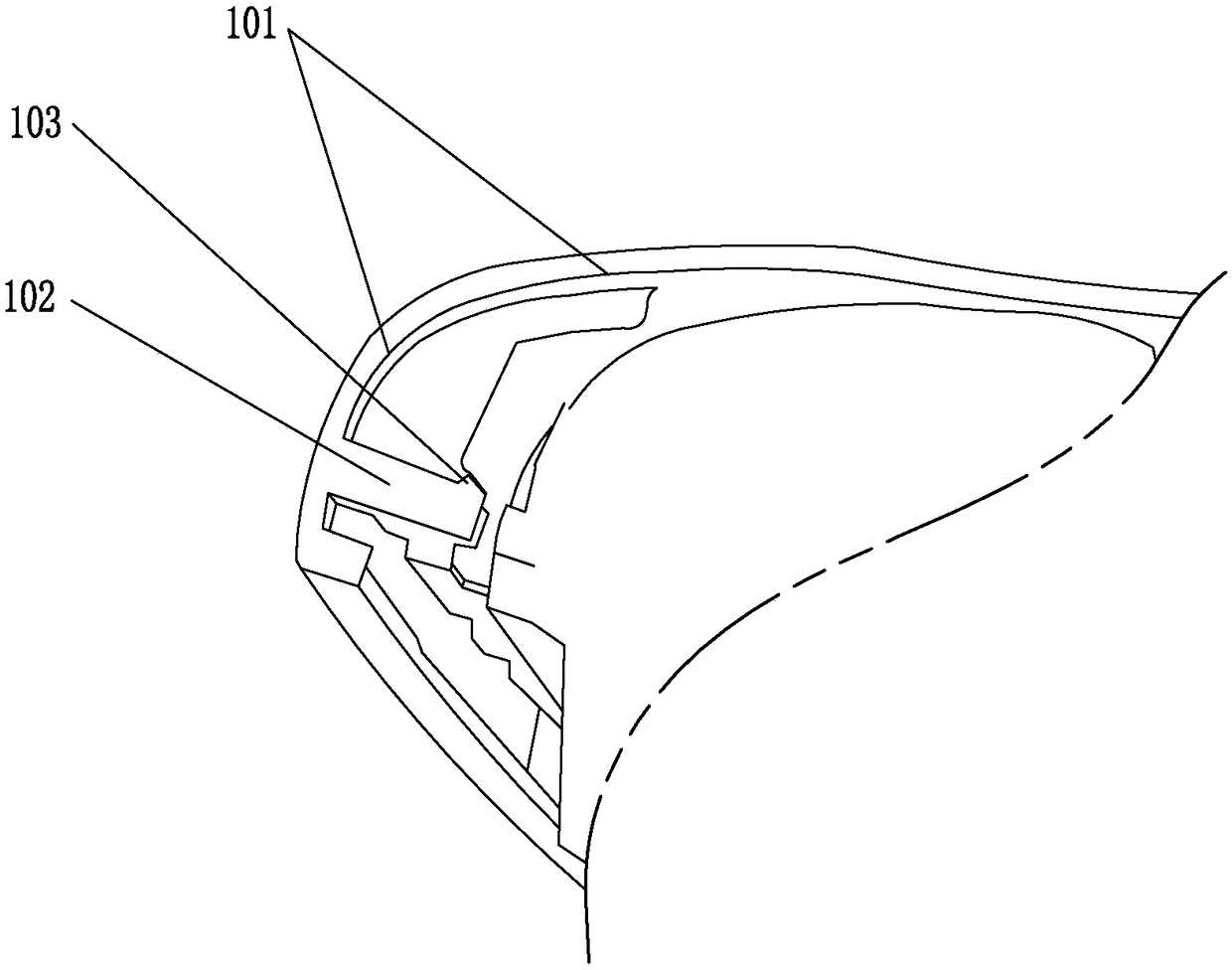

Transverse splitting exercise device

InactiveCN104857675ANo strainEasy to open and close automaticallyGymnastic exercisingMuscle strainsNarrow range

The invention relates to sport equipment, in particular to a transverse split exercise device, and the problems that in the prior art, when the two legs are split to the limit of an exerciser, swing of the two legs in an opening-closing mode within a narrow range at the limit position is inconvenient, and therefore the exercise effect is poor are solved. The transverse split exercise device comprises a seat and two leg frames, wherein the seat is provided with seat wheels, one ends of the leg frames are hinged to the seat, the other ends of the leg frames are respectively provided with a leg frame wheel, each leg frame wheel is arranged in a transverse rail, the seat wheels of the seat are arranged in seat tracks perpendicular to the transverse rails, and the back of the seat is connected with a slider-crank mechanism used for enabling the seat to move in a reciprocating mode. The back of the seat is connected with the slider-crank mechanism used for enabling the seat to move in the reciprocating mode, so that the swing of the two legs in the opening-closing mode within the narrow range at the limit position is facilitated, the exercise effect is improved, and muscle strain can not be caused.

Owner:SHAOXING TEXTILE MACHINERY GRP

Polymerizable Composition, Polymer, Image-Display Device, And Manufacturing Method Therefor

InactiveCN104011100ANo strainInhibition reflexAdhesive processesOrganic chemistryPolyolHeat resistance

Provided is a polymerizable composition for providing a thin image-display device that does not exhibit display problems due to deformation of an image-display unit, allows high-brightness, high-contrast image display, and tolerates heat well. A polymerizable composition for forming a polymer layer interposed between an image-display unit in an image-display device and a light-transmitting protective part. Said polymerizable composition is characterized by containing the following: (1) a (meth)acryloyl group-containing compound that has a structural unit derived from a (poly)ester polyol and / or a structural unit derived from a (poly)carbonate polyol; (2) a (meth)acryloyl group-containing compound that has a C9+ hydrocarbon group; and (3) a photopolymerization initiator.

Owner:SHOWA DENKO KK

Bus station vertical pull ring

The invention relates to a bus station vertical pull ring. The bus station vertical pull ring comprises a top plate and an adjusting mechanism, the lower end of the top plate is fixedly connected with a cross rod through the adjusting mechanism, the lower end of the cross rod is connected with a limiting part in an embedded mode, and the limiting part is fixedly connected with a pull ring body. By adopting the structure, compared with the prior art, the structure in the prior art is single, cannot provide buffering assist for a user and cannot avoid muscle strain when the user pulls the pull ring. By adopting the hydraulic buffering clamping method, the effect that the user can use the pull ring normally when a bus vibrates can be effectively achieved, and joint or muscle strain is avoided.

Owner:蒋潇

Integral metal-based polymer composite self-lubricating bearing and manufacturing method thereof

The invention provides an integrated metal-based macromolecular composite self-lubrication bearing. The integrated metal-based macromolecular composite self-lubrication bearing comprises an externally-circular metal shaft sleeve, a steel plate layer and a plastic layer, wherein an inner diameter ring groove is formed in the inner surface of the externally-circular metal shaft sleeve; the steel plate layer is fixed at the interior of the externally-circular metal shaft sleeve; the outer surface of the metal plate layer is in contact with the inner surface of the externally-circular metal shaft sleeve; a plurality of through holes are formed in the steel plate layer; the plastic layer is fixed on the steel plate layer; the plastic layer comprises an abrasion-proof layer and a fixing layer; the abrasion-proof layer is in contact with the inner surface of the steel plate layer; and the fixing layer is filled into the through holes of the steel plate layer and the inner diameter ring groove of the externally-circular metal shaft sleeve. The integrated metal-based macromolecular composite self-lubrication bearing takes the externally-circular metal shaft sleeve as a base material and is low in cost and easily available in materials; more importantly, the integrated metal-based macromolecular composite self-lubrication bearing is high in abrasion resistance; the experiment results show that the abrasion loss is smaller than 0.1mm after testing for 50 hours under the condition that the lubrication oil is coated at one time at the speed of 0.7m / s under the pressure of 1.2MPa.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

A molding die for round tube type automobile anti-collision bar

ActiveCN105414335BNo wrinklesMeet the process requirementsShaping toolsEjection devicesContact pressureEngineering

A molding die for a circular tube type automobile anti-collision bar, including a molding device, a pressing mechanism and a mandrel. , right pressing block, lower template, slider seat, upper template is pressed down with the punching machine, left and right wedge-shaped pressing blocks respectively match and touch left and right wedge-shaped sliders, left and right wedge-shaped sliders respectively push left and right pressing The block is closed, and the grooves of the left and right pressing blocks are closed to form an oblate hole that matches the outline of the oblate section of the processed anti-collision bar product; Components; the rear part of the mandrel is fixed, the front part extends between the grooves of the left and right pressing blocks, and the cross section of the front part of the mandrel gradually changes from circular to oblate. The present invention satisfies the processing requirements of product pieces at one time of molding, ensures product quality while significantly improving production efficiency, reduces labor intensity and production cost, and satisfies the requirements of batch production.

Owner:LINGYUN INDAL CORP

Full tantalum insulator cover and its manufacturing process

ActiveCN103337371BGuaranteed tightnessNo strainCapacitor housing/encapsulationTantalum capacitorManufacturing technology

The invention discloses a full-tantalum insulator cover and a manufacturing technology thereof. The full-tantalum insulator cover is a flat part formed by integrally processing a tantalum board material, comprises a center hole and flangings, and is characterized in that bosses are arranged at the periphery of the center hole; the bosses are formed by adopting a cold extrusion technology; a distance from the upper surface to the bottom surface of each boss is the thickness of the tantalum board material; and liquid injection holes are formed around the center hole. According to the full-tantalum insulator cover used for manufacturing a tantalum capacitor and the manufacturing technology of the full-tantalum insulator cover, the full-tantalum insulator cover is free from strain and residual internal stress, so that the sealability of a capacitor anode and the center hole of the full-tantalum insulator cover is ensured, liquid leakage is avoided, a defective rate of tantalum capacitor production is decreased, and liquid injection of the capacitor is facilitated.

Owner:湖南华旦新材料有限公司

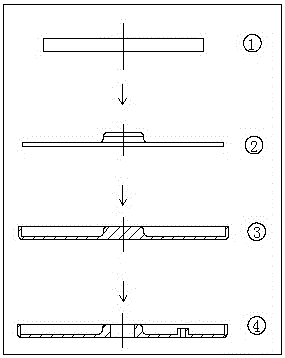

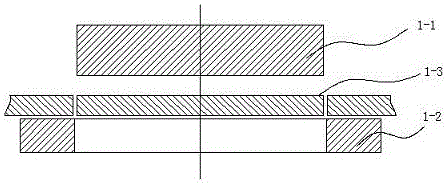

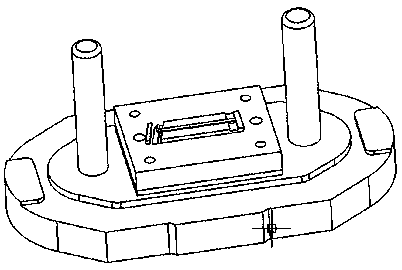

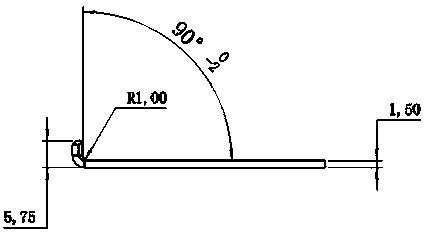

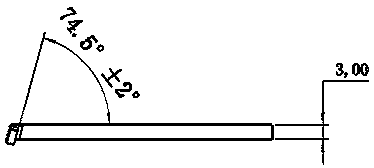

A kind of bending process method of turbine blade

ActiveCN106513479BAdjustable positioningReduce manufacturing costMetal-working apparatusHigh volume manufacturingTurbine blade

The invention discloses a bending machining technique method for a turbine blade. The bending machining technique method for the turbine blade comprises the following steps that a, a stainless steel sheet is chosen, an outer contour blank piece of the turbine blade is prefabricated, and the overall length demand of the outer contour blank piece is guaranteed; b, a lower mould structure of a manufactured bending and forming mould is fixedly arranged on a machine tool, and the other corresponding moving mould is an upper mould structure; c, the blank piece of the turbine blade is clamped on the bending and forming mould; d, the blank piece is subjected to a squeezing bending and forming process by the bending and forming mould, the other end of the blank piece is subjected to bending and forming operations with one end of the blank piece as the standard, forming machining of the blank piece is achieved, and the blank piece is bent till the radian and angle meet the requirements; and e, after machining is finished, the blank piece is detached from a clamp of the bending and forming mould, and a finished product is obtained. According to the bending machining technique method for the turbine blade, the problem of bending head straining is solved, the condition that multiple blades are simultaneously and continuously machined by one set of mould is achieved, production efficiency is high, surface quality is good, machining is stable and reliable, and the bending machining technique method is suitable for batch production.

Owner:GUIZHOU HANGFEI PRECISION MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com