Soilless capillary hydroponics rearing groove

A cultivation tank and hydroponics technology, which is applied in the field of soilless hydroponics capillary cultivation tank, can solve the problems of high labor intensity, plant root strain, change, etc., and achieve easy cleaning, convenient operation and management, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

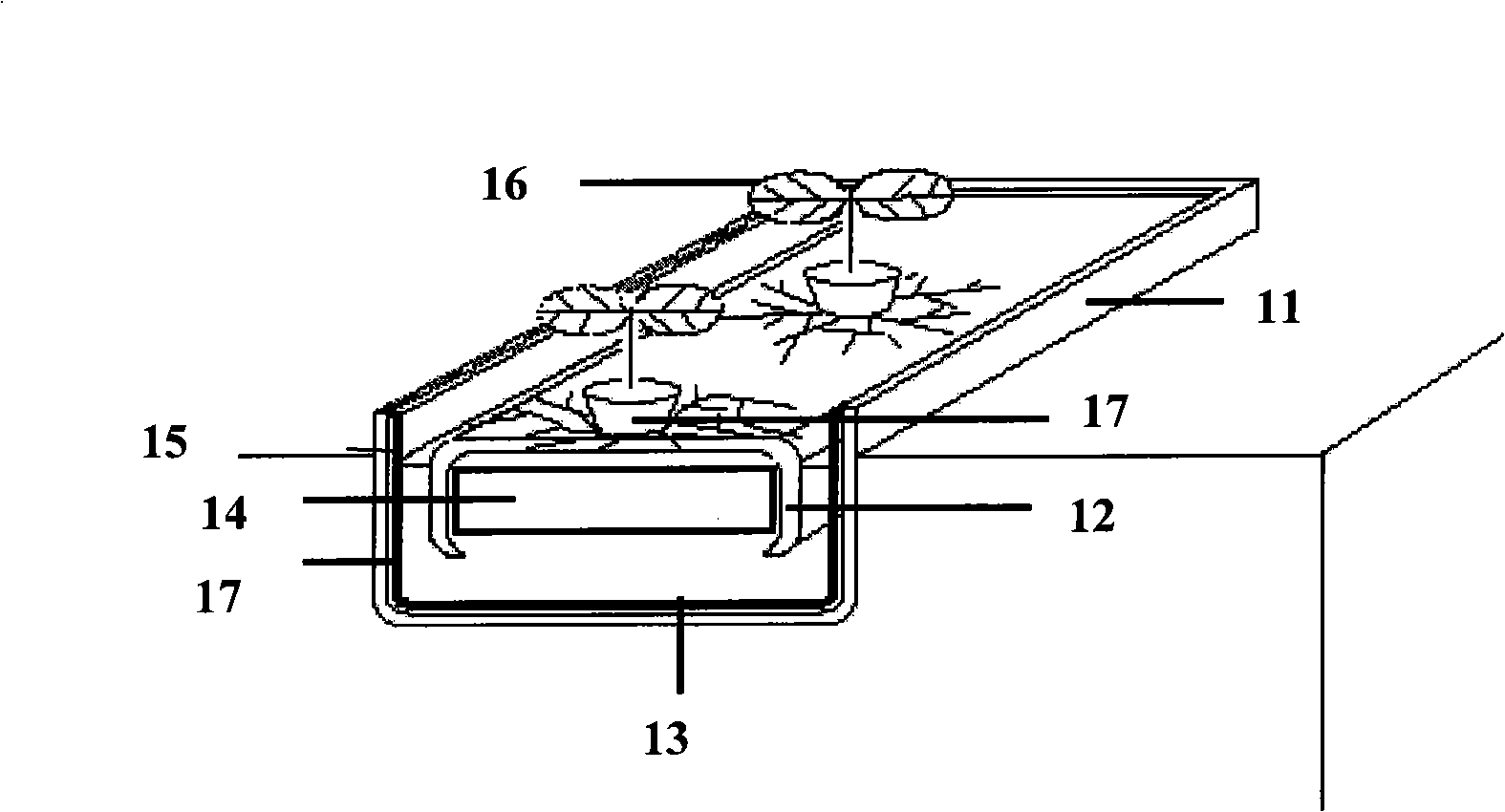

[0017] The soilless hydroponic capillary cultivation tank provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Such as Figure 4 As shown, the soilless hydroponic capillary method cultivation tank 20 provided by the present invention comprises a tank body 26, an anti-leakage film 24, a planting platform 23, a hydrophilic non-woven fabric 27 and a tank cover 25; wherein the tank body 26 is an open upper end cube-shaped, its inner surface is covered with a layer of anti-leakage film 24 for preventing nutrient solution 22 from leaking; the planting platform 23 is cube-shaped, and it is formed by protruding upwards from the inner bottom surface middle part of the tank body 26, and The height is less than the height of the tank body 26, so the nutrient solution 22 can circulate in the space between the inner surface of the tank body 26 and the side of the planting platform 23; the hydrop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com