Pre-forging die for forging aluminum alloy wheel

A technology of aluminum alloy and wheels, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve problems such as poor mechanical properties, inconvenient disassembly and replacement, and serious waste, so as to ensure mechanical properties and facilitate The effect of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

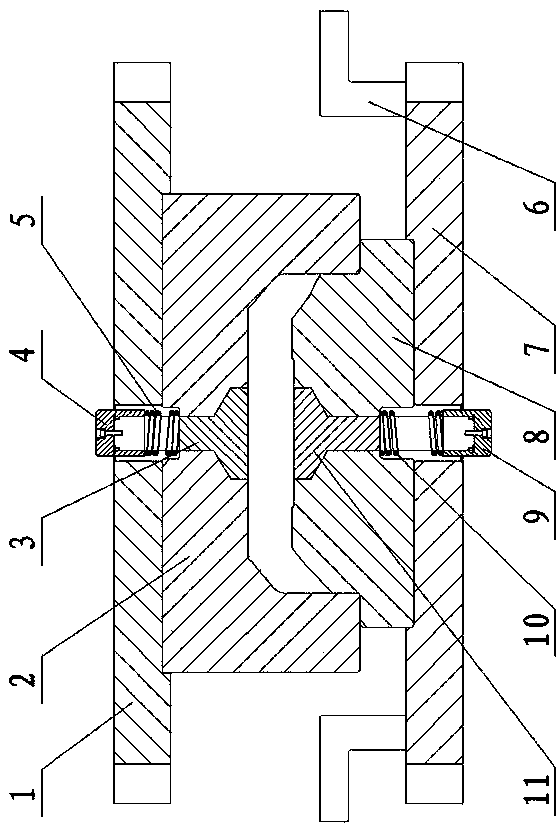

[0010] A pre-forging die for forging an aluminum alloy wheel, comprising an upper template 1 and a lower template 7, the upper template 1 is fixed downward with a die 2, the lower template 7 is fixed upward with a punch 8, and a ring stop is arranged around the punch 8 On the periphery of the die 2, there is a positioning edge that matches the spigot boss of the punch 8, and the positioning edge is in contact with the spigot boss downwards, forming a closed forging type between the die 2 and the punch 8. Cavity, at the very center of the punch 8 is provided with a lower ejector pin 11 which jacks up the workpiece, and at the exact center of the die 2 is provided with an upper ejector pin 3 which ejects the workpiece downward. Put the cut aluminum rod into the punch, and the forging machine presses the die and punch into place. Compared with the traditional open mold, it has the advantages of saving material, easy control of forming, and no shortage of material. When the die an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com