Vehicle door sheet injection mold demolding mechanism

A technology of injection mold and demoulding mechanism, which is applied to household appliances, other household appliances, household components, etc., and can solve problems such as stuck protrusions 103, deformed protrusions 103, and strained buckles 102

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

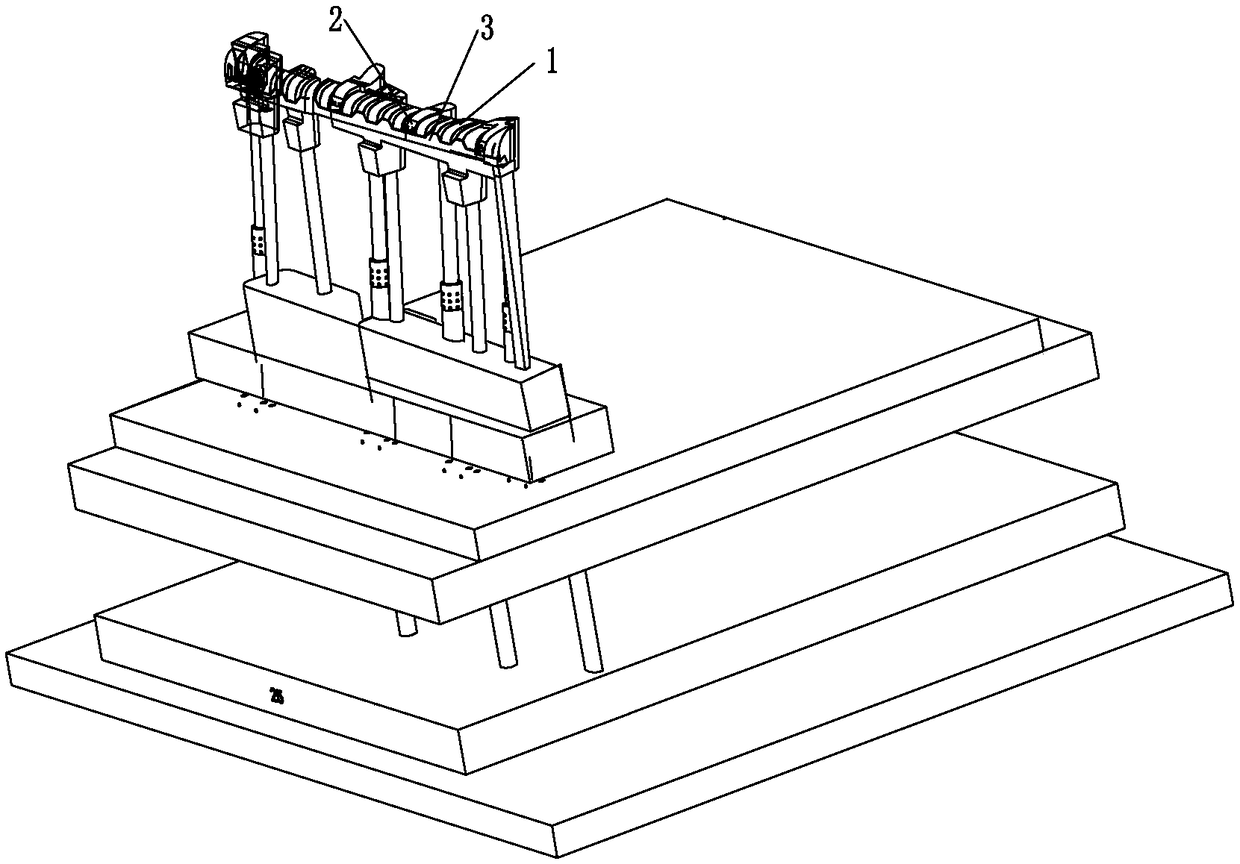

[0021] The present invention will be further described below in conjunction with accompanying drawing.

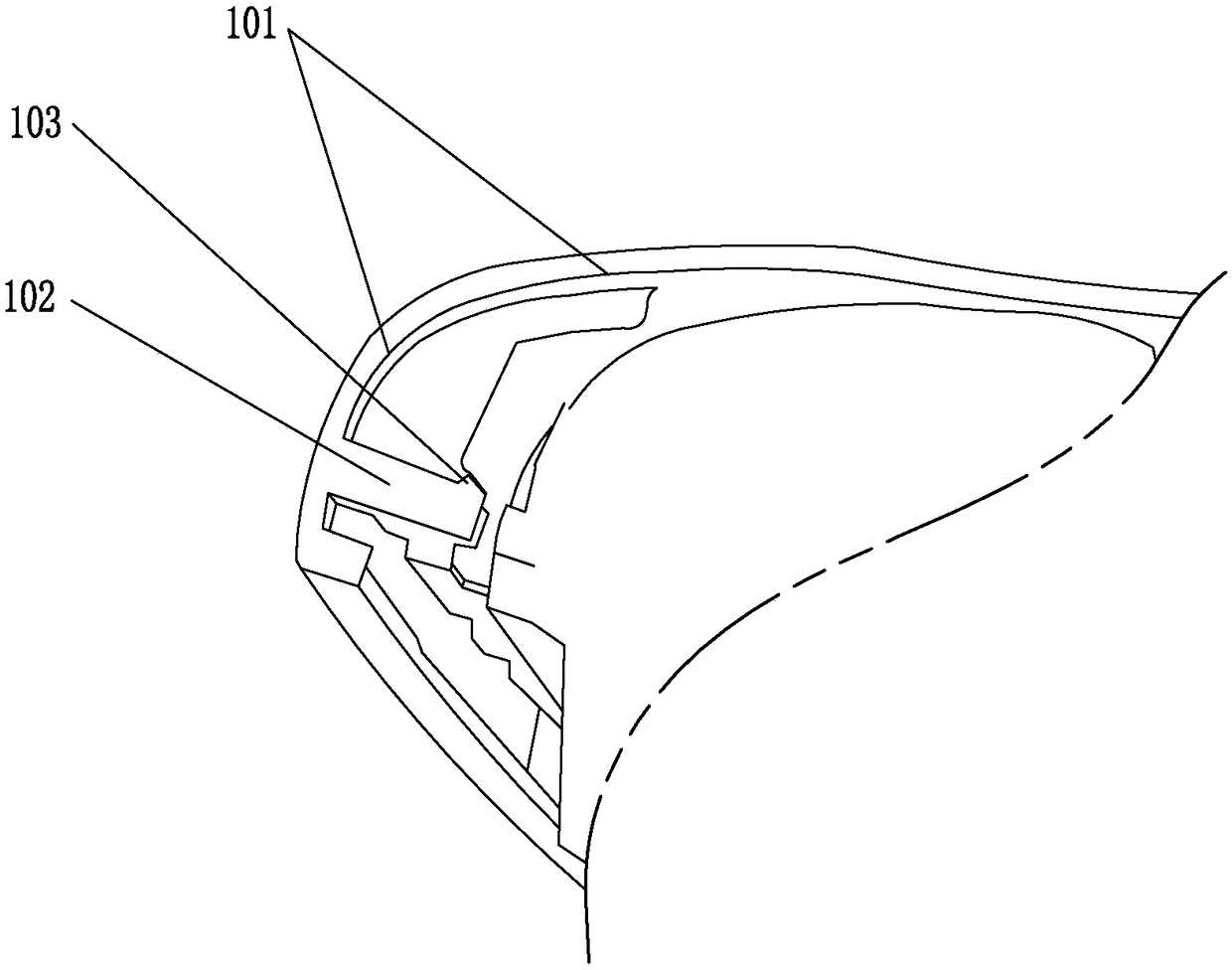

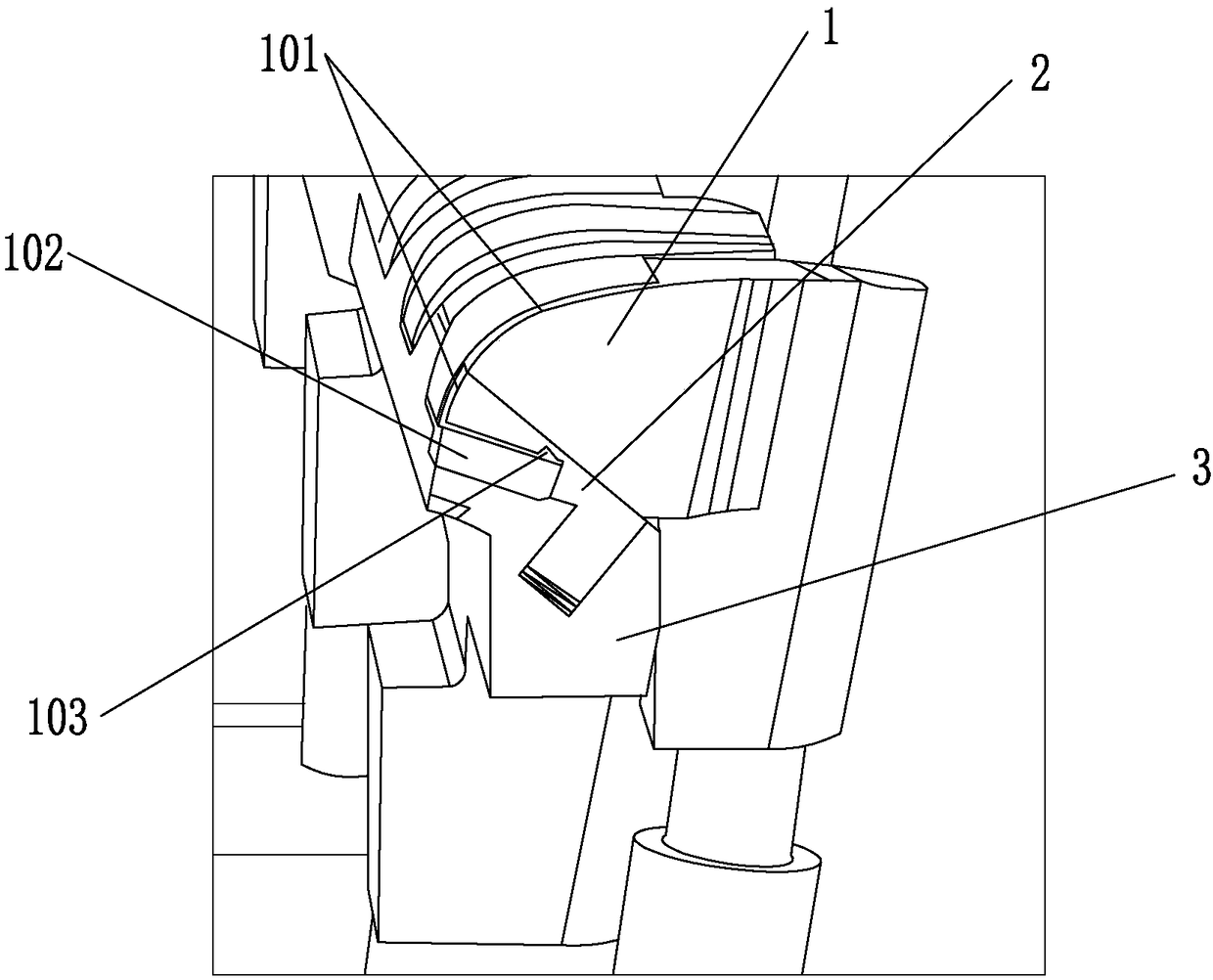

[0022] Such as Figure 1-5 As shown, the demoulding mechanism of the automobile door panel injection mold of the present invention comprises a first inclined jack block 1, a second inclined jack block 2 and a third inclined jack block 3 fixed to the top end of the jack rod, and the first inclined jack block The block 1, the second inclined top block 2 and the third inclined top block 3 form a part of the bottom surface 101 of the mold injection cavity,

[0023] The first inclined top block 1 is located below the second inclined top block 2, and the bonding surface of the two is a first slope, and the angle between the first slope and the lower formwork is 35-45°;

[0024] Described the 3rd slanting top block 3 is positioned at the below of the 2nd slanting top block 2, the first cavity between the bottom surface and the inner surface of the 2nd slanting top block 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com