Soilless capillary hydroponics rearing system

A hydroponic and capillary technology, applied in the field of facility agriculture, can solve the problems of affecting the normal growth of plants, straining the roots of plants, and difficult cleaning of residual roots, etc., to achieve easy cleaning, reduce labor intensity, and solve the contradiction between oxygen absorption and liquid supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

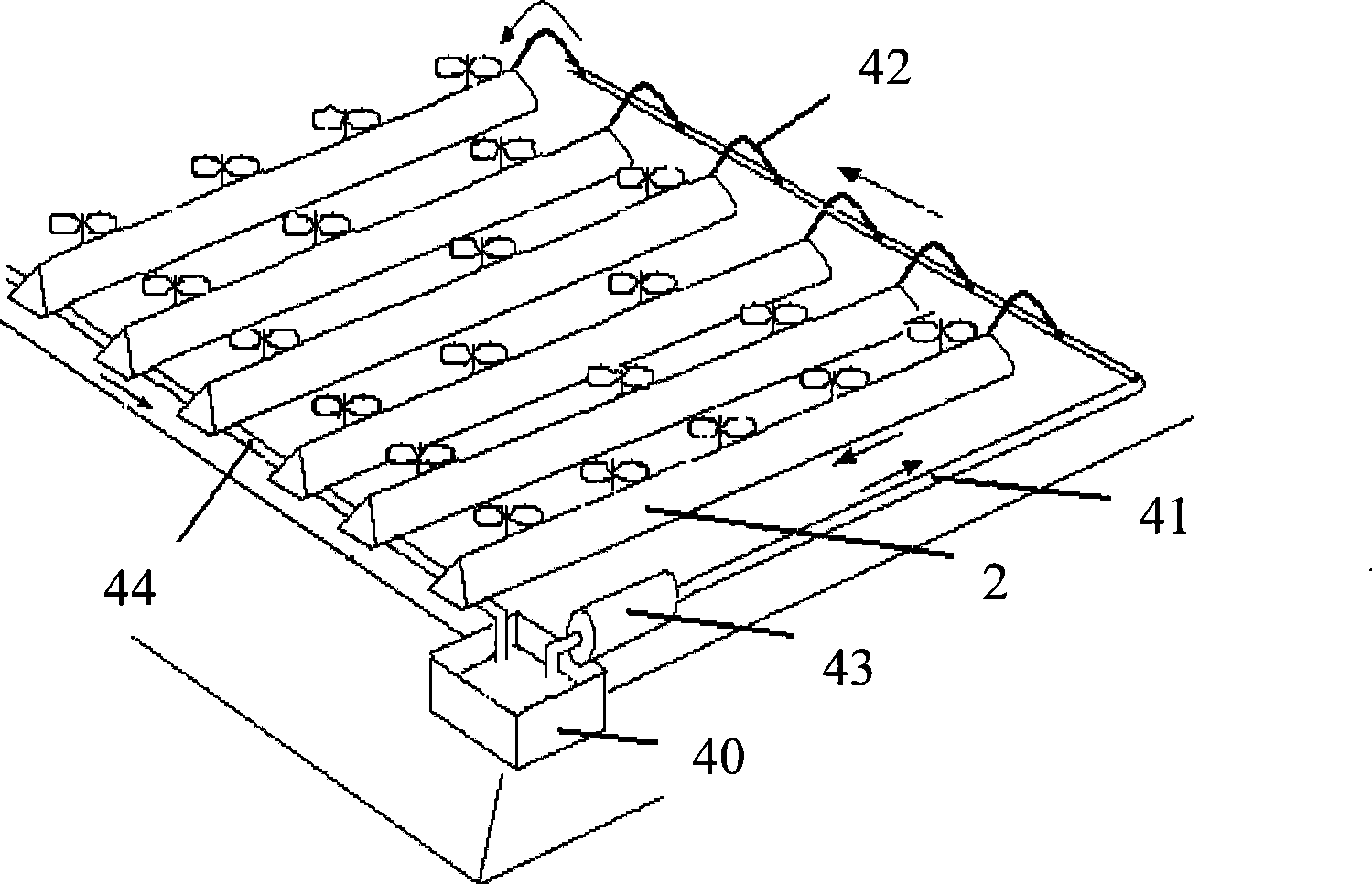

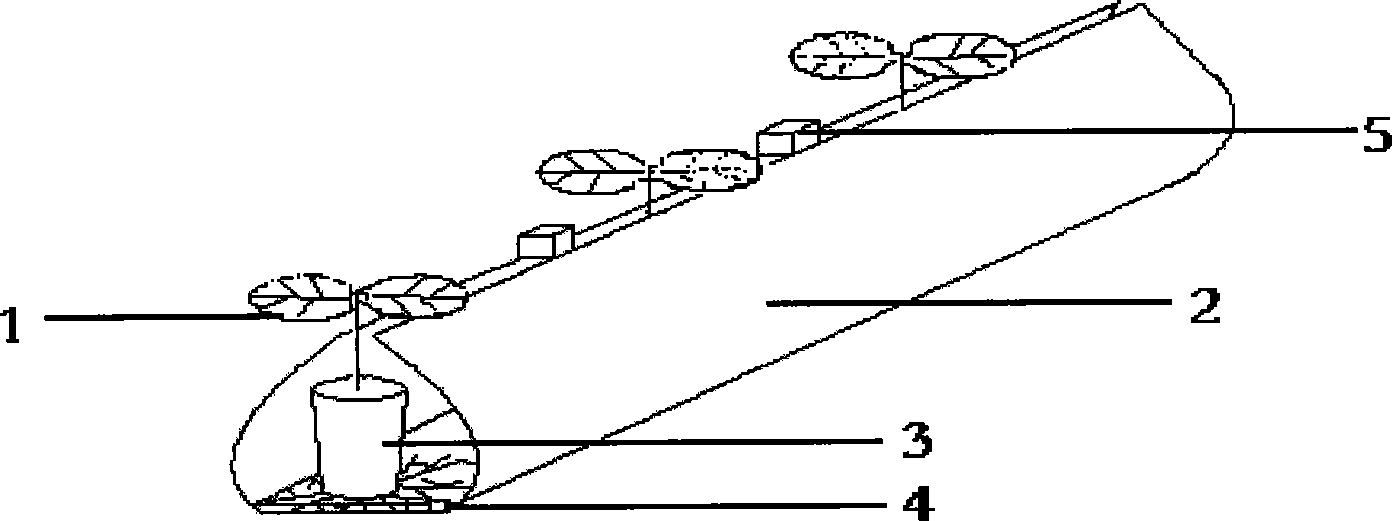

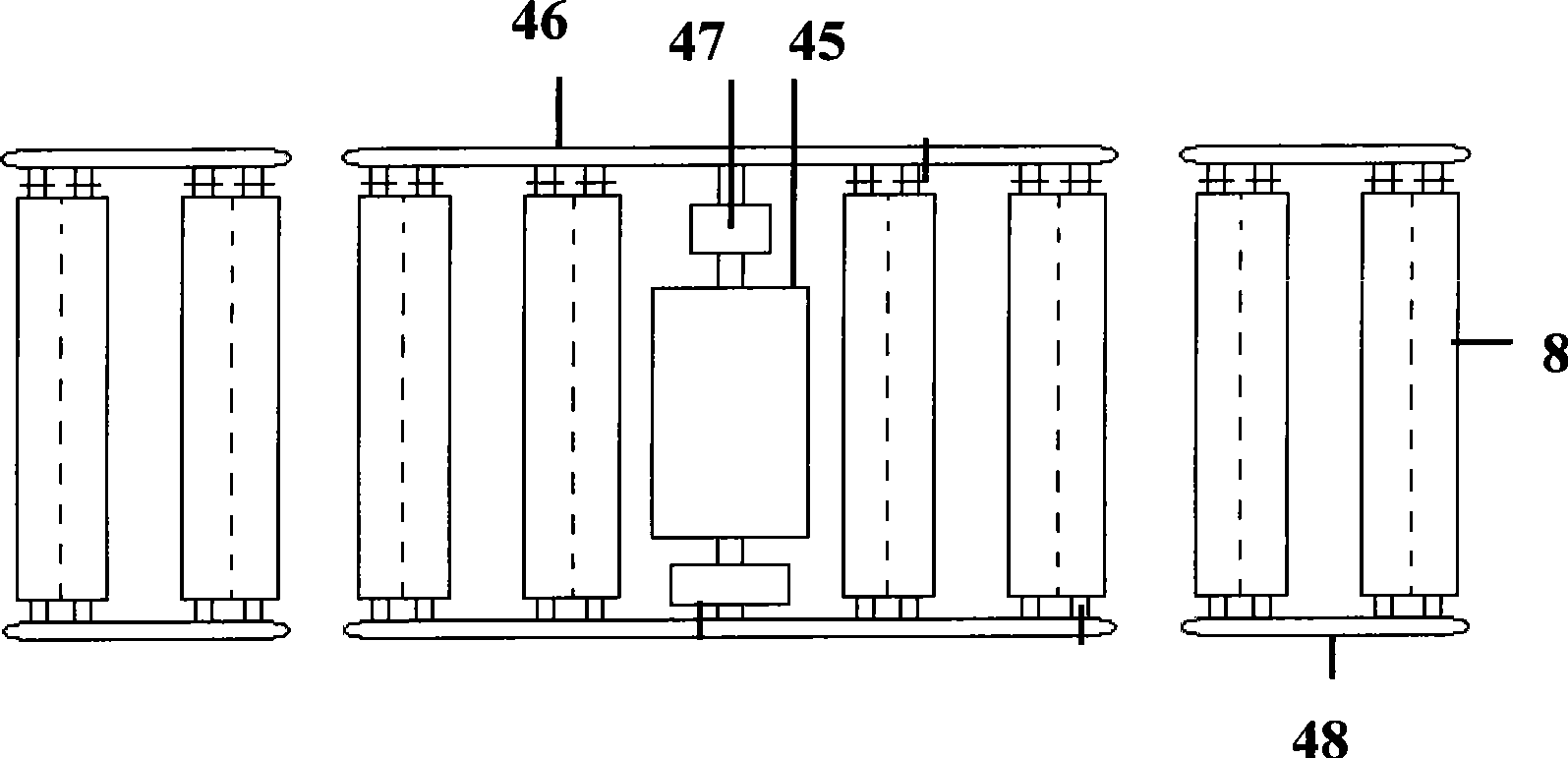

[0022] The soilless hydroponic capillary cultivation system provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as Figure 7 As shown, the soilless hydroponic capillary cultivation system provided by the present invention includes a plurality of cultivation tanks 20, a liquid storage tank 60, a liquid inlet pipe 61, a water pump 62, a flow meter 63, a timer 64, a first liquid return pipe 65, The second liquid return pipe 65', the liquid return tank 66, the pressure pump 67, the water filtration and disinfection device 68 and the fertilizer mixing tank 69; wherein the liquid inlet pipe 61 is connected to the liquid storage tank 60 and the liquid inlet of a plurality of cultivation tanks 20 between; water pump 62, flow meter 63 and timer 64 are installed on the liquid inlet pipe 61; the first liquid return pipe 65 is connected between the liquid outlet of return liquid tank 66 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com